Carbonyl-Driven Technologies for Future Manufacturing

JUL 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbonyl Tech Evolution

Carbonyl-driven technologies have undergone significant evolution since their inception in the early 20th century. The timeline of this technological progression can be divided into several key phases, each marked by groundbreaking discoveries and innovations that have shaped the field of carbonyl chemistry and its applications in manufacturing.

The first phase, spanning from the 1920s to the 1950s, saw the foundational development of carbonyl chemistry. This period was characterized by the elucidation of fundamental reaction mechanisms and the discovery of key carbonyl compounds. The Grignard reaction, aldol condensation, and Dieckmann cyclization were among the pivotal reactions that laid the groundwork for future advancements in carbonyl-driven technologies.

The second phase, from the 1960s to the 1980s, witnessed the expansion of carbonyl chemistry into industrial applications. This era saw the development of large-scale processes for the production of important chemicals such as acetic acid, acetone, and formaldehyde through carbonyl-based reactions. The advent of metal-catalyzed carbonylation reactions, particularly the Monsanto acetic acid process, revolutionized industrial synthesis and paved the way for more efficient manufacturing techniques.

The third phase, spanning the 1990s to the early 2000s, was marked by the integration of carbonyl chemistry with emerging fields such as green chemistry and catalysis. This period saw the development of more environmentally friendly carbonyl-based processes, including the use of supercritical CO2 as a solvent and the exploration of biocatalytic approaches to carbonyl transformations. Additionally, advances in asymmetric synthesis using chiral catalysts opened new avenues for the production of pharmaceuticals and fine chemicals.

The current phase, from the mid-2000s to the present, is characterized by the convergence of carbonyl chemistry with cutting-edge technologies such as nanotechnology, artificial intelligence, and flow chemistry. This era has seen the development of novel carbonyl-based materials, including metal-organic frameworks (MOFs) and covalent organic frameworks (COFs), which have potential applications in gas storage, catalysis, and drug delivery. Furthermore, the application of machine learning algorithms to predict and optimize carbonyl reactions has accelerated the discovery of new synthetic pathways and improved process efficiency.

Looking towards the future, carbonyl-driven technologies are poised to play a crucial role in addressing global challenges such as sustainable energy production and carbon dioxide utilization. Emerging research areas include the development of CO2-based polymers, electrochemical reduction of CO2 to valuable carbonyl compounds, and the use of carbonyl chemistry in the synthesis of advanced materials for energy storage and conversion. These advancements are expected to drive innovation in manufacturing processes, leading to more sustainable and efficient production methods across various industries.

The first phase, spanning from the 1920s to the 1950s, saw the foundational development of carbonyl chemistry. This period was characterized by the elucidation of fundamental reaction mechanisms and the discovery of key carbonyl compounds. The Grignard reaction, aldol condensation, and Dieckmann cyclization were among the pivotal reactions that laid the groundwork for future advancements in carbonyl-driven technologies.

The second phase, from the 1960s to the 1980s, witnessed the expansion of carbonyl chemistry into industrial applications. This era saw the development of large-scale processes for the production of important chemicals such as acetic acid, acetone, and formaldehyde through carbonyl-based reactions. The advent of metal-catalyzed carbonylation reactions, particularly the Monsanto acetic acid process, revolutionized industrial synthesis and paved the way for more efficient manufacturing techniques.

The third phase, spanning the 1990s to the early 2000s, was marked by the integration of carbonyl chemistry with emerging fields such as green chemistry and catalysis. This period saw the development of more environmentally friendly carbonyl-based processes, including the use of supercritical CO2 as a solvent and the exploration of biocatalytic approaches to carbonyl transformations. Additionally, advances in asymmetric synthesis using chiral catalysts opened new avenues for the production of pharmaceuticals and fine chemicals.

The current phase, from the mid-2000s to the present, is characterized by the convergence of carbonyl chemistry with cutting-edge technologies such as nanotechnology, artificial intelligence, and flow chemistry. This era has seen the development of novel carbonyl-based materials, including metal-organic frameworks (MOFs) and covalent organic frameworks (COFs), which have potential applications in gas storage, catalysis, and drug delivery. Furthermore, the application of machine learning algorithms to predict and optimize carbonyl reactions has accelerated the discovery of new synthetic pathways and improved process efficiency.

Looking towards the future, carbonyl-driven technologies are poised to play a crucial role in addressing global challenges such as sustainable energy production and carbon dioxide utilization. Emerging research areas include the development of CO2-based polymers, electrochemical reduction of CO2 to valuable carbonyl compounds, and the use of carbonyl chemistry in the synthesis of advanced materials for energy storage and conversion. These advancements are expected to drive innovation in manufacturing processes, leading to more sustainable and efficient production methods across various industries.

Market Demand Analysis

The market demand for carbonyl-driven technologies in future manufacturing is experiencing significant growth, driven by the increasing focus on sustainable and efficient production processes. As industries seek to reduce their carbon footprint and improve resource utilization, carbonyl-driven technologies offer promising solutions across various sectors.

In the chemical industry, there is a rising demand for carbonyl-based processes that enable the synthesis of high-value chemicals and materials. These technologies allow for more selective and energy-efficient reactions, reducing waste and improving overall process economics. The pharmaceutical sector, in particular, is showing keen interest in carbonyl-driven technologies for the production of complex drug molecules and intermediates.

The polymer and materials industry is another key market driver for carbonyl-driven technologies. With the growing emphasis on biodegradable and recyclable materials, carbonyl-based processes offer new pathways for developing sustainable polymers and composites. This aligns with the increasing consumer demand for environmentally friendly products and packaging solutions.

In the energy sector, carbonyl-driven technologies are gaining traction for their potential in carbon capture and utilization. As governments worldwide implement stricter emissions regulations, industries are exploring innovative methods to convert CO2 into valuable products. Carbonyl-based processes show promise in this area, potentially opening up new markets for carbon-neutral or carbon-negative products.

The food and beverage industry is also contributing to the market demand for carbonyl-driven technologies. These processes offer new possibilities for flavor and fragrance production, as well as the development of functional food ingredients. The ability to create complex molecules with specific properties is particularly valuable in this sector.

Market analysts project substantial growth in the adoption of carbonyl-driven technologies over the next decade. This growth is expected to be particularly strong in regions with stringent environmental regulations and a strong focus on innovation, such as Europe and North America. Emerging economies in Asia are also showing increased interest as they seek to modernize their manufacturing capabilities while addressing environmental concerns.

The market demand is further bolstered by the potential for cost savings and improved product quality offered by carbonyl-driven technologies. As these processes often require milder conditions and fewer steps compared to traditional methods, they can lead to significant reductions in energy consumption and operational costs. This economic incentive is driving interest across various industries, from specialty chemicals to consumer goods manufacturing.

In the chemical industry, there is a rising demand for carbonyl-based processes that enable the synthesis of high-value chemicals and materials. These technologies allow for more selective and energy-efficient reactions, reducing waste and improving overall process economics. The pharmaceutical sector, in particular, is showing keen interest in carbonyl-driven technologies for the production of complex drug molecules and intermediates.

The polymer and materials industry is another key market driver for carbonyl-driven technologies. With the growing emphasis on biodegradable and recyclable materials, carbonyl-based processes offer new pathways for developing sustainable polymers and composites. This aligns with the increasing consumer demand for environmentally friendly products and packaging solutions.

In the energy sector, carbonyl-driven technologies are gaining traction for their potential in carbon capture and utilization. As governments worldwide implement stricter emissions regulations, industries are exploring innovative methods to convert CO2 into valuable products. Carbonyl-based processes show promise in this area, potentially opening up new markets for carbon-neutral or carbon-negative products.

The food and beverage industry is also contributing to the market demand for carbonyl-driven technologies. These processes offer new possibilities for flavor and fragrance production, as well as the development of functional food ingredients. The ability to create complex molecules with specific properties is particularly valuable in this sector.

Market analysts project substantial growth in the adoption of carbonyl-driven technologies over the next decade. This growth is expected to be particularly strong in regions with stringent environmental regulations and a strong focus on innovation, such as Europe and North America. Emerging economies in Asia are also showing increased interest as they seek to modernize their manufacturing capabilities while addressing environmental concerns.

The market demand is further bolstered by the potential for cost savings and improved product quality offered by carbonyl-driven technologies. As these processes often require milder conditions and fewer steps compared to traditional methods, they can lead to significant reductions in energy consumption and operational costs. This economic incentive is driving interest across various industries, from specialty chemicals to consumer goods manufacturing.

Current Challenges

Carbonyl-driven technologies in manufacturing face several significant challenges that hinder their widespread adoption and full potential realization. One of the primary obstacles is the complexity of controlling carbonyl reactions in industrial settings. These reactions are often sensitive to environmental factors such as temperature, pressure, and the presence of catalysts, making it difficult to maintain consistent product quality and yield in large-scale production processes.

Another major challenge lies in the development of efficient and selective catalysts for carbonyl-driven reactions. While many catalysts have been identified in laboratory settings, scaling them up for industrial use often results in decreased efficiency and selectivity. This issue is particularly pronounced when dealing with complex substrates or when aiming for high-value, specialized products.

The energy intensity of many carbonyl-driven processes presents a significant hurdle in terms of sustainability and cost-effectiveness. Many of these reactions require high temperatures or pressures, leading to substantial energy consumption. This not only increases production costs but also contributes to the carbon footprint of manufacturing processes, contradicting the growing demand for more environmentally friendly industrial practices.

Raw material sourcing and supply chain management pose additional challenges. Many carbonyl-driven technologies rely on specific aldehydes or ketones as starting materials. Ensuring a stable, cost-effective supply of these compounds, especially for large-scale manufacturing, can be problematic. This is exacerbated by the fact that some of these raw materials are derived from fossil fuels, raising concerns about long-term sustainability and price volatility.

The integration of carbonyl-driven technologies into existing manufacturing infrastructure presents both technical and economic challenges. Retrofitting current production lines or building entirely new facilities to accommodate these technologies requires significant capital investment. Moreover, the transition often necessitates retraining of personnel and the development of new safety protocols, adding to the complexity and cost of implementation.

Regulatory compliance and safety considerations also pose significant challenges. Many carbonyl compounds are toxic or potentially hazardous, requiring stringent safety measures and environmental controls. Navigating the regulatory landscape, especially across different regions with varying standards, can be a complex and time-consuming process for manufacturers looking to adopt these technologies.

Lastly, there is a knowledge gap in understanding the full potential and limitations of carbonyl-driven technologies in diverse manufacturing applications. While research continues to uncover new possibilities, translating these findings into practical, scalable solutions remains a challenge. This gap hinders the development of innovative products and processes that could potentially revolutionize various sectors of the manufacturing industry.

Another major challenge lies in the development of efficient and selective catalysts for carbonyl-driven reactions. While many catalysts have been identified in laboratory settings, scaling them up for industrial use often results in decreased efficiency and selectivity. This issue is particularly pronounced when dealing with complex substrates or when aiming for high-value, specialized products.

The energy intensity of many carbonyl-driven processes presents a significant hurdle in terms of sustainability and cost-effectiveness. Many of these reactions require high temperatures or pressures, leading to substantial energy consumption. This not only increases production costs but also contributes to the carbon footprint of manufacturing processes, contradicting the growing demand for more environmentally friendly industrial practices.

Raw material sourcing and supply chain management pose additional challenges. Many carbonyl-driven technologies rely on specific aldehydes or ketones as starting materials. Ensuring a stable, cost-effective supply of these compounds, especially for large-scale manufacturing, can be problematic. This is exacerbated by the fact that some of these raw materials are derived from fossil fuels, raising concerns about long-term sustainability and price volatility.

The integration of carbonyl-driven technologies into existing manufacturing infrastructure presents both technical and economic challenges. Retrofitting current production lines or building entirely new facilities to accommodate these technologies requires significant capital investment. Moreover, the transition often necessitates retraining of personnel and the development of new safety protocols, adding to the complexity and cost of implementation.

Regulatory compliance and safety considerations also pose significant challenges. Many carbonyl compounds are toxic or potentially hazardous, requiring stringent safety measures and environmental controls. Navigating the regulatory landscape, especially across different regions with varying standards, can be a complex and time-consuming process for manufacturers looking to adopt these technologies.

Lastly, there is a knowledge gap in understanding the full potential and limitations of carbonyl-driven technologies in diverse manufacturing applications. While research continues to uncover new possibilities, translating these findings into practical, scalable solutions remains a challenge. This gap hinders the development of innovative products and processes that could potentially revolutionize various sectors of the manufacturing industry.

Existing Solutions

01 Carbonyl compounds in chemical synthesis

Carbonyl-driven technologies are utilized in various chemical synthesis processes. These technologies involve the use of carbonyl groups (C=O) as reactive centers for forming new chemical bonds. The carbonyl functionality plays a crucial role in organic synthesis, enabling the creation of complex molecules through reactions such as aldol condensations, Grignard reactions, and reductive aminations.- Carbonyl compounds in chemical synthesis: Carbonyl-driven technologies are utilized in various chemical synthesis processes. These technologies involve the use of carbonyl groups (C=O) as reactive centers for forming new chemical bonds. This approach is particularly useful in organic synthesis, pharmaceutical manufacturing, and the production of fine chemicals.

- Carbonyl-based materials for energy storage: Carbonyl compounds are being explored for their potential in energy storage applications. These materials can undergo reversible redox reactions, making them suitable for use in batteries and supercapacitors. Research is focused on developing high-performance carbonyl-based electrodes and electrolytes for next-generation energy storage devices.

- Carbonyl chemistry in environmental technologies: Carbonyl-driven technologies are being applied to address environmental challenges. This includes the development of catalysts for the conversion of harmful emissions, such as carbon dioxide and volatile organic compounds, into less harmful or valuable products. These technologies also play a role in water treatment and air purification processes.

- Carbonyl compounds in sensor technologies: The reactivity of carbonyl groups is being harnessed for the development of advanced sensor technologies. These sensors can detect specific molecules or environmental conditions based on interactions with carbonyl compounds. Applications include medical diagnostics, environmental monitoring, and industrial process control.

- Computational methods for carbonyl chemistry: Advanced computational methods are being developed to model and predict the behavior of carbonyl compounds in various chemical processes. These tools aid in the design of new reactions, materials, and processes involving carbonyl chemistry. Machine learning and quantum chemistry approaches are being integrated to enhance the accuracy and efficiency of these computational methods.

02 Carbonyl-based materials for energy applications

Carbonyl compounds are employed in the development of advanced materials for energy-related applications. These materials can be used in energy storage devices, such as batteries and supercapacitors, as well as in fuel cells and solar cells. The unique properties of carbonyl-containing compounds contribute to improved energy efficiency and performance in these applications.Expand Specific Solutions03 Carbonyl-driven processes in environmental technologies

Carbonyl-driven technologies play a significant role in environmental applications. These include processes for air and water purification, waste treatment, and the development of eco-friendly materials. The reactivity of carbonyl groups is harnessed to remove pollutants, convert waste into valuable products, and create biodegradable alternatives to conventional materials.Expand Specific Solutions04 Carbonyl chemistry in pharmaceutical development

Carbonyl-driven technologies are extensively used in the pharmaceutical industry for drug discovery and development. The carbonyl group serves as a versatile functional group in the synthesis of drug molecules, enabling the creation of diverse chemical structures with specific biological activities. These technologies are crucial in developing new medications and improving existing ones.Expand Specific Solutions05 Carbonyl-based sensors and detection methods

Carbonyl compounds are utilized in the development of sensors and detection methods for various applications. These technologies leverage the reactivity of carbonyl groups to create highly sensitive and selective sensors for detecting specific molecules or environmental conditions. Such sensors find applications in medical diagnostics, environmental monitoring, and industrial process control.Expand Specific Solutions

Key Industry Players

The research on carbonyl-driven technologies for future manufacturing is in an emerging stage, with significant potential for growth. The market is still relatively small but expanding rapidly as industries seek more sustainable and efficient manufacturing processes. Technological maturity varies across different applications, with some areas more advanced than others. Key players like Sumitomo Chemical, Wacker Chemie, and Covestro are driving innovation in this field, leveraging their expertise in chemical engineering and materials science. Academic institutions such as Zhejiang University and the University of Florida are contributing fundamental research, while government agencies like AIST and CSIR are supporting development efforts. As the technology progresses, collaboration between industry, academia, and government will be crucial for commercialization and widespread adoption.

Wacker Chemie AG

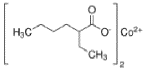

Technical Solution: Wacker Chemie has developed innovative carbonyl-driven technologies focusing on the utilization of CO in organic synthesis. Their approach involves the carbonylation of olefins and alkynes to produce valuable chemical intermediates and fine chemicals [1]. The company has made significant progress in developing highly selective catalysts for these transformations, enabling the production of aldehydes, carboxylic acids, and esters with improved atom economy [2]. Wacker's research also extends to the development of novel CO-based polymers, exploring the potential of carbonyl chemistry in creating sustainable materials with unique properties [3]. Additionally, they are investigating the use of CO2 as a C1 building block in combination with their established silicone chemistry expertise [4].

Strengths: Strong expertise in catalysis and process development, diverse product portfolio, and established market presence. Weaknesses: Potential safety concerns associated with CO handling and the need for specialized equipment for large-scale implementation.

Covestro Deutschland AG

Technical Solution: Covestro has made significant strides in carbonyl-driven technologies, particularly in CO2-based polyurethanes. Their flagship CO2 technology, cardyon®, incorporates up to 20% CO2 into polyols used for flexible foams, reducing the reliance on fossil-based raw materials [1][2]. The company has expanded this technology to produce thermoplastic polyurethanes (TPUs) and elastomers, demonstrating the versatility of their CO2-based approach [3]. Covestro is also exploring the use of CO2 in rigid foams for insulation applications, potentially revolutionizing the construction industry [4]. Their research extends to developing novel catalysts and process technologies to further increase CO2 incorporation and expand the range of CO2-based products.

Strengths: Established commercial products, strong market presence in polyurethanes, and commitment to sustainable innovation. Weaknesses: Current limitations in CO2 incorporation percentage and potential challenges in adapting existing manufacturing infrastructure.

Core Innovations

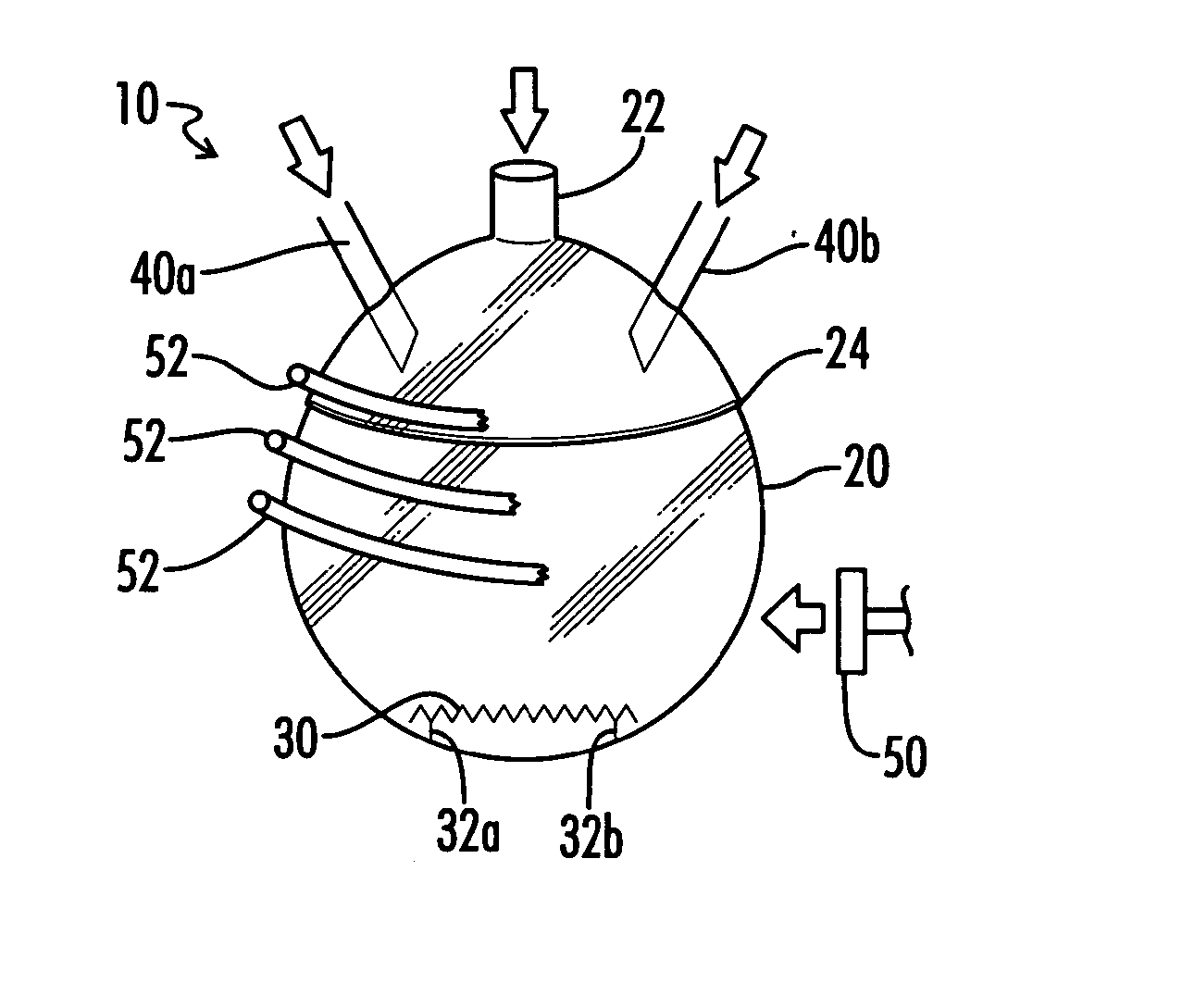

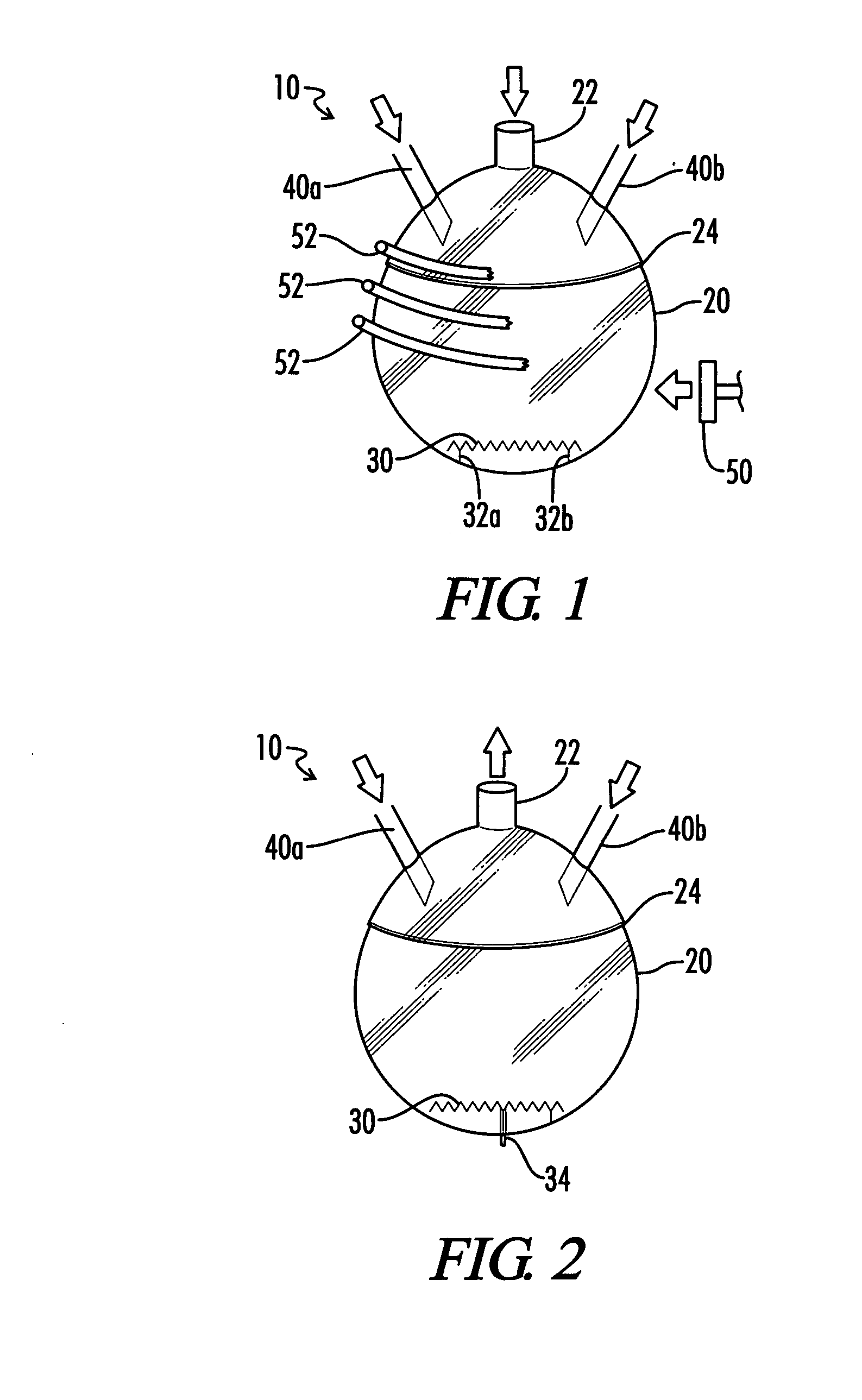

Continuous process for the use of metal carbonyls for the production of nano-scale metal particles formed of non-noble metals

PatentInactiveUS20070283784A1

Innovation

- A continuous process using metal carbonyls to produce non-noble metal nano-scale particles by decomposing them in a reactor vessel with controlled energy sources, allowing for deposition on a support or collection without the need for extreme conditions, utilizing a reactor system that can operate at atmospheric pressure and moderate temperatures.

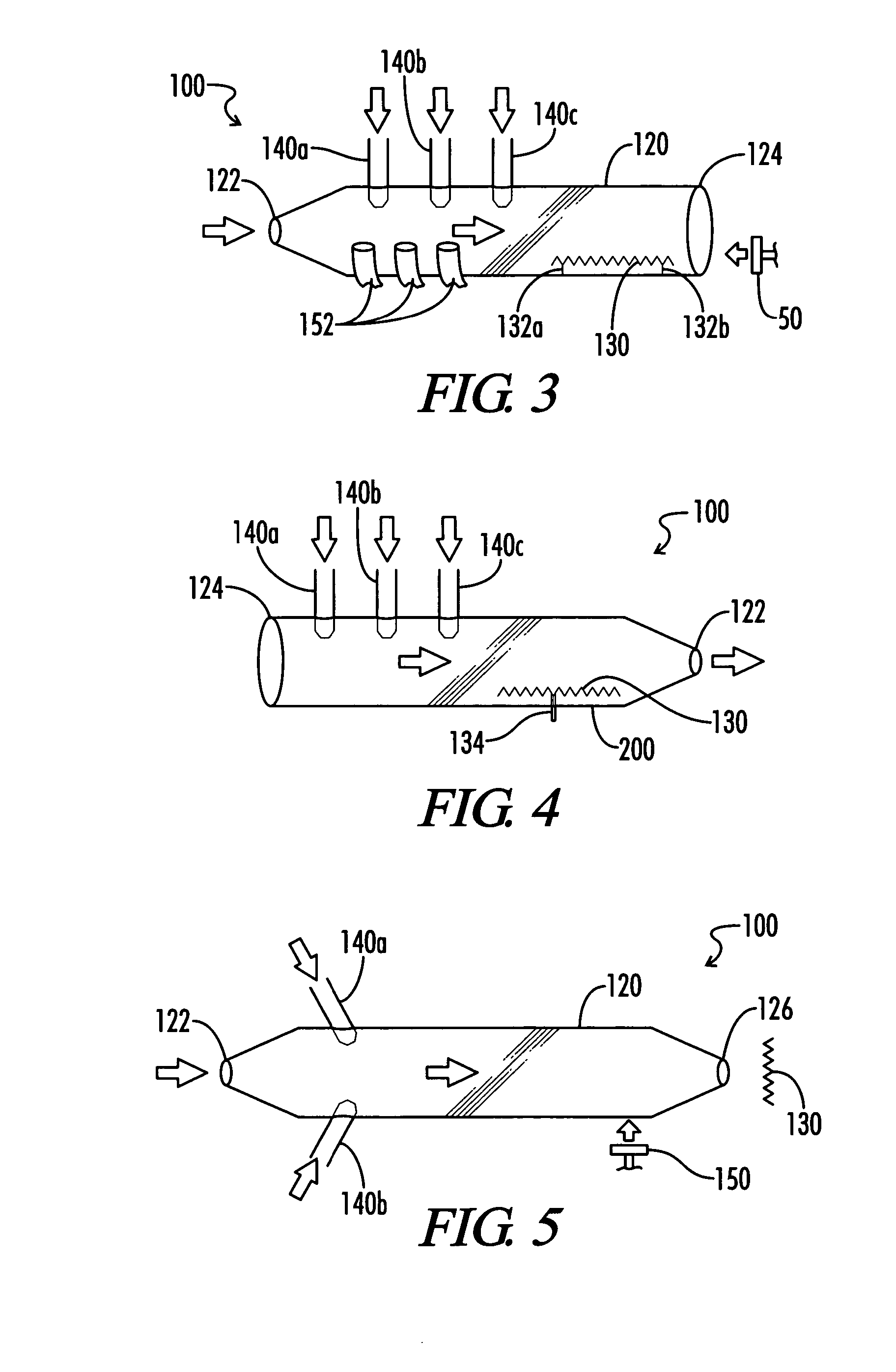

Process for the production of metal carbonyls

PatentWO2018149525A1

Innovation

- A continuous process involving a reaction mixture of a metal carboxylate, carbon monoxide, an aliphatic alcohol like butanol, and a hydrocarbon solvent in a reactor, with controlled temperatures and pressures, allowing for high yields and purity without additional contaminants like hydrogen, and enabling efficient scaling.

Environmental Impact

Carbonyl-driven technologies in future manufacturing processes have significant environmental implications that warrant careful consideration. These technologies, which leverage the reactivity of carbonyl groups, offer potential benefits in terms of efficiency and product quality. However, their environmental impact must be thoroughly assessed to ensure sustainable implementation.

One of the primary environmental concerns associated with carbonyl-driven technologies is the potential for volatile organic compound (VOC) emissions. Many carbonyl compounds are highly volatile and can contribute to air pollution if not properly managed. This is particularly relevant in industrial settings where large-scale processes may release substantial quantities of these compounds. Implementing effective emission control systems and adopting closed-loop manufacturing processes can help mitigate this risk.

Water pollution is another critical environmental aspect to consider. Some carbonyl-based reactions produce byproducts that, if discharged untreated, could contaminate water sources. Developing efficient wastewater treatment protocols specific to carbonyl-driven processes is essential to minimize the environmental footprint of these technologies.

On the positive side, carbonyl-driven technologies have the potential to reduce overall energy consumption in manufacturing processes. Many carbonyl reactions occur under mild conditions, requiring less energy input compared to traditional methods. This can lead to a decrease in greenhouse gas emissions associated with energy production, contributing to climate change mitigation efforts.

Furthermore, the selectivity of carbonyl-driven reactions can result in higher yields and fewer unwanted byproducts. This increased efficiency translates to reduced waste generation and more sustainable use of raw materials. By optimizing reaction conditions and catalysts, manufacturers can further enhance this benefit, leading to a more circular and environmentally friendly production model.

The life cycle assessment (LCA) of products manufactured using carbonyl-driven technologies is crucial for understanding their long-term environmental impact. This includes evaluating the sourcing of raw materials, production processes, product use, and end-of-life disposal or recycling. Initial studies suggest that in many cases, the improved efficiency and reduced waste of carbonyl-driven processes can lead to a lower overall environmental burden compared to conventional manufacturing methods.

As research in this field progresses, there is a growing focus on developing bio-based carbonyl compounds and green chemistry approaches. These innovations aim to replace petroleum-derived precursors with renewable alternatives, further reducing the environmental footprint of carbonyl-driven technologies. Additionally, the exploration of enzymatic and biocatalytic processes for carbonyl transformations offers promising avenues for more environmentally benign manufacturing practices.

One of the primary environmental concerns associated with carbonyl-driven technologies is the potential for volatile organic compound (VOC) emissions. Many carbonyl compounds are highly volatile and can contribute to air pollution if not properly managed. This is particularly relevant in industrial settings where large-scale processes may release substantial quantities of these compounds. Implementing effective emission control systems and adopting closed-loop manufacturing processes can help mitigate this risk.

Water pollution is another critical environmental aspect to consider. Some carbonyl-based reactions produce byproducts that, if discharged untreated, could contaminate water sources. Developing efficient wastewater treatment protocols specific to carbonyl-driven processes is essential to minimize the environmental footprint of these technologies.

On the positive side, carbonyl-driven technologies have the potential to reduce overall energy consumption in manufacturing processes. Many carbonyl reactions occur under mild conditions, requiring less energy input compared to traditional methods. This can lead to a decrease in greenhouse gas emissions associated with energy production, contributing to climate change mitigation efforts.

Furthermore, the selectivity of carbonyl-driven reactions can result in higher yields and fewer unwanted byproducts. This increased efficiency translates to reduced waste generation and more sustainable use of raw materials. By optimizing reaction conditions and catalysts, manufacturers can further enhance this benefit, leading to a more circular and environmentally friendly production model.

The life cycle assessment (LCA) of products manufactured using carbonyl-driven technologies is crucial for understanding their long-term environmental impact. This includes evaluating the sourcing of raw materials, production processes, product use, and end-of-life disposal or recycling. Initial studies suggest that in many cases, the improved efficiency and reduced waste of carbonyl-driven processes can lead to a lower overall environmental burden compared to conventional manufacturing methods.

As research in this field progresses, there is a growing focus on developing bio-based carbonyl compounds and green chemistry approaches. These innovations aim to replace petroleum-derived precursors with renewable alternatives, further reducing the environmental footprint of carbonyl-driven technologies. Additionally, the exploration of enzymatic and biocatalytic processes for carbonyl transformations offers promising avenues for more environmentally benign manufacturing practices.

Regulatory Framework

The regulatory framework surrounding carbonyl-driven technologies in manufacturing is evolving rapidly to address the unique challenges and opportunities presented by these innovative processes. At the international level, organizations such as the United Nations Environment Programme (UNEP) and the World Health Organization (WHO) are developing guidelines for the safe handling and disposal of carbonyl compounds in industrial settings. These guidelines aim to minimize environmental impact and protect worker health while fostering technological advancement.

In the United States, the Environmental Protection Agency (EPA) has taken a proactive approach to regulating carbonyl-driven technologies. The agency has established emission standards for volatile organic compounds (VOCs), many of which are carbonyl-based, under the Clean Air Act. Additionally, the Occupational Safety and Health Administration (OSHA) has set permissible exposure limits for various carbonyl compounds to ensure workplace safety.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which includes specific provisions for carbonyl compounds used in manufacturing processes. This comprehensive framework requires manufacturers to assess and manage the risks associated with these chemicals throughout their lifecycle.

In Asia, countries like China and Japan are developing their own regulatory approaches to carbonyl-driven technologies. China's Ministry of Ecology and Environment has introduced stricter emissions standards for industries utilizing carbonyl compounds, while Japan's Ministry of Economy, Trade, and Industry has launched initiatives to promote green chemistry practices in carbonyl-based manufacturing.

Emerging economies are also recognizing the importance of regulating these technologies. India, for instance, has incorporated guidelines for carbonyl compound management into its National Manufacturing Policy, emphasizing the need for sustainable and environmentally friendly production methods.

As the field of carbonyl-driven technologies continues to advance, regulatory bodies are increasingly focusing on promoting innovation while ensuring safety and sustainability. Many jurisdictions are exploring performance-based regulations that allow for flexibility in technological approaches while maintaining strict environmental and health standards. This approach aims to encourage the development of novel carbonyl-driven processes that can enhance manufacturing efficiency and reduce environmental impact.

Furthermore, international collaborations are being established to harmonize regulatory approaches across borders. These efforts seek to create a more consistent global framework for carbonyl-driven technologies, facilitating technology transfer and reducing barriers to trade while maintaining high standards of safety and environmental protection.

In the United States, the Environmental Protection Agency (EPA) has taken a proactive approach to regulating carbonyl-driven technologies. The agency has established emission standards for volatile organic compounds (VOCs), many of which are carbonyl-based, under the Clean Air Act. Additionally, the Occupational Safety and Health Administration (OSHA) has set permissible exposure limits for various carbonyl compounds to ensure workplace safety.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which includes specific provisions for carbonyl compounds used in manufacturing processes. This comprehensive framework requires manufacturers to assess and manage the risks associated with these chemicals throughout their lifecycle.

In Asia, countries like China and Japan are developing their own regulatory approaches to carbonyl-driven technologies. China's Ministry of Ecology and Environment has introduced stricter emissions standards for industries utilizing carbonyl compounds, while Japan's Ministry of Economy, Trade, and Industry has launched initiatives to promote green chemistry practices in carbonyl-based manufacturing.

Emerging economies are also recognizing the importance of regulating these technologies. India, for instance, has incorporated guidelines for carbonyl compound management into its National Manufacturing Policy, emphasizing the need for sustainable and environmentally friendly production methods.

As the field of carbonyl-driven technologies continues to advance, regulatory bodies are increasingly focusing on promoting innovation while ensuring safety and sustainability. Many jurisdictions are exploring performance-based regulations that allow for flexibility in technological approaches while maintaining strict environmental and health standards. This approach aims to encourage the development of novel carbonyl-driven processes that can enhance manufacturing efficiency and reduce environmental impact.

Furthermore, international collaborations are being established to harmonize regulatory approaches across borders. These efforts seek to create a more consistent global framework for carbonyl-driven technologies, facilitating technology transfer and reducing barriers to trade while maintaining high standards of safety and environmental protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!