Investigating Life Cycle Assessment of Polypropylene Products

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LCA Background and Objectives

Life Cycle Assessment (LCA) has emerged as a crucial tool in evaluating the environmental impacts of products and processes throughout their entire lifecycle. In the context of polypropylene products, LCA provides a comprehensive framework to assess the environmental footprint from raw material extraction to end-of-life disposal. This approach aligns with the growing global emphasis on sustainability and circular economy principles.

The primary objective of investigating the LCA of polypropylene products is to quantify and understand the environmental implications associated with their production, use, and disposal. This investigation aims to identify hotspots in the lifecycle where environmental impacts are most significant, enabling targeted interventions for improvement. By conducting a thorough LCA, stakeholders can make informed decisions to optimize resource efficiency, reduce emissions, and minimize waste generation.

Polypropylene, a versatile thermoplastic polymer, finds extensive applications across various industries, including packaging, automotive, textiles, and consumer goods. Its widespread use underscores the importance of understanding its lifecycle impacts. The LCA study seeks to evaluate key environmental indicators such as global warming potential, energy consumption, water usage, and resource depletion throughout the polypropylene product lifecycle.

The scope of this LCA investigation encompasses the entire value chain, from the extraction of raw materials (primarily derived from fossil fuels) to the manufacturing processes, distribution, use phase, and end-of-life scenarios. This cradle-to-grave approach ensures a holistic assessment of environmental impacts, considering both direct and indirect effects associated with polypropylene products.

Furthermore, this LCA study aims to compare different production methods, recycling technologies, and disposal options for polypropylene products. By analyzing various scenarios, the investigation can provide insights into the most environmentally favorable practices and identify opportunities for improvement in the polypropylene industry. This comparative analysis is crucial for informing policy decisions, guiding industry standards, and promoting sustainable innovation in polymer production and use.

The outcomes of this LCA investigation are expected to contribute to the broader discourse on sustainable materials and circular economy strategies. By providing a detailed understanding of the environmental impacts associated with polypropylene products, this study can support the development of eco-design principles, enhance product stewardship, and drive the adoption of more sustainable practices across the value chain.

The primary objective of investigating the LCA of polypropylene products is to quantify and understand the environmental implications associated with their production, use, and disposal. This investigation aims to identify hotspots in the lifecycle where environmental impacts are most significant, enabling targeted interventions for improvement. By conducting a thorough LCA, stakeholders can make informed decisions to optimize resource efficiency, reduce emissions, and minimize waste generation.

Polypropylene, a versatile thermoplastic polymer, finds extensive applications across various industries, including packaging, automotive, textiles, and consumer goods. Its widespread use underscores the importance of understanding its lifecycle impacts. The LCA study seeks to evaluate key environmental indicators such as global warming potential, energy consumption, water usage, and resource depletion throughout the polypropylene product lifecycle.

The scope of this LCA investigation encompasses the entire value chain, from the extraction of raw materials (primarily derived from fossil fuels) to the manufacturing processes, distribution, use phase, and end-of-life scenarios. This cradle-to-grave approach ensures a holistic assessment of environmental impacts, considering both direct and indirect effects associated with polypropylene products.

Furthermore, this LCA study aims to compare different production methods, recycling technologies, and disposal options for polypropylene products. By analyzing various scenarios, the investigation can provide insights into the most environmentally favorable practices and identify opportunities for improvement in the polypropylene industry. This comparative analysis is crucial for informing policy decisions, guiding industry standards, and promoting sustainable innovation in polymer production and use.

The outcomes of this LCA investigation are expected to contribute to the broader discourse on sustainable materials and circular economy strategies. By providing a detailed understanding of the environmental impacts associated with polypropylene products, this study can support the development of eco-design principles, enhance product stewardship, and drive the adoption of more sustainable practices across the value chain.

Market Demand Analysis

The market demand for polypropylene products has been steadily increasing over the past decade, driven by their versatility, cost-effectiveness, and favorable properties. As one of the most widely used plastics globally, polypropylene finds applications across various industries, including packaging, automotive, consumer goods, and construction.

In the packaging sector, which accounts for the largest share of polypropylene consumption, there is a growing demand for sustainable and recyclable packaging solutions. This trend is fueled by increasing environmental awareness and stringent regulations on single-use plastics. Consequently, manufacturers are focusing on developing polypropylene products with improved recyclability and reduced environmental impact.

The automotive industry represents another significant market for polypropylene products. With the push towards lightweight vehicles to improve fuel efficiency and reduce emissions, polypropylene components are increasingly replacing traditional materials in car interiors, exteriors, and under-the-hood applications. This shift is expected to continue, driving demand for innovative polypropylene formulations that meet stringent performance requirements.

In the consumer goods sector, polypropylene's durability, chemical resistance, and ease of processing make it a popular choice for a wide range of products, from household appliances to personal care items. The growing middle class in emerging economies is contributing to increased demand for these products, further boosting the market for polypropylene.

The construction industry is also witnessing a rise in polypropylene usage, particularly in piping systems, geotextiles, and insulation materials. The material's resistance to chemicals, heat, and moisture makes it an attractive option for various building applications.

However, the market demand for polypropylene products is not without challenges. Increasing concerns about plastic waste and its environmental impact have led to a growing interest in alternative materials and recycling technologies. This has created a need for life cycle assessments to evaluate the true environmental footprint of polypropylene products throughout their lifecycle.

Furthermore, fluctuations in raw material prices, particularly crude oil, can significantly impact the polypropylene market. As a result, there is a growing interest in bio-based polypropylene alternatives, which could potentially offer more stable pricing and reduced environmental impact.

The COVID-19 pandemic has also influenced market dynamics, with increased demand for polypropylene in medical applications and personal protective equipment. This surge has highlighted the material's importance in critical sectors and may lead to long-term changes in consumption patterns.

In conclusion, the market demand for polypropylene products remains strong, driven by their versatility and cost-effectiveness. However, the industry faces challenges in addressing sustainability concerns and adapting to changing regulatory landscapes. Life cycle assessments will play a crucial role in guiding future product development and market strategies, ensuring that polypropylene products can meet both performance and environmental requirements in an evolving market.

In the packaging sector, which accounts for the largest share of polypropylene consumption, there is a growing demand for sustainable and recyclable packaging solutions. This trend is fueled by increasing environmental awareness and stringent regulations on single-use plastics. Consequently, manufacturers are focusing on developing polypropylene products with improved recyclability and reduced environmental impact.

The automotive industry represents another significant market for polypropylene products. With the push towards lightweight vehicles to improve fuel efficiency and reduce emissions, polypropylene components are increasingly replacing traditional materials in car interiors, exteriors, and under-the-hood applications. This shift is expected to continue, driving demand for innovative polypropylene formulations that meet stringent performance requirements.

In the consumer goods sector, polypropylene's durability, chemical resistance, and ease of processing make it a popular choice for a wide range of products, from household appliances to personal care items. The growing middle class in emerging economies is contributing to increased demand for these products, further boosting the market for polypropylene.

The construction industry is also witnessing a rise in polypropylene usage, particularly in piping systems, geotextiles, and insulation materials. The material's resistance to chemicals, heat, and moisture makes it an attractive option for various building applications.

However, the market demand for polypropylene products is not without challenges. Increasing concerns about plastic waste and its environmental impact have led to a growing interest in alternative materials and recycling technologies. This has created a need for life cycle assessments to evaluate the true environmental footprint of polypropylene products throughout their lifecycle.

Furthermore, fluctuations in raw material prices, particularly crude oil, can significantly impact the polypropylene market. As a result, there is a growing interest in bio-based polypropylene alternatives, which could potentially offer more stable pricing and reduced environmental impact.

The COVID-19 pandemic has also influenced market dynamics, with increased demand for polypropylene in medical applications and personal protective equipment. This surge has highlighted the material's importance in critical sectors and may lead to long-term changes in consumption patterns.

In conclusion, the market demand for polypropylene products remains strong, driven by their versatility and cost-effectiveness. However, the industry faces challenges in addressing sustainability concerns and adapting to changing regulatory landscapes. Life cycle assessments will play a crucial role in guiding future product development and market strategies, ensuring that polypropylene products can meet both performance and environmental requirements in an evolving market.

Current LCA Challenges

Life Cycle Assessment (LCA) of polypropylene products faces several significant challenges in the current landscape. One of the primary issues is data quality and availability. Accurate and comprehensive data on raw material extraction, manufacturing processes, transportation, use phase, and end-of-life scenarios are crucial for a reliable LCA. However, obtaining such data for polypropylene products can be difficult due to the complexity of supply chains and the proprietary nature of certain manufacturing processes.

Another challenge is the variability in production methods and product compositions. Polypropylene can be produced through different polymerization techniques and with various additives, leading to products with different properties and environmental impacts. This variability makes it challenging to establish standardized LCA methodologies for polypropylene products, potentially leading to inconsistencies in results across different studies.

The allocation of environmental impacts in multi-output processes presents another hurdle. Polypropylene production often occurs alongside other petrochemical products, making it difficult to accurately attribute environmental burdens to specific outputs. This challenge is particularly pronounced in the case of recycled polypropylene, where the allocation of impacts between virgin and recycled materials can significantly affect LCA results.

Temporal and geographical variations also pose challenges in LCA studies of polypropylene products. Energy grids, transportation systems, and waste management practices differ across regions and can change over time. These variations can lead to significant differences in LCA results for identical products produced or used in different locations or time periods, complicating comparisons and decision-making based on LCA outcomes.

The end-of-life phase of polypropylene products presents unique challenges for LCA. The actual fate of these products after use, including recycling rates, incineration, and landfilling, can vary widely depending on local waste management infrastructure and consumer behavior. Accurately modeling these scenarios and their associated environmental impacts is crucial but often difficult due to data limitations and regional variations.

Lastly, the rapid evolution of polypropylene production technologies and recycling methods introduces uncertainty in LCA studies. Emerging technologies, such as chemical recycling or bio-based polypropylene production, may significantly alter the environmental profile of polypropylene products. However, these technologies are often not well-represented in existing LCA databases, making it challenging to accurately assess their potential benefits and drawbacks in a life cycle context.

Another challenge is the variability in production methods and product compositions. Polypropylene can be produced through different polymerization techniques and with various additives, leading to products with different properties and environmental impacts. This variability makes it challenging to establish standardized LCA methodologies for polypropylene products, potentially leading to inconsistencies in results across different studies.

The allocation of environmental impacts in multi-output processes presents another hurdle. Polypropylene production often occurs alongside other petrochemical products, making it difficult to accurately attribute environmental burdens to specific outputs. This challenge is particularly pronounced in the case of recycled polypropylene, where the allocation of impacts between virgin and recycled materials can significantly affect LCA results.

Temporal and geographical variations also pose challenges in LCA studies of polypropylene products. Energy grids, transportation systems, and waste management practices differ across regions and can change over time. These variations can lead to significant differences in LCA results for identical products produced or used in different locations or time periods, complicating comparisons and decision-making based on LCA outcomes.

The end-of-life phase of polypropylene products presents unique challenges for LCA. The actual fate of these products after use, including recycling rates, incineration, and landfilling, can vary widely depending on local waste management infrastructure and consumer behavior. Accurately modeling these scenarios and their associated environmental impacts is crucial but often difficult due to data limitations and regional variations.

Lastly, the rapid evolution of polypropylene production technologies and recycling methods introduces uncertainty in LCA studies. Emerging technologies, such as chemical recycling or bio-based polypropylene production, may significantly alter the environmental profile of polypropylene products. However, these technologies are often not well-represented in existing LCA databases, making it challenging to accurately assess their potential benefits and drawbacks in a life cycle context.

Existing LCA Approaches

01 Life Cycle Assessment Methodology for Polypropylene Products

This approach involves developing a comprehensive methodology for assessing the environmental impact of polypropylene products throughout their entire life cycle. It includes analyzing raw material extraction, manufacturing processes, use phase, and end-of-life disposal or recycling. The assessment considers factors such as energy consumption, emissions, and resource depletion to provide a holistic view of the product's environmental footprint.- Life cycle assessment methodologies for polypropylene products: Various methodologies and frameworks are developed for conducting life cycle assessments of polypropylene products. These approaches consider the entire lifecycle from raw material extraction to end-of-life disposal, evaluating environmental impacts at each stage. The assessments typically include factors such as energy consumption, greenhouse gas emissions, and resource depletion.

- Environmental impact analysis of polypropylene manufacturing: Studies focus on analyzing the environmental impacts of polypropylene production processes. This includes evaluating energy efficiency, emissions, and waste generation during manufacturing. Researchers aim to identify hotspots in the production chain and propose strategies for reducing the environmental footprint of polypropylene manufacturing.

- Recycling and end-of-life management of polypropylene products: Research explores various recycling technologies and end-of-life management strategies for polypropylene products. This includes mechanical recycling, chemical recycling, and energy recovery methods. The goal is to extend the useful life of polypropylene materials and reduce their environmental impact through improved circularity.

- Comparative analysis of polypropylene with alternative materials: Studies compare the life cycle impacts of polypropylene products with those made from alternative materials. This involves assessing factors such as durability, recyclability, and overall environmental footprint. The aim is to provide insights for material selection in various applications, considering both performance and sustainability aspects.

- Integration of life cycle assessment in product design and development: Approaches for incorporating life cycle assessment principles into the design and development of polypropylene products are explored. This includes the use of eco-design tools, sustainability metrics, and decision-support systems to optimize product lifecycle performance from the early stages of development.

02 Environmental Impact Reduction Strategies for Polypropylene Manufacturing

This focuses on implementing strategies to reduce the environmental impact of polypropylene production. It includes optimizing manufacturing processes, improving energy efficiency, reducing waste generation, and exploring alternative raw materials or production methods. The goal is to minimize the carbon footprint and overall environmental impact of polypropylene products from the production stage.Expand Specific Solutions03 End-of-Life Management and Recycling of Polypropylene Products

This aspect focuses on developing effective strategies for managing polypropylene products at the end of their life cycle. It includes improving recycling technologies, implementing take-back programs, and exploring innovative ways to repurpose or upcycle polypropylene waste. The aim is to reduce landfill waste and promote a circular economy for polypropylene products.Expand Specific Solutions04 Data-driven Life Cycle Assessment Tools for Polypropylene Products

This involves developing advanced software tools and databases to facilitate accurate and efficient life cycle assessments of polypropylene products. These tools incorporate big data analytics, machine learning, and real-time data collection to provide more precise and dynamic assessments of environmental impacts throughout the product lifecycle.Expand Specific Solutions05 Sustainable Design and Material Selection for Polypropylene Products

This approach focuses on integrating sustainability principles into the design phase of polypropylene products. It involves selecting eco-friendly additives, optimizing product design for recyclability, and exploring bio-based or recycled polypropylene alternatives. The goal is to reduce environmental impact from the initial stages of product development.Expand Specific Solutions

Key Players in PP LCA

The life cycle assessment of polypropylene products is currently in a mature stage of industry development, with a substantial global market size estimated at over $100 billion. The technology's maturity is evident from the involvement of major players across the petrochemical and plastics industries. Companies like ExxonMobil Chemical, SABIC, Borealis, and Dow Global Technologies have established strong positions in polypropylene production and research. Academic institutions such as Zhejiang University and the Indian Institute of Science contribute to advancing the field through research collaborations. The competitive landscape is characterized by ongoing efforts to improve sustainability and efficiency throughout the polypropylene lifecycle, with a focus on recycling technologies and bio-based alternatives.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed advanced Life Cycle Assessment (LCA) methodologies for polypropylene products, focusing on reducing environmental impacts throughout the entire product lifecycle. Their approach includes innovative catalysts and process technologies that improve energy efficiency in production, resulting in up to 25% lower greenhouse gas emissions compared to conventional methods[1]. They have also implemented a circular economy strategy, incorporating recycled content into new polypropylene products and designing for easier recyclability, which has led to a 15% reduction in overall carbon footprint for certain product lines[3].

Strengths: Industry-leading research capabilities, extensive global supply chain for implementation. Weaknesses: High capital costs for technology upgrades, potential resistance to rapid changes in established production methods.

SABIC Global Technologies BV

Technical Solution: SABIC has pioneered a comprehensive LCA approach for polypropylene, integrating renewable feedstocks and chemical recycling technologies. Their TRUCIRCLE™ portfolio includes certified circular polypropylene made from post-consumer recycled materials, reducing fossil resource depletion by up to 2 kg CO2eq/kg of polymer[2]. SABIC's LCA studies have shown that their bio-based polypropylene can achieve up to 4 kg CO2eq/kg reduction in carbon footprint compared to fossil-based alternatives[4]. They have also developed design for recyclability guidelines, ensuring that their polypropylene products are optimized for end-of-life scenarios.

Strengths: Strong focus on circular economy solutions, diverse portfolio of sustainable polypropylene options. Weaknesses: Dependency on the development of recycling infrastructure, potential higher costs for bio-based feedstocks.

Core LCA Innovations

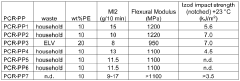

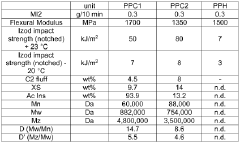

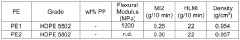

Process to produce polypropylene-based composition from post-consumer resins and articles made of said compositions

PatentWO2019224129A1

Innovation

- A process involving a combination of polypropylene post-consumer resin (PCR) and virgin impact propylene copolymer, along with polyethylene resin, is used to enhance the stiffness and impact properties of the polypropylene-based composition, achieving a balance suitable for applications requiring low MI2 values and good impact resistance at low temperatures.

Method of estimating the properties of a polymer product

PatentInactiveUS7024313B2

Innovation

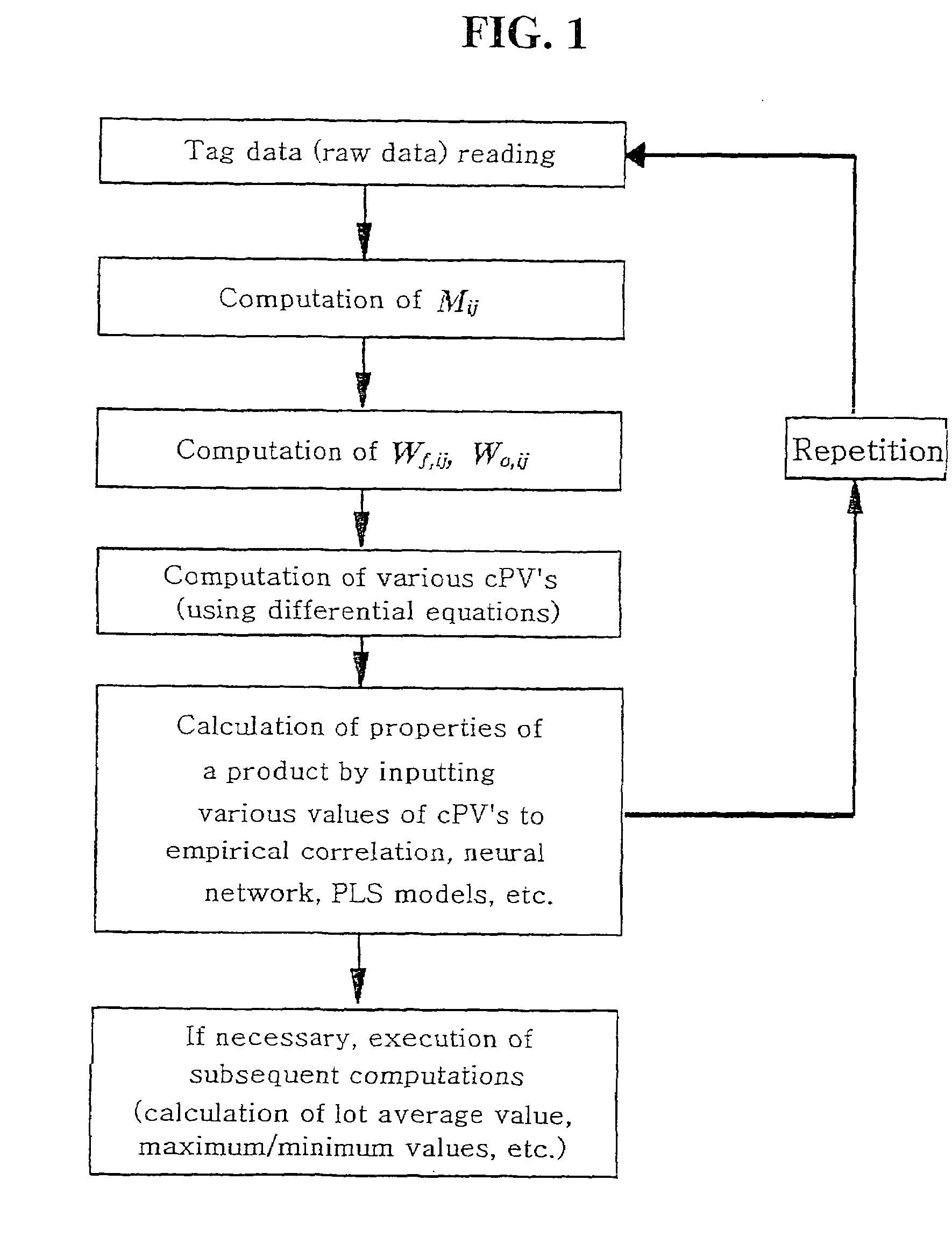

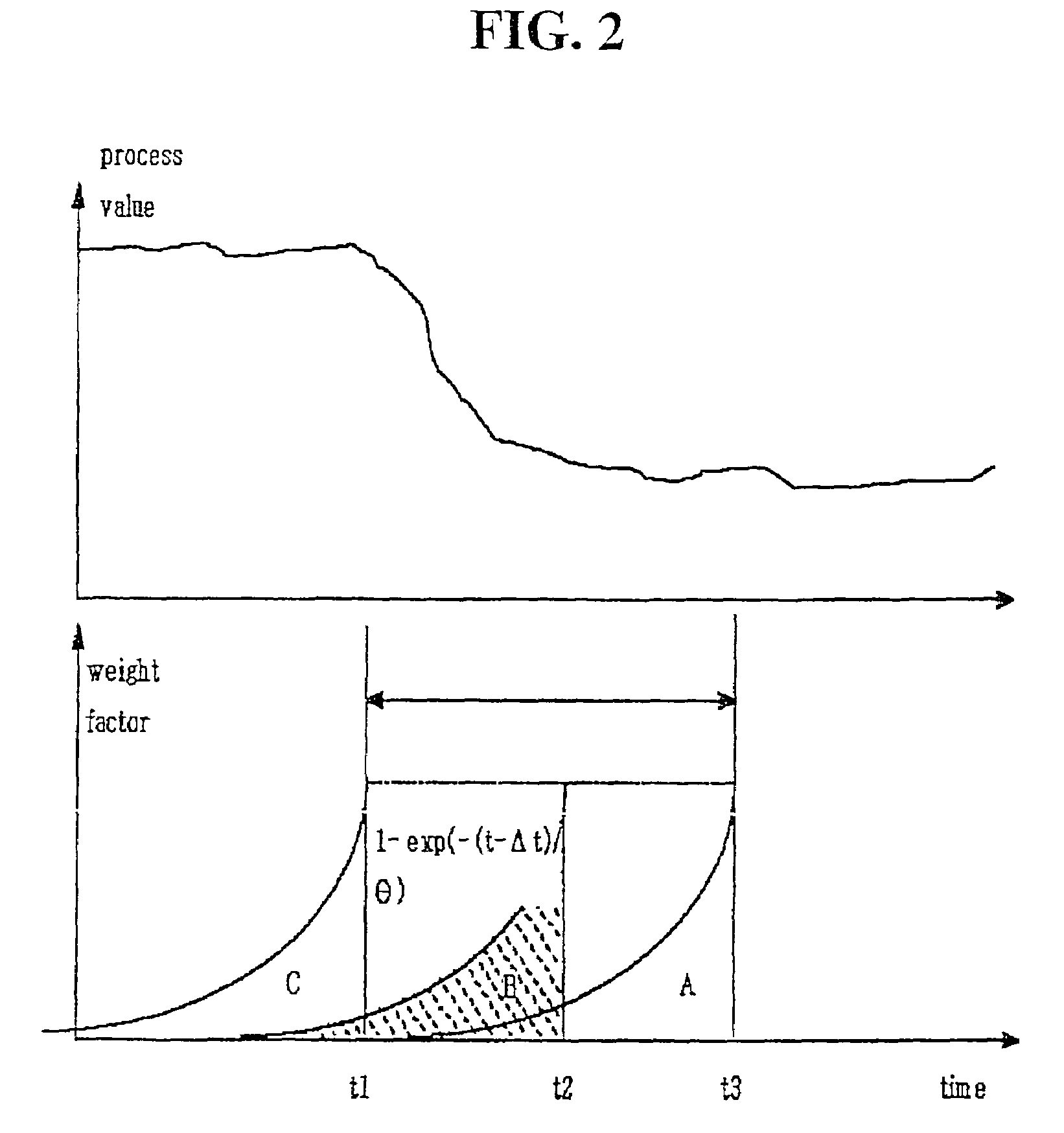

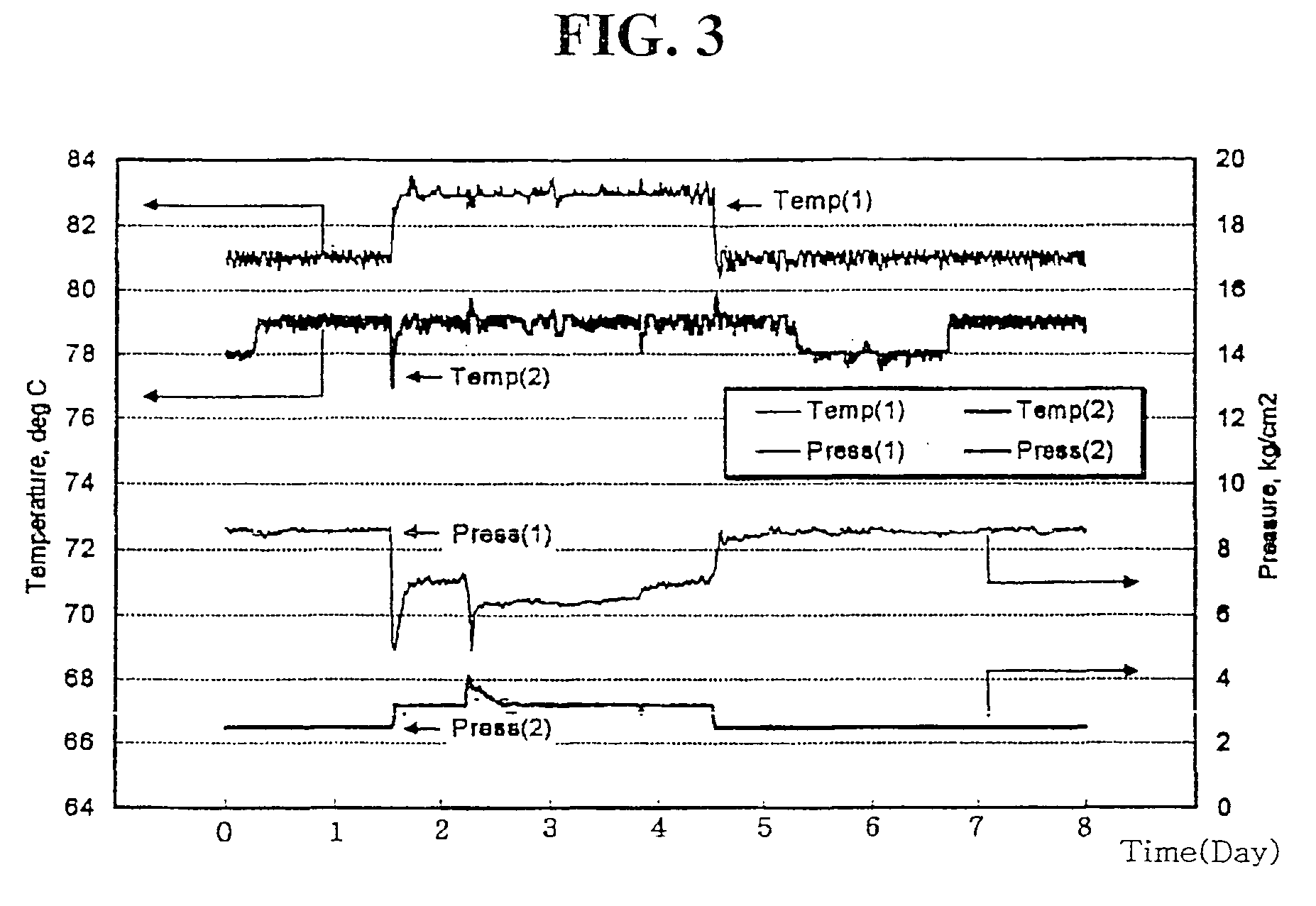

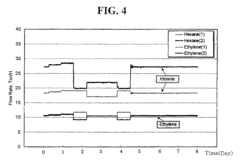

- A method that computes converted process variables (cPVs) by incorporating residence time distribution into process variables, solving balance equations for a hypothetical substance, and inputting these cPVs into property estimation models to accurately estimate polymer product properties at each reactor stage.

Environmental Regulations

Environmental regulations play a crucial role in shaping the life cycle assessment (LCA) of polypropylene products. These regulations are designed to mitigate the environmental impact of plastic production, use, and disposal, influencing every stage of the product's life cycle.

At the production stage, regulations focus on reducing emissions and resource consumption. Many countries have implemented strict air and water quality standards, requiring polypropylene manufacturers to adopt cleaner production technologies. For instance, the European Union's Industrial Emissions Directive (IED) sets emission limits for various pollutants and mandates the use of Best Available Techniques (BAT) in industrial processes.

During the use phase, regulations often target product design and composition. The EU's Restriction of Hazardous Substances (RoHS) Directive, for example, restricts the use of certain hazardous materials in electrical and electronic equipment, including those made with polypropylene. This influences the additives and colorants used in polypropylene products, potentially affecting their environmental impact and recyclability.

End-of-life management is a key focus of environmental regulations for polypropylene products. Many jurisdictions have implemented Extended Producer Responsibility (EPR) schemes, which make manufacturers responsible for the entire lifecycle of their products, including disposal and recycling. The EU's Packaging and Packaging Waste Directive sets targets for recycling and recovery of packaging materials, including polypropylene.

Waste management regulations also significantly impact the LCA of polypropylene products. Landfill bans for certain types of plastic waste, implemented in countries like Germany and the Netherlands, encourage recycling and more sustainable disposal methods. The EU's Waste Framework Directive establishes a waste hierarchy that prioritizes prevention, reuse, and recycling over energy recovery and disposal.

Carbon pricing mechanisms, such as cap-and-trade systems or carbon taxes, indirectly affect polypropylene LCA by increasing the cost of carbon-intensive production processes. This can incentivize manufacturers to adopt more energy-efficient technologies or switch to renewable energy sources, potentially reducing the carbon footprint of polypropylene products.

Emerging regulations are focusing on microplastics and marine pollution. The EU's proposed restrictions on intentionally added microplastics could affect certain polypropylene products, particularly in cosmetics and cleaning applications. Such regulations may lead to changes in product formulations or increased focus on biodegradable alternatives.

As environmental concerns grow, regulations are likely to become more stringent, potentially driving innovation in polypropylene production, use, and recycling. Future regulations may focus on increasing recycled content, improving recyclability, or promoting bio-based alternatives, all of which would significantly impact the life cycle assessment of polypropylene products.

At the production stage, regulations focus on reducing emissions and resource consumption. Many countries have implemented strict air and water quality standards, requiring polypropylene manufacturers to adopt cleaner production technologies. For instance, the European Union's Industrial Emissions Directive (IED) sets emission limits for various pollutants and mandates the use of Best Available Techniques (BAT) in industrial processes.

During the use phase, regulations often target product design and composition. The EU's Restriction of Hazardous Substances (RoHS) Directive, for example, restricts the use of certain hazardous materials in electrical and electronic equipment, including those made with polypropylene. This influences the additives and colorants used in polypropylene products, potentially affecting their environmental impact and recyclability.

End-of-life management is a key focus of environmental regulations for polypropylene products. Many jurisdictions have implemented Extended Producer Responsibility (EPR) schemes, which make manufacturers responsible for the entire lifecycle of their products, including disposal and recycling. The EU's Packaging and Packaging Waste Directive sets targets for recycling and recovery of packaging materials, including polypropylene.

Waste management regulations also significantly impact the LCA of polypropylene products. Landfill bans for certain types of plastic waste, implemented in countries like Germany and the Netherlands, encourage recycling and more sustainable disposal methods. The EU's Waste Framework Directive establishes a waste hierarchy that prioritizes prevention, reuse, and recycling over energy recovery and disposal.

Carbon pricing mechanisms, such as cap-and-trade systems or carbon taxes, indirectly affect polypropylene LCA by increasing the cost of carbon-intensive production processes. This can incentivize manufacturers to adopt more energy-efficient technologies or switch to renewable energy sources, potentially reducing the carbon footprint of polypropylene products.

Emerging regulations are focusing on microplastics and marine pollution. The EU's proposed restrictions on intentionally added microplastics could affect certain polypropylene products, particularly in cosmetics and cleaning applications. Such regulations may lead to changes in product formulations or increased focus on biodegradable alternatives.

As environmental concerns grow, regulations are likely to become more stringent, potentially driving innovation in polypropylene production, use, and recycling. Future regulations may focus on increasing recycled content, improving recyclability, or promoting bio-based alternatives, all of which would significantly impact the life cycle assessment of polypropylene products.

Circular Economy Impact

The impact of circular economy principles on the life cycle assessment (LCA) of polypropylene products is significant and multifaceted. Circular economy strategies aim to minimize waste, maximize resource efficiency, and extend product lifespans, all of which have profound implications for the environmental footprint of polypropylene products throughout their life cycle.

One of the primary ways circular economy practices influence LCA outcomes is through the increased use of recycled polypropylene. By incorporating recycled content into new products, manufacturers can substantially reduce the energy consumption and greenhouse gas emissions associated with virgin material production. This shift not only decreases the environmental burden of the production phase but also mitigates the impacts of waste disposal.

The implementation of design for recyclability principles further enhances the circular economy impact on polypropylene LCAs. Products engineered with end-of-life considerations in mind are more likely to be effectively recycled, creating a closed-loop system that reduces the need for virgin material inputs and minimizes waste generation. This approach can lead to significant improvements in overall life cycle environmental performance.

Circular economy initiatives also promote the development of more durable and repairable polypropylene products. By extending product lifespans through improved durability and repairability, the environmental impacts associated with frequent replacement and disposal are diminished. This shift towards longevity can result in lower cumulative impacts over time, as reflected in LCA studies that consider multiple use cycles.

The adoption of product-as-a-service models for polypropylene-based goods represents another circular economy strategy with LCA implications. These models incentivize manufacturers to design for durability and maintainability, potentially reducing the overall material throughput and associated environmental impacts across the product life cycle.

Furthermore, circular economy practices encourage the development of more efficient collection and sorting systems for polypropylene waste. Improved waste management infrastructure can lead to higher recycling rates and better quality recycled materials, positively influencing the end-of-life phase of LCAs. This, in turn, can create a feedback loop that enhances the environmental performance of subsequent product generations.

The integration of bio-based feedstocks in polypropylene production, aligned with circular bioeconomy principles, also impacts LCA results. While the use of renewable resources can potentially reduce fossil fuel dependence and carbon footprint, careful consideration must be given to land use changes and agricultural impacts to ensure a net positive effect on the overall life cycle assessment.

One of the primary ways circular economy practices influence LCA outcomes is through the increased use of recycled polypropylene. By incorporating recycled content into new products, manufacturers can substantially reduce the energy consumption and greenhouse gas emissions associated with virgin material production. This shift not only decreases the environmental burden of the production phase but also mitigates the impacts of waste disposal.

The implementation of design for recyclability principles further enhances the circular economy impact on polypropylene LCAs. Products engineered with end-of-life considerations in mind are more likely to be effectively recycled, creating a closed-loop system that reduces the need for virgin material inputs and minimizes waste generation. This approach can lead to significant improvements in overall life cycle environmental performance.

Circular economy initiatives also promote the development of more durable and repairable polypropylene products. By extending product lifespans through improved durability and repairability, the environmental impacts associated with frequent replacement and disposal are diminished. This shift towards longevity can result in lower cumulative impacts over time, as reflected in LCA studies that consider multiple use cycles.

The adoption of product-as-a-service models for polypropylene-based goods represents another circular economy strategy with LCA implications. These models incentivize manufacturers to design for durability and maintainability, potentially reducing the overall material throughput and associated environmental impacts across the product life cycle.

Furthermore, circular economy practices encourage the development of more efficient collection and sorting systems for polypropylene waste. Improved waste management infrastructure can lead to higher recycling rates and better quality recycled materials, positively influencing the end-of-life phase of LCAs. This, in turn, can create a feedback loop that enhances the environmental performance of subsequent product generations.

The integration of bio-based feedstocks in polypropylene production, aligned with circular bioeconomy principles, also impacts LCA results. While the use of renewable resources can potentially reduce fossil fuel dependence and carbon footprint, careful consideration must be given to land use changes and agricultural impacts to ensure a net positive effect on the overall life cycle assessment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!