Innovative Uses of Carbolic Acid in Surface Coating Technologies

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid Coating Evolution and Objectives

Carbolic acid, also known as phenol, has a rich history in surface coating technologies dating back to the early 20th century. Initially used as a disinfectant, its potential in coatings was recognized due to its unique chemical properties. The evolution of carbolic acid in coatings has been driven by the need for more durable, resistant, and environmentally friendly surface treatments.

In the 1930s, phenolic resins derived from carbolic acid emerged as a breakthrough in coating technology. These resins offered exceptional heat resistance and chemical stability, making them ideal for industrial applications. The subsequent decades saw continuous refinement of phenolic coatings, with improvements in curing processes and the development of water-based formulations to reduce environmental impact.

The 1970s and 1980s marked a significant shift in the industry's approach to carbolic acid coatings. Increased awareness of environmental and health concerns led to the exploration of modified phenolic resins with lower free phenol content. This period also saw the integration of carbolic acid derivatives in hybrid coating systems, combining the benefits of phenolic resins with other polymer technologies.

Recent advancements have focused on enhancing the performance and expanding the application range of carbolic acid-based coatings. Nanotechnology has played a crucial role, enabling the development of nanocomposite coatings that exhibit superior mechanical properties and corrosion resistance. Additionally, research into bio-based phenolic compounds has gained momentum, aligning with the global push towards sustainable materials.

The current objectives in carbolic acid coating technologies are multifaceted. Researchers aim to further reduce the environmental footprint of these coatings while maintaining or improving their performance characteristics. This includes developing formulations with ultra-low VOC emissions and exploring renewable sources for phenolic compounds. Another key goal is to enhance the versatility of carbolic acid coatings, enabling their use in emerging fields such as flexible electronics and biomedical devices.

Innovation in this field also targets the improvement of coating processes. Objectives include the development of faster curing systems, self-healing properties, and smart coatings that can respond to environmental stimuli. Additionally, there is a growing interest in leveraging the antimicrobial properties of carbolic acid to create functional coatings for healthcare and food packaging applications.

As the industry moves forward, the integration of carbolic acid coatings with other advanced materials and technologies presents exciting possibilities. The synergy between phenolic resins and cutting-edge materials like graphene or advanced ceramics could lead to coatings with unprecedented performance characteristics. These developments aim to address the evolving needs of industries ranging from aerospace to consumer electronics, positioning carbolic acid-based coatings at the forefront of surface protection and enhancement technologies.

In the 1930s, phenolic resins derived from carbolic acid emerged as a breakthrough in coating technology. These resins offered exceptional heat resistance and chemical stability, making them ideal for industrial applications. The subsequent decades saw continuous refinement of phenolic coatings, with improvements in curing processes and the development of water-based formulations to reduce environmental impact.

The 1970s and 1980s marked a significant shift in the industry's approach to carbolic acid coatings. Increased awareness of environmental and health concerns led to the exploration of modified phenolic resins with lower free phenol content. This period also saw the integration of carbolic acid derivatives in hybrid coating systems, combining the benefits of phenolic resins with other polymer technologies.

Recent advancements have focused on enhancing the performance and expanding the application range of carbolic acid-based coatings. Nanotechnology has played a crucial role, enabling the development of nanocomposite coatings that exhibit superior mechanical properties and corrosion resistance. Additionally, research into bio-based phenolic compounds has gained momentum, aligning with the global push towards sustainable materials.

The current objectives in carbolic acid coating technologies are multifaceted. Researchers aim to further reduce the environmental footprint of these coatings while maintaining or improving their performance characteristics. This includes developing formulations with ultra-low VOC emissions and exploring renewable sources for phenolic compounds. Another key goal is to enhance the versatility of carbolic acid coatings, enabling their use in emerging fields such as flexible electronics and biomedical devices.

Innovation in this field also targets the improvement of coating processes. Objectives include the development of faster curing systems, self-healing properties, and smart coatings that can respond to environmental stimuli. Additionally, there is a growing interest in leveraging the antimicrobial properties of carbolic acid to create functional coatings for healthcare and food packaging applications.

As the industry moves forward, the integration of carbolic acid coatings with other advanced materials and technologies presents exciting possibilities. The synergy between phenolic resins and cutting-edge materials like graphene or advanced ceramics could lead to coatings with unprecedented performance characteristics. These developments aim to address the evolving needs of industries ranging from aerospace to consumer electronics, positioning carbolic acid-based coatings at the forefront of surface protection and enhancement technologies.

Market Analysis for Carbolic Acid-Based Coatings

The market for carbolic acid-based coatings has shown significant growth potential in recent years, driven by increasing demand for durable and protective surface treatments across various industries. The global market size for these specialized coatings is expected to expand at a steady rate, with projections indicating substantial growth over the next five years.

Key factors contributing to market demand include the rising need for corrosion-resistant coatings in industrial applications, particularly in sectors such as oil and gas, marine, and chemical processing. The unique properties of carbolic acid, including its antimicrobial and preservative characteristics, have also sparked interest in its use for hygienic coatings in healthcare and food processing environments.

The construction industry represents another major market segment, with carbolic acid-based coatings finding applications in protective finishes for concrete structures, wood preservation, and anti-graffiti coatings for urban infrastructure. Additionally, the automotive sector has shown growing interest in these coatings for their potential in enhancing the durability and appearance of vehicle exteriors.

Geographically, the Asia-Pacific region is emerging as a key market for carbolic acid-based coatings, driven by rapid industrialization and infrastructure development in countries like China and India. North America and Europe continue to be significant markets, with a focus on high-performance coatings for specialized industrial applications.

Market trends indicate a shift towards environmentally friendly formulations, with manufacturers investing in research to develop low-VOC and water-based carbolic acid coatings. This trend aligns with increasingly stringent environmental regulations and growing consumer awareness of sustainable products.

The competitive landscape of the carbolic acid-based coatings market is characterized by a mix of established chemical companies and specialized coating manufacturers. Key players are focusing on product innovation and strategic partnerships to gain a competitive edge and expand their market share.

Challenges facing the market include fluctuations in raw material prices, particularly the cost of carbolic acid, which can impact product pricing and profitability. Additionally, concerns about the potential health and environmental impacts of carbolic acid have led to increased scrutiny and the need for ongoing research into safer alternatives and improved application methods.

Despite these challenges, the overall market outlook for carbolic acid-based coatings remains positive, with opportunities for growth in both established and emerging applications. The continued development of advanced formulations and expansion into new industry sectors are expected to drive market growth in the coming years.

Key factors contributing to market demand include the rising need for corrosion-resistant coatings in industrial applications, particularly in sectors such as oil and gas, marine, and chemical processing. The unique properties of carbolic acid, including its antimicrobial and preservative characteristics, have also sparked interest in its use for hygienic coatings in healthcare and food processing environments.

The construction industry represents another major market segment, with carbolic acid-based coatings finding applications in protective finishes for concrete structures, wood preservation, and anti-graffiti coatings for urban infrastructure. Additionally, the automotive sector has shown growing interest in these coatings for their potential in enhancing the durability and appearance of vehicle exteriors.

Geographically, the Asia-Pacific region is emerging as a key market for carbolic acid-based coatings, driven by rapid industrialization and infrastructure development in countries like China and India. North America and Europe continue to be significant markets, with a focus on high-performance coatings for specialized industrial applications.

Market trends indicate a shift towards environmentally friendly formulations, with manufacturers investing in research to develop low-VOC and water-based carbolic acid coatings. This trend aligns with increasingly stringent environmental regulations and growing consumer awareness of sustainable products.

The competitive landscape of the carbolic acid-based coatings market is characterized by a mix of established chemical companies and specialized coating manufacturers. Key players are focusing on product innovation and strategic partnerships to gain a competitive edge and expand their market share.

Challenges facing the market include fluctuations in raw material prices, particularly the cost of carbolic acid, which can impact product pricing and profitability. Additionally, concerns about the potential health and environmental impacts of carbolic acid have led to increased scrutiny and the need for ongoing research into safer alternatives and improved application methods.

Despite these challenges, the overall market outlook for carbolic acid-based coatings remains positive, with opportunities for growth in both established and emerging applications. The continued development of advanced formulations and expansion into new industry sectors are expected to drive market growth in the coming years.

Current Challenges in Carbolic Acid Surface Treatments

Despite the long-standing use of carbolic acid (phenol) in surface coating technologies, several challenges persist in its application, hindering its widespread adoption and optimal performance. One of the primary concerns is the toxicity of carbolic acid, which poses significant health and environmental risks. Prolonged exposure can lead to severe skin irritation, respiratory problems, and potential long-term health effects. This necessitates stringent safety measures during handling and application, increasing operational costs and complexity.

Another challenge lies in the volatility of carbolic acid, which can result in inconsistent coating quality and reduced effectiveness over time. The evaporation of the compound during and after application can lead to variations in coating thickness and uniformity, potentially compromising the protective properties of the surface treatment. This volatility also contributes to air pollution and odor issues, further complicating its use in various industrial settings.

The corrosive nature of carbolic acid presents additional difficulties in its application. It can react with certain substrate materials, particularly metals, leading to degradation or unwanted chemical reactions. This limits its use on a wide range of surfaces and requires careful material selection and pretreatment processes to ensure compatibility and longevity of the coating.

Furthermore, the stability of carbolic acid-based coatings under various environmental conditions remains a concern. Exposure to UV radiation, temperature fluctuations, and moisture can lead to degradation of the coating, reducing its protective capabilities and necessitating frequent reapplication. This lack of durability impacts the cost-effectiveness and reliability of carbolic acid surface treatments in long-term applications.

The regulatory landscape surrounding carbolic acid usage also presents challenges. Increasingly stringent environmental regulations and workplace safety standards are limiting the use of phenol-based coatings in many industries. Compliance with these regulations often requires significant investments in safety equipment, waste management systems, and worker training programs, adding to the overall cost of implementation.

Lastly, the development of alternative, less hazardous coating technologies is creating competitive pressure on carbolic acid-based solutions. As industries seek safer and more environmentally friendly options, there is a growing need for innovation in carbolic acid surface treatments to improve their safety profile and performance characteristics. This necessitates ongoing research and development efforts to address the current limitations and explore new formulations or application methods that can mitigate the existing challenges while maintaining the beneficial properties of carbolic acid in surface coatings.

Another challenge lies in the volatility of carbolic acid, which can result in inconsistent coating quality and reduced effectiveness over time. The evaporation of the compound during and after application can lead to variations in coating thickness and uniformity, potentially compromising the protective properties of the surface treatment. This volatility also contributes to air pollution and odor issues, further complicating its use in various industrial settings.

The corrosive nature of carbolic acid presents additional difficulties in its application. It can react with certain substrate materials, particularly metals, leading to degradation or unwanted chemical reactions. This limits its use on a wide range of surfaces and requires careful material selection and pretreatment processes to ensure compatibility and longevity of the coating.

Furthermore, the stability of carbolic acid-based coatings under various environmental conditions remains a concern. Exposure to UV radiation, temperature fluctuations, and moisture can lead to degradation of the coating, reducing its protective capabilities and necessitating frequent reapplication. This lack of durability impacts the cost-effectiveness and reliability of carbolic acid surface treatments in long-term applications.

The regulatory landscape surrounding carbolic acid usage also presents challenges. Increasingly stringent environmental regulations and workplace safety standards are limiting the use of phenol-based coatings in many industries. Compliance with these regulations often requires significant investments in safety equipment, waste management systems, and worker training programs, adding to the overall cost of implementation.

Lastly, the development of alternative, less hazardous coating technologies is creating competitive pressure on carbolic acid-based solutions. As industries seek safer and more environmentally friendly options, there is a growing need for innovation in carbolic acid surface treatments to improve their safety profile and performance characteristics. This necessitates ongoing research and development efforts to address the current limitations and explore new formulations or application methods that can mitigate the existing challenges while maintaining the beneficial properties of carbolic acid in surface coatings.

Existing Carbolic Acid Coating Solutions

01 Carbolic acid-based surface coatings for medical devices

Carbolic acid, also known as phenol, is used in surface coatings for medical devices to provide antimicrobial properties. These coatings can be applied to various medical instruments and equipment to reduce the risk of infections in healthcare settings. The carbolic acid-based coatings may be combined with other materials to enhance their effectiveness and durability.- Carbolic acid-based surface coatings for medical devices: Carbolic acid is used in surface coatings for medical devices to provide antimicrobial properties. These coatings can be applied to various medical instruments and equipment to reduce the risk of infections in healthcare settings. The carbolic acid-based coatings may be combined with other materials to enhance their effectiveness and durability.

- Industrial applications of carbolic acid coatings: Carbolic acid surface coatings find applications in various industrial settings. These coatings can be used to protect metal surfaces from corrosion, improve chemical resistance, and enhance the durability of equipment. The coatings may be formulated with additional components to tailor their properties for specific industrial requirements.

- Environmental protection and waste treatment using carbolic acid coatings: Carbolic acid-based surface coatings are utilized in environmental protection and waste treatment applications. These coatings can be applied to surfaces in waste management facilities, water treatment plants, and other environmental infrastructure to provide protection against chemical degradation and microbial growth.

- Carbolic acid coatings for construction materials: Surface coatings containing carbolic acid are used in the construction industry to protect building materials. These coatings can be applied to concrete, wood, and other construction materials to improve their resistance to weathering, chemical exposure, and microbial growth. The coatings may also enhance the aesthetic properties of the materials.

- Nanotechnology-enhanced carbolic acid coatings: Advanced surface coatings incorporating carbolic acid and nanotechnology are being developed. These coatings utilize nanoparticles or nanostructures to enhance the properties of carbolic acid, such as improved antimicrobial efficacy, increased durability, and better adhesion to surfaces. The nanotechnology-enhanced coatings may offer superior performance compared to traditional carbolic acid coatings.

02 Industrial applications of carbolic acid coatings

Carbolic acid surface coatings find applications in various industrial settings, such as in the protection of metal surfaces against corrosion and chemical attack. These coatings can be formulated to provide resistance to harsh environments, improving the longevity and performance of industrial equipment and structures.Expand Specific Solutions03 Carbolic acid-based wood preservatives

Carbolic acid is used in the formulation of wood preservatives to protect timber against decay, fungi, and insect infestation. These coatings can be applied to various wood products, including construction materials and outdoor furniture, to extend their lifespan and maintain their structural integrity.Expand Specific Solutions04 Environmental and safety considerations for carbolic acid coatings

The use of carbolic acid in surface coatings raises environmental and safety concerns due to its toxic nature. Research and development efforts focus on developing safer alternatives or improving the formulation of carbolic acid-based coatings to minimize potential health and environmental risks while maintaining their effectiveness.Expand Specific Solutions05 Novel applications and improvements in carbolic acid coating technology

Ongoing research explores new applications and improvements in carbolic acid coating technology. This includes the development of nanocomposite coatings, enhanced application methods, and the incorporation of additional functional properties such as self-cleaning or self-healing capabilities to expand the range of potential uses for carbolic acid-based surface treatments.Expand Specific Solutions

Key Industry Players in Carbolic Acid Coatings

The innovative uses of carbolic acid in surface coating technologies represent an evolving field with significant market potential. The industry is in a growth phase, driven by increasing demand for advanced coatings across various sectors. The global market size for specialty coatings is expanding, with projections indicating substantial growth in the coming years. Technologically, the field is advancing rapidly, with companies like BASF Coatings GmbH, PPG Industries Ohio, Inc., and Henkel AG & Co. KGaA leading innovation. These firms are investing heavily in R&D to develop novel applications and improve existing formulations, indicating a moderate to high level of technological maturity with room for further advancements.

BASF Coatings GmbH

Technical Solution: BASF Coatings GmbH has developed innovative uses of carbolic acid in surface coating technologies, focusing on enhancing the durability and performance of coatings. Their approach involves incorporating carbolic acid derivatives into polymer matrices to create highly resistant coatings. The company has developed a proprietary process that allows for the controlled polymerization of carbolic acid-based monomers, resulting in coatings with improved chemical resistance and thermal stability[1]. Additionally, BASF has explored the use of carbolic acid as a cross-linking agent in epoxy-based coatings, which has shown promising results in increasing the coating's hardness and scratch resistance[3]. The company has also invested in research to utilize carbolic acid in water-based coating formulations, aiming to reduce VOC emissions while maintaining high-performance standards[5].

Strengths: Superior chemical and thermal resistance, improved scratch resistance, and potential for eco-friendly formulations. Weaknesses: Possible higher production costs and the need for specialized application techniques.

PPG Industries Ohio, Inc.

Technical Solution: PPG Industries Ohio, Inc. has made significant strides in incorporating carbolic acid into their surface coating technologies. The company has developed a novel approach that utilizes carbolic acid as a key component in their anti-corrosion coatings for metal substrates. Their research has shown that the inclusion of carbolic acid derivatives can significantly enhance the barrier properties of the coating, providing superior protection against moisture and aggressive chemicals[2]. PPG has also explored the use of carbolic acid in UV-curable coatings, where it acts as a photoinitiator and contributes to rapid curing and improved adhesion[4]. Furthermore, the company has patented a process for synthesizing carbolic acid-based oligomers that can be incorporated into high-performance industrial coatings, offering exceptional durability and chemical resistance[6].

Strengths: Enhanced corrosion protection, rapid curing in UV systems, and high durability in industrial applications. Weaknesses: Potential for higher raw material costs and the need for specialized handling due to the reactive nature of carbolic acid.

Breakthrough Carbolic Acid Coating Patents

Surface formulations comprising phenols

PatentWO2019178527A1

Innovation

- Formulations comprising specific phenol structures that can form coatings with controlled water contact angles and adhesion properties, including 90-degree peel resistance, tape test ratings, and lap shear resistance, are developed to create effective surface treatments.

Compositions and methods for decontamination of surfaces

PatentPendingAU2022239312A9

Innovation

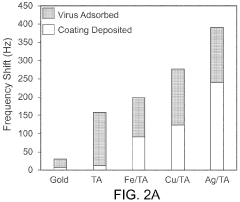

- Development of phenolic compound-based coatings that can be applied to various substrates to bind and inactivate a wide range of biological contaminants and pollutants, utilizing strong molecular adhesion forces and antimicrobial agents, ensuring effective capture and inactivation while being safe and easy to apply.

Environmental Impact of Carbolic Acid Coatings

The environmental impact of carbolic acid coatings is a critical consideration in the development and application of surface coating technologies. Carbolic acid, also known as phenol, has been widely used in various industrial processes, including surface treatments. However, its potential environmental consequences have raised concerns among researchers and regulatory bodies.

One of the primary environmental concerns associated with carbolic acid coatings is their potential for water pollution. When improperly disposed of or in the event of accidental spills, carbolic acid can leach into groundwater and surface water systems. This contamination can have severe effects on aquatic ecosystems, disrupting the balance of flora and fauna and potentially entering the food chain.

Air pollution is another significant environmental impact of carbolic acid coatings. During the application process and subsequent curing, volatile organic compounds (VOCs) may be released into the atmosphere. These emissions contribute to the formation of ground-level ozone and smog, which can have detrimental effects on air quality and human health.

The production and disposal of carbolic acid coatings also raise concerns about soil contamination. Improper handling or disposal practices can lead to soil pollution, affecting plant growth and soil microorganisms. This contamination can persist in the environment for extended periods, potentially impacting agricultural productivity and ecosystem health.

Furthermore, the use of carbolic acid in surface coatings may contribute to the depletion of non-renewable resources. The production of phenol often relies on petroleum-based feedstocks, which are finite resources. As the demand for these coatings increases, it puts additional pressure on already strained fossil fuel reserves.

From a lifecycle perspective, the environmental impact of carbolic acid coatings extends beyond their immediate use. The manufacturing process itself can be energy-intensive and may generate hazardous waste streams that require specialized treatment and disposal methods. Additionally, the end-of-life management of products treated with these coatings presents challenges in terms of recycling and waste management.

To address these environmental concerns, researchers and industry professionals are exploring alternative coating technologies and formulations. Bio-based phenols derived from renewable resources are being investigated as potential substitutes for petroleum-based carbolic acid. Additionally, efforts are being made to develop low-VOC and zero-VOC coating formulations that maintain the desired performance characteristics while minimizing environmental impact.

Regulatory frameworks are also evolving to mitigate the environmental risks associated with carbolic acid coatings. Many countries have implemented strict guidelines for the handling, use, and disposal of phenol-based products. These regulations aim to minimize environmental contamination and protect human health by enforcing proper safety measures and waste management practices.

One of the primary environmental concerns associated with carbolic acid coatings is their potential for water pollution. When improperly disposed of or in the event of accidental spills, carbolic acid can leach into groundwater and surface water systems. This contamination can have severe effects on aquatic ecosystems, disrupting the balance of flora and fauna and potentially entering the food chain.

Air pollution is another significant environmental impact of carbolic acid coatings. During the application process and subsequent curing, volatile organic compounds (VOCs) may be released into the atmosphere. These emissions contribute to the formation of ground-level ozone and smog, which can have detrimental effects on air quality and human health.

The production and disposal of carbolic acid coatings also raise concerns about soil contamination. Improper handling or disposal practices can lead to soil pollution, affecting plant growth and soil microorganisms. This contamination can persist in the environment for extended periods, potentially impacting agricultural productivity and ecosystem health.

Furthermore, the use of carbolic acid in surface coatings may contribute to the depletion of non-renewable resources. The production of phenol often relies on petroleum-based feedstocks, which are finite resources. As the demand for these coatings increases, it puts additional pressure on already strained fossil fuel reserves.

From a lifecycle perspective, the environmental impact of carbolic acid coatings extends beyond their immediate use. The manufacturing process itself can be energy-intensive and may generate hazardous waste streams that require specialized treatment and disposal methods. Additionally, the end-of-life management of products treated with these coatings presents challenges in terms of recycling and waste management.

To address these environmental concerns, researchers and industry professionals are exploring alternative coating technologies and formulations. Bio-based phenols derived from renewable resources are being investigated as potential substitutes for petroleum-based carbolic acid. Additionally, efforts are being made to develop low-VOC and zero-VOC coating formulations that maintain the desired performance characteristics while minimizing environmental impact.

Regulatory frameworks are also evolving to mitigate the environmental risks associated with carbolic acid coatings. Many countries have implemented strict guidelines for the handling, use, and disposal of phenol-based products. These regulations aim to minimize environmental contamination and protect human health by enforcing proper safety measures and waste management practices.

Safety Regulations for Carbolic Acid Use

The use of carbolic acid, also known as phenol, in surface coating technologies necessitates strict adherence to safety regulations due to its corrosive and toxic nature. Regulatory bodies worldwide have established comprehensive guidelines to ensure the safe handling, storage, and application of carbolic acid in industrial settings. These regulations typically cover several key areas, including personal protective equipment (PPE), storage requirements, handling procedures, and emergency response protocols.

Workers involved in the application of carbolic acid-based coatings must wear appropriate PPE, including chemical-resistant gloves, protective eyewear, and respiratory protection. The Occupational Safety and Health Administration (OSHA) in the United States mandates the use of impervious clothing and face shields when there is a risk of skin or eye contact. Additionally, proper ventilation systems must be in place to minimize inhalation exposure, with local exhaust ventilation being particularly important in confined spaces.

Storage regulations for carbolic acid are equally stringent. The chemical must be stored in tightly sealed containers in a cool, dry, and well-ventilated area, away from sources of heat or ignition. Incompatible materials, such as strong oxidizers, must be kept separate to prevent potentially hazardous reactions. Many jurisdictions require secondary containment systems to prevent spills from spreading in case of a primary container failure.

Handling procedures for carbolic acid in coating applications must follow strict protocols. These include using closed systems for transfer operations whenever possible, implementing spill prevention measures, and providing easily accessible eyewash stations and safety showers in work areas. The transport of carbolic acid is subject to dangerous goods regulations, requiring proper labeling, packaging, and documentation.

Emergency response plans are a critical component of safety regulations. Facilities using carbolic acid must have detailed procedures in place for addressing spills, fires, and accidental exposures. This includes training personnel in proper response techniques, maintaining appropriate fire suppression equipment, and establishing clear evacuation routes and assembly points.

Environmental regulations also play a significant role in the use of carbolic acid in surface coating technologies. Many countries have implemented strict controls on the disposal of phenol-containing waste to prevent environmental contamination. Proper waste management practices, including the use of licensed disposal facilities, are mandatory.

Compliance with these safety regulations is not only a legal requirement but also essential for protecting worker health and the environment. Regular audits and inspections are typically required to ensure ongoing compliance, and many regulatory bodies mandate detailed record-keeping of safety procedures, incidents, and training programs. As research continues to reveal more about the long-term effects of carbolic acid exposure, it is likely that safety regulations will continue to evolve, potentially becoming more stringent in the future.

Workers involved in the application of carbolic acid-based coatings must wear appropriate PPE, including chemical-resistant gloves, protective eyewear, and respiratory protection. The Occupational Safety and Health Administration (OSHA) in the United States mandates the use of impervious clothing and face shields when there is a risk of skin or eye contact. Additionally, proper ventilation systems must be in place to minimize inhalation exposure, with local exhaust ventilation being particularly important in confined spaces.

Storage regulations for carbolic acid are equally stringent. The chemical must be stored in tightly sealed containers in a cool, dry, and well-ventilated area, away from sources of heat or ignition. Incompatible materials, such as strong oxidizers, must be kept separate to prevent potentially hazardous reactions. Many jurisdictions require secondary containment systems to prevent spills from spreading in case of a primary container failure.

Handling procedures for carbolic acid in coating applications must follow strict protocols. These include using closed systems for transfer operations whenever possible, implementing spill prevention measures, and providing easily accessible eyewash stations and safety showers in work areas. The transport of carbolic acid is subject to dangerous goods regulations, requiring proper labeling, packaging, and documentation.

Emergency response plans are a critical component of safety regulations. Facilities using carbolic acid must have detailed procedures in place for addressing spills, fires, and accidental exposures. This includes training personnel in proper response techniques, maintaining appropriate fire suppression equipment, and establishing clear evacuation routes and assembly points.

Environmental regulations also play a significant role in the use of carbolic acid in surface coating technologies. Many countries have implemented strict controls on the disposal of phenol-containing waste to prevent environmental contamination. Proper waste management practices, including the use of licensed disposal facilities, are mandatory.

Compliance with these safety regulations is not only a legal requirement but also essential for protecting worker health and the environment. Regular audits and inspections are typically required to ensure ongoing compliance, and many regulatory bodies mandate detailed record-keeping of safety procedures, incidents, and training programs. As research continues to reveal more about the long-term effects of carbolic acid exposure, it is likely that safety regulations will continue to evolve, potentially becoming more stringent in the future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!