How to Overcome Limitations in Carbonyl Compound Processing?

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbonyl Compound Processing: Background and Objectives

Carbonyl compounds, characterized by the presence of a carbon-oxygen double bond, play a crucial role in organic chemistry and various industrial processes. These compounds, including aldehydes and ketones, are essential intermediates in the synthesis of numerous valuable products, ranging from pharmaceuticals to polymers. The processing of carbonyl compounds has been a subject of extensive research and development over the past century, driven by the need for more efficient and sustainable production methods.

The evolution of carbonyl compound processing has been marked by significant milestones in synthetic organic chemistry. Early methods relied heavily on traditional oxidation and reduction reactions, often involving harsh conditions and toxic reagents. As environmental concerns grew and industrial demands increased, researchers began exploring more selective and environmentally friendly approaches. This led to the development of catalytic processes, which allowed for milder reaction conditions and improved atom economy.

Despite these advancements, the processing of carbonyl compounds still faces several limitations that hinder its widespread application in various industries. These challenges include poor selectivity in complex molecule synthesis, low yields in certain transformations, and the use of expensive or environmentally harmful reagents. Additionally, the sensitivity of many carbonyl compounds to air and moisture poses significant challenges in handling and storage, often requiring specialized equipment and conditions.

The primary objective in overcoming these limitations is to develop more robust, efficient, and sustainable methods for carbonyl compound processing. This involves exploring novel catalytic systems, designing innovative reaction pathways, and leveraging emerging technologies such as flow chemistry and artificial intelligence in reaction optimization. Researchers are also focusing on expanding the scope of carbonyl chemistry to enable the synthesis of more complex molecules with higher precision and fewer steps.

Another critical goal is to improve the scalability of carbonyl compound processing methods. Many reactions that work well on a laboratory scale face significant challenges when scaled up for industrial production. Addressing these issues requires a multidisciplinary approach, combining expertise in chemical engineering, process design, and materials science to develop more efficient and cost-effective large-scale production methods.

As we look towards the future of carbonyl compound processing, the field is poised for significant advancements. The integration of green chemistry principles, the development of bio-based alternatives, and the application of advanced computational tools for reaction prediction and optimization are expected to drive innovation in this area. These efforts aim not only to overcome current limitations but also to unlock new possibilities in the synthesis and application of carbonyl compounds across various industries.

The evolution of carbonyl compound processing has been marked by significant milestones in synthetic organic chemistry. Early methods relied heavily on traditional oxidation and reduction reactions, often involving harsh conditions and toxic reagents. As environmental concerns grew and industrial demands increased, researchers began exploring more selective and environmentally friendly approaches. This led to the development of catalytic processes, which allowed for milder reaction conditions and improved atom economy.

Despite these advancements, the processing of carbonyl compounds still faces several limitations that hinder its widespread application in various industries. These challenges include poor selectivity in complex molecule synthesis, low yields in certain transformations, and the use of expensive or environmentally harmful reagents. Additionally, the sensitivity of many carbonyl compounds to air and moisture poses significant challenges in handling and storage, often requiring specialized equipment and conditions.

The primary objective in overcoming these limitations is to develop more robust, efficient, and sustainable methods for carbonyl compound processing. This involves exploring novel catalytic systems, designing innovative reaction pathways, and leveraging emerging technologies such as flow chemistry and artificial intelligence in reaction optimization. Researchers are also focusing on expanding the scope of carbonyl chemistry to enable the synthesis of more complex molecules with higher precision and fewer steps.

Another critical goal is to improve the scalability of carbonyl compound processing methods. Many reactions that work well on a laboratory scale face significant challenges when scaled up for industrial production. Addressing these issues requires a multidisciplinary approach, combining expertise in chemical engineering, process design, and materials science to develop more efficient and cost-effective large-scale production methods.

As we look towards the future of carbonyl compound processing, the field is poised for significant advancements. The integration of green chemistry principles, the development of bio-based alternatives, and the application of advanced computational tools for reaction prediction and optimization are expected to drive innovation in this area. These efforts aim not only to overcome current limitations but also to unlock new possibilities in the synthesis and application of carbonyl compounds across various industries.

Market Analysis for Carbonyl Compound Applications

The carbonyl compound market has experienced significant growth in recent years, driven by increasing demand across various industries. The global market for carbonyl compounds is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many other chemical sectors. This growth is primarily attributed to the versatility and wide-ranging applications of carbonyl compounds in industries such as pharmaceuticals, agrochemicals, and materials science.

In the pharmaceutical sector, carbonyl compounds play a crucial role in the synthesis of active pharmaceutical ingredients (APIs) and intermediates. The rising prevalence of chronic diseases and the increasing focus on drug discovery and development have led to a surge in demand for carbonyl compounds in this sector. Additionally, the growing trend towards personalized medicine and targeted therapies is expected to further boost the market for specialized carbonyl compounds.

The agrochemical industry represents another significant market for carbonyl compounds, particularly in the production of pesticides, herbicides, and plant growth regulators. As global food demand continues to rise, coupled with the need for sustainable agricultural practices, the demand for advanced agrochemicals is expected to drive the carbonyl compound market in this sector.

In the materials science industry, carbonyl compounds are extensively used in the production of polymers, resins, and coatings. The growing construction and automotive industries, especially in emerging economies, are fueling the demand for these materials, consequently driving the market for carbonyl compounds.

Geographically, Asia-Pacific is expected to dominate the carbonyl compound market, owing to rapid industrialization, increasing population, and rising disposable incomes in countries like China and India. North America and Europe are also significant markets, driven by technological advancements and research activities in the pharmaceutical and chemical industries.

However, the market faces challenges such as stringent environmental regulations and concerns over the toxicity of certain carbonyl compounds. This has led to increased focus on developing eco-friendly alternatives and sustainable production processes, which could potentially reshape the market landscape in the coming years.

Despite these challenges, the overall outlook for the carbonyl compound market remains positive. The continuous innovation in processing techniques and the development of novel applications are expected to create new opportunities and drive market growth. As industries continue to seek more efficient and sustainable solutions, the demand for advanced carbonyl compounds is likely to persist, making it a key area of focus for chemical manufacturers and researchers alike.

In the pharmaceutical sector, carbonyl compounds play a crucial role in the synthesis of active pharmaceutical ingredients (APIs) and intermediates. The rising prevalence of chronic diseases and the increasing focus on drug discovery and development have led to a surge in demand for carbonyl compounds in this sector. Additionally, the growing trend towards personalized medicine and targeted therapies is expected to further boost the market for specialized carbonyl compounds.

The agrochemical industry represents another significant market for carbonyl compounds, particularly in the production of pesticides, herbicides, and plant growth regulators. As global food demand continues to rise, coupled with the need for sustainable agricultural practices, the demand for advanced agrochemicals is expected to drive the carbonyl compound market in this sector.

In the materials science industry, carbonyl compounds are extensively used in the production of polymers, resins, and coatings. The growing construction and automotive industries, especially in emerging economies, are fueling the demand for these materials, consequently driving the market for carbonyl compounds.

Geographically, Asia-Pacific is expected to dominate the carbonyl compound market, owing to rapid industrialization, increasing population, and rising disposable incomes in countries like China and India. North America and Europe are also significant markets, driven by technological advancements and research activities in the pharmaceutical and chemical industries.

However, the market faces challenges such as stringent environmental regulations and concerns over the toxicity of certain carbonyl compounds. This has led to increased focus on developing eco-friendly alternatives and sustainable production processes, which could potentially reshape the market landscape in the coming years.

Despite these challenges, the overall outlook for the carbonyl compound market remains positive. The continuous innovation in processing techniques and the development of novel applications are expected to create new opportunities and drive market growth. As industries continue to seek more efficient and sustainable solutions, the demand for advanced carbonyl compounds is likely to persist, making it a key area of focus for chemical manufacturers and researchers alike.

Current Challenges in Carbonyl Compound Processing

Carbonyl compound processing faces several significant challenges that hinder its widespread application and efficiency in various industries. One of the primary obstacles is the high reactivity of carbonyl groups, which can lead to undesired side reactions and product degradation. This reactivity often necessitates stringent control of reaction conditions, including temperature, pH, and the presence of catalysts or inhibitors.

The sensitivity of carbonyl compounds to oxidation poses another major challenge. Many carbonyl-containing substances are prone to auto-oxidation, particularly in the presence of light or heat. This susceptibility can result in the formation of peroxides and other unwanted by-products, compromising the quality and stability of the final products. Consequently, manufacturers must implement costly measures to prevent oxidation during processing, storage, and transportation.

Another significant limitation in carbonyl compound processing is the difficulty in achieving selective reactions. Many carbonyl compounds possess multiple reactive sites, making it challenging to target specific functional groups without affecting others. This lack of selectivity can lead to complex product mixtures, reduced yields, and increased purification costs. The development of highly selective catalysts and reaction conditions remains an ongoing challenge in the field.

The environmental impact of carbonyl compound processing is also a growing concern. Traditional methods often involve the use of toxic solvents, harsh reaction conditions, and generate significant amounts of waste. As sustainability becomes increasingly important, there is a pressing need to develop greener processing techniques that minimize environmental footprint while maintaining efficiency and product quality.

Scale-up issues present another hurdle in carbonyl compound processing. Reactions that work well at laboratory scale may encounter unforeseen complications when translated to industrial production. Heat transfer, mixing efficiency, and reaction kinetics can all be affected by scale, leading to reduced yields, increased impurities, or even safety hazards. Overcoming these scale-up challenges requires careful engineering and process optimization.

Lastly, the handling and storage of carbonyl compounds pose significant safety concerns. Many of these substances are volatile, flammable, or toxic, necessitating specialized equipment and stringent safety protocols. This not only increases processing costs but also limits the accessibility of carbonyl compound processing to specialized facilities, potentially hindering innovation and widespread adoption in various industries.

The sensitivity of carbonyl compounds to oxidation poses another major challenge. Many carbonyl-containing substances are prone to auto-oxidation, particularly in the presence of light or heat. This susceptibility can result in the formation of peroxides and other unwanted by-products, compromising the quality and stability of the final products. Consequently, manufacturers must implement costly measures to prevent oxidation during processing, storage, and transportation.

Another significant limitation in carbonyl compound processing is the difficulty in achieving selective reactions. Many carbonyl compounds possess multiple reactive sites, making it challenging to target specific functional groups without affecting others. This lack of selectivity can lead to complex product mixtures, reduced yields, and increased purification costs. The development of highly selective catalysts and reaction conditions remains an ongoing challenge in the field.

The environmental impact of carbonyl compound processing is also a growing concern. Traditional methods often involve the use of toxic solvents, harsh reaction conditions, and generate significant amounts of waste. As sustainability becomes increasingly important, there is a pressing need to develop greener processing techniques that minimize environmental footprint while maintaining efficiency and product quality.

Scale-up issues present another hurdle in carbonyl compound processing. Reactions that work well at laboratory scale may encounter unforeseen complications when translated to industrial production. Heat transfer, mixing efficiency, and reaction kinetics can all be affected by scale, leading to reduced yields, increased impurities, or even safety hazards. Overcoming these scale-up challenges requires careful engineering and process optimization.

Lastly, the handling and storage of carbonyl compounds pose significant safety concerns. Many of these substances are volatile, flammable, or toxic, necessitating specialized equipment and stringent safety protocols. This not only increases processing costs but also limits the accessibility of carbonyl compound processing to specialized facilities, potentially hindering innovation and widespread adoption in various industries.

Existing Solutions for Carbonyl Compound Processing

01 Reaction conditions for carbonyl compounds

Optimizing reaction conditions is crucial for processing carbonyl compounds. This includes controlling temperature, pressure, and catalyst selection to improve yield and selectivity. Specific reaction parameters may vary depending on the type of carbonyl compound and desired product.- Carbonyl compound synthesis and purification: Various methods for synthesizing and purifying carbonyl compounds are explored, addressing processing limitations. These include novel catalytic processes, separation techniques, and reaction optimization strategies to improve yield and purity of carbonyl compounds.

- Carbonyl compound stabilization: Techniques for stabilizing carbonyl compounds during processing and storage are developed. These methods focus on preventing degradation, maintaining product quality, and extending shelf life through the use of additives, protective atmospheres, or specialized packaging.

- Carbonyl compound reactivity control: Strategies to control the reactivity of carbonyl compounds during processing are investigated. These include the use of protective groups, selective catalysts, and reaction condition optimization to manage unwanted side reactions and improve selectivity in desired transformations.

- Carbonyl compound handling and safety: Improved methods for handling carbonyl compounds safely during processing are developed. These include specialized equipment design, process automation, and safety protocols to minimize exposure risks and ensure worker protection when dealing with volatile or hazardous carbonyl compounds.

- Carbonyl compound process monitoring and control: Advanced techniques for monitoring and controlling carbonyl compound processing are implemented. These include real-time analysis methods, process analytical technology (PAT), and feedback control systems to optimize reaction conditions, detect impurities, and ensure consistent product quality.

02 Purification and separation techniques

Effective purification and separation methods are essential for processing carbonyl compounds. These may include distillation, crystallization, extraction, and chromatography. The choice of technique depends on the specific carbonyl compound and the desired purity level.Expand Specific Solutions03 Handling and storage limitations

Carbonyl compounds often require special handling and storage conditions due to their reactivity and potential instability. This may involve using inert atmospheres, controlling moisture exposure, and maintaining appropriate temperature ranges to prevent degradation or unwanted side reactions.Expand Specific Solutions04 Catalytic processes for carbonyl compounds

Catalytic processes play a significant role in carbonyl compound processing. The selection of appropriate catalysts can overcome limitations in reactivity, selectivity, and yield. Homogeneous and heterogeneous catalysts, including metal complexes and enzymes, are employed depending on the specific transformation required.Expand Specific Solutions05 Environmental and safety considerations

Processing carbonyl compounds often involves environmental and safety challenges. These include managing volatile organic compound (VOC) emissions, handling potentially toxic or flammable materials, and implementing proper waste disposal methods. Adherence to regulatory guidelines and use of green chemistry principles can help address these limitations.Expand Specific Solutions

Key Industry Players and Competitors

The carbonyl compound processing industry is in a mature stage, with a global market size estimated in the billions of dollars. The technology has reached a high level of maturity, but limitations persist, driving ongoing research and development efforts. Key players like BASF, Sumitomo Chemical, and Wacker Chemie are at the forefront of innovation, leveraging their extensive R&D capabilities to overcome processing challenges. Universities such as the University of Zurich and University of Houston contribute significantly to fundamental research. Emerging companies like Novomer are introducing novel catalytic technologies, while established firms like Evonik and Solvay focus on specialty chemicals and advanced materials to address specific limitations in carbonyl processing.

Sumitomo Chemical Co., Ltd.

Technical Solution: Sumitomo Chemical has addressed limitations in carbonyl compound processing through the development of advanced organometallic catalysts for carbonylation reactions. Their approach focuses on the use of palladium-based catalysts with tailored ligand systems, enabling highly selective carbonylation of challenging substrates[15]. They have also implemented microwave-assisted synthesis techniques for carbonyl compounds, significantly reducing reaction times and improving energy efficiency[17]. Sumitomo has explored the use of supercritical carbon dioxide as a reaction medium for certain carbonyl transformations, offering improved mass transfer and product separation[19]. Additionally, they have developed novel photocatalytic systems for the synthesis of carbonyl compounds under mild conditions, addressing limitations in traditional thermal processes[21].

Strengths: Highly selective catalysts, energy-efficient processes, and exploration of alternative reaction media. Weaknesses: Potential high costs of catalyst development, may require specialized equipment for microwave and photocatalytic processes.

BASF Corp.

Technical Solution: BASF has developed innovative catalytic processes to overcome limitations in carbonyl compound processing. Their approach involves using metal-organic frameworks (MOFs) as heterogeneous catalysts for selective carbonyl transformations[1]. These MOFs offer high surface area and tunable pore structures, allowing for improved reactant accessibility and product selectivity. BASF has also implemented continuous flow reactors for carbonyl processing, which enhance heat and mass transfer, leading to better reaction control and higher yields[3]. Additionally, they have explored the use of biocatalysts, such as engineered enzymes, for stereoselective carbonyl reductions, addressing challenges in pharmaceutical intermediate synthesis[5].

Strengths: Versatile catalyst design, improved selectivity, and scalable continuous processes. Weaknesses: Potential high costs for MOF synthesis and enzyme engineering, may require specialized equipment for implementation.

Innovative Approaches in Carbonyl Chemistry

Process for production of carbonyl compounds

PatentInactiveEP1609776B1

Innovation

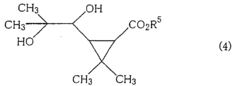

- A process involving the reaction of a diol with bromine or bromine chloride in the presence of a trivalent bismuth compound and a base to produce carbonyl compounds, which is more industrially advantageous and cost-effective.

Process for production of carbonyl compounds

PatentInactiveUS20060089506A1

Innovation

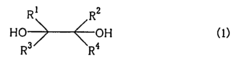

- A process involving the reaction of a diol with bromine or an inorganic bromine compound in the presence of a trivalent bismuth compound and a base to produce carbonyl compounds, which includes using a diol represented by formula (1) with specific substituents and a trivalent bismuth compound like triphenylbismuth, along with a base such as potassium carbonate, to form carbonyl compounds like aldehydes.

Environmental Impact of Carbonyl Processing

The environmental impact of carbonyl compound processing is a critical concern in the chemical industry, necessitating a comprehensive evaluation of its effects on ecosystems and human health. Carbonyl compounds, which include aldehydes and ketones, are widely used in various industrial processes, but their production and handling can lead to significant environmental challenges.

One of the primary environmental concerns associated with carbonyl processing is air pollution. Volatile organic compounds (VOCs) emitted during the production and use of carbonyl compounds contribute to the formation of ground-level ozone and smog. These emissions can have detrimental effects on air quality, particularly in urban and industrial areas, leading to respiratory issues and other health problems for both humans and wildlife.

Water pollution is another significant environmental impact of carbonyl processing. Improper disposal or accidental release of carbonyl compounds and their byproducts can contaminate water sources, affecting aquatic ecosystems and potentially entering the food chain. Some carbonyl compounds are known to be toxic to aquatic organisms, even at low concentrations, disrupting the delicate balance of aquatic ecosystems.

The production of carbonyl compounds often involves energy-intensive processes, contributing to greenhouse gas emissions and climate change. The carbon footprint of these operations can be substantial, particularly when considering the entire life cycle of carbonyl-based products. This aspect of environmental impact extends beyond the immediate processing facilities to include transportation and end-use emissions.

Soil contamination is an additional concern in areas where carbonyl compounds are produced or heavily used. Spills, leaks, or improper disposal practices can lead to the accumulation of these chemicals in soil, potentially affecting soil microorganisms, plant growth, and ultimately, the entire terrestrial ecosystem. Long-term soil contamination can also pose risks to groundwater resources through leaching.

To address these environmental challenges, the industry has been developing and implementing various mitigation strategies. These include the adoption of cleaner production technologies, improved waste management practices, and the implementation of more stringent emission control measures. Advanced air purification systems, such as catalytic oxidizers and scrubbers, are being employed to reduce VOC emissions from carbonyl processing facilities.

Water treatment technologies have also been enhanced to better handle carbonyl-containing wastewater. Techniques such as advanced oxidation processes and biological treatment systems are being utilized to break down carbonyl compounds before they are released into the environment. Additionally, closed-loop systems and water recycling initiatives are being implemented to minimize water consumption and reduce the risk of environmental contamination.

The shift towards green chemistry principles in carbonyl compound processing is gaining momentum. This approach focuses on designing chemical products and processes that reduce or eliminate the use and generation of hazardous substances. It includes exploring alternative, less toxic raw materials, developing more efficient catalysts, and optimizing reaction conditions to minimize waste and energy consumption.

One of the primary environmental concerns associated with carbonyl processing is air pollution. Volatile organic compounds (VOCs) emitted during the production and use of carbonyl compounds contribute to the formation of ground-level ozone and smog. These emissions can have detrimental effects on air quality, particularly in urban and industrial areas, leading to respiratory issues and other health problems for both humans and wildlife.

Water pollution is another significant environmental impact of carbonyl processing. Improper disposal or accidental release of carbonyl compounds and their byproducts can contaminate water sources, affecting aquatic ecosystems and potentially entering the food chain. Some carbonyl compounds are known to be toxic to aquatic organisms, even at low concentrations, disrupting the delicate balance of aquatic ecosystems.

The production of carbonyl compounds often involves energy-intensive processes, contributing to greenhouse gas emissions and climate change. The carbon footprint of these operations can be substantial, particularly when considering the entire life cycle of carbonyl-based products. This aspect of environmental impact extends beyond the immediate processing facilities to include transportation and end-use emissions.

Soil contamination is an additional concern in areas where carbonyl compounds are produced or heavily used. Spills, leaks, or improper disposal practices can lead to the accumulation of these chemicals in soil, potentially affecting soil microorganisms, plant growth, and ultimately, the entire terrestrial ecosystem. Long-term soil contamination can also pose risks to groundwater resources through leaching.

To address these environmental challenges, the industry has been developing and implementing various mitigation strategies. These include the adoption of cleaner production technologies, improved waste management practices, and the implementation of more stringent emission control measures. Advanced air purification systems, such as catalytic oxidizers and scrubbers, are being employed to reduce VOC emissions from carbonyl processing facilities.

Water treatment technologies have also been enhanced to better handle carbonyl-containing wastewater. Techniques such as advanced oxidation processes and biological treatment systems are being utilized to break down carbonyl compounds before they are released into the environment. Additionally, closed-loop systems and water recycling initiatives are being implemented to minimize water consumption and reduce the risk of environmental contamination.

The shift towards green chemistry principles in carbonyl compound processing is gaining momentum. This approach focuses on designing chemical products and processes that reduce or eliminate the use and generation of hazardous substances. It includes exploring alternative, less toxic raw materials, developing more efficient catalysts, and optimizing reaction conditions to minimize waste and energy consumption.

Safety Regulations in Carbonyl Compound Handling

Safety regulations in carbonyl compound handling are paramount due to the inherent risks associated with these chemicals. The primary concerns include toxicity, flammability, and reactivity. Regulatory bodies such as OSHA, EPA, and NIOSH have established comprehensive guidelines to ensure safe practices in industrial settings.

Personal protective equipment (PPE) is a crucial aspect of safety protocols. Workers must wear appropriate gloves, eye protection, and respiratory equipment when handling carbonyl compounds. The selection of PPE depends on the specific compound and its concentration. For instance, butyl rubber gloves are recommended for ketones, while nitrile gloves are suitable for aldehydes.

Proper ventilation is essential to minimize exposure to vapors. Local exhaust ventilation systems should be installed in areas where carbonyl compounds are processed. These systems must be regularly maintained and tested to ensure optimal performance. In addition, general room ventilation should be adequate to prevent the accumulation of vapors in the workspace.

Storage and handling procedures are critical components of safety regulations. Carbonyl compounds should be stored in cool, dry areas away from sources of ignition. Containers must be properly labeled and sealed to prevent leaks and spills. Incompatible chemicals should be segregated to avoid potential reactions. Regular inspections of storage areas are necessary to identify and address any issues promptly.

Emergency response plans are mandatory for facilities handling carbonyl compounds. These plans should include procedures for spill containment, evacuation protocols, and first aid measures. Employees must be trained in emergency procedures and have access to safety data sheets (SDS) for all chemicals in use.

Monitoring and exposure limits are established to protect workers from long-term health effects. OSHA has set permissible exposure limits (PELs) for many carbonyl compounds. Regular air monitoring should be conducted to ensure compliance with these limits. If exposure levels exceed the PELs, additional control measures must be implemented.

Waste disposal regulations are also crucial in carbonyl compound handling. Proper disposal methods must be followed to prevent environmental contamination. This may include neutralization, incineration, or other approved treatment methods. Facilities must comply with local, state, and federal regulations regarding hazardous waste disposal.

Training and education are fundamental aspects of safety regulations. All personnel involved in handling carbonyl compounds must receive comprehensive training on hazards, proper handling techniques, and emergency procedures. This training should be regularly updated to reflect changes in regulations and best practices.

Personal protective equipment (PPE) is a crucial aspect of safety protocols. Workers must wear appropriate gloves, eye protection, and respiratory equipment when handling carbonyl compounds. The selection of PPE depends on the specific compound and its concentration. For instance, butyl rubber gloves are recommended for ketones, while nitrile gloves are suitable for aldehydes.

Proper ventilation is essential to minimize exposure to vapors. Local exhaust ventilation systems should be installed in areas where carbonyl compounds are processed. These systems must be regularly maintained and tested to ensure optimal performance. In addition, general room ventilation should be adequate to prevent the accumulation of vapors in the workspace.

Storage and handling procedures are critical components of safety regulations. Carbonyl compounds should be stored in cool, dry areas away from sources of ignition. Containers must be properly labeled and sealed to prevent leaks and spills. Incompatible chemicals should be segregated to avoid potential reactions. Regular inspections of storage areas are necessary to identify and address any issues promptly.

Emergency response plans are mandatory for facilities handling carbonyl compounds. These plans should include procedures for spill containment, evacuation protocols, and first aid measures. Employees must be trained in emergency procedures and have access to safety data sheets (SDS) for all chemicals in use.

Monitoring and exposure limits are established to protect workers from long-term health effects. OSHA has set permissible exposure limits (PELs) for many carbonyl compounds. Regular air monitoring should be conducted to ensure compliance with these limits. If exposure levels exceed the PELs, additional control measures must be implemented.

Waste disposal regulations are also crucial in carbonyl compound handling. Proper disposal methods must be followed to prevent environmental contamination. This may include neutralization, incineration, or other approved treatment methods. Facilities must comply with local, state, and federal regulations regarding hazardous waste disposal.

Training and education are fundamental aspects of safety regulations. All personnel involved in handling carbonyl compounds must receive comprehensive training on hazards, proper handling techniques, and emergency procedures. This training should be regularly updated to reflect changes in regulations and best practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!