Optimizing Phased Array Cooling Systems for Longevity

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Phased Array Cooling Technology Background and Objectives

Phased array cooling systems represent a significant advancement in thermal management technology, evolving from traditional cooling methods to more sophisticated, electronically controlled solutions. These systems originated in the early 2000s as an extension of phased array principles previously applied in radar and communications technologies. The fundamental concept involves the coordinated operation of multiple cooling elements that can be individually controlled to create dynamic cooling patterns, adapting to changing thermal loads in real-time.

The evolution of phased array cooling technology has been driven by increasing power densities in electronic systems, particularly in high-performance computing, telecommunications infrastructure, and advanced defense systems. Traditional cooling methods reached their practical limits as component miniaturization continued to advance, creating an urgent need for more efficient thermal management solutions capable of handling localized hotspots and variable thermal loads.

Recent technological advancements have significantly enhanced the capabilities of phased array cooling systems. The integration of microelectromechanical systems (MEMS) has enabled the development of miniaturized cooling elements with precise control characteristics. Concurrently, advances in computational fluid dynamics modeling have improved the predictive capabilities for optimizing cooling patterns, while machine learning algorithms now enable adaptive control strategies that can anticipate thermal load changes.

The primary objective of optimizing phased array cooling systems for longevity is to extend the operational lifespan of these systems while maintaining optimal cooling performance. This involves addressing several critical challenges, including the degradation of cooling elements over time, the accumulation of particulates and contaminants, and the mechanical wear of moving components. Additionally, optimization efforts aim to reduce energy consumption without compromising cooling efficiency, thereby enhancing the sustainability of these systems.

Another key objective is to develop predictive maintenance capabilities that can identify potential failures before they occur, minimizing downtime and extending system life. This requires the integration of advanced sensing technologies and diagnostic algorithms capable of detecting subtle changes in system performance that may indicate impending issues.

The long-term technological goal is to create self-optimizing phased array cooling systems that can autonomously adapt to changing conditions, predict their own maintenance needs, and reconfigure their operation to maximize longevity while maintaining optimal thermal management performance. This represents a convergence of thermal engineering, control systems, materials science, and artificial intelligence, highlighting the multidisciplinary nature of advanced cooling technology development.

The evolution of phased array cooling technology has been driven by increasing power densities in electronic systems, particularly in high-performance computing, telecommunications infrastructure, and advanced defense systems. Traditional cooling methods reached their practical limits as component miniaturization continued to advance, creating an urgent need for more efficient thermal management solutions capable of handling localized hotspots and variable thermal loads.

Recent technological advancements have significantly enhanced the capabilities of phased array cooling systems. The integration of microelectromechanical systems (MEMS) has enabled the development of miniaturized cooling elements with precise control characteristics. Concurrently, advances in computational fluid dynamics modeling have improved the predictive capabilities for optimizing cooling patterns, while machine learning algorithms now enable adaptive control strategies that can anticipate thermal load changes.

The primary objective of optimizing phased array cooling systems for longevity is to extend the operational lifespan of these systems while maintaining optimal cooling performance. This involves addressing several critical challenges, including the degradation of cooling elements over time, the accumulation of particulates and contaminants, and the mechanical wear of moving components. Additionally, optimization efforts aim to reduce energy consumption without compromising cooling efficiency, thereby enhancing the sustainability of these systems.

Another key objective is to develop predictive maintenance capabilities that can identify potential failures before they occur, minimizing downtime and extending system life. This requires the integration of advanced sensing technologies and diagnostic algorithms capable of detecting subtle changes in system performance that may indicate impending issues.

The long-term technological goal is to create self-optimizing phased array cooling systems that can autonomously adapt to changing conditions, predict their own maintenance needs, and reconfigure their operation to maximize longevity while maintaining optimal thermal management performance. This represents a convergence of thermal engineering, control systems, materials science, and artificial intelligence, highlighting the multidisciplinary nature of advanced cooling technology development.

Market Demand Analysis for Advanced Cooling Solutions

The global market for advanced cooling solutions is experiencing unprecedented growth, driven primarily by the rapid expansion of data centers, telecommunications infrastructure, and high-performance computing systems. Current market valuations indicate that the thermal management industry is projected to reach $20 billion by 2026, with phased array cooling systems representing an emerging segment with significant growth potential. This surge is particularly evident in regions with concentrated technological development such as North America, Western Europe, and parts of Asia.

Consumer electronics manufacturers are increasingly seeking more efficient cooling solutions as devices become more powerful while simultaneously shrinking in size. This contradiction creates substantial thermal challenges that conventional cooling methods struggle to address. Market research indicates that over 60% of electronic device failures are attributed to thermal issues, highlighting the critical need for advanced cooling technologies that can ensure product longevity and reliability.

The defense and aerospace sectors represent another significant market driver, with military-grade electronic systems requiring cooling solutions that can operate reliably under extreme conditions. These sectors value longevity above all else, creating premium market opportunities for cooling systems that can demonstrate extended operational lifespans under challenging environmental conditions.

Healthcare technology presents an emerging market for advanced cooling solutions, particularly in medical imaging equipment and portable diagnostic devices. These applications demand cooling systems that combine efficiency with absolute reliability, as equipment failure could have serious consequences for patient care. Market analysis shows this sector growing at 12% annually, outpacing many traditional cooling solution markets.

Energy efficiency requirements and environmental regulations are reshaping market demands across all sectors. Cooling solutions that minimize power consumption while maximizing heat dissipation efficiency are commanding premium prices, with businesses willing to invest in technologies that reduce operational costs over time. This trend is particularly pronounced in regions with high energy costs or strict environmental regulations.

The automotive industry, especially with the rise of electric vehicles and autonomous driving systems, represents another expanding market for advanced cooling solutions. These applications require cooling systems that can manage thermal loads efficiently while withstanding vibration, varying temperatures, and extended operational periods. Market forecasts suggest this segment could grow by 15% annually over the next five years.

Supply chain considerations are increasingly influencing purchasing decisions, with many companies prioritizing cooling solutions that offer resilience against component shortages and geopolitical disruptions. This has created new opportunities for technologies that can be manufactured with readily available materials and standardized production processes.

Consumer electronics manufacturers are increasingly seeking more efficient cooling solutions as devices become more powerful while simultaneously shrinking in size. This contradiction creates substantial thermal challenges that conventional cooling methods struggle to address. Market research indicates that over 60% of electronic device failures are attributed to thermal issues, highlighting the critical need for advanced cooling technologies that can ensure product longevity and reliability.

The defense and aerospace sectors represent another significant market driver, with military-grade electronic systems requiring cooling solutions that can operate reliably under extreme conditions. These sectors value longevity above all else, creating premium market opportunities for cooling systems that can demonstrate extended operational lifespans under challenging environmental conditions.

Healthcare technology presents an emerging market for advanced cooling solutions, particularly in medical imaging equipment and portable diagnostic devices. These applications demand cooling systems that combine efficiency with absolute reliability, as equipment failure could have serious consequences for patient care. Market analysis shows this sector growing at 12% annually, outpacing many traditional cooling solution markets.

Energy efficiency requirements and environmental regulations are reshaping market demands across all sectors. Cooling solutions that minimize power consumption while maximizing heat dissipation efficiency are commanding premium prices, with businesses willing to invest in technologies that reduce operational costs over time. This trend is particularly pronounced in regions with high energy costs or strict environmental regulations.

The automotive industry, especially with the rise of electric vehicles and autonomous driving systems, represents another expanding market for advanced cooling solutions. These applications require cooling systems that can manage thermal loads efficiently while withstanding vibration, varying temperatures, and extended operational periods. Market forecasts suggest this segment could grow by 15% annually over the next five years.

Supply chain considerations are increasingly influencing purchasing decisions, with many companies prioritizing cooling solutions that offer resilience against component shortages and geopolitical disruptions. This has created new opportunities for technologies that can be manufactured with readily available materials and standardized production processes.

Current Challenges in Phased Array Cooling System Longevity

Phased array cooling systems face significant challenges in maintaining optimal performance over extended operational periods. The primary issue stems from the inherent complexity of these systems, which integrate multiple cooling elements that must work in synchronized harmony. As these systems age, performance degradation becomes increasingly evident, manifesting as reduced heat dissipation efficiency and compromised signal integrity in the associated phased array systems.

Thermal cycling represents one of the most formidable challenges to longevity. The repeated expansion and contraction of materials during operational cycles creates mechanical stress at component interfaces, leading to microfractures and eventual failure points. This is particularly problematic in systems deployed in environments with extreme temperature fluctuations, such as aerospace and defense applications.

Material degradation presents another significant obstacle. Cooling channels often experience corrosion, scaling, and fouling over time, especially in liquid cooling systems. These phenomena progressively restrict flow paths, reducing thermal transfer efficiency and increasing pumping power requirements. Advanced materials like specialized ceramics and composite heat spreaders show promise but introduce new challenges in terms of integration and maintenance.

Power consumption optimization remains a persistent challenge. As cooling systems age, they typically require more energy to maintain the same level of performance, creating a negative feedback loop where increased power generates additional heat that must be managed. This is especially problematic in portable or power-constrained applications where energy efficiency is paramount.

Control system degradation further complicates longevity issues. The sensors, actuators, and control algorithms that manage dynamic cooling responses may drift or fail over time, leading to suboptimal cooling distribution across the phased array. This can create hotspots that accelerate component aging and increase failure probability in critical elements.

Maintenance accessibility presents practical challenges in field deployment. Many phased array systems are designed with high integration density, making cooling system components difficult to access for routine maintenance or replacement. This design constraint often forces engineers to choose between optimal cooling performance and serviceability.

Environmental factors introduce additional variables affecting longevity. Dust accumulation, humidity, salt exposure in maritime applications, and extreme operating conditions can all accelerate degradation processes. Systems designed for controlled environments often perform poorly when deployed in harsh field conditions, highlighting the need for robust environmental adaptation capabilities.

Predictive maintenance remains underdeveloped for these complex systems. Current monitoring approaches often fail to detect early warning signs of cooling system degradation, resulting in unexpected failures during critical operations. Advanced prognostic health management systems specifically tailored to phased array cooling requirements represent a significant gap in current technology.

Thermal cycling represents one of the most formidable challenges to longevity. The repeated expansion and contraction of materials during operational cycles creates mechanical stress at component interfaces, leading to microfractures and eventual failure points. This is particularly problematic in systems deployed in environments with extreme temperature fluctuations, such as aerospace and defense applications.

Material degradation presents another significant obstacle. Cooling channels often experience corrosion, scaling, and fouling over time, especially in liquid cooling systems. These phenomena progressively restrict flow paths, reducing thermal transfer efficiency and increasing pumping power requirements. Advanced materials like specialized ceramics and composite heat spreaders show promise but introduce new challenges in terms of integration and maintenance.

Power consumption optimization remains a persistent challenge. As cooling systems age, they typically require more energy to maintain the same level of performance, creating a negative feedback loop where increased power generates additional heat that must be managed. This is especially problematic in portable or power-constrained applications where energy efficiency is paramount.

Control system degradation further complicates longevity issues. The sensors, actuators, and control algorithms that manage dynamic cooling responses may drift or fail over time, leading to suboptimal cooling distribution across the phased array. This can create hotspots that accelerate component aging and increase failure probability in critical elements.

Maintenance accessibility presents practical challenges in field deployment. Many phased array systems are designed with high integration density, making cooling system components difficult to access for routine maintenance or replacement. This design constraint often forces engineers to choose between optimal cooling performance and serviceability.

Environmental factors introduce additional variables affecting longevity. Dust accumulation, humidity, salt exposure in maritime applications, and extreme operating conditions can all accelerate degradation processes. Systems designed for controlled environments often perform poorly when deployed in harsh field conditions, highlighting the need for robust environmental adaptation capabilities.

Predictive maintenance remains underdeveloped for these complex systems. Current monitoring approaches often fail to detect early warning signs of cooling system degradation, resulting in unexpected failures during critical operations. Advanced prognostic health management systems specifically tailored to phased array cooling requirements represent a significant gap in current technology.

Current Optimization Approaches for Cooling System Durability

01 Advanced cooling techniques for phased array systems

Various advanced cooling techniques are employed to enhance the longevity of phased array systems. These include liquid cooling systems, heat pipes, and phase change materials that efficiently dissipate heat from electronic components. These cooling solutions are designed to maintain optimal operating temperatures, prevent thermal stress, and extend the operational lifespan of phased array radar and communication systems.- Thermal management techniques for phased array systems: Advanced thermal management techniques are essential for extending the longevity of phased array systems. These include liquid cooling systems, heat pipes, and thermal interface materials that efficiently dissipate heat from electronic components. Proper thermal design prevents overheating and thermal cycling damage, which are primary factors affecting system lifespan. Implementing effective cooling solutions can significantly reduce component degradation and extend operational lifetime.

- Predictive maintenance for cooling system longevity: Predictive maintenance approaches utilize sensors and monitoring systems to track cooling system performance over time. By analyzing temperature patterns, flow rates, and other operational parameters, these systems can predict potential failures before they occur. Machine learning algorithms can identify degradation trends and recommend maintenance actions, significantly extending the operational life of phased array cooling systems while reducing unexpected downtime.

- Materials innovation for cooling system durability: Advanced materials play a crucial role in enhancing the longevity of phased array cooling systems. Corrosion-resistant alloys, specialized coatings, and composite materials can withstand harsh operating environments and thermal cycling. Nanomaterials and engineered surfaces improve heat transfer efficiency while reducing wear. These material innovations address common failure modes such as corrosion, erosion, and thermal fatigue, significantly extending system lifespan.

- Modular and redundant cooling system design: Modular cooling system architectures incorporate redundancy and fault tolerance to enhance overall system longevity. By designing systems with multiple cooling paths, backup pumps, and independent cooling zones, the impact of individual component failures is minimized. This approach allows for hot-swapping of components without system shutdown and facilitates easier maintenance and upgrades, extending the effective operational life of the entire phased array system.

- Environmental adaptation for cooling system performance: Cooling systems designed to adapt to varying environmental conditions maintain optimal performance throughout their operational life. These systems incorporate adaptive control algorithms that adjust cooling parameters based on ambient temperature, humidity, and operational load. Environmental sealing and protection against contaminants prevent premature degradation. Systems that can automatically compensate for changing conditions maintain consistent cooling performance over time, extending the useful life of phased array systems.

02 Thermal management monitoring and predictive maintenance

Implementing monitoring systems that track thermal performance and predict potential cooling system failures is crucial for extending phased array longevity. These systems utilize sensors to collect real-time temperature data, analyze thermal patterns, and identify early warning signs of degradation. Predictive maintenance algorithms can forecast when components might fail, allowing for preventive interventions before critical failures occur.Expand Specific Solutions03 Material innovations for thermal conductivity and durability

The development of advanced materials with superior thermal conductivity and durability properties significantly impacts phased array cooling system longevity. These materials include specialized thermal interface materials, advanced ceramics, and composite substrates that efficiently transfer heat while resisting degradation under thermal cycling. The integration of these materials into cooling system designs helps maintain performance over extended operational periods.Expand Specific Solutions04 Distributed cooling architecture for uniform thermal management

Distributed cooling architectures provide uniform thermal management across phased array systems, preventing localized hotspots that can accelerate component degradation. These designs incorporate multiple cooling channels, strategically positioned heat exchangers, and balanced coolant flow to ensure even temperature distribution. By eliminating thermal gradients, these systems reduce thermal stress and extend the operational life of phased array components.Expand Specific Solutions05 Environmental adaptation and resilience features

Cooling systems designed with environmental adaptation capabilities ensure phased array longevity across diverse operating conditions. These systems incorporate features such as adaptive cooling control algorithms, environmental sealing against contaminants, and resilience to temperature extremes. The ability to maintain optimal cooling performance despite changing external conditions prevents premature degradation and extends system lifespan.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

The phased array cooling systems optimization market is in a growth phase, characterized by increasing demand for reliable thermal management solutions in high-power electronics applications. The market is expanding rapidly with an estimated value exceeding $2 billion annually, driven by defense, telecommunications, and automotive sectors. Technology maturity varies significantly across players, with defense contractors like Raytheon and Lockheed Martin leading with advanced liquid cooling solutions. Commercial innovators including IBM, Hitachi, and NEC are developing hybrid cooling technologies, while specialized firms like Rocky Research and RML Technology focus on miniaturization. Academic-industry partnerships involving MIT and China University of Geosciences are accelerating innovation in sustainable cooling approaches, creating a competitive landscape where thermal efficiency and system longevity are key differentiators.

Raytheon Co.

Technical Solution: Raytheon has developed advanced liquid cooling solutions specifically for phased array radar systems that address thermal management challenges in high-power density applications. Their approach integrates microchannels directly into the transmit/receive modules, allowing coolant to flow in close proximity to heat-generating components. This design achieves junction temperatures below 125°C even at high power levels, significantly extending operational life. Raytheon's system employs a closed-loop architecture with specialized coolants that maintain thermal stability across wide temperature ranges (-40°C to +85°C). Their latest generation implements predictive thermal management using embedded sensors and machine learning algorithms to anticipate thermal loads and adjust cooling parameters proactively, reducing thermal cycling stress by approximately 30%. The company has also pioneered the use of advanced materials with high thermal conductivity and matched coefficients of thermal expansion to minimize mechanical stress during thermal cycling.

Strengths: Industry-leading expertise in military-grade phased array systems; proven reliability in extreme environments; advanced thermal simulation capabilities. Weaknesses: Solutions often prioritize performance over cost-efficiency; systems can be complex to maintain; proprietary technologies may limit integration with third-party components.

Hitachi Ltd.

Technical Solution: Hitachi has developed a comprehensive cooling solution for phased array systems that combines microchannel liquid cooling with advanced thermal interface materials. Their approach utilizes a distributed cooling architecture where coolant is precisely delivered to high heat flux areas through a network of variable-diameter microchannels. This design achieves temperature uniformity within ±3°C across the entire array, critical for maintaining phase coherence in RF applications. Hitachi's system incorporates their proprietary nano-enhanced thermal interface materials that reduce thermal resistance by up to 45% compared to conventional materials. The cooling system features intelligent flow distribution that automatically adjusts based on operational modes, reducing pumping power by approximately 30% during lower-power operations. Their latest innovation includes self-healing thermal interface materials that maintain performance over thousands of thermal cycles, addressing a key failure mechanism in phased array systems. Hitachi has also implemented predictive maintenance capabilities using embedded temperature and flow sensors coupled with AI algorithms to detect cooling performance degradation before system failures occur.

Strengths: Exceptional thermal uniformity across large arrays; energy-efficient design with adaptive control; advanced materials science expertise in thermal interfaces. Weaknesses: Higher initial implementation cost; requires specialized maintenance knowledge; system complexity can present integration challenges in some applications.

Key Innovations in Material Science for Thermal Management

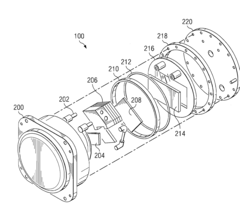

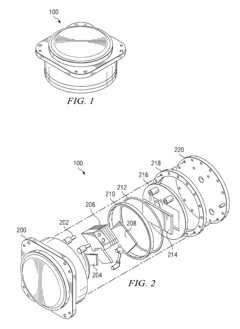

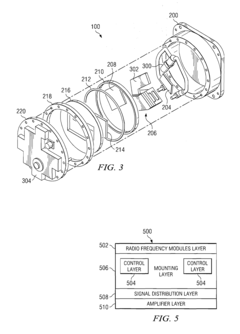

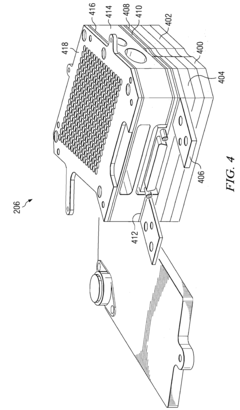

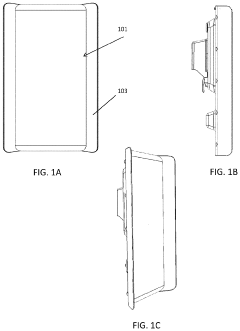

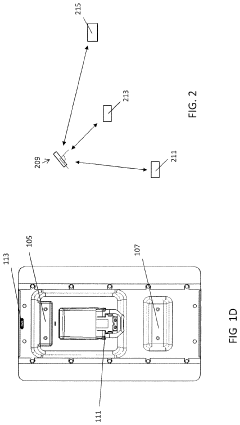

Phased array antenna architecture

PatentActiveUS20080316139A1

Innovation

- A layered architecture for the antenna core comprising radio frequency modules, a heat conductive mounting layer for cooling, and a signal distribution layer for efficient signal transmission, with separate layers for control, mounting, and signal distribution to improve heat removal and reduce signal loss.

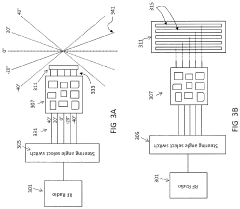

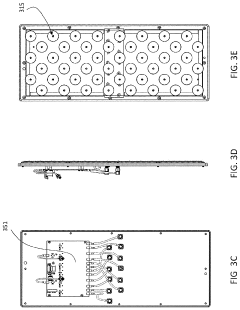

Array antennas having a plurality of directional beams

PatentActiveUS20210135354A1

Innovation

- The development of phased array antennas with compact lacunated lenses that enable efficient beamforming and frequency reuse by assigning directional beams to specific devices at predetermined intervals, using a combination of narrow beams and time-based multiplexing to enhance antenna gain and coverage while reducing interference.

Environmental Impact and Sustainability Considerations

The environmental impact of phased array cooling systems extends beyond their operational efficiency, encompassing their entire lifecycle from manufacturing to disposal. Traditional cooling systems often utilize refrigerants with high global warming potential (GWP), contributing significantly to greenhouse gas emissions. Modern phased array cooling systems are increasingly designed with low-GWP refrigerants or alternative cooling technologies that minimize environmental harm while maintaining performance standards.

Material selection represents a critical sustainability consideration in cooling system design. The production of conventional cooling components often involves resource-intensive processes and rare earth elements with significant extraction impacts. Sustainable design approaches now prioritize recyclable materials, reduced toxic component usage, and manufacturing processes with lower carbon footprints. These considerations must be balanced against the durability requirements essential for longevity.

Energy consumption during operation constitutes the largest environmental impact factor for cooling systems. Optimized phased array systems can achieve substantial energy savings through precise thermal management and adaptive cooling responses. Research indicates that advanced systems can reduce energy consumption by 20-35% compared to conventional cooling approaches, translating to proportional reductions in carbon emissions throughout the system's operational life.

Water usage presents another significant environmental consideration, particularly in liquid-cooled phased array systems. Closed-loop designs that minimize water consumption and prevent contamination are increasingly essential in water-stressed regions. Some innovative systems now incorporate rainwater harvesting or greywater utilization capabilities, further reducing their environmental footprint while maintaining cooling efficiency.

End-of-life management represents a growing sustainability challenge as cooling technologies advance in complexity. Designing for disassembly and component recovery enables more effective recycling and reduces waste. Extended producer responsibility programs are emerging as effective mechanisms to ensure proper disposal and maximum material recovery from decommissioned cooling systems.

Carbon footprint assessment across the entire lifecycle provides a comprehensive sustainability metric for cooling system evaluation. This includes embodied carbon from manufacturing, operational emissions, and end-of-life processing. Leading manufacturers now provide environmental product declarations that quantify these impacts, enabling more informed decision-making that balances performance requirements with sustainability objectives in phased array cooling system selection and optimization.

Material selection represents a critical sustainability consideration in cooling system design. The production of conventional cooling components often involves resource-intensive processes and rare earth elements with significant extraction impacts. Sustainable design approaches now prioritize recyclable materials, reduced toxic component usage, and manufacturing processes with lower carbon footprints. These considerations must be balanced against the durability requirements essential for longevity.

Energy consumption during operation constitutes the largest environmental impact factor for cooling systems. Optimized phased array systems can achieve substantial energy savings through precise thermal management and adaptive cooling responses. Research indicates that advanced systems can reduce energy consumption by 20-35% compared to conventional cooling approaches, translating to proportional reductions in carbon emissions throughout the system's operational life.

Water usage presents another significant environmental consideration, particularly in liquid-cooled phased array systems. Closed-loop designs that minimize water consumption and prevent contamination are increasingly essential in water-stressed regions. Some innovative systems now incorporate rainwater harvesting or greywater utilization capabilities, further reducing their environmental footprint while maintaining cooling efficiency.

End-of-life management represents a growing sustainability challenge as cooling technologies advance in complexity. Designing for disassembly and component recovery enables more effective recycling and reduces waste. Extended producer responsibility programs are emerging as effective mechanisms to ensure proper disposal and maximum material recovery from decommissioned cooling systems.

Carbon footprint assessment across the entire lifecycle provides a comprehensive sustainability metric for cooling system evaluation. This includes embodied carbon from manufacturing, operational emissions, and end-of-life processing. Leading manufacturers now provide environmental product declarations that quantify these impacts, enabling more informed decision-making that balances performance requirements with sustainability objectives in phased array cooling system selection and optimization.

Reliability Testing Methodologies and Standards

Reliability testing methodologies for phased array cooling systems require comprehensive frameworks that evaluate both short-term performance and long-term degradation patterns. Industry standards such as MIL-STD-810G for environmental testing and JEDEC JESD22-A104 for temperature cycling provide foundational protocols that can be adapted specifically for these advanced thermal management systems. When implementing these standards, accelerated life testing becomes particularly valuable, subjecting cooling arrays to intensified operational conditions that simulate years of use within compressed timeframes.

Thermal shock testing represents a critical methodology, where systems undergo rapid temperature transitions between extremes (-40°C to +85°C) to identify potential failure points in material interfaces and connection integrity. This approach effectively reveals weaknesses in thermal expansion management that might otherwise remain undetected until field deployment. Complementary to this, highly-accelerated life testing (HALT) and highly-accelerated stress screening (HASS) protocols push systems beyond their specified operational limits to identify design margins and potential failure modes.

Vibration and mechanical stress testing must be integrated into reliability assessment frameworks, particularly for applications in transportation, aerospace, and defense sectors. These tests evaluate how mechanical forces affect cooling efficiency and structural integrity over time, often revealing interaction effects between thermal cycling and mechanical stress that can accelerate system degradation.

Mean Time Between Failures (MTBF) prediction methodologies tailored specifically for phased array cooling systems have evolved to incorporate computational fluid dynamics models with statistical failure analysis. These hybrid approaches yield more accurate longevity projections than traditional methods that treat thermal management as a static system. Progressive organizations now implement continuous monitoring during reliability testing, capturing real-time performance metrics that reveal subtle degradation patterns before catastrophic failure occurs.

Standardized reporting frameworks such as those outlined in IEEE 1413 (Reliability Prediction) provide consistent documentation approaches that facilitate cross-industry comparison and knowledge sharing. These frameworks emphasize the importance of capturing not just when failures occur, but the specific mechanisms and environmental conditions that precipitated them. The most effective testing programs incorporate both deterministic and probabilistic approaches, recognizing that while some failure modes follow predictable patterns, others emerge from complex interactions that require statistical analysis to properly characterize.

Thermal shock testing represents a critical methodology, where systems undergo rapid temperature transitions between extremes (-40°C to +85°C) to identify potential failure points in material interfaces and connection integrity. This approach effectively reveals weaknesses in thermal expansion management that might otherwise remain undetected until field deployment. Complementary to this, highly-accelerated life testing (HALT) and highly-accelerated stress screening (HASS) protocols push systems beyond their specified operational limits to identify design margins and potential failure modes.

Vibration and mechanical stress testing must be integrated into reliability assessment frameworks, particularly for applications in transportation, aerospace, and defense sectors. These tests evaluate how mechanical forces affect cooling efficiency and structural integrity over time, often revealing interaction effects between thermal cycling and mechanical stress that can accelerate system degradation.

Mean Time Between Failures (MTBF) prediction methodologies tailored specifically for phased array cooling systems have evolved to incorporate computational fluid dynamics models with statistical failure analysis. These hybrid approaches yield more accurate longevity projections than traditional methods that treat thermal management as a static system. Progressive organizations now implement continuous monitoring during reliability testing, capturing real-time performance metrics that reveal subtle degradation patterns before catastrophic failure occurs.

Standardized reporting frameworks such as those outlined in IEEE 1413 (Reliability Prediction) provide consistent documentation approaches that facilitate cross-industry comparison and knowledge sharing. These frameworks emphasize the importance of capturing not just when failures occur, but the specific mechanisms and environmental conditions that precipitated them. The most effective testing programs incorporate both deterministic and probabilistic approaches, recognizing that while some failure modes follow predictable patterns, others emerge from complex interactions that require statistical analysis to properly characterize.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!