Investigating Long-Term Durability of Polypropylene Roofing Materials

JUL 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polypropylene Roofing Evolution and Objectives

Polypropylene roofing materials have undergone significant evolution since their introduction in the 1960s. Initially developed as a cost-effective alternative to traditional roofing materials, polypropylene has steadily gained popularity due to its lightweight nature, durability, and resistance to environmental factors. The journey of polypropylene in roofing applications has been marked by continuous improvements in material composition, manufacturing processes, and installation techniques.

In the early stages, polypropylene roofing faced challenges related to UV stability and thermal expansion. However, advancements in polymer science led to the development of UV-resistant additives and stabilizers, significantly enhancing the material's longevity. The introduction of reinforced polypropylene membranes in the 1980s marked a crucial milestone, addressing concerns about tensile strength and puncture resistance.

The 1990s saw the emergence of thermoplastic polyolefin (TPO) membranes, a blend of polypropylene and ethylene-propylene rubber, which combined the best properties of both materials. This innovation revolutionized the single-ply roofing industry, offering improved flexibility, weldability, and overall performance. The turn of the millennium brought about further refinements in TPO formulations, focusing on enhancing long-term weathering resistance and energy efficiency through reflective surfaces.

Recent years have witnessed a shift towards sustainable and environmentally friendly roofing solutions. Manufacturers have been exploring bio-based polypropylene and recycled content in roofing materials, aligning with global sustainability goals. Additionally, the integration of advanced nanotechnology has opened new avenues for improving the material's resistance to microbial growth, chemical exposure, and extreme weather conditions.

The primary objective in investigating the long-term durability of polypropylene roofing materials is to address the persistent challenges faced by the industry. These include enhancing UV resistance to prevent premature degradation, improving thermal stability to minimize expansion and contraction issues, and increasing overall lifespan to compete with traditional roofing materials. Researchers aim to develop next-generation polypropylene roofing systems that can withstand diverse climatic conditions while maintaining their structural integrity and performance characteristics over extended periods.

Another critical goal is to optimize the material's recyclability and end-of-life management, contributing to circular economy principles. This involves developing innovative recycling technologies and designing roofing systems with easy disassembly and material recovery in mind. Furthermore, there is a growing emphasis on improving the fire resistance of polypropylene roofing materials to meet stringent building safety standards across different regions.

As the industry looks towards the future, the focus is on creating multifunctional roofing systems that go beyond traditional protection. This includes integrating smart technologies for real-time monitoring of roof conditions, incorporating energy-harvesting capabilities, and developing self-healing properties to address minor damages autonomously. These advancements aim to position polypropylene roofing as a high-performance, sustainable, and technologically advanced solution for the construction industry.

In the early stages, polypropylene roofing faced challenges related to UV stability and thermal expansion. However, advancements in polymer science led to the development of UV-resistant additives and stabilizers, significantly enhancing the material's longevity. The introduction of reinforced polypropylene membranes in the 1980s marked a crucial milestone, addressing concerns about tensile strength and puncture resistance.

The 1990s saw the emergence of thermoplastic polyolefin (TPO) membranes, a blend of polypropylene and ethylene-propylene rubber, which combined the best properties of both materials. This innovation revolutionized the single-ply roofing industry, offering improved flexibility, weldability, and overall performance. The turn of the millennium brought about further refinements in TPO formulations, focusing on enhancing long-term weathering resistance and energy efficiency through reflective surfaces.

Recent years have witnessed a shift towards sustainable and environmentally friendly roofing solutions. Manufacturers have been exploring bio-based polypropylene and recycled content in roofing materials, aligning with global sustainability goals. Additionally, the integration of advanced nanotechnology has opened new avenues for improving the material's resistance to microbial growth, chemical exposure, and extreme weather conditions.

The primary objective in investigating the long-term durability of polypropylene roofing materials is to address the persistent challenges faced by the industry. These include enhancing UV resistance to prevent premature degradation, improving thermal stability to minimize expansion and contraction issues, and increasing overall lifespan to compete with traditional roofing materials. Researchers aim to develop next-generation polypropylene roofing systems that can withstand diverse climatic conditions while maintaining their structural integrity and performance characteristics over extended periods.

Another critical goal is to optimize the material's recyclability and end-of-life management, contributing to circular economy principles. This involves developing innovative recycling technologies and designing roofing systems with easy disassembly and material recovery in mind. Furthermore, there is a growing emphasis on improving the fire resistance of polypropylene roofing materials to meet stringent building safety standards across different regions.

As the industry looks towards the future, the focus is on creating multifunctional roofing systems that go beyond traditional protection. This includes integrating smart technologies for real-time monitoring of roof conditions, incorporating energy-harvesting capabilities, and developing self-healing properties to address minor damages autonomously. These advancements aim to position polypropylene roofing as a high-performance, sustainable, and technologically advanced solution for the construction industry.

Market Analysis for Durable Roofing Solutions

The global roofing market has been experiencing steady growth, driven by increasing construction activities, urbanization, and a growing focus on sustainable building practices. Within this market, the demand for durable roofing solutions, particularly those utilizing polypropylene materials, has been on the rise. This trend is primarily fueled by the need for long-lasting, cost-effective, and environmentally friendly roofing options.

Polypropylene roofing materials have gained significant traction due to their excellent durability, weather resistance, and low maintenance requirements. The market for these materials is expected to expand further as more building owners and contractors recognize their long-term cost benefits and performance advantages. Additionally, the increasing emphasis on energy efficiency in buildings has boosted the demand for reflective roofing materials, a category in which polypropylene excels.

The residential sector represents a substantial portion of the durable roofing solutions market, with homeowners increasingly opting for materials that offer extended lifespans and improved energy efficiency. Commercial and industrial sectors are also significant contributors to market growth, as businesses seek to reduce long-term maintenance costs and improve the overall sustainability of their facilities.

Geographically, North America and Europe lead the market for durable roofing solutions, including polypropylene-based products. These regions have well-established construction industries and stringent building codes that favor high-performance roofing materials. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in this market as urbanization accelerates and awareness of sustainable building practices increases.

The market for durable roofing solutions is also being shaped by evolving consumer preferences and regulatory landscapes. There is a growing demand for roofing materials that not only offer longevity but also contribute to improved energy efficiency and reduced environmental impact. This has led to innovations in polypropylene roofing technologies, including the development of cool roof systems and solar-reflective coatings.

Competition in the durable roofing solutions market is intense, with several major players vying for market share. These companies are investing heavily in research and development to enhance the performance and sustainability of their products. The market is also seeing the entry of new players, particularly those focusing on eco-friendly and technologically advanced roofing solutions.

Polypropylene roofing materials have gained significant traction due to their excellent durability, weather resistance, and low maintenance requirements. The market for these materials is expected to expand further as more building owners and contractors recognize their long-term cost benefits and performance advantages. Additionally, the increasing emphasis on energy efficiency in buildings has boosted the demand for reflective roofing materials, a category in which polypropylene excels.

The residential sector represents a substantial portion of the durable roofing solutions market, with homeowners increasingly opting for materials that offer extended lifespans and improved energy efficiency. Commercial and industrial sectors are also significant contributors to market growth, as businesses seek to reduce long-term maintenance costs and improve the overall sustainability of their facilities.

Geographically, North America and Europe lead the market for durable roofing solutions, including polypropylene-based products. These regions have well-established construction industries and stringent building codes that favor high-performance roofing materials. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in this market as urbanization accelerates and awareness of sustainable building practices increases.

The market for durable roofing solutions is also being shaped by evolving consumer preferences and regulatory landscapes. There is a growing demand for roofing materials that not only offer longevity but also contribute to improved energy efficiency and reduced environmental impact. This has led to innovations in polypropylene roofing technologies, including the development of cool roof systems and solar-reflective coatings.

Competition in the durable roofing solutions market is intense, with several major players vying for market share. These companies are investing heavily in research and development to enhance the performance and sustainability of their products. The market is also seeing the entry of new players, particularly those focusing on eco-friendly and technologically advanced roofing solutions.

Current Challenges in Polypropylene Roofing Longevity

Polypropylene roofing materials have gained significant popularity in the construction industry due to their cost-effectiveness and durability. However, several challenges persist in ensuring their long-term performance and longevity. One of the primary concerns is the material's susceptibility to UV degradation. Prolonged exposure to sunlight can lead to the breakdown of polymer chains, resulting in embrittlement and reduced mechanical properties over time.

Another significant challenge is the thermal expansion and contraction of polypropylene roofing materials. The material's high coefficient of thermal expansion can cause dimensional instability, leading to warping, buckling, or separation at seams and joints. This issue is particularly pronounced in regions with extreme temperature fluctuations, potentially compromising the roof's integrity and water-tightness.

Chemical resistance is also a critical factor affecting the longevity of polypropylene roofing. While generally resistant to many chemicals, certain pollutants, acid rain, or industrial emissions can degrade the material over time. This degradation can manifest as discoloration, loss of flexibility, or reduced structural integrity, ultimately shortening the roof's lifespan.

The potential for microbial growth presents another challenge for polypropylene roofing materials. Although inherently resistant to fungal and bacterial growth, the accumulation of organic matter on the roof surface can create conditions conducive to microbial colonization. This can lead to aesthetic issues, reduced reflectivity, and potential degradation of the roofing material.

Fire resistance remains a concern for polypropylene roofing, as the material is inherently combustible. While fire-retardant additives can improve its performance, achieving and maintaining adequate fire ratings over the long term can be challenging, especially as the material ages and weathering effects accumulate.

Installation and maintenance practices also play a crucial role in the longevity of polypropylene roofing. Improper installation techniques, such as inadequate seam welding or insufficient attachment to the substrate, can lead to premature failure. Additionally, the lack of regular maintenance, including cleaning and inspection, can exacerbate degradation processes and reduce the overall lifespan of the roofing system.

Addressing these challenges requires a multifaceted approach, combining material science innovations, improved manufacturing processes, and enhanced installation and maintenance protocols. Ongoing research focuses on developing advanced UV stabilizers, optimizing polymer formulations for improved thermal stability, and enhancing chemical resistance. Additionally, efforts are being made to improve fire-retardant technologies and develop more effective anti-microbial treatments for polypropylene roofing materials.

Another significant challenge is the thermal expansion and contraction of polypropylene roofing materials. The material's high coefficient of thermal expansion can cause dimensional instability, leading to warping, buckling, or separation at seams and joints. This issue is particularly pronounced in regions with extreme temperature fluctuations, potentially compromising the roof's integrity and water-tightness.

Chemical resistance is also a critical factor affecting the longevity of polypropylene roofing. While generally resistant to many chemicals, certain pollutants, acid rain, or industrial emissions can degrade the material over time. This degradation can manifest as discoloration, loss of flexibility, or reduced structural integrity, ultimately shortening the roof's lifespan.

The potential for microbial growth presents another challenge for polypropylene roofing materials. Although inherently resistant to fungal and bacterial growth, the accumulation of organic matter on the roof surface can create conditions conducive to microbial colonization. This can lead to aesthetic issues, reduced reflectivity, and potential degradation of the roofing material.

Fire resistance remains a concern for polypropylene roofing, as the material is inherently combustible. While fire-retardant additives can improve its performance, achieving and maintaining adequate fire ratings over the long term can be challenging, especially as the material ages and weathering effects accumulate.

Installation and maintenance practices also play a crucial role in the longevity of polypropylene roofing. Improper installation techniques, such as inadequate seam welding or insufficient attachment to the substrate, can lead to premature failure. Additionally, the lack of regular maintenance, including cleaning and inspection, can exacerbate degradation processes and reduce the overall lifespan of the roofing system.

Addressing these challenges requires a multifaceted approach, combining material science innovations, improved manufacturing processes, and enhanced installation and maintenance protocols. Ongoing research focuses on developing advanced UV stabilizers, optimizing polymer formulations for improved thermal stability, and enhancing chemical resistance. Additionally, efforts are being made to improve fire-retardant technologies and develop more effective anti-microbial treatments for polypropylene roofing materials.

Existing Durability Enhancement Techniques

01 UV stabilization for improved durability

Incorporating UV stabilizers into polypropylene roofing materials enhances their resistance to degradation caused by sunlight exposure. This helps maintain the material's structural integrity and color over time, significantly improving the overall durability of the roofing system.- UV stabilization for improved durability: Incorporating UV stabilizers into polypropylene roofing materials enhances their resistance to degradation caused by sunlight exposure. This helps maintain the material's structural integrity and color over time, significantly improving the overall durability of the roofing system.

- Reinforcement with fibers or fillers: Adding reinforcing fibers or fillers to polypropylene roofing materials increases their strength and durability. These additives can include glass fibers, carbon fibers, or mineral fillers, which enhance the material's resistance to impact, weathering, and thermal stress.

- Chemical modification for enhanced properties: Chemically modifying polypropylene through processes such as copolymerization or grafting can improve its durability for roofing applications. These modifications can enhance properties like heat resistance, weatherability, and flexibility, leading to longer-lasting roofing materials.

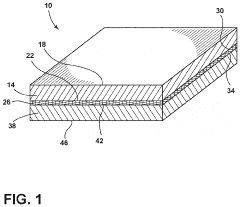

- Multilayer structure for improved performance: Developing multilayer polypropylene roofing materials with specialized layers for different functions can enhance overall durability. This may include weathering-resistant top layers, reinforced core layers, and adhesion-promoting bottom layers, resulting in a more robust and long-lasting roofing system.

- Antioxidant additives for long-term stability: Incorporating antioxidant additives into polypropylene roofing materials helps prevent oxidative degradation, which can lead to brittleness and cracking over time. These additives protect the polymer chains from breaking down due to heat and oxygen exposure, thereby extending the lifespan of the roofing material.

02 Reinforcement with fibers or fillers

Adding reinforcing fibers or fillers to polypropylene roofing materials increases their strength and durability. These additives can include glass fibers, carbon fibers, or mineral fillers, which enhance the material's resistance to impact, weathering, and thermal stress.Expand Specific Solutions03 Chemical modification for enhanced properties

Chemically modifying polypropylene through processes such as copolymerization or grafting can improve its durability for roofing applications. These modifications can enhance properties like heat resistance, flexibility, and weatherability, resulting in a more durable roofing material.Expand Specific Solutions04 Multilayer structure for improved performance

Developing multilayer polypropylene roofing materials with specialized layers for different functions can enhance overall durability. This may include weathering-resistant top layers, reinforced core layers, and adhesion-promoting bottom layers, creating a more robust and long-lasting roofing system.Expand Specific Solutions05 Surface treatment and coatings

Applying surface treatments or protective coatings to polypropylene roofing materials can significantly improve their durability. These treatments may include plasma treatment, corona discharge, or the application of specialized coatings that enhance resistance to UV radiation, moisture, and chemical degradation.Expand Specific Solutions

Key Manufacturers and Industry Landscape

The investigation into long-term durability of polypropylene roofing materials is at a mature stage, with significant market growth and technological advancements. The global market for polypropylene roofing is expanding due to increased construction activities and demand for durable, cost-effective roofing solutions. Key players like China Petroleum & Chemical Corp., Hanwha Total Energy Co., and Hyundai Motor Co. are investing in research and development to improve material performance and longevity. Companies such as Beijing Oriental Yuhong Waterproof Technology and Jiangsu Kingfa Sci. & Tech. Advanced Materials are focusing on innovative formulations and manufacturing processes to enhance the durability and weather resistance of polypropylene roofing materials.

Beijing Oriental Yuhong Waterproof Technology Co., Ltd.

Technical Solution: Beijing Oriental Yuhong has developed advanced polypropylene (PP) roofing materials with enhanced long-term durability. Their technology incorporates UV stabilizers and antioxidants into the PP matrix, significantly improving resistance to weathering and oxidation[1]. The company's proprietary manufacturing process ensures uniform distribution of these additives, resulting in a more consistent and longer-lasting product. They have also implemented a multi-layer structure in their PP roofing sheets, with each layer optimized for specific performance characteristics such as UV resistance, mechanical strength, and waterproofing[3]. This approach allows for a synergistic effect, enhancing overall durability and extending the lifespan of the roofing material.

Strengths: Superior UV and oxidation resistance, multi-layer optimization for enhanced performance. Weaknesses: Potentially higher production costs, may require specialized installation techniques.

SABIC Global Technologies BV

Technical Solution: SABIC has developed a range of PP compounds specifically tailored for long-lasting roofing applications. Their technology focuses on enhancing the polymer's resistance to thermo-oxidative degradation through the incorporation of proprietary stabilizer systems[6]. SABIC's research has led to the development of PP grades with improved impact resistance and low-temperature flexibility, crucial for withstanding extreme weather conditions over extended periods. They have also introduced flame-retardant PP compounds that maintain their protective properties throughout the material's lifetime, addressing both durability and safety concerns[7]. SABIC's materials undergo accelerated weathering tests simulating up to 20 years of exposure, providing valuable data on long-term performance[8].

Strengths: Advanced stabilizer systems, improved impact resistance and flexibility, integrated flame-retardant properties. Weaknesses: May have higher initial costs, potential limitations in color options due to additives.

Innovative Research in Polymer Longevity

Roofing Membranes, Compositions, and Methods Of Making The Same

PatentInactiveUS20210198465A1

Innovation

- A roofing membrane composed of a silane-crosslinked polyolefin elastomer blend with a specific ratio of polyolefin elastomers, functional fillers, UV/heat stabilizers, antioxidants, and fire retardants, which is crosslinkable at ambient temperatures, providing enhanced heat aging properties and UV stability without the need for autoclaving or hot air curing.

Polypropylene-based resin composition having excellent long-term stability

PatentInactiveJP2012224691A

Innovation

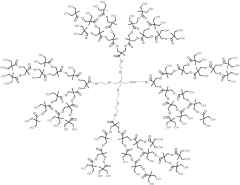

- A polypropylene resin composition is developed by incorporating hyperbranched polymers and stabilizing agents, optionally with inorganic fillers, to enhance long-term stability by maintaining dispersibility and mobility of the stabilizer.

Environmental Impact and Sustainability Considerations

The environmental impact and sustainability considerations of polypropylene roofing materials are crucial aspects to investigate when assessing their long-term durability. Polypropylene, a thermoplastic polymer, offers several advantages in terms of sustainability compared to traditional roofing materials.

One of the primary environmental benefits of polypropylene roofing is its recyclability. At the end of its lifecycle, polypropylene can be recycled and repurposed, reducing waste and conserving resources. This characteristic aligns with circular economy principles and contributes to overall sustainability in the construction industry.

Energy efficiency is another significant factor to consider. Polypropylene roofing materials can be engineered to have high solar reflectance and thermal emittance properties. These features help reduce the urban heat island effect and lower cooling energy demands in buildings, thereby decreasing overall energy consumption and associated carbon emissions.

The production process of polypropylene roofing materials generally requires less energy compared to some traditional roofing options, such as asphalt shingles or metal roofing. This lower embodied energy contributes to a reduced carbon footprint throughout the material's lifecycle.

Durability is a key aspect of sustainability, as longer-lasting materials reduce the need for frequent replacements and associated resource consumption. Polypropylene roofing materials have shown promising results in terms of resistance to weathering, UV radiation, and chemical exposure, potentially leading to extended service life.

However, it is essential to consider the environmental challenges associated with polypropylene roofing. The material is derived from fossil fuels, which raises concerns about resource depletion and greenhouse gas emissions during production. Efforts to develop bio-based polypropylene alternatives are ongoing but require further research and development.

The potential for microplastic pollution is another environmental consideration. As polypropylene roofing materials age and degrade, they may release microplastics into the environment through weathering and runoff. This issue necessitates further study to assess the long-term ecological impact and develop mitigation strategies.

In terms of end-of-life management, while polypropylene is recyclable, the presence of additives and coatings in roofing materials may complicate the recycling process. Developing effective recycling technologies and establishing robust collection systems are crucial for maximizing the material's sustainability potential.

Overall, the environmental impact and sustainability of polypropylene roofing materials present a complex picture. While offering advantages in recyclability, energy efficiency, and potential longevity, challenges remain in terms of raw material sourcing and end-of-life management. Continued research and innovation in these areas will be essential to enhance the overall sustainability profile of polypropylene roofing solutions.

One of the primary environmental benefits of polypropylene roofing is its recyclability. At the end of its lifecycle, polypropylene can be recycled and repurposed, reducing waste and conserving resources. This characteristic aligns with circular economy principles and contributes to overall sustainability in the construction industry.

Energy efficiency is another significant factor to consider. Polypropylene roofing materials can be engineered to have high solar reflectance and thermal emittance properties. These features help reduce the urban heat island effect and lower cooling energy demands in buildings, thereby decreasing overall energy consumption and associated carbon emissions.

The production process of polypropylene roofing materials generally requires less energy compared to some traditional roofing options, such as asphalt shingles or metal roofing. This lower embodied energy contributes to a reduced carbon footprint throughout the material's lifecycle.

Durability is a key aspect of sustainability, as longer-lasting materials reduce the need for frequent replacements and associated resource consumption. Polypropylene roofing materials have shown promising results in terms of resistance to weathering, UV radiation, and chemical exposure, potentially leading to extended service life.

However, it is essential to consider the environmental challenges associated with polypropylene roofing. The material is derived from fossil fuels, which raises concerns about resource depletion and greenhouse gas emissions during production. Efforts to develop bio-based polypropylene alternatives are ongoing but require further research and development.

The potential for microplastic pollution is another environmental consideration. As polypropylene roofing materials age and degrade, they may release microplastics into the environment through weathering and runoff. This issue necessitates further study to assess the long-term ecological impact and develop mitigation strategies.

In terms of end-of-life management, while polypropylene is recyclable, the presence of additives and coatings in roofing materials may complicate the recycling process. Developing effective recycling technologies and establishing robust collection systems are crucial for maximizing the material's sustainability potential.

Overall, the environmental impact and sustainability of polypropylene roofing materials present a complex picture. While offering advantages in recyclability, energy efficiency, and potential longevity, challenges remain in terms of raw material sourcing and end-of-life management. Continued research and innovation in these areas will be essential to enhance the overall sustainability profile of polypropylene roofing solutions.

Weathering and Degradation Testing Methodologies

Weathering and degradation testing methodologies play a crucial role in evaluating the long-term durability of polypropylene roofing materials. These methods simulate various environmental conditions to assess how the materials will perform over extended periods of exposure to natural elements.

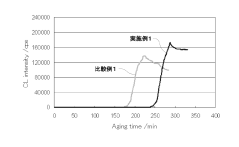

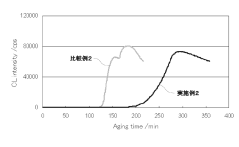

One of the primary testing methodologies is accelerated weathering, which employs specialized equipment to replicate and intensify natural weathering processes. UV exposure testing is a key component, utilizing UV lamps or xenon arc lamps to simulate solar radiation. This helps researchers understand how polypropylene roofing materials degrade under prolonged sunlight exposure, which can lead to discoloration, embrittlement, and loss of mechanical properties.

Thermal cycling tests are another essential aspect of weathering and degradation testing. These tests subject the materials to repeated cycles of heating and cooling, mimicking the temperature fluctuations experienced in real-world conditions. This process helps identify potential issues such as thermal expansion and contraction, which can lead to cracking or delamination of the roofing materials over time.

Moisture resistance testing is equally important, as water exposure can significantly impact the durability of polypropylene roofing materials. Methods such as water immersion, humidity chamber testing, and freeze-thaw cycling are employed to evaluate how the materials withstand prolonged exposure to moisture and temperature variations. These tests help assess the potential for water absorption, dimensional stability, and resistance to mold and mildew growth.

Chemical resistance testing is another critical methodology, particularly for roofing materials that may be exposed to various pollutants and atmospheric contaminants. This involves exposing the materials to different chemical agents, such as acid rain simulants or industrial pollutants, to evaluate their resistance to chemical degradation and discoloration.

Mechanical property testing is conducted throughout the weathering and degradation process to monitor changes in the material's physical characteristics. This includes tensile strength testing, flexural testing, and impact resistance testing. By periodically assessing these properties during accelerated aging, researchers can predict how the polypropylene roofing materials will maintain their structural integrity over time.

Long-term outdoor exposure testing complements laboratory-based accelerated testing methods. While more time-consuming, these real-world tests provide valuable data on how the materials perform under actual environmental conditions. Test sites are often selected in different geographic locations to account for variations in climate, pollution levels, and UV intensity.

The data collected from these various testing methodologies is analyzed using statistical methods and predictive modeling techniques. This allows researchers to extrapolate the results and estimate the expected lifespan of polypropylene roofing materials under different environmental conditions. By combining multiple testing approaches, a comprehensive understanding of the material's long-term durability can be achieved, informing product development and quality assurance processes in the roofing industry.

One of the primary testing methodologies is accelerated weathering, which employs specialized equipment to replicate and intensify natural weathering processes. UV exposure testing is a key component, utilizing UV lamps or xenon arc lamps to simulate solar radiation. This helps researchers understand how polypropylene roofing materials degrade under prolonged sunlight exposure, which can lead to discoloration, embrittlement, and loss of mechanical properties.

Thermal cycling tests are another essential aspect of weathering and degradation testing. These tests subject the materials to repeated cycles of heating and cooling, mimicking the temperature fluctuations experienced in real-world conditions. This process helps identify potential issues such as thermal expansion and contraction, which can lead to cracking or delamination of the roofing materials over time.

Moisture resistance testing is equally important, as water exposure can significantly impact the durability of polypropylene roofing materials. Methods such as water immersion, humidity chamber testing, and freeze-thaw cycling are employed to evaluate how the materials withstand prolonged exposure to moisture and temperature variations. These tests help assess the potential for water absorption, dimensional stability, and resistance to mold and mildew growth.

Chemical resistance testing is another critical methodology, particularly for roofing materials that may be exposed to various pollutants and atmospheric contaminants. This involves exposing the materials to different chemical agents, such as acid rain simulants or industrial pollutants, to evaluate their resistance to chemical degradation and discoloration.

Mechanical property testing is conducted throughout the weathering and degradation process to monitor changes in the material's physical characteristics. This includes tensile strength testing, flexural testing, and impact resistance testing. By periodically assessing these properties during accelerated aging, researchers can predict how the polypropylene roofing materials will maintain their structural integrity over time.

Long-term outdoor exposure testing complements laboratory-based accelerated testing methods. While more time-consuming, these real-world tests provide valuable data on how the materials perform under actual environmental conditions. Test sites are often selected in different geographic locations to account for variations in climate, pollution levels, and UV intensity.

The data collected from these various testing methodologies is analyzed using statistical methods and predictive modeling techniques. This allows researchers to extrapolate the results and estimate the expected lifespan of polypropylene roofing materials under different environmental conditions. By combining multiple testing approaches, a comprehensive understanding of the material's long-term durability can be achieved, informing product development and quality assurance processes in the roofing industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!