How to Innovate Packaging Materials with Graphene Oxide?

Graphene Oxide Packaging Evolution and Objectives

Graphene oxide (GO) has emerged as a revolutionary material in the packaging industry, offering unprecedented opportunities for innovation and advancement. The evolution of GO packaging materials can be traced back to the early 2000s when graphene was first isolated. Since then, researchers and industry experts have been exploring its potential applications in various fields, including packaging.

The primary objective of incorporating GO into packaging materials is to enhance their performance and functionality. GO's unique properties, such as high strength, excellent barrier properties, and antimicrobial activity, make it an ideal candidate for developing advanced packaging solutions. These properties address key challenges in the packaging industry, such as extending shelf life, improving food safety, and reducing environmental impact.

One of the main goals in GO packaging evolution is to develop sustainable and eco-friendly alternatives to traditional packaging materials. As environmental concerns continue to grow, there is an increasing demand for biodegradable and recyclable packaging solutions. GO-based materials offer the potential to create packaging that is not only high-performing but also environmentally responsible.

Another significant objective is to improve the barrier properties of packaging materials. GO's impermeable nature makes it an excellent candidate for creating packaging with enhanced gas and moisture barrier properties. This is particularly important in food packaging, where maintaining product freshness and preventing spoilage are critical concerns.

The evolution of GO packaging also aims to incorporate smart and active packaging functionalities. By leveraging GO's unique properties, researchers are working on developing packaging materials that can respond to environmental changes, indicate product freshness, or even actively preserve the contents. This aligns with the growing trend of intelligent packaging in the industry.

Scalability and cost-effectiveness are crucial objectives in the evolution of GO packaging materials. While the potential benefits of GO are significant, widespread adoption in the packaging industry requires economically viable production methods. Researchers and manufacturers are focusing on developing scalable production techniques and exploring ways to reduce costs associated with GO incorporation.

As the field progresses, there is a growing emphasis on tailoring GO-based packaging materials for specific applications. This includes developing specialized coatings, films, and composites that cater to the unique requirements of different industries, such as food, pharmaceuticals, and electronics.

In conclusion, the evolution of GO packaging materials is driven by the objectives of enhancing performance, sustainability, and functionality. As research continues and technology advances, GO-based packaging solutions are poised to revolutionize the industry, offering innovative and sustainable alternatives to traditional packaging materials.

Market Demand for Advanced Packaging Solutions

The packaging industry is experiencing a significant shift towards advanced materials that offer superior performance, sustainability, and functionality. This growing demand for innovative packaging solutions is driven by several key factors in the global market. Firstly, there is an increasing awareness of environmental issues, leading consumers and businesses to seek eco-friendly packaging alternatives. This trend has created a substantial market for materials that are biodegradable, recyclable, or derived from renewable sources.

Secondly, the rise of e-commerce has revolutionized the packaging sector, necessitating materials that can withstand the rigors of shipping while maintaining product integrity. This has led to a surge in demand for lightweight yet durable packaging solutions that can reduce transportation costs and carbon footprint. The food and beverage industry, in particular, is seeking advanced packaging materials that can extend shelf life, maintain freshness, and provide enhanced barrier properties against moisture, oxygen, and contaminants.

Furthermore, there is a growing need for smart packaging solutions that can incorporate sensors, indicators, and other interactive features. These advanced packaging materials can provide real-time information about product quality, freshness, and authenticity, addressing concerns related to food safety and counterfeit products. The healthcare and pharmaceutical sectors are also driving demand for advanced packaging materials that can ensure product stability, sterility, and compliance with stringent regulations.

The market for advanced packaging solutions is also being influenced by changing consumer preferences and lifestyles. There is an increasing demand for convenience packaging that is easy to open, reseal, and dispose of. Additionally, the trend towards personalization and customization in packaging design is creating opportunities for materials that can be easily modified or printed on-demand.

In the context of graphene oxide as an innovative packaging material, there is significant potential to address many of these market demands. Graphene oxide's exceptional barrier properties, mechanical strength, and potential for functionalization make it an attractive candidate for developing next-generation packaging solutions. Its ability to enhance the performance of existing materials or create entirely new composites aligns well with the industry's need for multifunctional, sustainable, and high-performance packaging materials.

However, the adoption of graphene oxide in packaging applications faces challenges related to cost, scalability, and regulatory approval. Overcoming these hurdles will be crucial to meeting the market demand for advanced packaging solutions and realizing the full potential of graphene oxide in this sector.

Current Challenges in Graphene Oxide Packaging

Despite the promising potential of graphene oxide (GO) in packaging materials, several significant challenges hinder its widespread adoption and innovation in this field. One of the primary obstacles is the high production cost associated with GO. The current manufacturing processes for high-quality GO are complex and energy-intensive, resulting in elevated prices that limit its commercial viability for large-scale packaging applications.

Another major challenge lies in the scalability of GO production. While laboratory-scale synthesis methods have been well-established, translating these processes to industrial-scale production while maintaining consistent quality and properties remains a significant hurdle. This scalability issue directly impacts the ability to meet the potential demand for GO-based packaging materials in various industries.

The integration of GO into existing packaging materials and manufacturing processes presents another set of challenges. Achieving uniform dispersion of GO within polymer matrices or other packaging substrates is crucial for optimal performance but can be technically demanding. Additionally, ensuring compatibility between GO and other packaging components without compromising the overall material properties requires extensive research and development efforts.

Stability and long-term performance of GO in packaging applications are also areas of concern. GO's tendency to agglomerate over time can lead to a reduction in its effectiveness and potentially alter the properties of the packaging material. Moreover, the potential for GO to migrate from packaging into food or other contents raises safety concerns that need to be thoroughly addressed through rigorous testing and regulatory compliance.

Environmental considerations pose another challenge in GO packaging innovation. While GO offers potential benefits in terms of improved recyclability and biodegradability of packaging materials, the environmental impact of GO production and its long-term effects on ecosystems are not yet fully understood. Balancing the potential environmental benefits with the ecological footprint of GO manufacturing is crucial for sustainable innovation in this field.

Lastly, regulatory hurdles and safety concerns present significant challenges for GO packaging innovation. The novel nature of GO-enhanced materials means that regulatory frameworks for their use in packaging, especially for food contact applications, are still evolving. Extensive safety studies and compliance with stringent regulations are necessary before GO-based packaging solutions can be widely adopted in the market.

Existing Graphene Oxide Packaging Technologies

01 Graphene oxide-based packaging materials

Graphene oxide is used to create advanced packaging materials with enhanced properties such as improved barrier performance, mechanical strength, and thermal stability. These materials can be applied in various industries including food packaging, electronics, and consumer goods.- Graphene oxide-based packaging materials: Graphene oxide is utilized in packaging materials to enhance their properties. These materials can provide improved barrier properties, mechanical strength, and thermal stability. The incorporation of graphene oxide into packaging materials can lead to extended shelf life for packaged products and reduced environmental impact.

- Graphene oxide composites for food packaging: Graphene oxide is combined with other materials to create composite packaging materials specifically designed for food applications. These composites can offer antimicrobial properties, improved gas barrier performance, and enhanced mechanical properties, making them suitable for extending the shelf life of food products.

- Graphene oxide-based films and coatings: Thin films and coatings containing graphene oxide are developed for packaging applications. These films can be applied to various substrates to improve their barrier properties, mechanical strength, and thermal stability. The use of graphene oxide in films and coatings can lead to lighter and more efficient packaging materials.

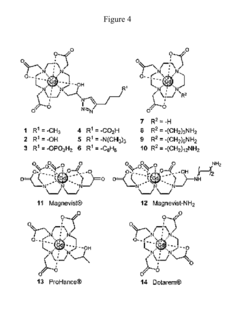

- Functionalized graphene oxide for packaging: Graphene oxide is functionalized with various chemical groups or molecules to enhance its properties for specific packaging applications. This functionalization can improve compatibility with other materials, increase dispersion in polymer matrices, or add specific functionalities such as antimicrobial properties or UV protection.

- Graphene oxide in smart packaging systems: Graphene oxide is incorporated into smart packaging systems that can monitor and respond to environmental conditions. These systems can include sensors for detecting spoilage, temperature changes, or gas permeation. The use of graphene oxide in smart packaging can lead to improved food safety and reduced waste.

02 Graphene oxide composites for packaging

Composite materials incorporating graphene oxide are developed for packaging applications. These composites often combine graphene oxide with polymers or other materials to create packaging solutions with superior mechanical, thermal, and barrier properties compared to traditional packaging materials.Expand Specific Solutions03 Graphene oxide films and coatings

Thin films and coatings made from graphene oxide are utilized in packaging to enhance barrier properties against gases, moisture, and other environmental factors. These films can be applied to various substrates to improve the overall performance of packaging materials.Expand Specific Solutions04 Functionalized graphene oxide for packaging

Graphene oxide is functionalized or modified to enhance specific properties for packaging applications. This can include improving compatibility with other materials, increasing dispersion in composites, or adding antimicrobial properties to the packaging material.Expand Specific Solutions05 Graphene oxide in smart packaging

Graphene oxide is incorporated into smart packaging solutions, enabling features such as sensors for monitoring product freshness, temperature indicators, or interactive elements. These advanced packaging materials can provide real-time information about the packaged product's condition or environment.Expand Specific Solutions

Key Players in Graphene Oxide Packaging Industry

The innovation of packaging materials with graphene oxide is in an emerging stage, with significant potential for market growth. The global graphene market is projected to expand rapidly, driven by increasing applications in various industries, including packaging. The technology's maturity is advancing, with key players like Northwestern University, Nanotek Instruments, and Peking University leading research efforts. Companies such as Tetra Laval Holdings & Finance SA are exploring graphene oxide's potential in food packaging, while institutions like the Centre National de la Recherche Scientifique and King Abdullah University of Science & Technology are contributing to fundamental research. The competitive landscape is diverse, with academic institutions, research centers, and industry players collaborating to overcome challenges in scalability and cost-effectiveness, aiming to unlock graphene oxide's full potential in innovative packaging solutions.

Northwestern University

Nanotek Instruments, Inc.

Breakthrough Innovations in Graphene Oxide Applications

- Development of a graphene oxide loaded nanocarrier for targeted delivery of Gemcitabine, synthesized using a modified Hummer's method, which enables controlled loading and release of the drug through functionalization with EDC, enhancing biocompatibility and physiological stability.

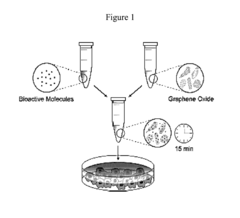

- A method involving unmodified graphene oxide in an aqueous medium with hydrophilic bioactive molecular components, where the two are co-incubated to allow binding and adsorption, enhancing cellular delivery through sedimentation and adsorption, with the option to conjugate with contrast agents for monitoring.

Environmental Impact of Graphene Oxide Packaging

The environmental impact of graphene oxide packaging is a critical consideration in the development and adoption of this innovative material. Graphene oxide, with its exceptional properties, offers potential benefits in reducing packaging waste and improving recyclability. However, its production and disposal processes require careful examination to ensure overall environmental sustainability.

One of the primary advantages of graphene oxide packaging is its potential to reduce material usage. The strength and barrier properties of graphene oxide allow for the creation of thinner, lighter packaging that maintains or even improves upon the performance of traditional materials. This reduction in material consumption can lead to decreased energy use in production and transportation, thereby lowering the carbon footprint associated with packaging.

Furthermore, graphene oxide's ability to enhance the properties of biodegradable polymers presents an opportunity for more environmentally friendly packaging solutions. By incorporating graphene oxide into bioplastics, it may be possible to create packaging that decomposes more readily in natural environments, reducing the persistence of plastic waste in ecosystems.

However, the production of graphene oxide itself raises environmental concerns. The process often involves the use of strong oxidizing agents and acids, which can generate hazardous waste. Efforts are underway to develop greener synthesis methods, but the current production processes may offset some of the environmental benefits gained from the material's use in packaging.

The end-of-life management of graphene oxide packaging is another crucial aspect to consider. While the material can potentially improve the recyclability of packaging by enhancing the properties of recycled plastics, questions remain about the long-term effects of graphene oxide nanoparticles in recycling streams and the environment. There is a need for comprehensive studies on the fate of these nanoparticles during recycling processes and their potential accumulation in ecosystems.

Additionally, the potential release of graphene oxide nanoparticles from packaging materials during use or disposal raises concerns about their impact on soil and aquatic environments. Research is ongoing to understand the ecotoxicological effects of these nanoparticles and to develop strategies for mitigating any negative impacts.

In conclusion, while graphene oxide packaging offers promising environmental benefits through material reduction and improved recyclability, a holistic approach is necessary to assess its true environmental impact. This includes considering the entire lifecycle of the packaging, from production to disposal, and addressing concerns related to nanoparticle release and ecosystem effects. As research progresses, it will be crucial to balance the innovative potential of graphene oxide packaging with rigorous environmental safeguards to ensure its sustainable implementation in the packaging industry.

Scalability and Cost Analysis

The scalability and cost analysis of graphene oxide (GO) in packaging materials innovation is crucial for its potential widespread adoption. Currently, the production of GO faces significant challenges in scaling up to industrial levels while maintaining cost-effectiveness. The primary methods for GO production, including modified Hummers' method and chemical vapor deposition (CVD), are limited in their ability to produce large quantities at competitive prices.

The modified Hummers' method, while effective for small-scale production, encounters difficulties in maintaining consistent quality and properties when scaled up. This inconsistency can lead to variability in the final packaging material's performance, potentially hindering its commercial viability. Additionally, the process involves hazardous chemicals and generates significant waste, which increases production costs and raises environmental concerns.

CVD, on the other hand, offers better control over GO quality but is currently more expensive and energy-intensive, making it less suitable for large-scale production of packaging materials. The high temperatures and specialized equipment required for CVD contribute to its elevated costs, limiting its application to high-value products rather than mass-market packaging solutions.

To address these scalability and cost issues, research is focusing on developing more efficient and cost-effective production methods. One promising approach is the electrochemical exfoliation of graphite, which has the potential for continuous production and reduced chemical usage. This method could significantly lower production costs and improve scalability, although it still requires optimization for consistent GO quality.

Another area of focus is the development of green synthesis methods that use environmentally friendly reagents and reduce waste generation. These approaches aim to lower production costs by minimizing the need for hazardous waste treatment and disposal, while also improving the sustainability profile of GO-based packaging materials.

The integration of GO into existing packaging production lines is another critical factor in scalability and cost reduction. Current packaging manufacturing processes may require significant modifications to incorporate GO effectively, potentially increasing initial implementation costs. Research into compatible processing techniques and the development of GO-based masterbatches or concentrates could facilitate easier integration and reduce overall production costs.

As production scales up, economies of scale are expected to play a significant role in reducing costs. However, this will require substantial initial investments in production facilities and equipment. The development of standardized quality control measures and characterization techniques for GO will be essential to ensure consistent performance across large-scale production batches, further contributing to cost reduction through improved yield and reduced waste.