Investigating Hydrolytic Stability in Polypropylene Applications

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polypropylene Hydrolysis Background and Objectives

Polypropylene, a versatile thermoplastic polymer, has been widely used in various industries since its commercial introduction in the 1950s. Its popularity stems from its excellent mechanical properties, chemical resistance, and cost-effectiveness. However, the hydrolytic stability of polypropylene has become an increasingly important area of study as applications expand into more demanding environments.

The evolution of polypropylene technology has been marked by continuous improvements in its properties and processing techniques. Initially, the focus was on enhancing mechanical strength and thermal stability. As the material found its way into more diverse applications, attention shifted towards improving its resistance to environmental factors, including hydrolysis.

Hydrolysis, the chemical breakdown of a compound due to reaction with water, poses a significant challenge to the long-term performance of polypropylene in certain applications. This is particularly relevant in scenarios where the material is exposed to moisture, elevated temperatures, or aggressive chemicals over extended periods. The hydrolytic degradation of polypropylene can lead to a reduction in mechanical properties, changes in appearance, and ultimately, failure of the material in its intended application.

The investigation of hydrolytic stability in polypropylene applications aims to address several key objectives. Firstly, it seeks to understand the mechanisms by which hydrolysis occurs in polypropylene under various conditions. This includes identifying the factors that accelerate or inhibit the hydrolytic degradation process, such as temperature, pH, and the presence of catalysts or stabilizers.

Secondly, the research aims to develop methods for accurately assessing and predicting the hydrolytic stability of polypropylene in different environments. This involves the creation of standardized testing protocols and the development of predictive models that can estimate the material's performance over time.

Another critical objective is the enhancement of polypropylene's resistance to hydrolysis through various strategies. This may include the development of new additives, modification of the polymer structure, or the creation of composite materials that combine the benefits of polypropylene with improved hydrolytic stability.

Furthermore, the investigation seeks to expand the application range of polypropylene by addressing its limitations in hydrolytically challenging environments. This could open up new markets and opportunities for the material in sectors such as automotive, construction, and medical devices, where long-term stability under moist conditions is crucial.

Ultimately, the goal is to establish a comprehensive understanding of polypropylene's behavior under hydrolytic conditions and to develop solutions that ensure its reliable performance across a broader spectrum of applications. This research not only aims to solve current challenges but also to anticipate future needs as the demand for more durable and environmentally resistant materials continues to grow.

The evolution of polypropylene technology has been marked by continuous improvements in its properties and processing techniques. Initially, the focus was on enhancing mechanical strength and thermal stability. As the material found its way into more diverse applications, attention shifted towards improving its resistance to environmental factors, including hydrolysis.

Hydrolysis, the chemical breakdown of a compound due to reaction with water, poses a significant challenge to the long-term performance of polypropylene in certain applications. This is particularly relevant in scenarios where the material is exposed to moisture, elevated temperatures, or aggressive chemicals over extended periods. The hydrolytic degradation of polypropylene can lead to a reduction in mechanical properties, changes in appearance, and ultimately, failure of the material in its intended application.

The investigation of hydrolytic stability in polypropylene applications aims to address several key objectives. Firstly, it seeks to understand the mechanisms by which hydrolysis occurs in polypropylene under various conditions. This includes identifying the factors that accelerate or inhibit the hydrolytic degradation process, such as temperature, pH, and the presence of catalysts or stabilizers.

Secondly, the research aims to develop methods for accurately assessing and predicting the hydrolytic stability of polypropylene in different environments. This involves the creation of standardized testing protocols and the development of predictive models that can estimate the material's performance over time.

Another critical objective is the enhancement of polypropylene's resistance to hydrolysis through various strategies. This may include the development of new additives, modification of the polymer structure, or the creation of composite materials that combine the benefits of polypropylene with improved hydrolytic stability.

Furthermore, the investigation seeks to expand the application range of polypropylene by addressing its limitations in hydrolytically challenging environments. This could open up new markets and opportunities for the material in sectors such as automotive, construction, and medical devices, where long-term stability under moist conditions is crucial.

Ultimately, the goal is to establish a comprehensive understanding of polypropylene's behavior under hydrolytic conditions and to develop solutions that ensure its reliable performance across a broader spectrum of applications. This research not only aims to solve current challenges but also to anticipate future needs as the demand for more durable and environmentally resistant materials continues to grow.

Market Analysis for Hydrolysis-Resistant Polypropylene

The market for hydrolysis-resistant polypropylene is experiencing significant growth, driven by increasing demand across various industries. This specialized form of polypropylene addresses the critical need for materials that can withstand prolonged exposure to water, chemicals, and high temperatures without degrading. The automotive sector represents a key market, where hydrolysis-resistant polypropylene finds applications in under-the-hood components, fluid reservoirs, and cooling systems. These parts require materials that can maintain their structural integrity in harsh environments over extended periods.

Another major market segment is the packaging industry, particularly for food and beverage containers. As consumers and regulators push for more sustainable and durable packaging solutions, hydrolysis-resistant polypropylene offers an attractive option that combines recyclability with enhanced performance. The material's resistance to degradation when exposed to hot liquids or high-humidity environments makes it ideal for reusable containers and packaging for hot-fill products.

The construction industry also presents significant opportunities for hydrolysis-resistant polypropylene. Its use in pipes, fittings, and membranes for water management systems is growing due to its ability to withstand constant water exposure without compromising structural integrity. This is particularly valuable in regions with aggressive water conditions or where long-term durability is paramount.

In the medical and healthcare sectors, hydrolysis-resistant polypropylene is gaining traction for applications such as sterilizable medical devices, laboratory equipment, and pharmaceutical packaging. The material's ability to withstand repeated sterilization processes without degradation is a key selling point in these high-value markets.

The global market size for hydrolysis-resistant polypropylene is projected to grow steadily over the next five years. This growth is fueled by increasing awareness of the material's benefits, stricter regulations on material performance and longevity, and ongoing research and development efforts to expand its applications. Geographically, Asia-Pacific is expected to be the fastest-growing market, driven by rapid industrialization and infrastructure development in countries like China and India.

However, challenges remain in the widespread adoption of hydrolysis-resistant polypropylene. These include higher production costs compared to standard polypropylene and the need for specialized processing techniques. Overcoming these barriers through technological advancements and economies of scale will be crucial for unlocking the full market potential of this material.

Another major market segment is the packaging industry, particularly for food and beverage containers. As consumers and regulators push for more sustainable and durable packaging solutions, hydrolysis-resistant polypropylene offers an attractive option that combines recyclability with enhanced performance. The material's resistance to degradation when exposed to hot liquids or high-humidity environments makes it ideal for reusable containers and packaging for hot-fill products.

The construction industry also presents significant opportunities for hydrolysis-resistant polypropylene. Its use in pipes, fittings, and membranes for water management systems is growing due to its ability to withstand constant water exposure without compromising structural integrity. This is particularly valuable in regions with aggressive water conditions or where long-term durability is paramount.

In the medical and healthcare sectors, hydrolysis-resistant polypropylene is gaining traction for applications such as sterilizable medical devices, laboratory equipment, and pharmaceutical packaging. The material's ability to withstand repeated sterilization processes without degradation is a key selling point in these high-value markets.

The global market size for hydrolysis-resistant polypropylene is projected to grow steadily over the next five years. This growth is fueled by increasing awareness of the material's benefits, stricter regulations on material performance and longevity, and ongoing research and development efforts to expand its applications. Geographically, Asia-Pacific is expected to be the fastest-growing market, driven by rapid industrialization and infrastructure development in countries like China and India.

However, challenges remain in the widespread adoption of hydrolysis-resistant polypropylene. These include higher production costs compared to standard polypropylene and the need for specialized processing techniques. Overcoming these barriers through technological advancements and economies of scale will be crucial for unlocking the full market potential of this material.

Current Challenges in Polypropylene Hydrolytic Stability

Polypropylene, a widely used thermoplastic polymer, faces significant challenges in maintaining hydrolytic stability across various applications. The primary concern lies in the material's susceptibility to degradation when exposed to moisture and elevated temperatures over extended periods. This degradation process, known as hydrolysis, can lead to a reduction in mechanical properties, compromising the integrity and performance of polypropylene-based products.

One of the key challenges in addressing hydrolytic stability is the inherent chemical structure of polypropylene. The polymer's carbon-carbon backbone is relatively resistant to hydrolysis, but the presence of additives, impurities, or oxidation products can create weak points susceptible to water attack. These vulnerabilities are particularly pronounced in applications involving hot water or steam, such as pipes, automotive components, and household appliances.

The rate and extent of hydrolytic degradation in polypropylene are influenced by several factors, including temperature, pH, and the presence of catalysts or stabilizers. Higher temperatures accelerate the hydrolysis process, while extreme pH conditions can exacerbate the breakdown of polymer chains. The challenge lies in developing formulations that can withstand these varied environmental conditions without compromising the material's desirable properties.

Another significant hurdle is the difficulty in accurately predicting and modeling the long-term hydrolytic stability of polypropylene in real-world applications. Laboratory tests often fail to fully replicate the complex interplay of factors present in actual use scenarios, leading to discrepancies between predicted and observed performance. This gap in predictive capabilities hampers the development of more resilient polypropylene formulations and limits the ability to provide accurate lifetime estimates for products.

The presence of additives, while often necessary for enhancing various properties of polypropylene, can inadvertently contribute to reduced hydrolytic stability. Antioxidants, UV stabilizers, and other functional additives may leach out over time, leaving the polymer more vulnerable to hydrolytic attack. Balancing the benefits of these additives with their potential negative impacts on long-term stability remains a significant challenge for material scientists and engineers.

Furthermore, the increasing demand for recycled and bio-based polypropylene introduces additional complexities in maintaining hydrolytic stability. Recycled materials may contain contaminants or degraded polymer chains that increase susceptibility to hydrolysis, while bio-based alternatives may have inherently different hydrolytic properties compared to their petroleum-based counterparts. Developing strategies to ensure consistent hydrolytic stability across these diverse material sources presents a formidable challenge for the industry.

One of the key challenges in addressing hydrolytic stability is the inherent chemical structure of polypropylene. The polymer's carbon-carbon backbone is relatively resistant to hydrolysis, but the presence of additives, impurities, or oxidation products can create weak points susceptible to water attack. These vulnerabilities are particularly pronounced in applications involving hot water or steam, such as pipes, automotive components, and household appliances.

The rate and extent of hydrolytic degradation in polypropylene are influenced by several factors, including temperature, pH, and the presence of catalysts or stabilizers. Higher temperatures accelerate the hydrolysis process, while extreme pH conditions can exacerbate the breakdown of polymer chains. The challenge lies in developing formulations that can withstand these varied environmental conditions without compromising the material's desirable properties.

Another significant hurdle is the difficulty in accurately predicting and modeling the long-term hydrolytic stability of polypropylene in real-world applications. Laboratory tests often fail to fully replicate the complex interplay of factors present in actual use scenarios, leading to discrepancies between predicted and observed performance. This gap in predictive capabilities hampers the development of more resilient polypropylene formulations and limits the ability to provide accurate lifetime estimates for products.

The presence of additives, while often necessary for enhancing various properties of polypropylene, can inadvertently contribute to reduced hydrolytic stability. Antioxidants, UV stabilizers, and other functional additives may leach out over time, leaving the polymer more vulnerable to hydrolytic attack. Balancing the benefits of these additives with their potential negative impacts on long-term stability remains a significant challenge for material scientists and engineers.

Furthermore, the increasing demand for recycled and bio-based polypropylene introduces additional complexities in maintaining hydrolytic stability. Recycled materials may contain contaminants or degraded polymer chains that increase susceptibility to hydrolysis, while bio-based alternatives may have inherently different hydrolytic properties compared to their petroleum-based counterparts. Developing strategies to ensure consistent hydrolytic stability across these diverse material sources presents a formidable challenge for the industry.

Existing Solutions for Enhancing Hydrolytic Stability

01 Use of stabilizers to improve hydrolytic stability

Various stabilizers can be added to polypropylene to enhance its hydrolytic stability. These additives help prevent degradation caused by moisture and maintain the polymer's properties over time. Common stabilizers include antioxidants, UV stabilizers, and hydrolysis inhibitors.- Use of stabilizers to improve hydrolytic stability: Various stabilizers can be added to polypropylene to enhance its hydrolytic stability. These additives help prevent degradation caused by moisture and maintain the polymer's properties over time. Common stabilizers include antioxidants, UV stabilizers, and hydrolysis inhibitors.

- Modification of polypropylene structure: The hydrolytic stability of polypropylene can be improved by modifying its molecular structure. This can involve techniques such as copolymerization, crosslinking, or the incorporation of specific functional groups that enhance resistance to hydrolysis.

- Processing techniques for enhanced stability: Specific processing techniques can be employed to improve the hydrolytic stability of polypropylene. These may include optimized extrusion conditions, controlled cooling rates, or post-processing treatments that alter the polymer's crystallinity or surface properties.

- Blending with other polymers or additives: Blending polypropylene with other polymers or specific additives can enhance its hydrolytic stability. This approach can create synergistic effects that improve moisture resistance and overall durability of the material.

- Surface treatment and coating methods: Applying surface treatments or coatings to polypropylene products can significantly improve their hydrolytic stability. These methods create a protective barrier that prevents moisture penetration and reduces the risk of hydrolytic degradation.

02 Modification of polypropylene structure

The hydrolytic stability of polypropylene can be improved by modifying its molecular structure. This can involve techniques such as copolymerization, crosslinking, or the incorporation of specific functional groups that enhance resistance to hydrolysis.Expand Specific Solutions03 Processing techniques for enhanced stability

Specific processing techniques can be employed to improve the hydrolytic stability of polypropylene. These may include optimized extrusion conditions, controlled cooling rates, or post-processing treatments that alter the polymer's crystallinity or surface properties.Expand Specific Solutions04 Blending with other polymers or additives

Blending polypropylene with other polymers or specific additives can enhance its hydrolytic stability. This approach can create synergistic effects that improve moisture resistance and overall durability of the material.Expand Specific Solutions05 Surface treatment and coating methods

Applying surface treatments or coatings to polypropylene products can significantly improve their hydrolytic stability. These methods create a protective barrier that prevents moisture penetration and reduces the risk of hydrolytic degradation.Expand Specific Solutions

Key Players in Hydrolysis-Resistant Polypropylene Industry

The hydrolytic stability of polypropylene applications is a mature field with ongoing research and development. The market for polypropylene-based products is substantial, driven by diverse industrial applications. Key players like Dow Global Technologies, BASF, ExxonMobil Chemical, and DuPont de Nemours are at the forefront of innovation in this area. Chinese companies, including Sinopec and PetroChina, are also making significant contributions. The technology's maturity is evident in the involvement of established chemical giants, while ongoing research at institutions like Soochow University and Sichuan University indicates potential for further advancements. The competitive landscape is characterized by a mix of global corporations and specialized research entities, reflecting the technology's importance across multiple sectors.

Dow Global Technologies LLC

Technical Solution: Dow has developed advanced stabilization technologies for polypropylene to enhance its hydrolytic stability. Their approach involves incorporating specialized antioxidants and hydrolysis inhibitors into the polymer matrix. These additives form a protective network within the material, effectively shielding the polymer chains from water molecules and preventing hydrolytic degradation[1]. Dow's research has shown that their stabilized polypropylene formulations can maintain mechanical properties and molecular weight distribution even after prolonged exposure to high humidity and elevated temperatures[3]. The company has also explored the use of nanocomposites to further improve hydrolytic resistance, incorporating nanoclays that create tortuous paths for water diffusion[5].

Strengths: Comprehensive stabilization approach, proven effectiveness in harsh environments. Weaknesses: Potential increased cost due to specialized additives, may affect recyclability.

BASF Corp.

Technical Solution: BASF has focused on developing multi-functional stabilizer packages for polypropylene that address hydrolytic stability alongside other degradation mechanisms. Their approach combines hindered amine light stabilizers (HALS) with novel hydrolysis inhibitors to create synergistic effects[2]. BASF's research has demonstrated that these stabilizer packages can significantly extend the service life of polypropylene in high-moisture environments, such as automotive under-the-hood applications[4]. The company has also invested in the development of water-repellent surface treatments that can be applied to polypropylene parts, creating an additional barrier against moisture ingress[6]. BASF's solutions are designed to be compatible with various polypropylene grades and processing methods, ensuring broad applicability across different industries.

Strengths: Holistic approach to stability, versatile solutions for various applications. Weaknesses: May require optimization for specific end-use conditions, potential impact on surface properties.

Innovative Approaches to Polypropylene Hydrolysis Prevention

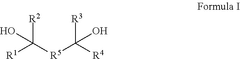

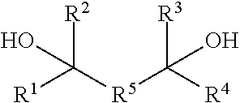

Polypropylene composition having improved radiation stability

PatentPendingUS20240360294A1

Innovation

- A polypropylene composition comprising a propylene polymer and an aliphatic alcohol with at least two hydroxyl groups, such as straight chain C5-C20 diols, C4-C30 cyclic alcohols, polycarbohydrates, and branched acyclic diols, which maintains mechanical and optical properties even after radiation exposure.

Stabilisation of aqueous solutions of homopolymers and copolymers of n-vinylpyrrolidones

PatentActiveEP1799756A1

Innovation

- The stabilization of aqueous polymer solutions is achieved by adding hydrogen peroxide in concentrations ranging from 100 to 5000 ppm, with specific adjustments based on polymer types, and using suitable comonomers like quaternized N-vinylimidazole, which maintains stability over time without negative impacts on secondary products.

Environmental Impact of Hydrolysis-Resistant Polypropylene

The environmental impact of hydrolysis-resistant polypropylene is a crucial consideration in the development and application of this advanced material. As industries strive for more durable and long-lasting products, the adoption of hydrolysis-resistant polypropylene has significant implications for sustainability and environmental conservation.

One of the primary environmental benefits of hydrolysis-resistant polypropylene is its extended lifespan. By resisting degradation caused by water and moisture, products made from this material can remain functional for longer periods, reducing the need for frequent replacements. This longevity directly translates to a decrease in waste generation and resource consumption, aligning with global efforts to minimize environmental footprints.

In the context of marine environments, hydrolysis-resistant polypropylene offers potential advantages. Traditional plastics often degrade in aquatic settings, releasing microplastics that pose severe threats to marine ecosystems. Hydrolysis-resistant polypropylene, with its enhanced stability, may contribute to reducing the release of microplastics in marine environments, thereby mitigating potential harm to aquatic life.

However, the improved durability of hydrolysis-resistant polypropylene also raises concerns about its end-of-life management. While the material's resistance to degradation is beneficial during its use phase, it may pose challenges for biodegradation or recycling processes. This necessitates the development of specialized recycling techniques or end-of-life solutions to ensure that the material does not contribute to long-term environmental pollution.

The production process of hydrolysis-resistant polypropylene also warrants environmental scrutiny. The additives or modifications required to enhance hydrolytic stability may involve additional chemical processes or materials, potentially increasing the overall environmental impact of manufacturing. Life cycle assessments are crucial to comprehensively evaluate the net environmental effect, considering factors such as energy consumption, emissions, and resource utilization throughout the material's lifecycle.

In terms of carbon footprint, the extended lifespan of products made from hydrolysis-resistant polypropylene may contribute to reduced carbon emissions associated with manufacturing and transportation of replacement products. However, this benefit must be weighed against any potential increase in emissions during the production of the enhanced material.

The application of hydrolysis-resistant polypropylene in various industries, such as automotive, construction, and packaging, presents opportunities for improved sustainability. For instance, in automotive applications, the material's durability can lead to lighter vehicles with longer-lasting components, potentially improving fuel efficiency and reducing overall environmental impact.

One of the primary environmental benefits of hydrolysis-resistant polypropylene is its extended lifespan. By resisting degradation caused by water and moisture, products made from this material can remain functional for longer periods, reducing the need for frequent replacements. This longevity directly translates to a decrease in waste generation and resource consumption, aligning with global efforts to minimize environmental footprints.

In the context of marine environments, hydrolysis-resistant polypropylene offers potential advantages. Traditional plastics often degrade in aquatic settings, releasing microplastics that pose severe threats to marine ecosystems. Hydrolysis-resistant polypropylene, with its enhanced stability, may contribute to reducing the release of microplastics in marine environments, thereby mitigating potential harm to aquatic life.

However, the improved durability of hydrolysis-resistant polypropylene also raises concerns about its end-of-life management. While the material's resistance to degradation is beneficial during its use phase, it may pose challenges for biodegradation or recycling processes. This necessitates the development of specialized recycling techniques or end-of-life solutions to ensure that the material does not contribute to long-term environmental pollution.

The production process of hydrolysis-resistant polypropylene also warrants environmental scrutiny. The additives or modifications required to enhance hydrolytic stability may involve additional chemical processes or materials, potentially increasing the overall environmental impact of manufacturing. Life cycle assessments are crucial to comprehensively evaluate the net environmental effect, considering factors such as energy consumption, emissions, and resource utilization throughout the material's lifecycle.

In terms of carbon footprint, the extended lifespan of products made from hydrolysis-resistant polypropylene may contribute to reduced carbon emissions associated with manufacturing and transportation of replacement products. However, this benefit must be weighed against any potential increase in emissions during the production of the enhanced material.

The application of hydrolysis-resistant polypropylene in various industries, such as automotive, construction, and packaging, presents opportunities for improved sustainability. For instance, in automotive applications, the material's durability can lead to lighter vehicles with longer-lasting components, potentially improving fuel efficiency and reducing overall environmental impact.

Regulatory Framework for Polymer Stability Standards

The regulatory framework for polymer stability standards plays a crucial role in ensuring the safety, quality, and performance of polypropylene applications across various industries. These standards are established and enforced by regulatory bodies and industry organizations to maintain consistency and reliability in polymer products, particularly in terms of hydrolytic stability.

In the United States, the Food and Drug Administration (FDA) sets forth guidelines for polymers used in food contact applications, including polypropylene. The FDA's Code of Federal Regulations (CFR) Title 21, Part 177 specifically addresses polymer stability and migration limits for substances used in food packaging. These regulations require manufacturers to demonstrate the hydrolytic stability of their polypropylene products through rigorous testing and documentation.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which encompasses polymer stability standards. Under REACH, manufacturers must assess and manage the risks associated with the chemicals used in their products, including those that may affect hydrolytic stability. Additionally, the European Food Safety Authority (EFSA) provides guidelines for food contact materials, including specific requirements for polypropylene stability.

International standards organizations, such as the International Organization for Standardization (ISO) and ASTM International, have developed specific test methods and specifications for evaluating polymer stability. ISO 22088 series focuses on the environmental stress cracking of plastics, while ASTM D6693 provides standard test methods for determining the hydrolytic stability of polyolefins, including polypropylene.

The automotive industry has its own set of standards for polymer stability, as outlined in the SAE International's J2236 standard. This standard addresses the performance requirements for polymeric materials used in automotive applications, including their resistance to hydrolysis and other environmental factors.

In the medical device industry, the International Electrotechnical Commission (IEC) 60601 series of standards includes requirements for the stability and biocompatibility of polymers used in medical equipment. These standards ensure that polypropylene components maintain their integrity and performance under various conditions, including exposure to moisture and sterilization processes.

Compliance with these regulatory frameworks and standards is essential for manufacturers and suppliers of polypropylene products. It not only ensures product safety and quality but also facilitates global trade by harmonizing requirements across different regions. As research into hydrolytic stability in polypropylene applications continues to advance, regulatory bodies and standards organizations are likely to update their guidelines to reflect new findings and technological developments in the field.

In the United States, the Food and Drug Administration (FDA) sets forth guidelines for polymers used in food contact applications, including polypropylene. The FDA's Code of Federal Regulations (CFR) Title 21, Part 177 specifically addresses polymer stability and migration limits for substances used in food packaging. These regulations require manufacturers to demonstrate the hydrolytic stability of their polypropylene products through rigorous testing and documentation.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which encompasses polymer stability standards. Under REACH, manufacturers must assess and manage the risks associated with the chemicals used in their products, including those that may affect hydrolytic stability. Additionally, the European Food Safety Authority (EFSA) provides guidelines for food contact materials, including specific requirements for polypropylene stability.

International standards organizations, such as the International Organization for Standardization (ISO) and ASTM International, have developed specific test methods and specifications for evaluating polymer stability. ISO 22088 series focuses on the environmental stress cracking of plastics, while ASTM D6693 provides standard test methods for determining the hydrolytic stability of polyolefins, including polypropylene.

The automotive industry has its own set of standards for polymer stability, as outlined in the SAE International's J2236 standard. This standard addresses the performance requirements for polymeric materials used in automotive applications, including their resistance to hydrolysis and other environmental factors.

In the medical device industry, the International Electrotechnical Commission (IEC) 60601 series of standards includes requirements for the stability and biocompatibility of polymers used in medical equipment. These standards ensure that polypropylene components maintain their integrity and performance under various conditions, including exposure to moisture and sterilization processes.

Compliance with these regulatory frameworks and standards is essential for manufacturers and suppliers of polypropylene products. It not only ensures product safety and quality but also facilitates global trade by harmonizing requirements across different regions. As research into hydrolytic stability in polypropylene applications continues to advance, regulatory bodies and standards organizations are likely to update their guidelines to reflect new findings and technological developments in the field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!