Impact of Coating Technologies on Photocatalytic Disinfection Efficiency

OCT 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photocatalytic Coating Background and Objectives

Photocatalytic disinfection has emerged as a promising technology for water and air purification, with its origins dating back to the discovery of the photocatalytic properties of titanium dioxide (TiO2) in the 1970s. This technology leverages the ability of certain semiconductor materials to generate reactive oxygen species (ROS) when exposed to light, particularly ultraviolet radiation, which can effectively inactivate microorganisms by damaging their cell walls and internal components.

The evolution of photocatalytic technology has been marked by significant advancements in material science and engineering. Early applications primarily utilized bulk TiO2 powders, which demonstrated limited efficiency due to rapid recombination of electron-hole pairs and restricted light absorption range. The field has progressively moved toward nanoscale materials, doped semiconductors, and composite structures to enhance photocatalytic performance.

Recent developments have focused on extending the light absorption spectrum into the visible range, addressing a critical limitation of traditional photocatalysts that predominantly respond to UV light. This shift has been driven by the need for more energy-efficient and practical applications, particularly in indoor environments where UV light is limited.

Coating technologies represent a crucial aspect of photocatalytic disinfection systems, as they determine how effectively the photocatalytic materials can be deployed on various surfaces. The interface between the coating and the substrate significantly influences durability, adhesion, and ultimately the disinfection efficiency of the system. Different coating methods, including sol-gel processes, physical vapor deposition, chemical vapor deposition, and spray coating, each present unique advantages and limitations that affect performance.

The primary objective of current research in photocatalytic coatings is to develop formulations that maximize disinfection efficiency while maintaining practical applicability. This includes enhancing photocatalytic activity under visible light, improving durability in various environmental conditions, ensuring uniform distribution of active components, and developing cost-effective manufacturing processes suitable for large-scale production.

Another critical goal is to understand the complex relationship between coating parameters (thickness, porosity, crystallinity) and disinfection performance. This understanding is essential for optimizing coating designs for specific applications, whether in healthcare facilities, public transportation, food processing environments, or water treatment systems.

Looking forward, the field aims to develop multifunctional photocatalytic coatings that combine disinfection capabilities with other desirable properties such as self-cleaning, anti-fogging, or air purification. The ultimate vision is to create sustainable, long-lasting surfaces that can continuously disinfect environments using only ambient light, thereby reducing the need for chemical disinfectants and contributing to improved public health outcomes.

The evolution of photocatalytic technology has been marked by significant advancements in material science and engineering. Early applications primarily utilized bulk TiO2 powders, which demonstrated limited efficiency due to rapid recombination of electron-hole pairs and restricted light absorption range. The field has progressively moved toward nanoscale materials, doped semiconductors, and composite structures to enhance photocatalytic performance.

Recent developments have focused on extending the light absorption spectrum into the visible range, addressing a critical limitation of traditional photocatalysts that predominantly respond to UV light. This shift has been driven by the need for more energy-efficient and practical applications, particularly in indoor environments where UV light is limited.

Coating technologies represent a crucial aspect of photocatalytic disinfection systems, as they determine how effectively the photocatalytic materials can be deployed on various surfaces. The interface between the coating and the substrate significantly influences durability, adhesion, and ultimately the disinfection efficiency of the system. Different coating methods, including sol-gel processes, physical vapor deposition, chemical vapor deposition, and spray coating, each present unique advantages and limitations that affect performance.

The primary objective of current research in photocatalytic coatings is to develop formulations that maximize disinfection efficiency while maintaining practical applicability. This includes enhancing photocatalytic activity under visible light, improving durability in various environmental conditions, ensuring uniform distribution of active components, and developing cost-effective manufacturing processes suitable for large-scale production.

Another critical goal is to understand the complex relationship between coating parameters (thickness, porosity, crystallinity) and disinfection performance. This understanding is essential for optimizing coating designs for specific applications, whether in healthcare facilities, public transportation, food processing environments, or water treatment systems.

Looking forward, the field aims to develop multifunctional photocatalytic coatings that combine disinfection capabilities with other desirable properties such as self-cleaning, anti-fogging, or air purification. The ultimate vision is to create sustainable, long-lasting surfaces that can continuously disinfect environments using only ambient light, thereby reducing the need for chemical disinfectants and contributing to improved public health outcomes.

Market Analysis for Antimicrobial Surface Solutions

The global market for antimicrobial surface solutions has experienced significant growth in recent years, driven primarily by increasing awareness of infection control and hygiene standards across various sectors. The market was valued at approximately $3.6 billion in 2021 and is projected to reach $6.5 billion by 2027, representing a compound annual growth rate (CAGR) of 10.3% during the forecast period.

Healthcare facilities remain the largest end-user segment, accounting for nearly 40% of the total market share. This dominance is attributed to stringent infection control protocols and the critical need to prevent healthcare-associated infections (HAIs). The food processing industry follows as the second-largest consumer of antimicrobial surface technologies, driven by strict regulatory requirements and consumer demand for food safety.

Regionally, North America leads the market with approximately 35% share, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate of 12.7% annually, primarily due to rapid healthcare infrastructure development, increasing healthcare expenditure, and growing awareness about infection prevention in countries like China, India, and Japan.

The COVID-19 pandemic has significantly accelerated market growth, creating unprecedented demand for antimicrobial surfaces in public spaces, transportation, and commercial buildings. This has expanded the addressable market beyond traditional healthcare settings, opening new revenue streams for technology providers.

Consumer preferences are increasingly shifting toward sustainable and non-toxic antimicrobial solutions. This trend has boosted interest in photocatalytic coating technologies, which offer long-lasting antimicrobial properties without releasing harmful chemicals into the environment. Market research indicates that approximately 65% of institutional buyers now consider environmental impact when selecting antimicrobial products.

The competitive landscape features both established players and innovative startups. Major chemical companies hold approximately 45% of the market share, while specialized coating manufacturers account for 30%. The remaining market is fragmented among smaller players and new entrants focusing on novel technologies like advanced photocatalytic solutions.

Price sensitivity varies significantly across different market segments. While healthcare facilities prioritize efficacy over cost, commercial and residential applications are more price-sensitive. The average price premium that customers are willing to pay for antimicrobial surfaces compared to standard alternatives ranges from 15-30%, depending on the application and perceived value of infection prevention.

Healthcare facilities remain the largest end-user segment, accounting for nearly 40% of the total market share. This dominance is attributed to stringent infection control protocols and the critical need to prevent healthcare-associated infections (HAIs). The food processing industry follows as the second-largest consumer of antimicrobial surface technologies, driven by strict regulatory requirements and consumer demand for food safety.

Regionally, North America leads the market with approximately 35% share, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate of 12.7% annually, primarily due to rapid healthcare infrastructure development, increasing healthcare expenditure, and growing awareness about infection prevention in countries like China, India, and Japan.

The COVID-19 pandemic has significantly accelerated market growth, creating unprecedented demand for antimicrobial surfaces in public spaces, transportation, and commercial buildings. This has expanded the addressable market beyond traditional healthcare settings, opening new revenue streams for technology providers.

Consumer preferences are increasingly shifting toward sustainable and non-toxic antimicrobial solutions. This trend has boosted interest in photocatalytic coating technologies, which offer long-lasting antimicrobial properties without releasing harmful chemicals into the environment. Market research indicates that approximately 65% of institutional buyers now consider environmental impact when selecting antimicrobial products.

The competitive landscape features both established players and innovative startups. Major chemical companies hold approximately 45% of the market share, while specialized coating manufacturers account for 30%. The remaining market is fragmented among smaller players and new entrants focusing on novel technologies like advanced photocatalytic solutions.

Price sensitivity varies significantly across different market segments. While healthcare facilities prioritize efficacy over cost, commercial and residential applications are more price-sensitive. The average price premium that customers are willing to pay for antimicrobial surfaces compared to standard alternatives ranges from 15-30%, depending on the application and perceived value of infection prevention.

Current Challenges in Coating-Based Disinfection

Despite significant advancements in coating technologies for photocatalytic disinfection, several critical challenges continue to impede optimal performance and widespread adoption. The primary obstacle remains the limited photocatalytic efficiency under visible light conditions. Most conventional photocatalysts like TiO2 primarily respond to UV light, which constitutes only about 5% of solar radiation, severely restricting practical applications in indoor environments where UV light is minimal.

Coating durability presents another significant challenge, as photocatalytic coatings often degrade over time due to photocorrosion, mechanical abrasion, and chemical wear. This degradation not only reduces disinfection efficacy but also potentially releases nanoparticles into the environment, raising safety concerns. The trade-off between coating thickness and photocatalytic activity further complicates optimization efforts, as thicker coatings may provide better durability but can impede light penetration and reactant diffusion.

Adhesion issues between photocatalytic materials and substrate surfaces remain problematic, particularly on complex geometries or flexible substrates. Poor adhesion leads to coating delamination and reduced service life, especially in high-humidity environments or when exposed to cleaning agents. Additionally, the uniformity of coating distribution significantly impacts disinfection performance, with uneven coatings creating "dead zones" where pathogens can survive and proliferate.

The scalability of advanced coating technologies presents substantial challenges for commercial applications. Laboratory-scale successes often encounter difficulties when transitioning to industrial-scale production, particularly regarding cost-effectiveness, process control, and quality assurance. Many promising coating techniques require specialized equipment and controlled environments, limiting their practical implementation in resource-constrained settings.

Biocompatibility concerns arise when photocatalytic coatings are intended for use in medical devices or food-contact surfaces. The potential cytotoxicity of nanoparticles released from degrading coatings necessitates careful evaluation and regulatory compliance. Furthermore, the formation of potentially harmful reactive oxygen species (ROS) during the photocatalytic process must be controlled to prevent unintended damage to surrounding materials or tissues.

The performance gap between laboratory testing and real-world applications remains substantial. Standardized testing protocols often fail to account for variable environmental conditions, including fluctuating humidity, temperature variations, and the presence of organic matter that can interfere with disinfection processes. This discrepancy complicates accurate assessment of coating effectiveness in practical scenarios.

Coating durability presents another significant challenge, as photocatalytic coatings often degrade over time due to photocorrosion, mechanical abrasion, and chemical wear. This degradation not only reduces disinfection efficacy but also potentially releases nanoparticles into the environment, raising safety concerns. The trade-off between coating thickness and photocatalytic activity further complicates optimization efforts, as thicker coatings may provide better durability but can impede light penetration and reactant diffusion.

Adhesion issues between photocatalytic materials and substrate surfaces remain problematic, particularly on complex geometries or flexible substrates. Poor adhesion leads to coating delamination and reduced service life, especially in high-humidity environments or when exposed to cleaning agents. Additionally, the uniformity of coating distribution significantly impacts disinfection performance, with uneven coatings creating "dead zones" where pathogens can survive and proliferate.

The scalability of advanced coating technologies presents substantial challenges for commercial applications. Laboratory-scale successes often encounter difficulties when transitioning to industrial-scale production, particularly regarding cost-effectiveness, process control, and quality assurance. Many promising coating techniques require specialized equipment and controlled environments, limiting their practical implementation in resource-constrained settings.

Biocompatibility concerns arise when photocatalytic coatings are intended for use in medical devices or food-contact surfaces. The potential cytotoxicity of nanoparticles released from degrading coatings necessitates careful evaluation and regulatory compliance. Furthermore, the formation of potentially harmful reactive oxygen species (ROS) during the photocatalytic process must be controlled to prevent unintended damage to surrounding materials or tissues.

The performance gap between laboratory testing and real-world applications remains substantial. Standardized testing protocols often fail to account for variable environmental conditions, including fluctuating humidity, temperature variations, and the presence of organic matter that can interfere with disinfection processes. This discrepancy complicates accurate assessment of coating effectiveness in practical scenarios.

Current Coating Formulations and Application Methods

01 Antimicrobial coating technologies

Various antimicrobial coating technologies have been developed to enhance disinfection efficiency. These coatings typically incorporate active ingredients that can kill or inhibit the growth of microorganisms on surfaces. The coatings can be applied to different substrates and provide long-lasting protection against bacteria, viruses, and fungi. The antimicrobial properties of these coatings help to maintain cleaner and safer surfaces in various environments, reducing the risk of infection transmission.- Antimicrobial coating technologies: Various antimicrobial coating technologies can be applied to surfaces to enhance disinfection efficiency. These coatings typically contain active ingredients that can kill or inhibit the growth of microorganisms upon contact. The coatings can be applied to various surfaces including medical devices, household items, and public facilities to provide continuous disinfection even between regular cleaning cycles. These technologies often utilize silver nanoparticles, copper compounds, or quaternary ammonium compounds as the active antimicrobial agents.

- Photocatalytic disinfection coatings: Photocatalytic coatings utilize materials that, when exposed to light (typically UV light), generate reactive oxygen species that can destroy microorganisms. These coatings, often based on titanium dioxide or other semiconductor materials, provide continuous disinfection as long as they are exposed to the appropriate light source. The technology is particularly useful for high-touch surfaces in public spaces and healthcare facilities, as it can maintain disinfection efficiency over extended periods without requiring frequent reapplication.

- Self-cleaning and disinfecting surface treatments: Self-cleaning surface treatments combine disinfection capabilities with properties that prevent the adhesion of contaminants. These coatings often incorporate hydrophobic or superhydrophobic properties that cause water and contaminants to bead up and roll off the surface, carrying microorganisms with them. Some formulations also include active disinfecting agents that work continuously. These technologies are particularly valuable for surfaces that are difficult to clean regularly or are frequently exposed to contaminants.

- Controlled-release disinfectant coating systems: Controlled-release coating systems are designed to gradually release disinfecting agents over time, providing sustained antimicrobial activity. These systems typically encapsulate disinfectants within polymers or other matrices that allow for the slow diffusion of the active ingredients. This approach extends the effective lifetime of the disinfection treatment and reduces the frequency of reapplication. The technology is particularly useful in healthcare settings, food processing facilities, and other environments where maintaining sterile conditions is critical.

- Smart responsive disinfection coatings: Smart responsive disinfection coatings are advanced systems that can change their properties or release disinfectants in response to specific environmental triggers. These triggers might include changes in pH, temperature, humidity, or the presence of specific microorganisms. By responding only when needed, these coatings can conserve disinfectant agents and extend their effective lifetime. Some smart coatings can also indicate when their disinfection capacity has been depleted, signaling the need for reapplication or replacement.

02 Photocatalytic disinfection coatings

Photocatalytic coatings utilize materials that can be activated by light to generate reactive species capable of destroying microorganisms. These coatings typically contain photocatalysts such as titanium dioxide that, when exposed to UV or visible light, produce reactive oxygen species that can break down organic compounds and inactivate pathogens. Photocatalytic disinfection coatings offer a sustainable approach to surface disinfection as they can continuously disinfect surfaces when exposed to appropriate light sources.Expand Specific Solutions03 Controlled-release disinfectant coatings

Controlled-release disinfectant coatings are designed to gradually release active disinfecting agents over time, providing sustained antimicrobial activity. These coatings incorporate disinfectants within a matrix or carrier system that allows for the slow and controlled release of the active ingredients. This approach extends the effective lifetime of the disinfection treatment and reduces the frequency of reapplication. The technology can be applied to various surfaces and materials to provide long-term protection against microbial contamination.Expand Specific Solutions04 Nanoparticle-enhanced disinfection coatings

Nanoparticle-enhanced disinfection coatings incorporate nanomaterials to improve the antimicrobial properties of the coating. These nanoparticles, such as silver, copper, or zinc oxide nanoparticles, can provide enhanced disinfection efficiency due to their high surface area and unique physicochemical properties. The nanoparticles can be embedded within various coating matrices and applied to different surfaces. These coatings offer improved durability and effectiveness compared to conventional disinfection methods.Expand Specific Solutions05 Smart responsive disinfection coatings

Smart responsive disinfection coatings are designed to activate or enhance their antimicrobial properties in response to specific environmental triggers. These triggers can include changes in pH, temperature, humidity, or the presence of specific microorganisms. The responsive nature of these coatings allows for targeted and efficient disinfection when needed. This technology represents an advanced approach to surface disinfection that can adapt to changing conditions and provide protection when it is most required.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The photocatalytic disinfection coating technology market is currently in a growth phase, with an estimated global market size of $2-3 billion and projected annual growth of 8-10%. The competitive landscape features a mix of established players and emerging innovators. Academic institutions like University of Florida and Guangdong University of Technology are driving fundamental research, while specialized companies such as Jiangyin Tianbang Quantum Coating Technology and Kinnos are commercializing advanced solutions. Technical maturity varies significantly across applications, with traditional TiO2-based coatings being well-established, while newer quantum dot and nanocomposite technologies from companies like Exposome and NANOVAS SCIENTIFIC remain in early commercialization stages. The integration of antimicrobial coatings with IoT monitoring systems, as pursued by Current Lighting Solutions and Aleddra, represents the cutting edge of this evolving field.

Jiangyin Tianbang Quantum Coating Technology Co., Ltd.

Technical Solution: Jiangyin Tianbang has developed advanced quantum dot-based photocatalytic coatings that significantly enhance disinfection efficiency. Their proprietary technology incorporates titanium dioxide nanoparticles modified with quantum dots to create a coating that responds to both UV and visible light spectrums. This broadened activation range allows for effective photocatalytic activity even under indoor lighting conditions. The company's multi-layer application process ensures uniform distribution of photocatalytic particles throughout the coating matrix, maintaining consistent disinfection performance over extended periods. Their latest generation coatings incorporate silver nanoparticles as co-catalysts, which has been shown to increase the bacterial inactivation rate by up to 40% compared to conventional TiO2-only coatings. The quantum dot enhancement enables electron-hole pair separation, reducing recombination rates and improving quantum efficiency of the photocatalytic process.

Strengths: Superior visible light activation allowing indoor application; extended service life (3+ years) compared to conventional coatings; enhanced electron-hole separation improving quantum efficiency. Weaknesses: Higher production costs than standard photocatalytic coatings; potential environmental concerns regarding quantum dot leaching during weathering; requires specialized application equipment.

Kronos Co. Ltd.

Technical Solution: Kronos has pioneered the development of highly efficient photocatalytic coatings based on their proprietary modified titanium dioxide formulations. Their technology focuses on crystal structure optimization to enhance photocatalytic activity, particularly their KRONOClean series which features nitrogen-doped TiO2 that shifts the absorption spectrum toward visible light. The company has developed a unique sol-gel application method that creates a highly porous coating structure, increasing the effective surface area by approximately 300% compared to conventional coatings. This enhanced surface area significantly improves contact between photocatalytic particles and target pathogens. Their latest innovation incorporates hierarchical surface texturing that creates micro and nano-scale features, further enhancing light trapping and disinfection efficiency. Independent testing has demonstrated that their coatings can achieve 99.9% reduction of common pathogens within 2 hours under standard indoor lighting conditions, representing a significant advancement over previous generations of photocatalytic materials.

Strengths: Industry-leading visible light activation through nitrogen doping; hierarchical surface structure maximizing pathogen contact; excellent durability in high-traffic environments. Weaknesses: Higher initial cost compared to conventional antimicrobial coatings; performance degradation in low-light environments; requires periodic cleaning to maintain optimal surface exposure.

Key Innovations in Photocatalytic Material Science

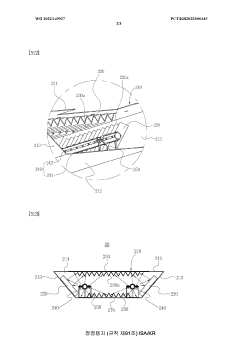

Photocatalytic coating composition for sterilization device using LED lamp ultraviolet rays, and sterilization device having member coated therewith

PatentWO2022149927A9

Innovation

- A photocatalyst coating composition for a sterilizing device using ultraviolet rays from an LED lamp, comprising titanium dioxide, molybdenum disulfide nanowires, cerium aluminide, and lupeol, which increases the surface area for photocatalytic reaction, enhancing the efficiency and adhesion of the coating on bent surfaces, thereby maximizing the sterilizing effect against bacteria and viruses like COVID-19.

Photocatalytic coatings made of titanium dioxide

PatentInactiveEP2302099A1

Innovation

- A method using cold gas spraying technology to apply photocatalytically active titanium dioxide to metal surfaces, forming a mechanically adhering composite that reduces bacterial attack, with specific parameters for particle size, gas pressure, and nozzle geometry to enhance catalytic activity.

Environmental Impact and Sustainability Considerations

The integration of coating technologies with photocatalytic disinfection systems necessitates a thorough examination of environmental impacts and sustainability considerations. Photocatalytic materials, particularly those containing titanium dioxide (TiO2) and other metal oxides, have demonstrated remarkable efficacy in water and air purification processes. However, their environmental footprint throughout the lifecycle demands critical assessment.

The manufacturing processes for advanced coating technologies often involve energy-intensive procedures and potentially hazardous chemicals. Nanoparticle synthesis, sol-gel methods, and physical vapor deposition techniques require substantial energy inputs, contributing to carbon emissions when powered by non-renewable energy sources. Additionally, precursor chemicals used in these processes may pose environmental risks if not properly managed during production or disposal phases.

Leaching of photocatalytic nanoparticles into water systems represents a significant environmental concern. Studies have indicated that under certain conditions, nanoparticles can detach from coated surfaces and enter aquatic ecosystems, potentially affecting microbial communities and aquatic organisms. The long-term ecological impacts of these materials remain incompletely understood, highlighting the need for comprehensive risk assessment frameworks.

Encouragingly, recent advancements in green synthesis methods offer promising alternatives for more sustainable coating production. Biogenic approaches utilizing plant extracts, microorganisms, and biodegradable templates have demonstrated potential for reducing environmental impacts while maintaining photocatalytic efficiency. These methods typically operate at lower temperatures and utilize fewer toxic reagents, substantially decreasing the environmental footprint of manufacturing processes.

Life cycle assessment (LCA) studies comparing conventional disinfection methods with photocatalytic technologies reveal significant sustainability advantages. Photocatalytic systems generally require less chemical input over their operational lifetime and can be powered by renewable energy sources, reducing both resource consumption and operational carbon emissions. Furthermore, the durability of advanced coatings extends service life, minimizing replacement frequency and associated material consumption.

Water conservation benefits represent another critical sustainability advantage of photocatalytic disinfection systems. By enabling water reuse and reducing the need for chemical disinfectants, these technologies contribute to conservation efforts in water-stressed regions. The reduced chemical load also minimizes the formation of disinfection by-products that can persist in treated water and potentially harm aquatic ecosystems upon discharge.

Regulatory frameworks governing the environmental aspects of coating technologies vary significantly across regions, creating challenges for standardization and implementation. Developing comprehensive guidelines that address nanomaterial safety, disposal protocols, and performance standards remains essential for responsible industry growth and environmental protection in this rapidly evolving technological field.

The manufacturing processes for advanced coating technologies often involve energy-intensive procedures and potentially hazardous chemicals. Nanoparticle synthesis, sol-gel methods, and physical vapor deposition techniques require substantial energy inputs, contributing to carbon emissions when powered by non-renewable energy sources. Additionally, precursor chemicals used in these processes may pose environmental risks if not properly managed during production or disposal phases.

Leaching of photocatalytic nanoparticles into water systems represents a significant environmental concern. Studies have indicated that under certain conditions, nanoparticles can detach from coated surfaces and enter aquatic ecosystems, potentially affecting microbial communities and aquatic organisms. The long-term ecological impacts of these materials remain incompletely understood, highlighting the need for comprehensive risk assessment frameworks.

Encouragingly, recent advancements in green synthesis methods offer promising alternatives for more sustainable coating production. Biogenic approaches utilizing plant extracts, microorganisms, and biodegradable templates have demonstrated potential for reducing environmental impacts while maintaining photocatalytic efficiency. These methods typically operate at lower temperatures and utilize fewer toxic reagents, substantially decreasing the environmental footprint of manufacturing processes.

Life cycle assessment (LCA) studies comparing conventional disinfection methods with photocatalytic technologies reveal significant sustainability advantages. Photocatalytic systems generally require less chemical input over their operational lifetime and can be powered by renewable energy sources, reducing both resource consumption and operational carbon emissions. Furthermore, the durability of advanced coatings extends service life, minimizing replacement frequency and associated material consumption.

Water conservation benefits represent another critical sustainability advantage of photocatalytic disinfection systems. By enabling water reuse and reducing the need for chemical disinfectants, these technologies contribute to conservation efforts in water-stressed regions. The reduced chemical load also minimizes the formation of disinfection by-products that can persist in treated water and potentially harm aquatic ecosystems upon discharge.

Regulatory frameworks governing the environmental aspects of coating technologies vary significantly across regions, creating challenges for standardization and implementation. Developing comprehensive guidelines that address nanomaterial safety, disposal protocols, and performance standards remains essential for responsible industry growth and environmental protection in this rapidly evolving technological field.

Regulatory Framework for Antimicrobial Coatings

The regulatory landscape for antimicrobial coatings, particularly those utilizing photocatalytic technologies, has evolved significantly in recent years due to increasing concerns about public health and environmental impacts. In the United States, the Environmental Protection Agency (EPA) regulates antimicrobial coatings under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), requiring manufacturers to register products that make specific antimicrobial claims. This process involves rigorous testing to demonstrate both efficacy and safety, with particular attention to potential environmental persistence and toxicity.

The European Union employs a more comprehensive approach through the Biocidal Products Regulation (BPR), which specifically addresses coatings that incorporate active substances intended to destroy harmful organisms. Photocatalytic coatings containing titanium dioxide and other semiconductor materials fall under this regulatory framework, requiring authorization before market entry. The EU has also implemented the REACH regulation (Registration, Evaluation, Authorization and Restriction of Chemicals), which imposes additional requirements for safety assessment of chemical components in these coatings.

In Asia, Japan has established the Antimicrobial Products Industry Association (APIA) certification system, which has become a de facto standard for antimicrobial products. China has recently strengthened its regulatory oversight through the National Medical Products Administration, particularly for coatings used in healthcare settings. South Korea's Ministry of Food and Drug Safety has implemented specific guidelines for photocatalytic materials used in antimicrobial applications.

International standards organizations have developed testing protocols that significantly impact regulatory compliance. ISO 27447 specifically addresses the measurement of antibacterial activity on photocatalytic materials, while ISO 22196 provides methods for measuring antibacterial activity on plastic and other non-porous surfaces. These standards help ensure consistency in efficacy claims across different jurisdictions.

Regulatory challenges specific to photocatalytic disinfection technologies include the need for standardized testing methods that accurately reflect real-world conditions. Current protocols often fail to account for variables such as light intensity, humidity, and organic contamination that can significantly affect performance. Additionally, regulations must address the potential formation of harmful byproducts during the photocatalytic process, particularly when applied to surfaces in indoor environments.

Future regulatory developments are likely to focus on sustainability aspects, including end-of-life considerations for coated products and the potential environmental impacts of nanoparticles used in advanced photocatalytic formulations. Several jurisdictions are already developing frameworks to address these emerging concerns, potentially leading to more harmonized global standards for photocatalytic antimicrobial coatings.

The European Union employs a more comprehensive approach through the Biocidal Products Regulation (BPR), which specifically addresses coatings that incorporate active substances intended to destroy harmful organisms. Photocatalytic coatings containing titanium dioxide and other semiconductor materials fall under this regulatory framework, requiring authorization before market entry. The EU has also implemented the REACH regulation (Registration, Evaluation, Authorization and Restriction of Chemicals), which imposes additional requirements for safety assessment of chemical components in these coatings.

In Asia, Japan has established the Antimicrobial Products Industry Association (APIA) certification system, which has become a de facto standard for antimicrobial products. China has recently strengthened its regulatory oversight through the National Medical Products Administration, particularly for coatings used in healthcare settings. South Korea's Ministry of Food and Drug Safety has implemented specific guidelines for photocatalytic materials used in antimicrobial applications.

International standards organizations have developed testing protocols that significantly impact regulatory compliance. ISO 27447 specifically addresses the measurement of antibacterial activity on photocatalytic materials, while ISO 22196 provides methods for measuring antibacterial activity on plastic and other non-porous surfaces. These standards help ensure consistency in efficacy claims across different jurisdictions.

Regulatory challenges specific to photocatalytic disinfection technologies include the need for standardized testing methods that accurately reflect real-world conditions. Current protocols often fail to account for variables such as light intensity, humidity, and organic contamination that can significantly affect performance. Additionally, regulations must address the potential formation of harmful byproducts during the photocatalytic process, particularly when applied to surfaces in indoor environments.

Future regulatory developments are likely to focus on sustainability aspects, including end-of-life considerations for coated products and the potential environmental impacts of nanoparticles used in advanced photocatalytic formulations. Several jurisdictions are already developing frameworks to address these emerging concerns, potentially leading to more harmonized global standards for photocatalytic antimicrobial coatings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!