Investigating Mechanical Properties of Random Copolymer Polypropylene

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Background and Objectives

Random copolymer polypropylene (RCPP) has emerged as a significant material in the polymer industry due to its unique combination of properties. The development of RCPP can be traced back to the 1950s when researchers began exploring ways to modify the properties of conventional polypropylene. Over the decades, advancements in catalyst technology and polymerization processes have led to the creation of RCPP with tailored mechanical properties.

The evolution of RCPP technology has been driven by the growing demand for materials with enhanced flexibility, impact resistance, and optical clarity while maintaining the desirable characteristics of polypropylene. This has resulted in a continuous effort to understand and optimize the relationship between the copolymer structure and its mechanical properties.

The primary objective of investigating the mechanical properties of RCPP is to develop a comprehensive understanding of how the incorporation of comonomers, typically ethylene, affects the material's behavior under various conditions. This includes studying the impact on tensile strength, elongation at break, flexural modulus, and impact resistance. By gaining insights into these properties, researchers and manufacturers aim to fine-tune the copolymer composition to meet specific application requirements.

Another crucial aspect of this investigation is to explore the influence of molecular weight distribution, crystallinity, and morphology on the mechanical performance of RCPP. These factors play a significant role in determining the material's overall behavior and can be manipulated through careful control of the polymerization process and post-production treatments.

The research in this field also extends to understanding the long-term performance of RCPP, including its resistance to environmental factors, thermal stability, and aging characteristics. This knowledge is essential for predicting the material's lifespan and suitability for various applications, ranging from automotive components to packaging materials.

Furthermore, the investigation of RCPP's mechanical properties aims to address the growing demand for sustainable and recyclable materials. By optimizing the copolymer structure, researchers seek to enhance the material's recyclability without compromising its mechanical performance, aligning with global efforts towards circular economy principles.

As the polymer industry continues to evolve, the study of RCPP's mechanical properties remains at the forefront of materials science research. The ongoing efforts in this field are expected to lead to the development of new grades of RCPP with enhanced properties, expanding its potential applications and market reach.

The evolution of RCPP technology has been driven by the growing demand for materials with enhanced flexibility, impact resistance, and optical clarity while maintaining the desirable characteristics of polypropylene. This has resulted in a continuous effort to understand and optimize the relationship between the copolymer structure and its mechanical properties.

The primary objective of investigating the mechanical properties of RCPP is to develop a comprehensive understanding of how the incorporation of comonomers, typically ethylene, affects the material's behavior under various conditions. This includes studying the impact on tensile strength, elongation at break, flexural modulus, and impact resistance. By gaining insights into these properties, researchers and manufacturers aim to fine-tune the copolymer composition to meet specific application requirements.

Another crucial aspect of this investigation is to explore the influence of molecular weight distribution, crystallinity, and morphology on the mechanical performance of RCPP. These factors play a significant role in determining the material's overall behavior and can be manipulated through careful control of the polymerization process and post-production treatments.

The research in this field also extends to understanding the long-term performance of RCPP, including its resistance to environmental factors, thermal stability, and aging characteristics. This knowledge is essential for predicting the material's lifespan and suitability for various applications, ranging from automotive components to packaging materials.

Furthermore, the investigation of RCPP's mechanical properties aims to address the growing demand for sustainable and recyclable materials. By optimizing the copolymer structure, researchers seek to enhance the material's recyclability without compromising its mechanical performance, aligning with global efforts towards circular economy principles.

As the polymer industry continues to evolve, the study of RCPP's mechanical properties remains at the forefront of materials science research. The ongoing efforts in this field are expected to lead to the development of new grades of RCPP with enhanced properties, expanding its potential applications and market reach.

Market Analysis

The market for random copolymer polypropylene (RCPP) has been experiencing steady growth due to its superior mechanical properties compared to homopolymer polypropylene. RCPP offers improved impact strength, transparency, and flexibility, making it increasingly attractive for various applications across industries.

In the automotive sector, RCPP is gaining traction for interior components, bumpers, and trim parts due to its enhanced impact resistance and aesthetic appeal. The automotive industry's shift towards lightweight materials for fuel efficiency is further driving the demand for RCPP.

The packaging industry represents another significant market for RCPP. Its clarity and toughness make it ideal for food packaging, containers, and films. The growing emphasis on sustainable packaging solutions has also boosted the adoption of RCPP, as it can be easily recycled and offers good barrier properties.

In the construction sector, RCPP is finding applications in pipes, fittings, and profiles due to its excellent chemical resistance and durability. The material's ability to withstand harsh environmental conditions makes it suitable for outdoor applications, contributing to market growth.

The consumer goods industry is also embracing RCPP for household appliances, furniture, and toys. The material's versatility, combined with its ability to be easily molded and colored, makes it an attractive choice for manufacturers looking to create innovative and durable products.

Geographically, Asia-Pacific dominates the RCPP market, driven by rapid industrialization and urbanization in countries like China and India. North America and Europe follow, with increasing demand from automotive and packaging sectors.

The global RCPP market is expected to continue its growth trajectory, with a compound annual growth rate (CAGR) projected to be in the mid-single digits over the next five years. This growth is attributed to the material's expanding applications and the ongoing research and development efforts to further enhance its properties.

However, the market faces challenges such as volatility in raw material prices and competition from alternative materials like high-density polyethylene (HDPE) and polyethylene terephthalate (PET). Additionally, environmental concerns regarding plastic usage may impact market growth, although RCPP's recyclability positions it favorably compared to some other plastics.

Overall, the market analysis indicates a positive outlook for RCPP, driven by its superior mechanical properties and diverse applications across multiple industries. The ongoing focus on sustainability and technological advancements in polymer science are likely to further propel the market forward in the coming years.

In the automotive sector, RCPP is gaining traction for interior components, bumpers, and trim parts due to its enhanced impact resistance and aesthetic appeal. The automotive industry's shift towards lightweight materials for fuel efficiency is further driving the demand for RCPP.

The packaging industry represents another significant market for RCPP. Its clarity and toughness make it ideal for food packaging, containers, and films. The growing emphasis on sustainable packaging solutions has also boosted the adoption of RCPP, as it can be easily recycled and offers good barrier properties.

In the construction sector, RCPP is finding applications in pipes, fittings, and profiles due to its excellent chemical resistance and durability. The material's ability to withstand harsh environmental conditions makes it suitable for outdoor applications, contributing to market growth.

The consumer goods industry is also embracing RCPP for household appliances, furniture, and toys. The material's versatility, combined with its ability to be easily molded and colored, makes it an attractive choice for manufacturers looking to create innovative and durable products.

Geographically, Asia-Pacific dominates the RCPP market, driven by rapid industrialization and urbanization in countries like China and India. North America and Europe follow, with increasing demand from automotive and packaging sectors.

The global RCPP market is expected to continue its growth trajectory, with a compound annual growth rate (CAGR) projected to be in the mid-single digits over the next five years. This growth is attributed to the material's expanding applications and the ongoing research and development efforts to further enhance its properties.

However, the market faces challenges such as volatility in raw material prices and competition from alternative materials like high-density polyethylene (HDPE) and polyethylene terephthalate (PET). Additionally, environmental concerns regarding plastic usage may impact market growth, although RCPP's recyclability positions it favorably compared to some other plastics.

Overall, the market analysis indicates a positive outlook for RCPP, driven by its superior mechanical properties and diverse applications across multiple industries. The ongoing focus on sustainability and technological advancements in polymer science are likely to further propel the market forward in the coming years.

Technical Challenges

The investigation of mechanical properties of random copolymer polypropylene (RCPP) faces several technical challenges that researchers and industry professionals must address. One of the primary difficulties lies in the complex molecular structure of RCPP, which combines propylene with small amounts of other olefins. This heterogeneous composition leads to variations in crystallinity, affecting the material's mechanical behavior in ways that are not fully predictable or easily modeled.

The relationship between the copolymer composition and its mechanical properties is not linear, making it challenging to optimize the material for specific applications. Researchers struggle to develop accurate structure-property relationships that can reliably predict how changes in the copolymer ratio will impact strength, stiffness, and toughness. This complexity is further compounded by the influence of processing conditions on the final material properties, as factors such as cooling rates and shear history during molding can significantly alter the crystalline structure.

Another significant challenge is the characterization of RCPP at different length scales. While bulk properties can be measured using standard mechanical testing methods, understanding the behavior at the molecular and microstructural levels requires advanced techniques. Techniques such as atomic force microscopy (AFM) and nanoindentation can provide insights into local mechanical properties, but correlating these nano-scale measurements with macroscopic behavior remains difficult.

The long-term performance of RCPP under various environmental conditions poses additional challenges. Factors such as temperature fluctuations, UV exposure, and chemical interactions can lead to property degradation over time. Developing accelerated aging tests that accurately predict long-term mechanical behavior is crucial but technically demanding, as the degradation mechanisms in RCPP can be complex and multifaceted.

Furthermore, the industry faces challenges in achieving consistent mechanical properties across different batches of RCPP. The random nature of the copolymerization process can lead to variations in molecular weight distribution and comonomer incorporation, which in turn affect mechanical properties. Ensuring reproducibility and tight quality control in large-scale production remains a significant technical hurdle.

Lastly, the development of reliable computational models for predicting the mechanical behavior of RCPP is an ongoing challenge. Current models often struggle to account for the material's heterogeneity and the complex interplay between its amorphous and crystalline regions. Improving these models requires a deeper understanding of the structure-property relationships and more sophisticated simulation techniques that can bridge multiple length scales, from molecular dynamics to continuum mechanics.

The relationship between the copolymer composition and its mechanical properties is not linear, making it challenging to optimize the material for specific applications. Researchers struggle to develop accurate structure-property relationships that can reliably predict how changes in the copolymer ratio will impact strength, stiffness, and toughness. This complexity is further compounded by the influence of processing conditions on the final material properties, as factors such as cooling rates and shear history during molding can significantly alter the crystalline structure.

Another significant challenge is the characterization of RCPP at different length scales. While bulk properties can be measured using standard mechanical testing methods, understanding the behavior at the molecular and microstructural levels requires advanced techniques. Techniques such as atomic force microscopy (AFM) and nanoindentation can provide insights into local mechanical properties, but correlating these nano-scale measurements with macroscopic behavior remains difficult.

The long-term performance of RCPP under various environmental conditions poses additional challenges. Factors such as temperature fluctuations, UV exposure, and chemical interactions can lead to property degradation over time. Developing accelerated aging tests that accurately predict long-term mechanical behavior is crucial but technically demanding, as the degradation mechanisms in RCPP can be complex and multifaceted.

Furthermore, the industry faces challenges in achieving consistent mechanical properties across different batches of RCPP. The random nature of the copolymerization process can lead to variations in molecular weight distribution and comonomer incorporation, which in turn affect mechanical properties. Ensuring reproducibility and tight quality control in large-scale production remains a significant technical hurdle.

Lastly, the development of reliable computational models for predicting the mechanical behavior of RCPP is an ongoing challenge. Current models often struggle to account for the material's heterogeneity and the complex interplay between its amorphous and crystalline regions. Improving these models requires a deeper understanding of the structure-property relationships and more sophisticated simulation techniques that can bridge multiple length scales, from molecular dynamics to continuum mechanics.

Current Solutions

01 Composition and structure of random copolymer polypropylene

Random copolymer polypropylene is composed of propylene and one or more comonomers randomly distributed along the polymer chain. The incorporation of comonomers affects the crystallinity and molecular structure, which in turn influences the mechanical properties. The type and amount of comonomer, as well as the polymerization conditions, can be adjusted to tailor the mechanical properties of the resulting copolymer.- Composition and structure of random copolymer polypropylene: Random copolymer polypropylene is composed of propylene and one or more α-olefin comonomers randomly distributed along the polymer chain. The incorporation of comonomers disrupts the crystalline structure of polypropylene, leading to unique mechanical properties. The comonomer content and distribution significantly influence the material's flexibility, impact resistance, and transparency.

- Impact resistance and toughness enhancement: Random copolymer polypropylene exhibits improved impact resistance and toughness compared to homopolymer polypropylene. This enhancement is attributed to the disruption of the crystalline structure by the comonomer units, which allows for better energy absorption during impact. The impact strength can be further improved by optimizing the comonomer content and molecular weight distribution.

- Thermal properties and processing characteristics: The incorporation of comonomers in random copolymer polypropylene affects its thermal properties, including melting temperature and crystallization behavior. These changes influence the processing characteristics of the material, such as melt flow rate and moldability. The altered thermal properties also contribute to improved heat seal strength and lower seal initiation temperature in packaging applications.

- Optical properties and clarity: Random copolymer polypropylene typically exhibits enhanced clarity and transparency compared to homopolymer polypropylene. The incorporation of comonomers reduces the size and number of crystallites, leading to less light scattering. This property makes random copolymer polypropylene suitable for applications requiring high clarity, such as packaging and consumer goods.

- Modification and blending for tailored properties: The mechanical properties of random copolymer polypropylene can be further tailored through various modification techniques and blending with other polymers or additives. These methods include the addition of nucleating agents to control crystallization, incorporation of impact modifiers for enhanced toughness, and blending with other polyolefins to achieve a balance of properties suitable for specific applications.

02 Impact resistance and toughness enhancement

Random copolymer polypropylene often exhibits improved impact resistance and toughness compared to homopolymer polypropylene. This enhancement is attributed to the disruption of the crystalline structure by the comonomer units, which allows for better energy absorption during impact. Various methods, such as optimizing comonomer content and molecular weight distribution, can be employed to further improve these properties.Expand Specific Solutions03 Thermal and processing characteristics

The incorporation of comonomers in random copolymer polypropylene affects its thermal properties, including melting point and crystallization behavior. These changes influence the processing characteristics and final mechanical properties of the material. Careful control of the copolymer composition and processing conditions can lead to improved flow properties and broader processing windows, while maintaining desirable mechanical properties.Expand Specific Solutions04 Modulus and stiffness control

The modulus and stiffness of random copolymer polypropylene can be tailored by adjusting the comonomer content and distribution. Generally, increasing comonomer content leads to a decrease in modulus and stiffness due to reduced crystallinity. However, by carefully balancing the copolymer composition and molecular structure, it is possible to achieve a desired combination of stiffness and other mechanical properties for specific applications.Expand Specific Solutions05 Additives and blends for property enhancement

The mechanical properties of random copolymer polypropylene can be further modified through the use of additives or by blending with other polymers. Nucleating agents, for example, can enhance crystallization and improve stiffness. Elastomeric components can be added to increase impact strength and flexibility. These modifications allow for a wide range of mechanical property combinations to suit various end-use requirements.Expand Specific Solutions

Key Industry Players

The investigation of mechanical properties of random copolymer polypropylene is at a mature stage, with significant market growth and technological advancements. The global polypropylene market size is substantial, driven by diverse applications across industries. Key players like Borealis AG, Mitsui Chemicals, and Kingfa Sci. & Tech. Co., Ltd. have demonstrated high technical maturity in this field. Companies such as Total Petrochemicals & Refining USA, Prime Polymer Co. Ltd., and China Petroleum & Chemical Corp. are also making notable contributions. The competitive landscape is characterized by ongoing research and development efforts, with companies like Sumitomo Chemical and Japan Polypropylene Corp. focusing on enhancing the mechanical properties of random copolymer polypropylene to meet evolving industry demands.

Borealis AG

Technical Solution: Borealis AG has developed a proprietary Borstar® technology for producing random copolymer polypropylene (RCP) with enhanced mechanical properties. Their RCP grades exhibit improved impact strength and transparency compared to conventional RCPs. The company utilizes a multi-reactor cascade system with advanced catalysts to control the comonomer distribution precisely[1]. This results in a homogeneous ethylene incorporation throughout the polymer chain, leading to a balance of stiffness and impact resistance. Borealis has also implemented nucleating agents to enhance crystallization behavior, resulting in improved optical properties and processing characteristics[2].

Strengths: Superior impact-stiffness balance, excellent optical properties, and enhanced processability. Weaknesses: Potentially higher production costs due to complex reactor system and specialized catalysts.

Mitsui Chemicals, Inc.

Technical Solution: Mitsui Chemicals has developed a series of metallocene-catalyzed random copolymer polypropylenes under their TAFMER™ brand. These RCPs feature a narrow molecular weight distribution and uniform comonomer incorporation, resulting in improved mechanical properties. The company employs a single-site metallocene catalyst system that allows for precise control over the polymer architecture[3]. This technology enables the production of RCPs with enhanced low-temperature impact strength and excellent transparency. Mitsui has also introduced long-chain branching into their RCPs, which improves melt strength and processability without significantly compromising other mechanical properties[4].

Strengths: Excellent low-temperature impact resistance, high transparency, and improved melt strength. Weaknesses: Higher production costs associated with metallocene catalysts and potential limitations in high-temperature applications.

Core Innovations

Propylene random copolymer with specific comonomer distribution

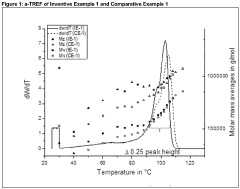

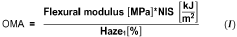

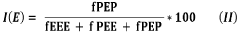

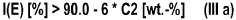

PatentPendingEP3617238A1

Innovation

- A unimodal propylene random copolymer with a specific ethylene content and comonomer distribution, determined via analytical temperature rising elution fractionation (a-TREF), is produced using a Ziegler-Natta catalyst, offering improved stiffness, impact resistance, and low haze, along with a well-balanced optomechanical ability through a one-step polymerization process.

Mini-random copolymer resins having improved mechanical toughness and related properties suitable for thin wall thermoforming applications

PatentInactiveUS8399587B2

Innovation

- Propylene random copolymer compositions are developed, comprising 95.0 wt.% to 99.0 wt.% propylene, 0.2 wt.% to 0.8 wt.% ethylene, and additives such as clarifiers and nucleators, which result in a melt flow rate of 0.5 g/10 min. to 4.0 g/10 min. and a flexural modulus of 180,000 psi to 260,000 psi, enhancing the polymer's properties for demanding packaging applications.

Environmental Impact

The environmental impact of random copolymer polypropylene (RCPP) is a crucial consideration in its production, use, and disposal. RCPP, while offering improved mechanical properties compared to homopolymer polypropylene, still faces environmental challenges common to many plastics. The production process of RCPP involves the use of fossil fuels and energy-intensive manufacturing, contributing to greenhouse gas emissions and climate change.

During its lifecycle, RCPP products can have both positive and negative environmental effects. On the positive side, the enhanced mechanical properties of RCPP often lead to more durable and longer-lasting products, potentially reducing the need for frequent replacements and thus decreasing overall resource consumption. Additionally, the improved impact resistance and flexibility of RCPP can lead to thinner, lighter products, which may reduce material usage and transportation-related emissions.

However, the end-of-life management of RCPP presents significant environmental challenges. Like many plastics, RCPP is not biodegradable and can persist in the environment for hundreds of years. Improper disposal can lead to pollution of terrestrial and aquatic ecosystems, contributing to the global plastic waste crisis. While RCPP is theoretically recyclable, the presence of copolymers can complicate the recycling process, potentially reducing the quality of recycled materials or making recycling economically unfeasible in some cases.

The production of RCPP also raises concerns about microplastic pollution. During manufacturing, use, and disposal, tiny plastic particles can be released into the environment, potentially entering food chains and causing harm to wildlife and human health. The long-term effects of these microplastics are still being studied, but early research suggests potential negative impacts on ecosystems and organisms.

Efforts to mitigate the environmental impact of RCPP are ongoing. Research into more sustainable production methods, such as using renewable energy sources or bio-based feedstocks, is being conducted. Additionally, improvements in recycling technologies and infrastructure are being developed to better handle complex plastic compositions like RCPP. Some manufacturers are also exploring the development of additives that could enhance the biodegradability of RCPP without compromising its mechanical properties.

The regulatory landscape surrounding RCPP and similar plastics is evolving, with many countries implementing stricter regulations on plastic production, use, and disposal. These regulations aim to reduce plastic waste, increase recycling rates, and promote the development of more environmentally friendly alternatives. As environmental concerns continue to grow, the plastics industry, including RCPP manufacturers, faces increasing pressure to innovate and adopt more sustainable practices throughout the product lifecycle.

During its lifecycle, RCPP products can have both positive and negative environmental effects. On the positive side, the enhanced mechanical properties of RCPP often lead to more durable and longer-lasting products, potentially reducing the need for frequent replacements and thus decreasing overall resource consumption. Additionally, the improved impact resistance and flexibility of RCPP can lead to thinner, lighter products, which may reduce material usage and transportation-related emissions.

However, the end-of-life management of RCPP presents significant environmental challenges. Like many plastics, RCPP is not biodegradable and can persist in the environment for hundreds of years. Improper disposal can lead to pollution of terrestrial and aquatic ecosystems, contributing to the global plastic waste crisis. While RCPP is theoretically recyclable, the presence of copolymers can complicate the recycling process, potentially reducing the quality of recycled materials or making recycling economically unfeasible in some cases.

The production of RCPP also raises concerns about microplastic pollution. During manufacturing, use, and disposal, tiny plastic particles can be released into the environment, potentially entering food chains and causing harm to wildlife and human health. The long-term effects of these microplastics are still being studied, but early research suggests potential negative impacts on ecosystems and organisms.

Efforts to mitigate the environmental impact of RCPP are ongoing. Research into more sustainable production methods, such as using renewable energy sources or bio-based feedstocks, is being conducted. Additionally, improvements in recycling technologies and infrastructure are being developed to better handle complex plastic compositions like RCPP. Some manufacturers are also exploring the development of additives that could enhance the biodegradability of RCPP without compromising its mechanical properties.

The regulatory landscape surrounding RCPP and similar plastics is evolving, with many countries implementing stricter regulations on plastic production, use, and disposal. These regulations aim to reduce plastic waste, increase recycling rates, and promote the development of more environmentally friendly alternatives. As environmental concerns continue to grow, the plastics industry, including RCPP manufacturers, faces increasing pressure to innovate and adopt more sustainable practices throughout the product lifecycle.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and application of random copolymer polypropylene (RCPP) materials, particularly when investigating their mechanical properties. The regulatory landscape for RCPP encompasses various standards and guidelines set by international, regional, and national bodies to ensure product safety, quality, and environmental sustainability.

One of the primary regulatory considerations for RCPP is compliance with food contact regulations. As RCPP is often used in food packaging applications, manufacturers must adhere to strict guidelines set by organizations such as the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). These regulations typically focus on the migration of substances from the polymer to food, requiring extensive testing and documentation to demonstrate compliance.

In the automotive industry, where RCPP finds widespread use due to its mechanical properties, manufacturers must comply with regulations such as the End-of-Life Vehicle (ELV) Directive in the European Union. This directive aims to reduce the environmental impact of vehicles by promoting recyclability and limiting the use of hazardous substances. RCPP producers must ensure their materials meet these requirements, particularly concerning heavy metal content and recyclability.

The construction sector, another significant market for RCPP, is subject to building codes and standards that regulate the use of plastic materials. These regulations often focus on fire safety, structural integrity, and long-term durability. Manufacturers must demonstrate compliance through rigorous testing and certification processes, such as those outlined in the International Building Code (IBC) or European standards like EN 13501 for fire classification.

Environmental regulations also significantly impact the RCPP industry. Initiatives such as the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation require manufacturers to assess and manage the risks associated with the chemicals used in their products. This includes providing detailed information on the substances present in RCPP and their potential environmental and health impacts.

As sustainability becomes an increasingly important focus, regulations promoting the circular economy are gaining prominence. The European Union's Circular Economy Action Plan, for instance, sets targets for plastic recycling and encourages the use of recycled content in new products. RCPP manufacturers must adapt their processes and formulations to meet these evolving requirements, potentially impacting the mechanical properties of their materials.

Occupational health and safety regulations also play a role in the production and handling of RCPP. Organizations such as the Occupational Safety and Health Administration (OSHA) in the United States set standards for worker protection, including exposure limits to chemical substances and safety protocols for manufacturing processes.

To navigate this complex regulatory landscape, RCPP manufacturers must implement robust quality management systems and maintain comprehensive documentation of their compliance efforts. This often involves regular testing, audits, and certifications to demonstrate ongoing adherence to relevant standards and regulations. As regulatory requirements continue to evolve, particularly in response to environmental concerns and emerging scientific knowledge, manufacturers must remain vigilant and adaptable in their approach to compliance.

One of the primary regulatory considerations for RCPP is compliance with food contact regulations. As RCPP is often used in food packaging applications, manufacturers must adhere to strict guidelines set by organizations such as the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). These regulations typically focus on the migration of substances from the polymer to food, requiring extensive testing and documentation to demonstrate compliance.

In the automotive industry, where RCPP finds widespread use due to its mechanical properties, manufacturers must comply with regulations such as the End-of-Life Vehicle (ELV) Directive in the European Union. This directive aims to reduce the environmental impact of vehicles by promoting recyclability and limiting the use of hazardous substances. RCPP producers must ensure their materials meet these requirements, particularly concerning heavy metal content and recyclability.

The construction sector, another significant market for RCPP, is subject to building codes and standards that regulate the use of plastic materials. These regulations often focus on fire safety, structural integrity, and long-term durability. Manufacturers must demonstrate compliance through rigorous testing and certification processes, such as those outlined in the International Building Code (IBC) or European standards like EN 13501 for fire classification.

Environmental regulations also significantly impact the RCPP industry. Initiatives such as the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation require manufacturers to assess and manage the risks associated with the chemicals used in their products. This includes providing detailed information on the substances present in RCPP and their potential environmental and health impacts.

As sustainability becomes an increasingly important focus, regulations promoting the circular economy are gaining prominence. The European Union's Circular Economy Action Plan, for instance, sets targets for plastic recycling and encourages the use of recycled content in new products. RCPP manufacturers must adapt their processes and formulations to meet these evolving requirements, potentially impacting the mechanical properties of their materials.

Occupational health and safety regulations also play a role in the production and handling of RCPP. Organizations such as the Occupational Safety and Health Administration (OSHA) in the United States set standards for worker protection, including exposure limits to chemical substances and safety protocols for manufacturing processes.

To navigate this complex regulatory landscape, RCPP manufacturers must implement robust quality management systems and maintain comprehensive documentation of their compliance efforts. This often involves regular testing, audits, and certifications to demonstrate ongoing adherence to relevant standards and regulations. As regulatory requirements continue to evolve, particularly in response to environmental concerns and emerging scientific knowledge, manufacturers must remain vigilant and adaptable in their approach to compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!