Carbonyl Chemistry in Cutting-Edge Waste Reduction Programs

JUL 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbonyl Chemistry in Waste Reduction: Background and Objectives

Carbonyl chemistry has emerged as a pivotal field in the development of cutting-edge waste reduction programs. The evolution of this technology can be traced back to the early 20th century when the fundamental principles of carbonyl compounds were first established. Over the decades, the understanding of carbonyl reactions has significantly expanded, leading to innovative applications in waste management and environmental protection.

The current trend in carbonyl chemistry research focuses on leveraging these compounds' unique properties to address pressing environmental challenges. Particularly, the ability of carbonyl groups to undergo various transformations has opened new avenues for waste reduction and recycling. This trend aligns with the global push towards sustainable development and circular economy principles.

The primary objective of research in this field is to develop efficient and environmentally friendly methods for waste reduction using carbonyl chemistry. This includes exploring novel catalytic systems, designing selective reaction pathways, and optimizing process conditions to maximize the conversion of waste materials into valuable products. The ultimate goal is to create a paradigm shift in waste management, moving from traditional disposal methods to innovative recycling and upcycling techniques.

One of the key areas of focus is the transformation of carbonyl-containing waste materials, such as plastics and biomass residues, into high-value chemicals or fuels. This approach not only reduces waste but also contributes to resource conservation and energy recovery. Additionally, researchers are investigating the potential of carbonyl chemistry in developing biodegradable materials that can replace conventional, non-degradable plastics.

The technological evolution in this field is closely linked to advancements in analytical techniques, computational modeling, and process engineering. These tools enable researchers to gain deeper insights into reaction mechanisms, predict outcomes, and scale up laboratory findings to industrial applications. The integration of artificial intelligence and machine learning is also expected to accelerate the discovery of new carbonyl-based waste reduction strategies.

As the field progresses, there is a growing emphasis on developing green chemistry approaches that minimize the use of hazardous substances and reduce the environmental footprint of waste reduction processes. This includes exploring bio-based catalysts, utilizing renewable feedstocks, and designing closed-loop systems that maximize resource efficiency.

The anticipated outcomes of this research include the development of more efficient waste treatment technologies, the creation of new value chains for waste materials, and a significant reduction in the environmental impact of industrial and consumer waste. These advancements are expected to contribute to global efforts in achieving sustainable development goals and transitioning towards a more circular and resource-efficient economy.

The current trend in carbonyl chemistry research focuses on leveraging these compounds' unique properties to address pressing environmental challenges. Particularly, the ability of carbonyl groups to undergo various transformations has opened new avenues for waste reduction and recycling. This trend aligns with the global push towards sustainable development and circular economy principles.

The primary objective of research in this field is to develop efficient and environmentally friendly methods for waste reduction using carbonyl chemistry. This includes exploring novel catalytic systems, designing selective reaction pathways, and optimizing process conditions to maximize the conversion of waste materials into valuable products. The ultimate goal is to create a paradigm shift in waste management, moving from traditional disposal methods to innovative recycling and upcycling techniques.

One of the key areas of focus is the transformation of carbonyl-containing waste materials, such as plastics and biomass residues, into high-value chemicals or fuels. This approach not only reduces waste but also contributes to resource conservation and energy recovery. Additionally, researchers are investigating the potential of carbonyl chemistry in developing biodegradable materials that can replace conventional, non-degradable plastics.

The technological evolution in this field is closely linked to advancements in analytical techniques, computational modeling, and process engineering. These tools enable researchers to gain deeper insights into reaction mechanisms, predict outcomes, and scale up laboratory findings to industrial applications. The integration of artificial intelligence and machine learning is also expected to accelerate the discovery of new carbonyl-based waste reduction strategies.

As the field progresses, there is a growing emphasis on developing green chemistry approaches that minimize the use of hazardous substances and reduce the environmental footprint of waste reduction processes. This includes exploring bio-based catalysts, utilizing renewable feedstocks, and designing closed-loop systems that maximize resource efficiency.

The anticipated outcomes of this research include the development of more efficient waste treatment technologies, the creation of new value chains for waste materials, and a significant reduction in the environmental impact of industrial and consumer waste. These advancements are expected to contribute to global efforts in achieving sustainable development goals and transitioning towards a more circular and resource-efficient economy.

Market Analysis for Carbonyl-based Waste Reduction Solutions

The market for carbonyl-based waste reduction solutions is experiencing significant growth, driven by increasing environmental concerns and stringent regulations on waste management. This sector encompasses a wide range of applications, from industrial waste treatment to consumer-level recycling programs, all leveraging the unique properties of carbonyl compounds to break down and repurpose waste materials.

In the industrial sector, there is a growing demand for carbonyl-based solutions in treating organic waste from manufacturing processes. Chemical plants, food processing facilities, and pharmaceutical companies are increasingly adopting these technologies to comply with environmental standards and reduce their carbon footprint. The market size for industrial applications is projected to expand rapidly over the next five years, with a particular focus on solutions that can handle complex organic waste streams.

The consumer market is also showing promising trends, with a rising interest in household products that utilize carbonyl chemistry for waste reduction. This includes innovative cleaning products, composting accelerators, and odor-neutralizing agents. Consumers are becoming more environmentally conscious, driving the demand for eco-friendly solutions that can effectively break down organic waste at home.

Municipal waste management represents another significant market segment. Cities and local governments are exploring carbonyl-based technologies for large-scale waste treatment facilities. These solutions offer the potential to significantly reduce landfill volumes and generate valuable by-products, such as biogas or fertilizers. The market for municipal applications is expected to grow steadily, supported by government initiatives and public pressure for sustainable waste management practices.

Geographically, North America and Europe are currently leading the market for carbonyl-based waste reduction solutions, due to their advanced regulatory frameworks and high environmental awareness. However, rapid industrialization and urbanization in Asia-Pacific countries are creating new opportunities, with China and India emerging as potentially large markets for these technologies.

The market is characterized by a mix of established chemical companies and innovative startups. Large corporations are investing in research and development to improve existing carbonyl-based solutions, while startups are introducing novel applications and more efficient processes. This competitive landscape is driving innovation and pushing the boundaries of what's possible in waste reduction through carbonyl chemistry.

Looking ahead, the market for carbonyl-based waste reduction solutions is expected to continue its upward trajectory. Factors such as increasing waste generation, tightening environmental regulations, and growing public awareness of sustainability issues will likely fuel further demand. Additionally, advancements in carbonyl chemistry and process engineering are expected to open up new applications and improve the efficiency of existing solutions, further expanding the market potential.

In the industrial sector, there is a growing demand for carbonyl-based solutions in treating organic waste from manufacturing processes. Chemical plants, food processing facilities, and pharmaceutical companies are increasingly adopting these technologies to comply with environmental standards and reduce their carbon footprint. The market size for industrial applications is projected to expand rapidly over the next five years, with a particular focus on solutions that can handle complex organic waste streams.

The consumer market is also showing promising trends, with a rising interest in household products that utilize carbonyl chemistry for waste reduction. This includes innovative cleaning products, composting accelerators, and odor-neutralizing agents. Consumers are becoming more environmentally conscious, driving the demand for eco-friendly solutions that can effectively break down organic waste at home.

Municipal waste management represents another significant market segment. Cities and local governments are exploring carbonyl-based technologies for large-scale waste treatment facilities. These solutions offer the potential to significantly reduce landfill volumes and generate valuable by-products, such as biogas or fertilizers. The market for municipal applications is expected to grow steadily, supported by government initiatives and public pressure for sustainable waste management practices.

Geographically, North America and Europe are currently leading the market for carbonyl-based waste reduction solutions, due to their advanced regulatory frameworks and high environmental awareness. However, rapid industrialization and urbanization in Asia-Pacific countries are creating new opportunities, with China and India emerging as potentially large markets for these technologies.

The market is characterized by a mix of established chemical companies and innovative startups. Large corporations are investing in research and development to improve existing carbonyl-based solutions, while startups are introducing novel applications and more efficient processes. This competitive landscape is driving innovation and pushing the boundaries of what's possible in waste reduction through carbonyl chemistry.

Looking ahead, the market for carbonyl-based waste reduction solutions is expected to continue its upward trajectory. Factors such as increasing waste generation, tightening environmental regulations, and growing public awareness of sustainability issues will likely fuel further demand. Additionally, advancements in carbonyl chemistry and process engineering are expected to open up new applications and improve the efficiency of existing solutions, further expanding the market potential.

Current Challenges in Carbonyl Chemistry for Waste Management

Carbonyl chemistry plays a crucial role in modern waste reduction programs, yet it faces several significant challenges that hinder its full potential in waste management applications. One of the primary obstacles is the complexity of carbonyl compounds present in diverse waste streams. Industrial, municipal, and agricultural wastes contain a wide array of carbonyl-containing substances, each with unique reactivity and environmental impact. This heterogeneity makes it difficult to develop universal treatment methods, necessitating tailored approaches for different waste types.

Another major challenge lies in the stability and reactivity of carbonyl compounds under various environmental conditions. Many carbonyl-containing pollutants are resistant to conventional degradation processes, persisting in the environment and potentially causing long-term ecological damage. This persistence is particularly problematic in aqueous environments, where carbonyl compounds can undergo transformations that may increase their toxicity or bioavailability.

The efficient detection and quantification of carbonyl compounds in complex waste matrices present another significant hurdle. Current analytical methods often lack the sensitivity and specificity required to accurately measure trace levels of diverse carbonyl species in heterogeneous waste samples. This limitation hampers the development of effective monitoring strategies and complicates the assessment of treatment efficacy.

Furthermore, the potential for carbonyl compounds to form harmful byproducts during waste treatment processes poses a considerable challenge. Some carbonyl reduction or oxidation reactions can lead to the formation of secondary pollutants that may be more toxic or persistent than the original compounds. This risk necessitates careful consideration of reaction pathways and product distributions in the design of waste treatment technologies.

The economic viability of carbonyl-based waste reduction technologies also presents a significant obstacle. Many advanced treatment methods, such as catalytic processes or advanced oxidation techniques, require substantial capital investment and operational costs. Balancing the effectiveness of these technologies with their economic feasibility remains a key challenge for widespread implementation in waste management facilities.

Lastly, the regulatory landscape surrounding carbonyl chemistry in waste management is complex and often inconsistent across different regions. The lack of standardized protocols for the treatment and disposal of carbonyl-containing wastes creates uncertainty for industry stakeholders and complicates the development of globally applicable solutions. Addressing these regulatory challenges is essential for fostering innovation and promoting the adoption of advanced carbonyl-based waste reduction technologies.

Another major challenge lies in the stability and reactivity of carbonyl compounds under various environmental conditions. Many carbonyl-containing pollutants are resistant to conventional degradation processes, persisting in the environment and potentially causing long-term ecological damage. This persistence is particularly problematic in aqueous environments, where carbonyl compounds can undergo transformations that may increase their toxicity or bioavailability.

The efficient detection and quantification of carbonyl compounds in complex waste matrices present another significant hurdle. Current analytical methods often lack the sensitivity and specificity required to accurately measure trace levels of diverse carbonyl species in heterogeneous waste samples. This limitation hampers the development of effective monitoring strategies and complicates the assessment of treatment efficacy.

Furthermore, the potential for carbonyl compounds to form harmful byproducts during waste treatment processes poses a considerable challenge. Some carbonyl reduction or oxidation reactions can lead to the formation of secondary pollutants that may be more toxic or persistent than the original compounds. This risk necessitates careful consideration of reaction pathways and product distributions in the design of waste treatment technologies.

The economic viability of carbonyl-based waste reduction technologies also presents a significant obstacle. Many advanced treatment methods, such as catalytic processes or advanced oxidation techniques, require substantial capital investment and operational costs. Balancing the effectiveness of these technologies with their economic feasibility remains a key challenge for widespread implementation in waste management facilities.

Lastly, the regulatory landscape surrounding carbonyl chemistry in waste management is complex and often inconsistent across different regions. The lack of standardized protocols for the treatment and disposal of carbonyl-containing wastes creates uncertainty for industry stakeholders and complicates the development of globally applicable solutions. Addressing these regulatory challenges is essential for fostering innovation and promoting the adoption of advanced carbonyl-based waste reduction technologies.

Existing Carbonyl Chemistry Solutions for Waste Reduction

01 Catalytic processes for waste reduction

Catalytic processes are employed to reduce waste in carbonyl chemistry reactions. These processes can improve reaction efficiency, selectivity, and yield, thereby minimizing the generation of unwanted by-products. Advanced catalysts can enable reactions to occur under milder conditions, reducing energy consumption and waste production.- Catalytic processes for waste reduction: Catalytic processes are employed to reduce waste in carbonyl chemistry reactions. These processes can improve reaction efficiency, selectivity, and yield, thereby minimizing the generation of unwanted by-products and reducing overall waste. Advanced catalysts and reaction conditions are optimized to achieve more sustainable carbonyl transformations.

- Solvent-free or green solvent systems: Implementing solvent-free reactions or using green solvents in carbonyl chemistry can significantly reduce waste generation. This approach eliminates or minimizes the use of harmful organic solvents, leading to more environmentally friendly processes. Alternative reaction media, such as ionic liquids or supercritical fluids, may be utilized to achieve similar or improved reaction outcomes with reduced environmental impact.

- Continuous flow chemistry for waste minimization: Continuous flow chemistry techniques are applied to carbonyl reactions to minimize waste production. This approach allows for better control of reaction parameters, improved heat and mass transfer, and the ability to perform multistep syntheses in a single, integrated process. As a result, reaction efficiency is enhanced, and the generation of waste products is reduced.

- Recycling and reuse of reagents and catalysts: Developing methods for recycling and reusing reagents and catalysts in carbonyl chemistry processes contributes to waste reduction. This may involve the implementation of separation and purification techniques to recover valuable materials from reaction mixtures, as well as the design of more robust catalysts that can be reused multiple times without significant loss of activity.

- Process intensification and optimization: Process intensification and optimization strategies are employed to reduce waste in carbonyl chemistry. This includes the use of advanced reactor designs, microreactor technology, and process analytical tools to maximize reaction efficiency and minimize side product formation. Additionally, computational modeling and machine learning techniques may be utilized to predict optimal reaction conditions and reduce experimental waste.

02 Solvent-free or green solvent systems

Implementing solvent-free reactions or using green solvents in carbonyl chemistry can significantly reduce waste. This approach eliminates or minimizes the use of harmful organic solvents, reducing environmental impact and waste disposal issues. Green solvents, such as water or bio-based solvents, can be used as alternatives to traditional organic solvents.Expand Specific Solutions03 Continuous flow chemistry techniques

Continuous flow chemistry techniques are applied to carbonyl reactions to enhance efficiency and reduce waste. These methods allow for better control of reaction parameters, improved heat and mass transfer, and the ability to perform multi-step syntheses in a single, integrated process. This can lead to higher yields, reduced solvent use, and minimized by-product formation.Expand Specific Solutions04 Recycling and reuse of reagents and catalysts

Developing methods for recycling and reusing reagents and catalysts in carbonyl chemistry can significantly reduce waste. This includes techniques for catalyst recovery and regeneration, as well as the implementation of closed-loop systems that allow for the continuous reuse of reaction components. Such approaches minimize the need for fresh reagents and reduce waste disposal.Expand Specific Solutions05 Process intensification and optimization

Process intensification and optimization techniques are applied to carbonyl chemistry reactions to minimize waste generation. This involves the use of advanced reactor designs, precise control of reaction conditions, and the integration of multiple unit operations. By optimizing reaction parameters and improving overall process efficiency, waste production can be significantly reduced.Expand Specific Solutions

Key Players in Carbonyl-based Waste Reduction Research

The research on carbonyl chemistry in cutting-edge waste reduction programs is in a nascent stage, with the market showing significant growth potential. The global focus on sustainability and environmental protection is driving increased interest and investment in this field. The market size is expanding, though still relatively small compared to established chemical sectors. Technologically, the field is rapidly evolving, with companies like CNOOC Tianjin Chemical Research & Design Institute, Celanese International Corp., and Sumitomo Chemical Co., Ltd. leading innovation. These firms are developing advanced catalysts and processes to efficiently convert carbonyl compounds in waste streams into valuable products. However, the technology is not yet fully mature, with ongoing research aimed at improving efficiency and scalability.

Sumitomo Chemical Co., Ltd.

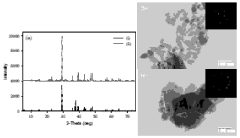

Technical Solution: Sumitomo Chemical has made significant strides in carbonyl chemistry for waste reduction, particularly in the area of plastic recycling and sustainable chemical production. The company has developed a chemical recycling technology for acrylic resin that depolymerizes waste materials back into monomers, which can then be reused to produce new plastics[14]. This process significantly reduces waste and the need for virgin petroleum-based feedstocks. Sumitomo has also invested in bio-based production methods, including the development of bio-succinic acid production from renewable resources, which serves as a platform chemical for various carbonyl compounds[15]. Their research extends to the development of novel catalysts for more efficient and selective carbonyl transformations, aiming to minimize by-product formation and energy consumption in chemical processes[16].

Strengths: Advanced recycling technologies, integration of bio-based feedstocks, and strong R&D capabilities. Weaknesses: Potential high costs associated with new technology implementation and market acceptance of recycled materials.

Evonik Operations GmbH

Technical Solution: Evonik has developed innovative carbonyl chemistry processes for waste reduction, focusing on the conversion of bio-based feedstocks into valuable chemicals. Their approach involves catalytic oxidation of renewable alcohols to produce aldehydes and ketones, which serve as building blocks for various industrial applications[1]. The company has also implemented a circular economy strategy, utilizing CO2 as a raw material for the production of high-value chemicals, effectively reducing carbon emissions and waste[2]. Evonik's research extends to the development of novel catalysts that enable more efficient and selective carbonyl transformations, minimizing by-product formation and energy consumption in chemical processes[3].

Strengths: Advanced catalytic technologies, integration of renewable feedstocks, and circular economy approach. Weaknesses: Potential high initial investment costs and dependency on specific bio-based raw materials.

Innovative Carbonyl Reactions for Efficient Waste Processing

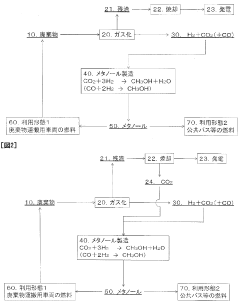

Waste processing system

PatentWO2012017893A1

Innovation

- A waste treatment system that includes gasification of waste to produce hydrogen and carbon dioxide, followed by methanol synthesis using a copper-based catalyst, which is resistant to water, allowing for the creation of a carbon dioxide utilization cycle by using methanol as fuel for transportation vehicles.

Bio-conversion of refinery waste streams

PatentActiveIN1467MUM2015A

Innovation

- Utilization of carbonic anhydrase enzyme that can function at high pH (>13) and high salinity (>4%) for waste treatment.

- Integration of refinery waste streams (spent caustic, brine) with CO2-rich flue gases for production of nano-sized carbonates.

- Elimination of costly buffers for enzyme activity, making the process more economically feasible.

Environmental Impact Assessment of Carbonyl-based Waste Reduction

The environmental impact assessment of carbonyl-based waste reduction programs is a critical component in evaluating the overall effectiveness and sustainability of these initiatives. Carbonyl compounds, characterized by their carbon-oxygen double bond, play a significant role in various industrial processes and are often present in waste streams. The implementation of waste reduction programs targeting these compounds can have far-reaching environmental implications.

One of the primary environmental benefits of carbonyl-based waste reduction is the decrease in air pollution. Many carbonyl compounds are volatile organic compounds (VOCs) that contribute to smog formation and poor air quality. By reducing the release of these compounds into the atmosphere, waste reduction programs can lead to improved air quality in urban and industrial areas. This, in turn, can have positive effects on human health, reducing the incidence of respiratory issues and other air pollution-related illnesses.

Water pollution is another area where carbonyl-based waste reduction can have a substantial impact. Carbonyl compounds that enter water systems can be harmful to aquatic ecosystems, disrupting the balance of flora and fauna. Effective waste reduction programs can significantly decrease the amount of these pollutants entering rivers, lakes, and oceans, thereby protecting aquatic biodiversity and maintaining the health of water resources.

Soil contamination is also mitigated through the implementation of carbonyl waste reduction initiatives. Many carbonyl compounds can persist in soil, potentially affecting plant growth and soil microorganisms. By reducing the release of these compounds into the environment, the risk of soil degradation and long-term ecological damage is minimized.

The carbon footprint associated with the production and disposal of carbonyl-containing products is another important consideration. Waste reduction programs often lead to more efficient use of resources and energy, resulting in lower greenhouse gas emissions. This contributes to broader climate change mitigation efforts and aligns with global sustainability goals.

Furthermore, the assessment must consider the potential for unintended consequences. For instance, some waste reduction techniques may require energy-intensive processes or the use of alternative chemicals, which could potentially offset the environmental benefits. A comprehensive life cycle analysis is crucial to ensure that the overall environmental impact is indeed positive.

The long-term effects on ecosystem health and biodiversity should also be evaluated. Reducing carbonyl waste can lead to the recovery of previously impacted ecosystems, allowing for the return of sensitive species and the restoration of ecological balance. This can have cascading positive effects throughout the food chain and contribute to overall environmental resilience.

In conclusion, the environmental impact assessment of carbonyl-based waste reduction programs reveals a complex interplay of factors. While the overall impact is generally positive, careful consideration must be given to all aspects of the program to ensure maximum environmental benefit and minimal unintended negative consequences.

One of the primary environmental benefits of carbonyl-based waste reduction is the decrease in air pollution. Many carbonyl compounds are volatile organic compounds (VOCs) that contribute to smog formation and poor air quality. By reducing the release of these compounds into the atmosphere, waste reduction programs can lead to improved air quality in urban and industrial areas. This, in turn, can have positive effects on human health, reducing the incidence of respiratory issues and other air pollution-related illnesses.

Water pollution is another area where carbonyl-based waste reduction can have a substantial impact. Carbonyl compounds that enter water systems can be harmful to aquatic ecosystems, disrupting the balance of flora and fauna. Effective waste reduction programs can significantly decrease the amount of these pollutants entering rivers, lakes, and oceans, thereby protecting aquatic biodiversity and maintaining the health of water resources.

Soil contamination is also mitigated through the implementation of carbonyl waste reduction initiatives. Many carbonyl compounds can persist in soil, potentially affecting plant growth and soil microorganisms. By reducing the release of these compounds into the environment, the risk of soil degradation and long-term ecological damage is minimized.

The carbon footprint associated with the production and disposal of carbonyl-containing products is another important consideration. Waste reduction programs often lead to more efficient use of resources and energy, resulting in lower greenhouse gas emissions. This contributes to broader climate change mitigation efforts and aligns with global sustainability goals.

Furthermore, the assessment must consider the potential for unintended consequences. For instance, some waste reduction techniques may require energy-intensive processes or the use of alternative chemicals, which could potentially offset the environmental benefits. A comprehensive life cycle analysis is crucial to ensure that the overall environmental impact is indeed positive.

The long-term effects on ecosystem health and biodiversity should also be evaluated. Reducing carbonyl waste can lead to the recovery of previously impacted ecosystems, allowing for the return of sensitive species and the restoration of ecological balance. This can have cascading positive effects throughout the food chain and contribute to overall environmental resilience.

In conclusion, the environmental impact assessment of carbonyl-based waste reduction programs reveals a complex interplay of factors. While the overall impact is generally positive, careful consideration must be given to all aspects of the program to ensure maximum environmental benefit and minimal unintended negative consequences.

Regulatory Framework for Chemical Waste Management Technologies

The regulatory framework for chemical waste management technologies plays a crucial role in shaping the landscape of carbonyl chemistry research in cutting-edge waste reduction programs. Governments and international organizations have established comprehensive guidelines and regulations to ensure the safe handling, treatment, and disposal of chemical waste, particularly those containing carbonyl compounds.

At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides a global framework for managing hazardous waste, including carbonyl-containing substances. This convention sets standards for the classification, labeling, and transportation of chemical waste across borders, ensuring a coordinated approach to waste management.

In the United States, the Environmental Protection Agency (EPA) enforces the Resource Conservation and Recovery Act (RCRA), which regulates the generation, transportation, treatment, storage, and disposal of hazardous waste. The RCRA specifically addresses carbonyl compounds and their derivatives, outlining strict protocols for their handling and disposal.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which aims to protect human health and the environment from the risks posed by chemicals. This regulation impacts the management of carbonyl-containing waste by requiring manufacturers and importers to assess and manage the risks associated with these substances.

Many countries have adopted the Globally Harmonized System of Classification and Labeling of Chemicals (GHS), which provides a standardized approach to communicating chemical hazards. This system is particularly relevant for carbonyl compounds, as it ensures consistent labeling and safety data sheets across different jurisdictions.

Regulatory bodies also focus on promoting waste reduction and recycling initiatives. For instance, the EU's Waste Framework Directive establishes a waste hierarchy that prioritizes prevention, reuse, and recycling over disposal. This directive encourages research into innovative waste reduction technologies, including those targeting carbonyl chemistry.

Compliance with these regulations often requires advanced technologies for waste treatment and monitoring. As a result, the regulatory framework has spurred the development of cutting-edge waste reduction programs that focus on carbonyl chemistry. These programs aim to minimize the generation of carbonyl-containing waste, develop more efficient recycling methods, and create safer disposal techniques.

The regulatory landscape continues to evolve, with increasing emphasis on circular economy principles and sustainable chemistry practices. This evolution drives ongoing research in carbonyl chemistry, pushing for the development of greener synthesis methods, more efficient catalysts, and innovative waste treatment technologies that align with stringent regulatory requirements.

At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides a global framework for managing hazardous waste, including carbonyl-containing substances. This convention sets standards for the classification, labeling, and transportation of chemical waste across borders, ensuring a coordinated approach to waste management.

In the United States, the Environmental Protection Agency (EPA) enforces the Resource Conservation and Recovery Act (RCRA), which regulates the generation, transportation, treatment, storage, and disposal of hazardous waste. The RCRA specifically addresses carbonyl compounds and their derivatives, outlining strict protocols for their handling and disposal.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which aims to protect human health and the environment from the risks posed by chemicals. This regulation impacts the management of carbonyl-containing waste by requiring manufacturers and importers to assess and manage the risks associated with these substances.

Many countries have adopted the Globally Harmonized System of Classification and Labeling of Chemicals (GHS), which provides a standardized approach to communicating chemical hazards. This system is particularly relevant for carbonyl compounds, as it ensures consistent labeling and safety data sheets across different jurisdictions.

Regulatory bodies also focus on promoting waste reduction and recycling initiatives. For instance, the EU's Waste Framework Directive establishes a waste hierarchy that prioritizes prevention, reuse, and recycling over disposal. This directive encourages research into innovative waste reduction technologies, including those targeting carbonyl chemistry.

Compliance with these regulations often requires advanced technologies for waste treatment and monitoring. As a result, the regulatory framework has spurred the development of cutting-edge waste reduction programs that focus on carbonyl chemistry. These programs aim to minimize the generation of carbonyl-containing waste, develop more efficient recycling methods, and create safer disposal techniques.

The regulatory landscape continues to evolve, with increasing emphasis on circular economy principles and sustainable chemistry practices. This evolution drives ongoing research in carbonyl chemistry, pushing for the development of greener synthesis methods, more efficient catalysts, and innovative waste treatment technologies that align with stringent regulatory requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!