How to Implement QLED Displays at Scale in Industries?

JUN 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QLED Technology Evolution and Objectives

Quantum Dot Light Emitting Diode (QLED) technology has emerged as a promising advancement in display technology, offering superior color performance and energy efficiency compared to traditional LED displays. The evolution of QLED technology can be traced back to the early 2000s when researchers first began exploring the potential of quantum dots in display applications.

Initially, the focus was on developing quantum dots that could emit light with high efficiency and color purity. As the technology progressed, researchers and manufacturers aimed to overcome challenges such as stability, manufacturing scalability, and integration with existing display architectures. The primary objective of QLED technology development has been to create displays with enhanced color gamut, improved brightness, and reduced power consumption.

Over the past decade, significant milestones have been achieved in QLED technology. These include the development of more stable quantum dot materials, improved manufacturing processes for quantum dot synthesis, and the integration of quantum dots into display backlight systems. The industry has also made strides in developing direct-emissive QLED displays, which promise even better performance than current quantum dot-enhanced LED displays.

The current objectives for QLED technology implementation at scale in industries include further improving manufacturing efficiency, reducing production costs, and enhancing the longevity of QLED displays. There is a strong focus on developing environmentally friendly quantum dot materials that are free from heavy metals, addressing concerns about toxicity and environmental impact.

Another key objective is to expand the application of QLED technology beyond traditional display markets. Industries are exploring the use of QLED in automotive displays, signage, and even lighting applications. This diversification aims to leverage the technology's strengths in various sectors, driving innovation and economies of scale.

Researchers and manufacturers are also working on improving the blue QLED performance, which has historically lagged behind red and green quantum dots in terms of efficiency and stability. Achieving high-performance blue QLEDs is crucial for creating full-color displays without relying on color conversion techniques.

As the technology continues to evolve, there is a growing emphasis on developing flexible and transparent QLED displays. These advancements could open up new possibilities for integrating displays into various surfaces and products, potentially revolutionizing user interfaces and information display in multiple industries.

In conclusion, the evolution of QLED technology has been marked by continuous improvements in performance, efficiency, and manufacturability. The objectives for implementing QLED displays at scale in industries are centered around overcoming remaining technical challenges, reducing costs, expanding applications, and pushing the boundaries of display technology to create more immersive and versatile visual experiences.

Initially, the focus was on developing quantum dots that could emit light with high efficiency and color purity. As the technology progressed, researchers and manufacturers aimed to overcome challenges such as stability, manufacturing scalability, and integration with existing display architectures. The primary objective of QLED technology development has been to create displays with enhanced color gamut, improved brightness, and reduced power consumption.

Over the past decade, significant milestones have been achieved in QLED technology. These include the development of more stable quantum dot materials, improved manufacturing processes for quantum dot synthesis, and the integration of quantum dots into display backlight systems. The industry has also made strides in developing direct-emissive QLED displays, which promise even better performance than current quantum dot-enhanced LED displays.

The current objectives for QLED technology implementation at scale in industries include further improving manufacturing efficiency, reducing production costs, and enhancing the longevity of QLED displays. There is a strong focus on developing environmentally friendly quantum dot materials that are free from heavy metals, addressing concerns about toxicity and environmental impact.

Another key objective is to expand the application of QLED technology beyond traditional display markets. Industries are exploring the use of QLED in automotive displays, signage, and even lighting applications. This diversification aims to leverage the technology's strengths in various sectors, driving innovation and economies of scale.

Researchers and manufacturers are also working on improving the blue QLED performance, which has historically lagged behind red and green quantum dots in terms of efficiency and stability. Achieving high-performance blue QLEDs is crucial for creating full-color displays without relying on color conversion techniques.

As the technology continues to evolve, there is a growing emphasis on developing flexible and transparent QLED displays. These advancements could open up new possibilities for integrating displays into various surfaces and products, potentially revolutionizing user interfaces and information display in multiple industries.

In conclusion, the evolution of QLED technology has been marked by continuous improvements in performance, efficiency, and manufacturability. The objectives for implementing QLED displays at scale in industries are centered around overcoming remaining technical challenges, reducing costs, expanding applications, and pushing the boundaries of display technology to create more immersive and versatile visual experiences.

QLED Display Market Analysis

The QLED display market has been experiencing significant growth in recent years, driven by the increasing demand for high-quality displays in various industries. QLED technology offers superior color reproduction, brightness, and energy efficiency compared to traditional LED displays, making it an attractive option for manufacturers and consumers alike.

The global QLED display market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to be in the double digits over the next five years. This growth is primarily fueled by the rising adoption of QLED technology in televisions, smartphones, and other consumer electronics devices. Additionally, the expanding application of QLED displays in automotive infotainment systems and digital signage is contributing to market expansion.

Consumer electronics remain the dominant segment in the QLED display market, with televisions accounting for the largest share of revenue. The increasing consumer preference for larger screen sizes and higher resolution displays is driving the demand for QLED TVs. Smartphone manufacturers are also incorporating QLED technology into their high-end devices, further boosting market growth.

The automotive industry is emerging as a promising market for QLED displays, with automakers integrating these advanced displays into their vehicle dashboards and infotainment systems. The superior brightness and color accuracy of QLED technology make it well-suited for automotive applications, where visibility in varying light conditions is crucial.

Geographically, Asia Pacific leads the QLED display market, with South Korea and China being the major contributors. This dominance is attributed to the presence of key manufacturers and the region's strong consumer electronics industry. North America and Europe follow closely, driven by the high adoption rate of advanced display technologies in these regions.

The competitive landscape of the QLED display market is characterized by intense rivalry among major players. Key manufacturers are investing heavily in research and development to improve QLED technology and reduce production costs. Strategic partnerships and collaborations between display manufacturers and consumer electronics brands are becoming increasingly common, as companies seek to gain a competitive edge in this rapidly evolving market.

Despite the positive outlook, the QLED display market faces challenges such as high production costs and competition from other display technologies like OLED. However, ongoing technological advancements and economies of scale are expected to address these challenges, paving the way for wider adoption of QLED displays across various industries.

The global QLED display market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to be in the double digits over the next five years. This growth is primarily fueled by the rising adoption of QLED technology in televisions, smartphones, and other consumer electronics devices. Additionally, the expanding application of QLED displays in automotive infotainment systems and digital signage is contributing to market expansion.

Consumer electronics remain the dominant segment in the QLED display market, with televisions accounting for the largest share of revenue. The increasing consumer preference for larger screen sizes and higher resolution displays is driving the demand for QLED TVs. Smartphone manufacturers are also incorporating QLED technology into their high-end devices, further boosting market growth.

The automotive industry is emerging as a promising market for QLED displays, with automakers integrating these advanced displays into their vehicle dashboards and infotainment systems. The superior brightness and color accuracy of QLED technology make it well-suited for automotive applications, where visibility in varying light conditions is crucial.

Geographically, Asia Pacific leads the QLED display market, with South Korea and China being the major contributors. This dominance is attributed to the presence of key manufacturers and the region's strong consumer electronics industry. North America and Europe follow closely, driven by the high adoption rate of advanced display technologies in these regions.

The competitive landscape of the QLED display market is characterized by intense rivalry among major players. Key manufacturers are investing heavily in research and development to improve QLED technology and reduce production costs. Strategic partnerships and collaborations between display manufacturers and consumer electronics brands are becoming increasingly common, as companies seek to gain a competitive edge in this rapidly evolving market.

Despite the positive outlook, the QLED display market faces challenges such as high production costs and competition from other display technologies like OLED. However, ongoing technological advancements and economies of scale are expected to address these challenges, paving the way for wider adoption of QLED displays across various industries.

QLED Scaling Challenges

The implementation of QLED displays at scale in industries faces several significant challenges. One of the primary obstacles is the complexity of the manufacturing process. QLED technology requires precise control over quantum dot synthesis and deposition, which can be difficult to maintain consistently across large-scale production lines. This challenge is compounded by the need for high-quality, uniform quantum dots, as even minor variations can lead to noticeable differences in display performance.

Another major hurdle is the cost-effectiveness of QLED production. While QLEDs offer superior color performance and energy efficiency compared to traditional LED displays, the materials and processes involved in their manufacture are currently more expensive. Scaling up production to industrial levels requires substantial investment in specialized equipment and facilities, which can be a significant barrier for many companies.

The stability and longevity of QLED displays also present challenges for large-scale implementation. Quantum dots are sensitive to environmental factors such as heat and moisture, which can degrade their performance over time. Developing robust encapsulation methods to protect the quantum dots without compromising display quality is crucial for ensuring the long-term reliability of QLED products in various industrial applications.

Furthermore, the integration of QLED technology with existing display manufacturing infrastructure poses a significant challenge. Many industries have invested heavily in current display technologies, and transitioning to QLED production may require substantial modifications to production lines and processes. This transition can be both costly and time-consuming, potentially disrupting existing supply chains and production schedules.

Quality control and consistency are also major concerns when scaling QLED production. Ensuring uniform color reproduction and brightness across large displays and between different batches of products requires sophisticated quality assurance processes. Developing and implementing these processes at an industrial scale can be complex and resource-intensive.

Lastly, the environmental impact of large-scale QLED production must be considered. While QLEDs are more energy-efficient in operation, the production of quantum dots often involves the use of heavy metals and other potentially harmful materials. Developing eco-friendly production methods and ensuring proper disposal or recycling of QLED displays at the end of their lifecycle are important challenges that need to be addressed for sustainable large-scale implementation.

Another major hurdle is the cost-effectiveness of QLED production. While QLEDs offer superior color performance and energy efficiency compared to traditional LED displays, the materials and processes involved in their manufacture are currently more expensive. Scaling up production to industrial levels requires substantial investment in specialized equipment and facilities, which can be a significant barrier for many companies.

The stability and longevity of QLED displays also present challenges for large-scale implementation. Quantum dots are sensitive to environmental factors such as heat and moisture, which can degrade their performance over time. Developing robust encapsulation methods to protect the quantum dots without compromising display quality is crucial for ensuring the long-term reliability of QLED products in various industrial applications.

Furthermore, the integration of QLED technology with existing display manufacturing infrastructure poses a significant challenge. Many industries have invested heavily in current display technologies, and transitioning to QLED production may require substantial modifications to production lines and processes. This transition can be both costly and time-consuming, potentially disrupting existing supply chains and production schedules.

Quality control and consistency are also major concerns when scaling QLED production. Ensuring uniform color reproduction and brightness across large displays and between different batches of products requires sophisticated quality assurance processes. Developing and implementing these processes at an industrial scale can be complex and resource-intensive.

Lastly, the environmental impact of large-scale QLED production must be considered. While QLEDs are more energy-efficient in operation, the production of quantum dots often involves the use of heavy metals and other potentially harmful materials. Developing eco-friendly production methods and ensuring proper disposal or recycling of QLED displays at the end of their lifecycle are important challenges that need to be addressed for sustainable large-scale implementation.

Current QLED Scaling Solutions

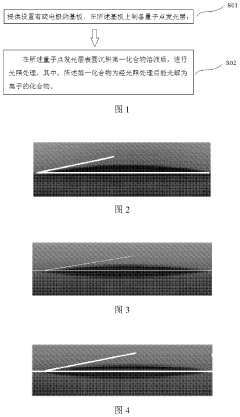

01 Quantum dot light-emitting diode structure

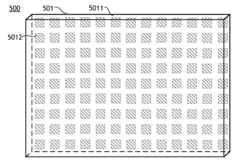

QLED displays utilize a structure incorporating quantum dots as the light-emitting material. This structure typically includes layers such as a substrate, electrodes, quantum dot layer, and charge transport layers. The quantum dots are engineered to emit specific colors when electrically excited, providing high color purity and efficiency.- Quantum dot light-emitting diode structure: QLED displays utilize a structure incorporating quantum dots as the light-emitting material. This structure typically includes layers such as a substrate, electrodes, quantum dot layer, and charge transport layers. The quantum dots are engineered to emit specific colors when electrically excited, providing high color purity and efficiency.

- Color conversion layer using quantum dots: Some QLED display designs use quantum dots as a color conversion layer rather than direct light emitters. In this approach, blue LEDs are used as a backlight, and quantum dots convert the blue light to red and green, creating a full-color display. This method can improve color gamut and energy efficiency compared to traditional LCD displays.

- Quantum dot synthesis and composition: The performance of QLED displays heavily depends on the properties of the quantum dots used. Research focuses on developing new quantum dot materials and synthesis methods to improve color purity, efficiency, and stability. This includes exploring various core-shell structures and doping techniques to enhance quantum dot characteristics.

- Encapsulation and protection of quantum dots: Quantum dots are sensitive to environmental factors such as oxygen and moisture. QLED display technology incorporates various encapsulation and protection methods to enhance the longevity and stability of the quantum dots. This may include the use of barrier films, sealants, and specialized packaging techniques.

- Driving and control circuits for QLED displays: QLED displays require specialized driving and control circuits to manage the electrical excitation of quantum dots and ensure uniform brightness and color across the display. This includes the development of thin-film transistor (TFT) backplanes, voltage control schemes, and compensation algorithms to address issues such as non-uniformity and aging effects.

02 Color conversion and enhancement techniques

Various methods are employed to improve color performance in QLED displays. These include using color filters, optimizing quantum dot compositions, and implementing color conversion layers. Such techniques aim to enhance color gamut, improve color accuracy, and increase overall display efficiency.Expand Specific Solutions03 Manufacturing processes for QLED displays

Specialized manufacturing techniques are developed for QLED displays, including methods for depositing quantum dot layers, patterning electrodes, and integrating various display components. These processes focus on improving yield, reducing costs, and enhancing the overall quality and performance of QLED displays.Expand Specific Solutions04 Driving and control systems for QLED displays

Advanced driving and control systems are designed to optimize the performance of QLED displays. These include circuits for precise current control, voltage regulation, and timing management. Such systems aim to improve image quality, reduce power consumption, and extend the lifespan of QLED displays.Expand Specific Solutions05 Integration of QLED technology with other display innovations

QLED technology is combined with other display innovations to create advanced display solutions. This includes integration with flexible or transparent substrates, incorporation into micro-LED displays, and development of hybrid QLED-OLED systems. These integrations aim to expand the application range and enhance the capabilities of QLED displays.Expand Specific Solutions

QLED Industry Leaders

The implementation of QLED displays at scale in industries is currently in a growth phase, with the market size expanding rapidly due to increasing demand for high-quality displays in various sectors. The technology's maturity is advancing, with key players like BOE Technology Group, TCL China Star Optoelectronics, and Sharp Corp. leading the way in research and development. Companies such as Nanosys and Lumileds are focusing on improving quantum dot materials, while universities like The Hong Kong University of Science & Technology and Zhejiang University are contributing to fundamental research. The competitive landscape is diverse, with both established electronics giants and specialized startups like Chengdu Vistar Optoelectronics vying for market share, indicating a dynamic and evolving industry poised for significant technological breakthroughs and commercial applications.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a proprietary QLED technology called ART (Advanced Reflective Technology). This technology utilizes quantum dots to enhance color gamut and brightness while reducing power consumption. BOE's QLED displays feature a unique light-guiding structure that improves light efficiency and color purity. They have also implemented a specialized quantum dot deposition process that ensures uniform distribution and longevity of the quantum dots, addressing common issues in QLED manufacturing.

Strengths: Wide color gamut, high brightness, and energy efficiency. Weaknesses: Higher production costs compared to traditional LCD, potential for color shift over time.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has developed a QLED technology called Q-Light, which combines quantum dot technology with mini-LED backlighting. This approach allows for precise local dimming, enhancing contrast and HDR performance. Their manufacturing process includes a patented quantum dot film application method that improves uniformity and reduces material waste. TCL CSOT has also focused on developing flexible QLED displays, enabling curved and foldable screen applications.

Strengths: Excellent contrast and HDR performance, versatility in form factors. Weaknesses: Complexity in manufacturing process, potential for higher costs in flexible display applications.

Key QLED Patents and Innovations

QLED and manufacturing method thereof

PatentActiveUS20220081313A1

Innovation

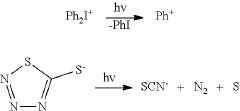

- A QLED manufacturing method involving the use of a first compound solution that photodegrades into ions under illumination, applied to the quantum dot light emitting layer, which reduces the contact angle and improves the compatibility between layers, enhancing the flatness and luminous efficiency of the QLED.

QLED device and manufacturing method thereof, QLED display panel and QLED display device

PatentActiveUS20180294414A1

Innovation

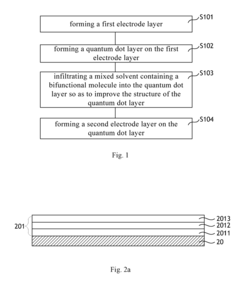

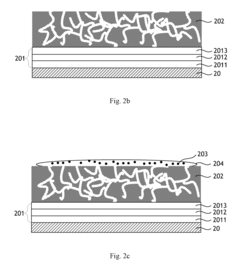

- A method involving the infiltration of a mixed solvent containing bifunctional molecules into the quantum dot layer to form bridges between loose quantum dots, improving the compactness and regularity of both the surface and internal structure, using a process that includes temperature adjustment, rotation, and annealing to enhance solubility and diffusion.

QLED Supply Chain Analysis

The QLED supply chain is a complex network of manufacturers, suppliers, and distributors that work together to produce and deliver Quantum Dot Light Emitting Diode (QLED) displays. This analysis focuses on the key components and processes involved in scaling QLED production for industrial applications.

At the core of the QLED supply chain are the quantum dot manufacturers. These specialized companies produce the nanocrystal semiconductors that give QLED displays their superior color performance. Key players in this segment include Nanosys, QD Vision, and Nanoco Technologies. These firms have developed proprietary methods for synthesizing quantum dots with high efficiency and stability, crucial for large-scale industrial implementation.

The next critical link in the chain is the QLED panel manufacturers. Companies like Samsung, TCL, and Hisense have invested heavily in QLED technology and have established production lines capable of mass-producing QLED displays. These manufacturers integrate quantum dots into their existing LCD production processes, which allows for relatively easy scaling of QLED technology.

Component suppliers play a vital role in the QLED supply chain. These include providers of backlight units, color filters, and driver ICs. As QLED technology advances, these suppliers must adapt their products to meet the specific requirements of QLED displays, such as enhanced color gamut and brightness capabilities.

The distribution network for QLED displays involves both direct sales to industrial clients and partnerships with system integrators. These integrators specialize in incorporating QLED displays into various industrial applications, such as digital signage, control rooms, and automotive displays.

Raw material suppliers are another crucial element of the QLED supply chain. The production of quantum dots requires specific materials, including cadmium selenide, indium phosphide, and zinc selenide. Ensuring a stable supply of these materials is essential for scaling QLED production.

Logistics and transportation providers play a significant role in the QLED supply chain, especially when considering global production and distribution. The fragile nature of display components necessitates specialized handling and transportation methods to ensure product integrity.

As QLED technology continues to evolve, research institutions and universities contribute to the supply chain by developing new quantum dot materials and manufacturing processes. This ongoing research is crucial for improving QLED performance and reducing production costs, which are essential factors for large-scale industrial adoption.

At the core of the QLED supply chain are the quantum dot manufacturers. These specialized companies produce the nanocrystal semiconductors that give QLED displays their superior color performance. Key players in this segment include Nanosys, QD Vision, and Nanoco Technologies. These firms have developed proprietary methods for synthesizing quantum dots with high efficiency and stability, crucial for large-scale industrial implementation.

The next critical link in the chain is the QLED panel manufacturers. Companies like Samsung, TCL, and Hisense have invested heavily in QLED technology and have established production lines capable of mass-producing QLED displays. These manufacturers integrate quantum dots into their existing LCD production processes, which allows for relatively easy scaling of QLED technology.

Component suppliers play a vital role in the QLED supply chain. These include providers of backlight units, color filters, and driver ICs. As QLED technology advances, these suppliers must adapt their products to meet the specific requirements of QLED displays, such as enhanced color gamut and brightness capabilities.

The distribution network for QLED displays involves both direct sales to industrial clients and partnerships with system integrators. These integrators specialize in incorporating QLED displays into various industrial applications, such as digital signage, control rooms, and automotive displays.

Raw material suppliers are another crucial element of the QLED supply chain. The production of quantum dots requires specific materials, including cadmium selenide, indium phosphide, and zinc selenide. Ensuring a stable supply of these materials is essential for scaling QLED production.

Logistics and transportation providers play a significant role in the QLED supply chain, especially when considering global production and distribution. The fragile nature of display components necessitates specialized handling and transportation methods to ensure product integrity.

As QLED technology continues to evolve, research institutions and universities contribute to the supply chain by developing new quantum dot materials and manufacturing processes. This ongoing research is crucial for improving QLED performance and reducing production costs, which are essential factors for large-scale industrial adoption.

Environmental Impact of QLED Manufacturing

The environmental impact of QLED manufacturing is a critical consideration as the technology scales up for industrial implementation. QLED displays offer several environmental advantages over traditional LED and OLED technologies, but their production process still poses significant challenges.

One of the primary environmental concerns in QLED manufacturing is the use of heavy metals, particularly cadmium, in quantum dots. While the amount of cadmium used is minimal, its toxicity raises concerns about potential environmental contamination during production and disposal. Efforts are underway to develop cadmium-free quantum dots, which could significantly reduce the environmental risks associated with QLED manufacturing.

The production of quantum dots also requires energy-intensive processes, contributing to the overall carbon footprint of QLED displays. However, the energy efficiency of QLEDs in operation may offset some of these manufacturing-related emissions over the product lifecycle. Manufacturers are exploring ways to optimize production processes and reduce energy consumption during manufacturing to mitigate this impact.

Water usage and potential contamination are additional environmental concerns in QLED production. The manufacturing process involves various chemical treatments and cleaning steps that consume substantial amounts of water. Proper wastewater treatment and recycling systems are essential to minimize the environmental impact and conserve water resources.

The use of rare earth elements in QLED displays also raises sustainability concerns. While QLEDs generally require fewer rare earth materials compared to some other display technologies, the extraction and processing of these elements can have significant environmental consequences, including habitat destruction and water pollution.

On a positive note, QLEDs have the potential to be more recyclable than some other display technologies due to their simpler structure and fewer layers. However, the presence of quantum dots complicates the recycling process, and specialized recycling facilities may be required to handle QLED waste effectively.

As QLED technology scales up for industrial implementation, manufacturers are increasingly focusing on developing more sustainable production methods. This includes research into alternative materials, improved manufacturing processes, and enhanced recycling techniques. The industry is also working towards establishing comprehensive lifecycle assessments to better understand and mitigate the environmental impact of QLED displays from production to disposal.

One of the primary environmental concerns in QLED manufacturing is the use of heavy metals, particularly cadmium, in quantum dots. While the amount of cadmium used is minimal, its toxicity raises concerns about potential environmental contamination during production and disposal. Efforts are underway to develop cadmium-free quantum dots, which could significantly reduce the environmental risks associated with QLED manufacturing.

The production of quantum dots also requires energy-intensive processes, contributing to the overall carbon footprint of QLED displays. However, the energy efficiency of QLEDs in operation may offset some of these manufacturing-related emissions over the product lifecycle. Manufacturers are exploring ways to optimize production processes and reduce energy consumption during manufacturing to mitigate this impact.

Water usage and potential contamination are additional environmental concerns in QLED production. The manufacturing process involves various chemical treatments and cleaning steps that consume substantial amounts of water. Proper wastewater treatment and recycling systems are essential to minimize the environmental impact and conserve water resources.

The use of rare earth elements in QLED displays also raises sustainability concerns. While QLEDs generally require fewer rare earth materials compared to some other display technologies, the extraction and processing of these elements can have significant environmental consequences, including habitat destruction and water pollution.

On a positive note, QLEDs have the potential to be more recyclable than some other display technologies due to their simpler structure and fewer layers. However, the presence of quantum dots complicates the recycling process, and specialized recycling facilities may be required to handle QLED waste effectively.

As QLED technology scales up for industrial implementation, manufacturers are increasingly focusing on developing more sustainable production methods. This includes research into alternative materials, improved manufacturing processes, and enhanced recycling techniques. The industry is also working towards establishing comprehensive lifecycle assessments to better understand and mitigate the environmental impact of QLED displays from production to disposal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!