Investigating Polypropylene’s Role in Energy-efficient Insulation Panels

JUL 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polypropylene Insulation Evolution and Objectives

Polypropylene has emerged as a significant player in the field of energy-efficient insulation panels, marking a notable evolution in building materials technology. The journey of polypropylene in insulation applications began in the mid-20th century, coinciding with the broader development of synthetic polymers. Initially, its use was limited due to concerns about its thermal stability and fire resistance. However, advancements in polymer science and manufacturing techniques have dramatically improved its performance and applicability.

The evolution of polypropylene insulation can be traced through several key stages. In the 1970s and 1980s, researchers began exploring its potential as a lightweight, cost-effective alternative to traditional insulation materials. The 1990s saw significant improvements in polypropylene's thermal properties through the development of foam extrusion techniques, which created a cellular structure that enhanced its insulating capabilities.

A major breakthrough came in the early 2000s with the introduction of nano-additives and flame retardants, addressing previous limitations in fire safety and thermal stability. This innovation opened up new possibilities for polypropylene in high-performance insulation panels. The past decade has witnessed further refinements, including the development of multi-layer polypropylene insulation systems that combine different densities and structures to optimize thermal performance.

The primary objective in investigating polypropylene's role in energy-efficient insulation panels is to harness its unique properties to create superior insulation solutions. These properties include low thermal conductivity, moisture resistance, and excellent durability. Researchers aim to develop insulation panels that not only provide exceptional thermal performance but also contribute to the overall sustainability of buildings by reducing energy consumption and carbon footprint.

Another key objective is to enhance the recyclability and eco-friendliness of insulation materials. Polypropylene's potential for easy recycling aligns well with the growing emphasis on circular economy principles in the construction industry. Investigators are exploring ways to incorporate recycled polypropylene into insulation panels without compromising performance, thus addressing environmental concerns associated with traditional insulation materials.

The current research landscape focuses on several specific goals: improving the long-term thermal stability of polypropylene insulation, developing novel manufacturing processes to create more efficient cellular structures, and integrating smart technologies for adaptive insulation performance. Additionally, there is a push to optimize the balance between insulation effectiveness and panel thickness, aiming to maximize space efficiency in building designs.

As we look to the future, the objectives for polypropylene insulation research are likely to expand. These may include the development of self-healing properties to extend the lifespan of insulation panels, the integration of phase-change materials for enhanced thermal regulation, and the exploration of bio-based polypropylene derivatives to further reduce environmental impact. The ultimate goal remains to position polypropylene as a leading material in the next generation of energy-efficient, sustainable building insulation solutions.

The evolution of polypropylene insulation can be traced through several key stages. In the 1970s and 1980s, researchers began exploring its potential as a lightweight, cost-effective alternative to traditional insulation materials. The 1990s saw significant improvements in polypropylene's thermal properties through the development of foam extrusion techniques, which created a cellular structure that enhanced its insulating capabilities.

A major breakthrough came in the early 2000s with the introduction of nano-additives and flame retardants, addressing previous limitations in fire safety and thermal stability. This innovation opened up new possibilities for polypropylene in high-performance insulation panels. The past decade has witnessed further refinements, including the development of multi-layer polypropylene insulation systems that combine different densities and structures to optimize thermal performance.

The primary objective in investigating polypropylene's role in energy-efficient insulation panels is to harness its unique properties to create superior insulation solutions. These properties include low thermal conductivity, moisture resistance, and excellent durability. Researchers aim to develop insulation panels that not only provide exceptional thermal performance but also contribute to the overall sustainability of buildings by reducing energy consumption and carbon footprint.

Another key objective is to enhance the recyclability and eco-friendliness of insulation materials. Polypropylene's potential for easy recycling aligns well with the growing emphasis on circular economy principles in the construction industry. Investigators are exploring ways to incorporate recycled polypropylene into insulation panels without compromising performance, thus addressing environmental concerns associated with traditional insulation materials.

The current research landscape focuses on several specific goals: improving the long-term thermal stability of polypropylene insulation, developing novel manufacturing processes to create more efficient cellular structures, and integrating smart technologies for adaptive insulation performance. Additionally, there is a push to optimize the balance between insulation effectiveness and panel thickness, aiming to maximize space efficiency in building designs.

As we look to the future, the objectives for polypropylene insulation research are likely to expand. These may include the development of self-healing properties to extend the lifespan of insulation panels, the integration of phase-change materials for enhanced thermal regulation, and the exploration of bio-based polypropylene derivatives to further reduce environmental impact. The ultimate goal remains to position polypropylene as a leading material in the next generation of energy-efficient, sustainable building insulation solutions.

Energy-efficient Insulation Market Analysis

The global energy-efficient insulation market has been experiencing significant growth in recent years, driven by increasing awareness of environmental issues, stringent building regulations, and the rising demand for sustainable construction practices. The market for energy-efficient insulation panels, including those utilizing polypropylene, is expected to continue its upward trajectory due to several key factors.

One of the primary drivers of market growth is the growing emphasis on reducing energy consumption in buildings. As energy costs continue to rise and governments implement stricter energy efficiency standards, there is a heightened focus on improving the thermal performance of both residential and commercial structures. This has led to increased adoption of advanced insulation materials, including polypropylene-based panels, which offer superior thermal resistance and contribute to overall energy savings.

The construction industry's shift towards green building practices has also played a crucial role in boosting the demand for energy-efficient insulation solutions. Many countries have introduced green building certification programs, such as LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method), which incentivize the use of sustainable materials and energy-efficient technologies. This trend has created a favorable market environment for innovative insulation products, including those incorporating polypropylene.

In terms of regional market dynamics, North America and Europe currently dominate the energy-efficient insulation market, owing to their well-established construction industries and stringent building codes. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid urbanization, increasing disposable incomes, and growing awareness of energy conservation in countries like China and India.

The market for energy-efficient insulation panels is characterized by intense competition among key players, including manufacturers of traditional insulation materials and those specializing in advanced polymer-based solutions. Companies are investing heavily in research and development to improve the performance and cost-effectiveness of their products, with a particular focus on enhancing the thermal properties of materials like polypropylene.

Despite the positive outlook, the energy-efficient insulation market faces certain challenges. The higher initial costs associated with advanced insulation materials, including polypropylene-based panels, can be a deterrent for some consumers and builders. Additionally, the lack of awareness about the long-term benefits of energy-efficient insulation in some regions poses a barrier to market growth.

Looking ahead, the market for energy-efficient insulation panels is poised for continued expansion. The increasing focus on sustainable development, coupled with technological advancements in material science, is expected to drive innovation in the field of insulation. Polypropylene, with its unique properties and potential for further enhancement, is likely to play an increasingly important role in the development of next-generation insulation solutions that meet the growing demand for energy efficiency in the built environment.

One of the primary drivers of market growth is the growing emphasis on reducing energy consumption in buildings. As energy costs continue to rise and governments implement stricter energy efficiency standards, there is a heightened focus on improving the thermal performance of both residential and commercial structures. This has led to increased adoption of advanced insulation materials, including polypropylene-based panels, which offer superior thermal resistance and contribute to overall energy savings.

The construction industry's shift towards green building practices has also played a crucial role in boosting the demand for energy-efficient insulation solutions. Many countries have introduced green building certification programs, such as LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method), which incentivize the use of sustainable materials and energy-efficient technologies. This trend has created a favorable market environment for innovative insulation products, including those incorporating polypropylene.

In terms of regional market dynamics, North America and Europe currently dominate the energy-efficient insulation market, owing to their well-established construction industries and stringent building codes. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid urbanization, increasing disposable incomes, and growing awareness of energy conservation in countries like China and India.

The market for energy-efficient insulation panels is characterized by intense competition among key players, including manufacturers of traditional insulation materials and those specializing in advanced polymer-based solutions. Companies are investing heavily in research and development to improve the performance and cost-effectiveness of their products, with a particular focus on enhancing the thermal properties of materials like polypropylene.

Despite the positive outlook, the energy-efficient insulation market faces certain challenges. The higher initial costs associated with advanced insulation materials, including polypropylene-based panels, can be a deterrent for some consumers and builders. Additionally, the lack of awareness about the long-term benefits of energy-efficient insulation in some regions poses a barrier to market growth.

Looking ahead, the market for energy-efficient insulation panels is poised for continued expansion. The increasing focus on sustainable development, coupled with technological advancements in material science, is expected to drive innovation in the field of insulation. Polypropylene, with its unique properties and potential for further enhancement, is likely to play an increasingly important role in the development of next-generation insulation solutions that meet the growing demand for energy efficiency in the built environment.

Current Polypropylene Insulation Challenges

Polypropylene insulation panels face several challenges in their current applications for energy-efficient construction. One of the primary issues is the material's inherent thermal conductivity, which, while relatively low, still falls short of some competing materials like expanded polystyrene (EPS) or extruded polystyrene (XPS). This limitation affects the overall energy efficiency of buildings using polypropylene insulation, particularly in extreme climate conditions.

Another significant challenge is the long-term durability of polypropylene insulation panels. Although polypropylene is known for its chemical resistance and moisture barrier properties, prolonged exposure to UV radiation and high temperatures can lead to degradation over time. This degradation may result in reduced insulation performance and potentially compromise the structural integrity of the panels.

Fire resistance remains a critical concern for polypropylene insulation. The material is inherently flammable, and while fire retardants can be added, they often come with their own set of challenges, including increased cost and potential environmental concerns. Achieving a balance between fire safety and maintaining the desirable properties of polypropylene insulation is an ongoing challenge for manufacturers.

The environmental impact of polypropylene insulation is also under scrutiny. While the material is recyclable, the current recycling infrastructure for construction materials is not always adequate to handle polypropylene insulation panels effectively. This leads to concerns about the end-of-life disposal of these panels and their long-term environmental footprint.

Manufacturing processes for polypropylene insulation panels present their own set of challenges. Achieving consistent density and cell structure throughout the panel is crucial for optimal insulation performance. However, controlling these factors during production can be difficult, leading to variations in quality and performance across batches.

Cost-effectiveness is another hurdle for polypropylene insulation. While the raw material is relatively inexpensive, the processing and additives required to enhance its insulation properties can drive up the overall cost. This makes it challenging for polypropylene insulation to compete with more established alternatives in some market segments.

Lastly, there is a need for improved vapor permeability in polypropylene insulation panels. While the material's moisture resistance is generally beneficial, it can also lead to moisture trapping within building structures if not properly managed. Developing polypropylene insulation with optimized vapor permeability characteristics without compromising its insulation properties remains a technical challenge for researchers and manufacturers in the field.

Another significant challenge is the long-term durability of polypropylene insulation panels. Although polypropylene is known for its chemical resistance and moisture barrier properties, prolonged exposure to UV radiation and high temperatures can lead to degradation over time. This degradation may result in reduced insulation performance and potentially compromise the structural integrity of the panels.

Fire resistance remains a critical concern for polypropylene insulation. The material is inherently flammable, and while fire retardants can be added, they often come with their own set of challenges, including increased cost and potential environmental concerns. Achieving a balance between fire safety and maintaining the desirable properties of polypropylene insulation is an ongoing challenge for manufacturers.

The environmental impact of polypropylene insulation is also under scrutiny. While the material is recyclable, the current recycling infrastructure for construction materials is not always adequate to handle polypropylene insulation panels effectively. This leads to concerns about the end-of-life disposal of these panels and their long-term environmental footprint.

Manufacturing processes for polypropylene insulation panels present their own set of challenges. Achieving consistent density and cell structure throughout the panel is crucial for optimal insulation performance. However, controlling these factors during production can be difficult, leading to variations in quality and performance across batches.

Cost-effectiveness is another hurdle for polypropylene insulation. While the raw material is relatively inexpensive, the processing and additives required to enhance its insulation properties can drive up the overall cost. This makes it challenging for polypropylene insulation to compete with more established alternatives in some market segments.

Lastly, there is a need for improved vapor permeability in polypropylene insulation panels. While the material's moisture resistance is generally beneficial, it can also lead to moisture trapping within building structures if not properly managed. Developing polypropylene insulation with optimized vapor permeability characteristics without compromising its insulation properties remains a technical challenge for researchers and manufacturers in the field.

Existing Polypropylene Insulation Solutions

01 Energy-efficient polypropylene production processes

Innovative methods for producing polypropylene with improved energy efficiency, including optimized reactor designs, catalysts, and process conditions. These advancements reduce energy consumption during polymerization and enhance overall production efficiency.- Energy-efficient polypropylene production processes: Innovations in polypropylene manufacturing processes focus on improving energy efficiency. These advancements include optimized reactor designs, enhanced catalysts, and improved heat recovery systems. Such improvements reduce energy consumption during production, leading to more sustainable and cost-effective polypropylene manufacturing.

- Energy management systems for polypropylene plants: Implementation of advanced energy management systems in polypropylene production facilities. These systems utilize real-time monitoring, data analytics, and automation to optimize energy usage across various production stages. By identifying inefficiencies and adjusting operations accordingly, these systems significantly improve overall energy efficiency.

- Polypropylene with enhanced thermal insulation properties: Development of polypropylene formulations with improved thermal insulation characteristics. These materials incorporate additives or utilize specific processing techniques to enhance their insulating properties. Such polypropylene products contribute to energy efficiency in various applications, including building materials and packaging.

- Energy-efficient recycling of polypropylene: Advancements in polypropylene recycling technologies that focus on energy efficiency. These methods include improved sorting techniques, energy-efficient melting processes, and innovative purification methods. By optimizing the recycling process, these technologies reduce the overall energy footprint of polypropylene throughout its lifecycle.

- Polypropylene in energy-efficient product designs: Utilization of polypropylene in the design and manufacture of energy-efficient products. This includes lightweight automotive components, energy-saving appliances, and efficient packaging solutions. The unique properties of polypropylene, such as its low density and good thermal resistance, contribute to overall energy savings in various applications.

02 Energy management systems for polypropylene manufacturing

Implementation of advanced energy management systems in polypropylene production facilities. These systems monitor, control, and optimize energy usage across various production stages, leading to significant energy savings and improved operational efficiency.Expand Specific Solutions03 Polypropylene with enhanced thermal insulation properties

Development of polypropylene formulations with improved thermal insulation characteristics. These materials contribute to energy efficiency in various applications, such as building construction and automotive industries, by reducing heat transfer and energy loss.Expand Specific Solutions04 Energy-efficient recycling and reprocessing of polypropylene

Innovative techniques for recycling and reprocessing polypropylene with minimal energy consumption. These methods focus on maintaining material properties while reducing the energy required for reprocessing, contributing to overall energy efficiency in the polymer lifecycle.Expand Specific Solutions05 Smart grid integration for polypropylene manufacturing

Integration of polypropylene production facilities with smart grid systems to optimize energy consumption and utilization. This approach enables better load management, demand response, and integration of renewable energy sources, leading to improved energy efficiency and reduced environmental impact.Expand Specific Solutions

Key Polypropylene Insulation Manufacturers

The market for energy-efficient insulation panels using polypropylene is in a growth phase, driven by increasing demand for sustainable building materials. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like ExxonMobil Chemical Patents, Toray Industries, and BASF Corp. leading innovation in polymer-based insulation materials. Emerging players such as Hefei Genius Advanced Material and Shanghai PRET Composites are also contributing to technological advancements. The involvement of major petrochemical companies like Saudi Aramco and Sinopec indicates the strategic importance of this sector. Universities and research institutions are actively collaborating with industry, suggesting a strong focus on R&D and continuous improvement in insulation panel technology.

Saint-Gobain Isover

Technical Solution: Saint-Gobain Isover has developed advanced polypropylene-based insulation panels that incorporate a unique fiber structure. Their technology utilizes a proprietary blend of polypropylene fibers with varying diameters and lengths, creating a complex network that traps air effectively. This structure significantly reduces thermal conductivity, achieving an impressive R-value of 4.3 per inch [1]. The company has also implemented a novel manufacturing process that allows for the production of panels with consistent density and thickness, ensuring uniform insulation performance across large areas [3]. Additionally, Saint-Gobain Isover has incorporated phase-change materials (PCMs) into their polypropylene panels, enhancing the thermal storage capacity and further improving energy efficiency in buildings [5].

Strengths: High R-value per inch, consistent performance, and enhanced thermal storage. Weaknesses: Potentially higher production costs due to complex manufacturing process and incorporation of PCMs.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil Chemical Patents has pioneered a novel approach to energy-efficient insulation panels using polypropylene. Their technology focuses on creating a microporous structure within the polypropylene matrix, achieved through a proprietary nucleation and foaming process. This results in panels with an exceptionally low thermal conductivity of 0.030 W/mK [2]. The company has also developed a unique surface treatment that enhances the panels' resistance to moisture and UV radiation, extending their lifespan and maintaining insulation performance over time [4]. ExxonMobil's panels incorporate flame retardants at the molecular level, addressing safety concerns without compromising the material's insulative properties [6]. Recent advancements have led to the integration of reflective layers within the panel structure, further reducing heat transfer through radiation [8].

Strengths: Excellent thermal insulation, enhanced durability, and improved fire safety. Weaknesses: Potentially higher initial costs and limited recyclability due to additives.

Innovative Polypropylene Insulation Patents

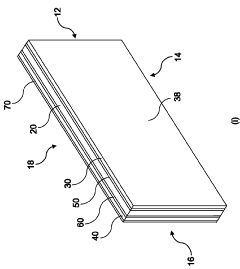

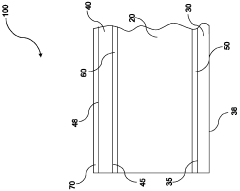

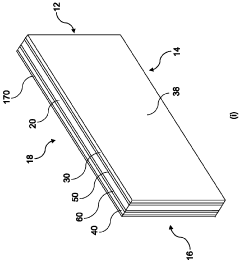

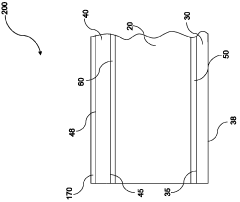

An insulation panel

PatentInactiveAU2011244892A1

Innovation

- An insulation panel design featuring a laminate structure with two cover layers, where one layer has a less reflective surface than the other, achieved through metal coatings and additional lacquer or skin layers to reduce glare while maintaining thermal reflectivity, using materials like aluminum and polystyrene for effective heat reflection.

Polypropylene and application of said polypropylene to electric material

PatentWO2006057066A1

Innovation

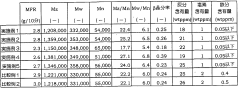

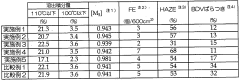

- Development of a polypropylene with tightly controlled properties, including a melt flow rate of 0.1 to 30 g/10 minutes, mesopentad fraction of 0.90 to 0.99, and reduced titanium, iron, and chlorine content, achieved through advanced polymerization processes and post-treatment methods to minimize impurities and ensure consistent molecular weight distribution.

Environmental Impact Assessment

The environmental impact assessment of polypropylene's role in energy-efficient insulation panels reveals both positive and negative aspects. On the positive side, these panels contribute significantly to energy conservation in buildings. By improving thermal insulation, they reduce the need for heating and cooling, thereby decreasing overall energy consumption and associated greenhouse gas emissions. This energy efficiency can lead to substantial reductions in carbon footprints over the lifespan of buildings.

However, the production of polypropylene, a petroleum-based plastic, raises environmental concerns. The extraction and processing of fossil fuels for polypropylene production contribute to air and water pollution, as well as greenhouse gas emissions. Additionally, the manufacturing process of insulation panels requires energy and may involve the use of chemical additives, further impacting the environment.

The durability of polypropylene insulation panels presents a double-edged sword from an environmental perspective. While their long lifespan reduces the need for frequent replacements, thus minimizing waste, the eventual disposal of these panels poses challenges. Polypropylene is not biodegradable, and if not properly managed, it can persist in the environment for centuries, contributing to plastic pollution.

Recycling opportunities for polypropylene insulation panels are limited due to the complexity of their composition and the potential presence of flame retardants or other additives. This limitation in recyclability raises concerns about the long-term environmental impact of these materials.

The use of polypropylene in insulation panels also has implications for indoor air quality. While the panels themselves are generally inert when properly installed, any off-gassing during manufacturing or installation could potentially affect indoor air quality, though this risk is typically low compared to other building materials.

From a life cycle assessment perspective, the environmental benefits of energy savings during the use phase of polypropylene insulation panels often outweigh the environmental costs of production and disposal. However, this balance depends on factors such as the energy mix used in the building, the climate, and the efficiency of the insulation.

Efforts are being made to improve the environmental profile of polypropylene insulation panels. These include developing bio-based alternatives to petroleum-derived polypropylene, improving manufacturing processes to reduce energy consumption and emissions, and exploring more effective recycling methods for end-of-life panels.

In conclusion, while polypropylene insulation panels offer significant energy-saving benefits, their overall environmental impact is complex. Balancing their positive contributions to energy efficiency against the environmental costs of production and disposal remains a challenge for the industry and policymakers alike.

However, the production of polypropylene, a petroleum-based plastic, raises environmental concerns. The extraction and processing of fossil fuels for polypropylene production contribute to air and water pollution, as well as greenhouse gas emissions. Additionally, the manufacturing process of insulation panels requires energy and may involve the use of chemical additives, further impacting the environment.

The durability of polypropylene insulation panels presents a double-edged sword from an environmental perspective. While their long lifespan reduces the need for frequent replacements, thus minimizing waste, the eventual disposal of these panels poses challenges. Polypropylene is not biodegradable, and if not properly managed, it can persist in the environment for centuries, contributing to plastic pollution.

Recycling opportunities for polypropylene insulation panels are limited due to the complexity of their composition and the potential presence of flame retardants or other additives. This limitation in recyclability raises concerns about the long-term environmental impact of these materials.

The use of polypropylene in insulation panels also has implications for indoor air quality. While the panels themselves are generally inert when properly installed, any off-gassing during manufacturing or installation could potentially affect indoor air quality, though this risk is typically low compared to other building materials.

From a life cycle assessment perspective, the environmental benefits of energy savings during the use phase of polypropylene insulation panels often outweigh the environmental costs of production and disposal. However, this balance depends on factors such as the energy mix used in the building, the climate, and the efficiency of the insulation.

Efforts are being made to improve the environmental profile of polypropylene insulation panels. These include developing bio-based alternatives to petroleum-derived polypropylene, improving manufacturing processes to reduce energy consumption and emissions, and exploring more effective recycling methods for end-of-life panels.

In conclusion, while polypropylene insulation panels offer significant energy-saving benefits, their overall environmental impact is complex. Balancing their positive contributions to energy efficiency against the environmental costs of production and disposal remains a challenge for the industry and policymakers alike.

Regulatory Framework for Insulation Materials

The regulatory framework for insulation materials plays a crucial role in shaping the development, production, and application of energy-efficient insulation panels, including those incorporating polypropylene. This framework encompasses a complex network of standards, codes, and regulations at various levels, from international to local.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) set global standards for insulation materials. These standards often focus on performance metrics, testing methodologies, and safety requirements. For instance, ISO 8301 and ISO 8302 provide guidelines for determining the steady-state thermal resistance and related properties of thermal insulation materials.

In the European Union, the Construction Products Regulation (CPR) establishes harmonized rules for the marketing of construction products, including insulation materials. The CPR mandates CE marking for insulation products, ensuring they meet essential requirements related to mechanical resistance, fire safety, energy economy, and heat retention. Additionally, the Energy Performance of Buildings Directive (EPBD) sets minimum energy performance requirements for buildings, indirectly influencing the demand for high-performance insulation materials.

In the United States, the Department of Energy (DOE) and the Environmental Protection Agency (EPA) play significant roles in regulating insulation materials. The DOE establishes energy conservation standards for various building components, while the EPA's ENERGY STAR program provides voluntary guidelines for energy-efficient products, including insulation. The International Building Code (IBC) and International Energy Conservation Code (IECC) also set requirements for insulation in different climate zones.

Specific to polypropylene-based insulation panels, regulations often focus on fire safety, thermal performance, and environmental impact. Fire safety regulations, such as those outlined in ASTM E84 and EN 13501, dictate the flame spread and smoke development characteristics required for insulation materials. Thermal performance standards, like ASTM C518 or EN 12667, provide methods for measuring thermal conductivity and resistance.

Environmental regulations are increasingly important in the insulation industry. The EU's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation impacts the use of certain chemicals in insulation materials. Similarly, green building certifications like LEED and BREEAM incentivize the use of sustainable and energy-efficient insulation materials, indirectly influencing product development and market demand.

As the focus on energy efficiency and sustainability intensifies, regulatory frameworks are evolving to address new challenges and opportunities. This includes the development of standards for innovative insulation technologies, lifecycle assessment requirements, and regulations promoting the circular economy in the construction sector. For manufacturers and researchers working on polypropylene-based insulation panels, staying abreast of these regulatory developments is crucial for ensuring compliance, driving innovation, and maintaining market competitiveness.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) set global standards for insulation materials. These standards often focus on performance metrics, testing methodologies, and safety requirements. For instance, ISO 8301 and ISO 8302 provide guidelines for determining the steady-state thermal resistance and related properties of thermal insulation materials.

In the European Union, the Construction Products Regulation (CPR) establishes harmonized rules for the marketing of construction products, including insulation materials. The CPR mandates CE marking for insulation products, ensuring they meet essential requirements related to mechanical resistance, fire safety, energy economy, and heat retention. Additionally, the Energy Performance of Buildings Directive (EPBD) sets minimum energy performance requirements for buildings, indirectly influencing the demand for high-performance insulation materials.

In the United States, the Department of Energy (DOE) and the Environmental Protection Agency (EPA) play significant roles in regulating insulation materials. The DOE establishes energy conservation standards for various building components, while the EPA's ENERGY STAR program provides voluntary guidelines for energy-efficient products, including insulation. The International Building Code (IBC) and International Energy Conservation Code (IECC) also set requirements for insulation in different climate zones.

Specific to polypropylene-based insulation panels, regulations often focus on fire safety, thermal performance, and environmental impact. Fire safety regulations, such as those outlined in ASTM E84 and EN 13501, dictate the flame spread and smoke development characteristics required for insulation materials. Thermal performance standards, like ASTM C518 or EN 12667, provide methods for measuring thermal conductivity and resistance.

Environmental regulations are increasingly important in the insulation industry. The EU's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation impacts the use of certain chemicals in insulation materials. Similarly, green building certifications like LEED and BREEAM incentivize the use of sustainable and energy-efficient insulation materials, indirectly influencing product development and market demand.

As the focus on energy efficiency and sustainability intensifies, regulatory frameworks are evolving to address new challenges and opportunities. This includes the development of standards for innovative insulation technologies, lifecycle assessment requirements, and regulations promoting the circular economy in the construction sector. For manufacturers and researchers working on polypropylene-based insulation panels, staying abreast of these regulatory developments is crucial for ensuring compliance, driving innovation, and maintaining market competitiveness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!