Carbonyl Chemistry in Biodegradable Polymer Production

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbonyl Chemistry in Biodegradable Polymers: Background and Objectives

Carbonyl chemistry plays a pivotal role in the development and production of biodegradable polymers, offering a sustainable alternative to conventional plastics. The field has evolved significantly over the past few decades, driven by increasing environmental concerns and the need for more eco-friendly materials. The primary objective of research in this area is to harness the reactivity of carbonyl groups to create polymers that can decompose naturally in the environment without leaving harmful residues.

The journey of carbonyl chemistry in biodegradable polymers began with the exploration of naturally occurring polymers like cellulose and starch. These materials contain abundant carbonyl functionalities, which contribute to their biodegradability. As research progressed, scientists started focusing on synthetic polymers that could mimic the biodegradable properties of natural materials while offering improved mechanical and thermal characteristics.

One of the key milestones in this field was the development of polylactic acid (PLA), a biodegradable polyester derived from renewable resources. The carbonyl groups in PLA's ester linkages are crucial for its biodegradability, as they are susceptible to hydrolysis under appropriate conditions. This breakthrough opened up new avenues for research into other carbonyl-containing biodegradable polymers.

The current technological landscape is characterized by a growing emphasis on tailoring the properties of biodegradable polymers through precise control of carbonyl chemistry. Researchers are exploring various strategies, including copolymerization, blending, and chemical modification, to enhance the performance of these materials while maintaining their biodegradability.

A significant trend in the field is the development of "smart" biodegradable polymers that can respond to specific environmental stimuli. These materials often incorporate carbonyl groups that can undergo reversible reactions, allowing for controlled degradation or release of active compounds. This approach has potential applications in fields ranging from agriculture to biomedical engineering.

The overarching goal of research in carbonyl chemistry for biodegradable polymer production is to create materials that can compete with traditional plastics in terms of performance and cost, while offering superior end-of-life options. This involves optimizing polymerization processes, improving material properties, and ensuring consistent biodegradability across various environmental conditions.

As we look to the future, the integration of carbonyl chemistry with other emerging technologies, such as nanotechnology and artificial intelligence, is expected to drive further innovations in biodegradable polymer design and production. These advancements aim to address current limitations and expand the range of applications for these environmentally friendly materials.

The journey of carbonyl chemistry in biodegradable polymers began with the exploration of naturally occurring polymers like cellulose and starch. These materials contain abundant carbonyl functionalities, which contribute to their biodegradability. As research progressed, scientists started focusing on synthetic polymers that could mimic the biodegradable properties of natural materials while offering improved mechanical and thermal characteristics.

One of the key milestones in this field was the development of polylactic acid (PLA), a biodegradable polyester derived from renewable resources. The carbonyl groups in PLA's ester linkages are crucial for its biodegradability, as they are susceptible to hydrolysis under appropriate conditions. This breakthrough opened up new avenues for research into other carbonyl-containing biodegradable polymers.

The current technological landscape is characterized by a growing emphasis on tailoring the properties of biodegradable polymers through precise control of carbonyl chemistry. Researchers are exploring various strategies, including copolymerization, blending, and chemical modification, to enhance the performance of these materials while maintaining their biodegradability.

A significant trend in the field is the development of "smart" biodegradable polymers that can respond to specific environmental stimuli. These materials often incorporate carbonyl groups that can undergo reversible reactions, allowing for controlled degradation or release of active compounds. This approach has potential applications in fields ranging from agriculture to biomedical engineering.

The overarching goal of research in carbonyl chemistry for biodegradable polymer production is to create materials that can compete with traditional plastics in terms of performance and cost, while offering superior end-of-life options. This involves optimizing polymerization processes, improving material properties, and ensuring consistent biodegradability across various environmental conditions.

As we look to the future, the integration of carbonyl chemistry with other emerging technologies, such as nanotechnology and artificial intelligence, is expected to drive further innovations in biodegradable polymer design and production. These advancements aim to address current limitations and expand the range of applications for these environmentally friendly materials.

Market Analysis for Biodegradable Polymer Products

The biodegradable polymer market has experienced significant growth in recent years, driven by increasing environmental concerns and regulatory pressures to reduce plastic waste. This market segment is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to exceed 15% over the next five years. The global market value for biodegradable polymers is estimated to reach several billion dollars by 2025, reflecting the growing demand across various industries.

Key factors contributing to this market expansion include the rising consumer awareness of environmental issues, government initiatives to promote sustainable materials, and the development of innovative biodegradable polymer technologies. Industries such as packaging, agriculture, textiles, and consumer goods are the primary drivers of demand for biodegradable polymer products.

The packaging sector, in particular, represents the largest market share for biodegradable polymers. With the increasing focus on reducing single-use plastics, biodegradable packaging solutions are gaining traction in food and beverage, personal care, and retail industries. The agricultural sector is another significant market, where biodegradable mulch films and plant pots are becoming increasingly popular due to their ability to decompose naturally in soil.

Geographically, Europe leads the biodegradable polymer market, followed by North America and Asia-Pacific. European countries have implemented stringent regulations on plastic use, fostering the adoption of biodegradable alternatives. The Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing environmental awareness, and supportive government policies in countries like China and India.

Despite the positive market outlook, challenges remain in the widespread adoption of biodegradable polymers. These include higher production costs compared to conventional plastics, limited waste management infrastructure for proper composting, and the need for improved performance characteristics to match traditional plastics in certain applications.

The competitive landscape of the biodegradable polymer market is characterized by a mix of established chemical companies and innovative start-ups. Key players are investing heavily in research and development to enhance product properties and reduce production costs. Collaborations between industry players, research institutions, and government bodies are also driving innovation in this field.

As the market continues to evolve, new opportunities are emerging in niche applications such as 3D printing filaments, medical implants, and smart packaging solutions. The integration of carbonyl chemistry in biodegradable polymer production is expected to play a crucial role in developing next-generation materials with improved properties and broader applications, further expanding the market potential for these sustainable alternatives.

Key factors contributing to this market expansion include the rising consumer awareness of environmental issues, government initiatives to promote sustainable materials, and the development of innovative biodegradable polymer technologies. Industries such as packaging, agriculture, textiles, and consumer goods are the primary drivers of demand for biodegradable polymer products.

The packaging sector, in particular, represents the largest market share for biodegradable polymers. With the increasing focus on reducing single-use plastics, biodegradable packaging solutions are gaining traction in food and beverage, personal care, and retail industries. The agricultural sector is another significant market, where biodegradable mulch films and plant pots are becoming increasingly popular due to their ability to decompose naturally in soil.

Geographically, Europe leads the biodegradable polymer market, followed by North America and Asia-Pacific. European countries have implemented stringent regulations on plastic use, fostering the adoption of biodegradable alternatives. The Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing environmental awareness, and supportive government policies in countries like China and India.

Despite the positive market outlook, challenges remain in the widespread adoption of biodegradable polymers. These include higher production costs compared to conventional plastics, limited waste management infrastructure for proper composting, and the need for improved performance characteristics to match traditional plastics in certain applications.

The competitive landscape of the biodegradable polymer market is characterized by a mix of established chemical companies and innovative start-ups. Key players are investing heavily in research and development to enhance product properties and reduce production costs. Collaborations between industry players, research institutions, and government bodies are also driving innovation in this field.

As the market continues to evolve, new opportunities are emerging in niche applications such as 3D printing filaments, medical implants, and smart packaging solutions. The integration of carbonyl chemistry in biodegradable polymer production is expected to play a crucial role in developing next-generation materials with improved properties and broader applications, further expanding the market potential for these sustainable alternatives.

Current Challenges in Carbonyl-based Biodegradable Polymer Synthesis

The synthesis of carbonyl-based biodegradable polymers faces several significant challenges that hinder their widespread adoption and commercial viability. One of the primary obstacles is the control of molecular weight and polydispersity during polymerization. The carbonyl group's reactivity can lead to undesired side reactions, resulting in branching or crosslinking, which affects the polymer's properties and degradation profile.

Another major challenge is the optimization of reaction conditions to achieve high conversion rates while maintaining the desired polymer structure. Factors such as temperature, pressure, and catalyst selection play crucial roles in determining the final product's characteristics. Balancing these parameters to obtain consistent and reproducible results remains a complex task for researchers and manufacturers alike.

The selection and availability of suitable monomers pose additional difficulties. Many carbonyl-containing monomers are derived from renewable resources, but their production and purification processes are often costly and energy-intensive. This economic barrier limits the scalability of biodegradable polymer production and hinders their competitiveness against conventional petroleum-based plastics.

Furthermore, the incorporation of functional groups to enhance the polymer's properties or enable post-polymerization modifications presents its own set of challenges. Introducing these functionalities without compromising the polymer's biodegradability or mechanical properties requires careful molecular design and synthesis strategies.

The stability of carbonyl-based biodegradable polymers during processing and storage is another area of concern. These materials can be sensitive to moisture, heat, and light, which may lead to premature degradation or loss of desired properties. Developing effective stabilization techniques and appropriate packaging solutions is essential for ensuring product quality and shelf life.

Lastly, achieving precise control over the degradation rate and mechanism of carbonyl-based biodegradable polymers remains a significant challenge. The degradation behavior can be influenced by various factors, including polymer composition, molecular weight, crystallinity, and environmental conditions. Tailoring these parameters to meet specific application requirements while maintaining biodegradability is a complex task that requires extensive research and optimization efforts.

Addressing these challenges requires a multidisciplinary approach, combining expertise in polymer chemistry, materials science, and process engineering. Overcoming these hurdles will be crucial for advancing the field of carbonyl-based biodegradable polymers and realizing their potential as sustainable alternatives to conventional plastics.

Another major challenge is the optimization of reaction conditions to achieve high conversion rates while maintaining the desired polymer structure. Factors such as temperature, pressure, and catalyst selection play crucial roles in determining the final product's characteristics. Balancing these parameters to obtain consistent and reproducible results remains a complex task for researchers and manufacturers alike.

The selection and availability of suitable monomers pose additional difficulties. Many carbonyl-containing monomers are derived from renewable resources, but their production and purification processes are often costly and energy-intensive. This economic barrier limits the scalability of biodegradable polymer production and hinders their competitiveness against conventional petroleum-based plastics.

Furthermore, the incorporation of functional groups to enhance the polymer's properties or enable post-polymerization modifications presents its own set of challenges. Introducing these functionalities without compromising the polymer's biodegradability or mechanical properties requires careful molecular design and synthesis strategies.

The stability of carbonyl-based biodegradable polymers during processing and storage is another area of concern. These materials can be sensitive to moisture, heat, and light, which may lead to premature degradation or loss of desired properties. Developing effective stabilization techniques and appropriate packaging solutions is essential for ensuring product quality and shelf life.

Lastly, achieving precise control over the degradation rate and mechanism of carbonyl-based biodegradable polymers remains a significant challenge. The degradation behavior can be influenced by various factors, including polymer composition, molecular weight, crystallinity, and environmental conditions. Tailoring these parameters to meet specific application requirements while maintaining biodegradability is a complex task that requires extensive research and optimization efforts.

Addressing these challenges requires a multidisciplinary approach, combining expertise in polymer chemistry, materials science, and process engineering. Overcoming these hurdles will be crucial for advancing the field of carbonyl-based biodegradable polymers and realizing their potential as sustainable alternatives to conventional plastics.

Existing Carbonyl-based Biodegradable Polymer Production Methods

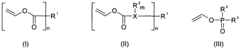

01 Biodegradable carbonyl compounds in polymers

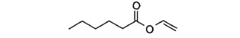

Incorporation of carbonyl groups into polymer structures can enhance their biodegradability. These compounds can be introduced through various chemical modifications, allowing for the development of environmentally friendly materials that break down more easily in natural conditions.- Biodegradable carbonyl compounds in polymers: Incorporation of carbonyl groups into polymer structures can enhance their biodegradability. These compounds can be introduced through various methods, such as oxidation or copolymerization with carbonyl-containing monomers. The presence of carbonyl groups makes the polymer more susceptible to environmental degradation, particularly through photodegradation and hydrolysis.

- Enzymatic degradation of carbonyl-containing materials: Certain enzymes can catalyze the breakdown of carbonyl-containing materials, promoting their biodegradability. These enzymes typically target specific carbonyl structures, such as ketones or aldehydes, and facilitate their conversion into more easily degradable compounds. This approach is particularly useful for enhancing the biodegradability of complex organic molecules in environmental applications.

- Carbonyl chemistry in biodegradable packaging: Carbonyl chemistry plays a crucial role in developing biodegradable packaging materials. By incorporating carbonyl groups into packaging polymers, manufacturers can create materials that degrade more readily in the environment. This approach often involves using renewable resources and designing materials that break down into non-toxic components.

- Photodegradation of carbonyl-containing compounds: Carbonyl groups in organic compounds can undergo photodegradation when exposed to sunlight, leading to the breakdown of the material. This process is particularly relevant for outdoor applications and can be enhanced by incorporating photosensitizers or other additives that promote light-induced degradation of carbonyl bonds.

- Biodegradable carbonyl-based adhesives: Development of biodegradable adhesives utilizing carbonyl chemistry focuses on creating strong bonding agents that can decompose naturally over time. These adhesives often incorporate carbonyl groups that are susceptible to hydrolysis or enzymatic degradation, allowing for the breakdown of the adhesive under specific environmental conditions while maintaining necessary performance characteristics during use.

02 Enzymatic degradation of carbonyl-containing substances

Certain enzymes can catalyze the breakdown of carbonyl-containing compounds, facilitating their biodegradation. This approach is particularly useful in environmental remediation and waste treatment processes, where specific enzymes can be employed to target and degrade carbonyl pollutants.Expand Specific Solutions03 Photodegradation of carbonyl compounds

Carbonyl groups can undergo photochemical reactions when exposed to light, leading to the breakdown of the compound. This property is exploited in the development of photodegradable materials and in environmental cleanup strategies targeting carbonyl-based pollutants.Expand Specific Solutions04 Microbial degradation of carbonyl-containing molecules

Microorganisms play a crucial role in the biodegradation of carbonyl compounds in natural environments. Certain bacteria and fungi have evolved metabolic pathways to break down these molecules, converting them into simpler, less harmful substances.Expand Specific Solutions05 Chemical modification for improved biodegradability

Altering the chemical structure of carbonyl-containing compounds can enhance their susceptibility to biodegradation. This may involve introducing additional functional groups or modifying existing ones to make the molecule more accessible to degradative processes in the environment.Expand Specific Solutions

Key Players in Biodegradable Polymer Industry

The research on carbonyl chemistry in biodegradable polymer production is currently in a growth phase, with increasing market demand and technological advancements. The global biodegradable plastics market is expanding rapidly, driven by environmental concerns and regulatory pressures. Key players like BASF, Novamont, and Eastman Chemical are investing heavily in R&D to develop innovative solutions. While the technology is maturing, there is still significant room for improvement in performance and cost-effectiveness. Companies such as Novomer and Teysha Technologies are pioneering novel approaches, leveraging carbonyl chemistry to create more sustainable polymers. Academic institutions and research organizations are also contributing to the field's progress, fostering collaborations with industry partners to accelerate commercialization efforts.

DSM IP Assets BV

Technical Solution: DSM has developed innovative carbonyl chemistry approaches for biodegradable polymer production. They utilize renewable feedstocks like succinic acid to create bio-based and biodegradable polyesters[1]. Their process involves polycondensation reactions of dicarboxylic acids and diols, with careful control of carbonyl reactivity to achieve desired polymer properties[2]. DSM has also explored enzymatic polymerization methods to produce polyesters with precisely controlled structures[3]. Their technology enables the production of high-performance biodegradable materials for packaging, textiles, and biomedical applications.

Strengths: Expertise in renewable feedstocks, advanced polymerization techniques, and tailored material properties. Weaknesses: Higher production costs compared to conventional plastics, limited scalability of some processes.

Novomer, Inc.

Technical Solution: Novomer has pioneered the use of carbon monoxide as a carbonyl source in biodegradable polymer synthesis. Their proprietary catalyst technology enables the copolymerization of CO with epoxides to produce aliphatic polycarbonates[4]. These materials offer excellent barrier properties and biodegradability. Novomer has also developed methods to incorporate CO2 into polymer backbones, creating poly(propylene carbonate) with up to 50% CO2 content[5]. Their carbonyl insertion technology allows for the production of novel biodegradable polyesters and polyurethanes with tunable properties.

Strengths: Unique CO/CO2 utilization technology, high carbon sequestration potential, versatile polymer platform. Weaknesses: Reliance on specialized catalysts, potential safety concerns with CO handling.

Innovative Carbonyl Chemistry Approaches for Biodegradability

Production method of biodegradable polymer using organic acid as catalyst and initiator

PatentInactiveKR1020220152127A

Innovation

- A method using an organic acid with both a carboxyl and hydroxyl group as both catalyst and initiator for lactone-based monomer polymerization, introducing a carboxyl group during synthesis without additional processing, simplifying the process and enhancing biocompatibility.

Use of compounds hardened by means of polymerisation for producing biodegradable, biocompatible, networked polymers

PatentInactiveEP2428235A2

Innovation

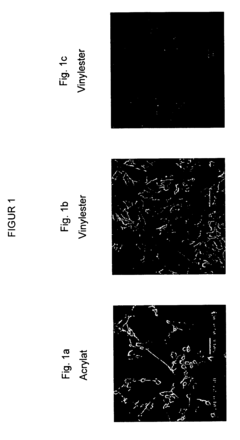

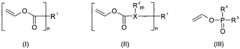

- A polymerization-curable composition based on polyvinyl alcohol is developed, incorporating vinyl ester monomers, ethylenically unsaturated comonomers, polymerization initiators, and solvents to create biodegradable, biocompatible, cross-linked polymers with controlled crosslinking density and low toxicity, suitable for use as implants and tissue support materials.

Environmental Impact Assessment of Biodegradable Polymers

The environmental impact assessment of biodegradable polymers is a crucial aspect of their production and use, particularly in the context of carbonyl chemistry research. These polymers offer potential solutions to plastic pollution, but their overall environmental footprint must be carefully evaluated.

Biodegradable polymers, when properly disposed of, can decompose into natural substances, reducing long-term environmental accumulation. However, their production process and life cycle must be scrutinized. The synthesis of these polymers often involves the use of renewable resources, which can lead to reduced dependency on fossil fuels. This shift can potentially lower greenhouse gas emissions associated with polymer production.

The degradation process of these polymers in various environments is a key consideration. While they break down more readily than conventional plastics, the rate and completeness of degradation can vary significantly depending on environmental conditions. Factors such as temperature, humidity, and microbial activity play crucial roles. In some cases, incomplete degradation may result in microplastic formation, which poses its own set of environmental challenges.

Water consumption and pollution during the production of biodegradable polymers are important factors to assess. Some biodegradable polymers require less water in their production compared to traditional plastics, but others may have a higher water footprint. Additionally, the potential release of chemicals during degradation must be evaluated for their impact on soil and water ecosystems.

The end-of-life management of biodegradable polymers presents both opportunities and challenges. While they can be composted in industrial facilities, not all regions have the necessary infrastructure. Improper disposal in landfills may lead to methane emissions, a potent greenhouse gas. Therefore, the development of appropriate waste management systems is crucial for realizing the full environmental benefits of these materials.

Land use changes associated with the cultivation of feedstocks for bio-based biodegradable polymers must also be considered. While using agricultural waste can be beneficial, dedicating land specifically for polymer production may compete with food crops or lead to deforestation, potentially offsetting the environmental benefits.

In conclusion, while biodegradable polymers show promise in reducing plastic pollution, a comprehensive life cycle assessment is essential to fully understand their environmental impact. This assessment should consider raw material sourcing, production processes, use phase, and end-of-life scenarios to ensure that the shift towards these materials truly results in a net positive environmental outcome.

Biodegradable polymers, when properly disposed of, can decompose into natural substances, reducing long-term environmental accumulation. However, their production process and life cycle must be scrutinized. The synthesis of these polymers often involves the use of renewable resources, which can lead to reduced dependency on fossil fuels. This shift can potentially lower greenhouse gas emissions associated with polymer production.

The degradation process of these polymers in various environments is a key consideration. While they break down more readily than conventional plastics, the rate and completeness of degradation can vary significantly depending on environmental conditions. Factors such as temperature, humidity, and microbial activity play crucial roles. In some cases, incomplete degradation may result in microplastic formation, which poses its own set of environmental challenges.

Water consumption and pollution during the production of biodegradable polymers are important factors to assess. Some biodegradable polymers require less water in their production compared to traditional plastics, but others may have a higher water footprint. Additionally, the potential release of chemicals during degradation must be evaluated for their impact on soil and water ecosystems.

The end-of-life management of biodegradable polymers presents both opportunities and challenges. While they can be composted in industrial facilities, not all regions have the necessary infrastructure. Improper disposal in landfills may lead to methane emissions, a potent greenhouse gas. Therefore, the development of appropriate waste management systems is crucial for realizing the full environmental benefits of these materials.

Land use changes associated with the cultivation of feedstocks for bio-based biodegradable polymers must also be considered. While using agricultural waste can be beneficial, dedicating land specifically for polymer production may compete with food crops or lead to deforestation, potentially offsetting the environmental benefits.

In conclusion, while biodegradable polymers show promise in reducing plastic pollution, a comprehensive life cycle assessment is essential to fully understand their environmental impact. This assessment should consider raw material sourcing, production processes, use phase, and end-of-life scenarios to ensure that the shift towards these materials truly results in a net positive environmental outcome.

Regulatory Framework for Biodegradable Materials

The regulatory framework for biodegradable materials plays a crucial role in shaping the development and adoption of carbonyl chemistry in biodegradable polymer production. As environmental concerns continue to grow, governments and international organizations have implemented various policies and standards to promote the use of sustainable materials and reduce plastic waste.

In the European Union, the European Committee for Standardization (CEN) has established EN 13432 as the primary standard for biodegradable and compostable packaging. This standard sets specific requirements for packaging to be considered biodegradable, including the material's ability to disintegrate and biodegrade within a specified timeframe under controlled composting conditions.

Similarly, the United States has implemented ASTM D6400, which outlines the specifications for compostable plastics. This standard ensures that materials labeled as biodegradable meet specific criteria for decomposition in industrial composting facilities. The Federal Trade Commission (FTC) also enforces guidelines on environmental marketing claims, including those related to biodegradability.

In Asia, countries like Japan and South Korea have established their own certification systems for biodegradable materials. Japan's GreenPla certification and South Korea's EL724 standard provide frameworks for evaluating and approving biodegradable plastics in their respective markets.

The regulatory landscape also includes restrictions on certain chemicals used in polymer production. For instance, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation impacts the use of specific carbonyl compounds in biodegradable polymer synthesis, requiring manufacturers to assess and manage the risks associated with these substances.

As research on carbonyl chemistry in biodegradable polymer production advances, regulatory bodies are adapting their frameworks to accommodate new technologies and materials. This includes the development of standards for marine biodegradability, as concerns about plastic pollution in oceans continue to grow.

The regulatory framework also extends to end-of-life management of biodegradable materials. Many countries have implemented extended producer responsibility (EPR) programs, which hold manufacturers accountable for the entire lifecycle of their products, including disposal and recycling. These regulations incentivize the development of truly biodegradable materials that can be safely returned to the environment.

As the field of biodegradable polymers evolves, researchers and manufacturers must navigate an increasingly complex regulatory landscape. Compliance with these regulations not only ensures market access but also drives innovation in carbonyl chemistry to develop materials that meet both performance and environmental requirements.

In the European Union, the European Committee for Standardization (CEN) has established EN 13432 as the primary standard for biodegradable and compostable packaging. This standard sets specific requirements for packaging to be considered biodegradable, including the material's ability to disintegrate and biodegrade within a specified timeframe under controlled composting conditions.

Similarly, the United States has implemented ASTM D6400, which outlines the specifications for compostable plastics. This standard ensures that materials labeled as biodegradable meet specific criteria for decomposition in industrial composting facilities. The Federal Trade Commission (FTC) also enforces guidelines on environmental marketing claims, including those related to biodegradability.

In Asia, countries like Japan and South Korea have established their own certification systems for biodegradable materials. Japan's GreenPla certification and South Korea's EL724 standard provide frameworks for evaluating and approving biodegradable plastics in their respective markets.

The regulatory landscape also includes restrictions on certain chemicals used in polymer production. For instance, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation impacts the use of specific carbonyl compounds in biodegradable polymer synthesis, requiring manufacturers to assess and manage the risks associated with these substances.

As research on carbonyl chemistry in biodegradable polymer production advances, regulatory bodies are adapting their frameworks to accommodate new technologies and materials. This includes the development of standards for marine biodegradability, as concerns about plastic pollution in oceans continue to grow.

The regulatory framework also extends to end-of-life management of biodegradable materials. Many countries have implemented extended producer responsibility (EPR) programs, which hold manufacturers accountable for the entire lifecycle of their products, including disposal and recycling. These regulations incentivize the development of truly biodegradable materials that can be safely returned to the environment.

As the field of biodegradable polymers evolves, researchers and manufacturers must navigate an increasingly complex regulatory landscape. Compliance with these regulations not only ensures market access but also drives innovation in carbonyl chemistry to develop materials that meet both performance and environmental requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!