Investigating Polypropylene's Role in Personal Protective Equipment

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PPE Evolution and Goals

Personal Protective Equipment (PPE) has undergone significant evolution since its inception, driven by advancements in materials science and changing workplace safety requirements. The journey of PPE began in the early 20th century with basic protective gear such as hard hats and safety goggles. As industrial processes became more complex and hazardous, the need for more sophisticated protective equipment grew.

The mid-20th century saw a surge in PPE development, particularly during World War II, when the military's demand for protective gear accelerated innovation. This period marked the introduction of more advanced respiratory protection and chemical-resistant clothing. The 1970s brought about a new era in PPE with the establishment of the Occupational Safety and Health Administration (OSHA) in the United States, which set standards for workplace safety and PPE use.

In recent decades, the focus has shifted towards developing PPE that not only provides protection but also enhances comfort and usability. This shift has been crucial in improving compliance rates among workers. The integration of smart technologies into PPE, such as sensors and communication devices, represents the latest frontier in this evolution, allowing for real-time monitoring of worker safety and environmental conditions.

Polypropylene has played a pivotal role in this evolution, particularly in the realm of disposable protective equipment. Its introduction in the 1960s revolutionized the manufacturing of protective garments and masks due to its unique properties. Polypropylene's lightweight nature, coupled with its ability to form nonwoven fabrics, made it an ideal material for creating breathable yet protective barriers against particulates and liquids.

The goals of modern PPE development, with a focus on polypropylene's role, are multifaceted. Firstly, there is a continuous drive to improve the protective capabilities of PPE against an ever-widening range of hazards, including biological agents, nanoparticles, and emerging chemical threats. Secondly, enhancing the comfort and breathability of PPE remains a priority to ensure prolonged use without compromising worker performance.

Another critical goal is the development of sustainable PPE solutions. With the increased use of disposable PPE, particularly during global health crises, there is a growing emphasis on creating biodegradable or recyclable polypropylene-based products to reduce environmental impact. Additionally, researchers are exploring ways to improve the filtration efficiency of polypropylene materials while maintaining breathability, a balance that is crucial for respiratory protection.

The future of PPE, with polypropylene at its core, aims to integrate smart technologies for active protection. This includes developing polypropylene-based materials that can adapt to changing environmental conditions or incorporate sensors for real-time monitoring of both the wearer's health and surrounding hazards. Ultimately, the goal is to create PPE that not only protects but also enhances the wearer's capabilities, marking a new era in occupational safety and health.

The mid-20th century saw a surge in PPE development, particularly during World War II, when the military's demand for protective gear accelerated innovation. This period marked the introduction of more advanced respiratory protection and chemical-resistant clothing. The 1970s brought about a new era in PPE with the establishment of the Occupational Safety and Health Administration (OSHA) in the United States, which set standards for workplace safety and PPE use.

In recent decades, the focus has shifted towards developing PPE that not only provides protection but also enhances comfort and usability. This shift has been crucial in improving compliance rates among workers. The integration of smart technologies into PPE, such as sensors and communication devices, represents the latest frontier in this evolution, allowing for real-time monitoring of worker safety and environmental conditions.

Polypropylene has played a pivotal role in this evolution, particularly in the realm of disposable protective equipment. Its introduction in the 1960s revolutionized the manufacturing of protective garments and masks due to its unique properties. Polypropylene's lightweight nature, coupled with its ability to form nonwoven fabrics, made it an ideal material for creating breathable yet protective barriers against particulates and liquids.

The goals of modern PPE development, with a focus on polypropylene's role, are multifaceted. Firstly, there is a continuous drive to improve the protective capabilities of PPE against an ever-widening range of hazards, including biological agents, nanoparticles, and emerging chemical threats. Secondly, enhancing the comfort and breathability of PPE remains a priority to ensure prolonged use without compromising worker performance.

Another critical goal is the development of sustainable PPE solutions. With the increased use of disposable PPE, particularly during global health crises, there is a growing emphasis on creating biodegradable or recyclable polypropylene-based products to reduce environmental impact. Additionally, researchers are exploring ways to improve the filtration efficiency of polypropylene materials while maintaining breathability, a balance that is crucial for respiratory protection.

The future of PPE, with polypropylene at its core, aims to integrate smart technologies for active protection. This includes developing polypropylene-based materials that can adapt to changing environmental conditions or incorporate sensors for real-time monitoring of both the wearer's health and surrounding hazards. Ultimately, the goal is to create PPE that not only protects but also enhances the wearer's capabilities, marking a new era in occupational safety and health.

Market Demand Analysis

The global market for personal protective equipment (PPE) has experienced unprecedented growth in recent years, with polypropylene playing a crucial role in meeting the surging demand. The COVID-19 pandemic has been a significant catalyst, driving the need for PPE across healthcare, industrial, and consumer sectors. Market research indicates that the global PPE market size was valued at $77.36 billion in 2020 and is projected to reach $123.38 billion by 2027, growing at a CAGR of 9.6% during the forecast period.

Polypropylene, a versatile thermoplastic polymer, has emerged as a key material in PPE production due to its excellent properties and cost-effectiveness. The demand for polypropylene in PPE manufacturing has skyrocketed, particularly in the production of face masks, protective gowns, and other medical textiles. The global polypropylene market size was estimated at $126.03 billion in 2020 and is expected to grow at a CAGR of 5.7% from 2021 to 2028, with PPE applications contributing significantly to this growth.

In the healthcare sector, the demand for polypropylene-based PPE remains high, even as the acute phase of the pandemic subsides. Hospitals, clinics, and long-term care facilities continue to maintain higher inventory levels of PPE to ensure preparedness for future health crises. The industrial sector, including manufacturing, construction, and chemical industries, also shows a steady increase in PPE demand, driven by stricter workplace safety regulations and growing awareness of occupational hazards.

Consumer demand for PPE has created a new market segment, with individuals purchasing masks, gloves, and other protective items for personal use. This trend is expected to continue, albeit at a slower pace, as public health consciousness remains elevated post-pandemic. The e-commerce channel has played a significant role in meeting this consumer demand, with online sales of PPE growing substantially.

Geographically, North America and Europe lead in PPE consumption, but the Asia-Pacific region is experiencing the fastest growth. Countries like China and India are not only major consumers but also key producers of polypropylene and PPE, influencing global supply chains and market dynamics.

The market demand for polypropylene in PPE is also driven by its sustainability advantages. As environmental concerns gain prominence, the recyclability of polypropylene positions it favorably against other materials. This aligns with the growing trend of sustainable and circular economy practices in the PPE industry.

Looking ahead, the market demand for polypropylene in PPE is expected to stabilize but remain significantly higher than pre-pandemic levels. Factors such as ongoing healthcare needs, industrial safety requirements, and the potential for future public health emergencies will continue to support demand. Innovation in polypropylene formulations and PPE design is likely to further expand market opportunities, addressing evolving user needs and regulatory standards.

Polypropylene, a versatile thermoplastic polymer, has emerged as a key material in PPE production due to its excellent properties and cost-effectiveness. The demand for polypropylene in PPE manufacturing has skyrocketed, particularly in the production of face masks, protective gowns, and other medical textiles. The global polypropylene market size was estimated at $126.03 billion in 2020 and is expected to grow at a CAGR of 5.7% from 2021 to 2028, with PPE applications contributing significantly to this growth.

In the healthcare sector, the demand for polypropylene-based PPE remains high, even as the acute phase of the pandemic subsides. Hospitals, clinics, and long-term care facilities continue to maintain higher inventory levels of PPE to ensure preparedness for future health crises. The industrial sector, including manufacturing, construction, and chemical industries, also shows a steady increase in PPE demand, driven by stricter workplace safety regulations and growing awareness of occupational hazards.

Consumer demand for PPE has created a new market segment, with individuals purchasing masks, gloves, and other protective items for personal use. This trend is expected to continue, albeit at a slower pace, as public health consciousness remains elevated post-pandemic. The e-commerce channel has played a significant role in meeting this consumer demand, with online sales of PPE growing substantially.

Geographically, North America and Europe lead in PPE consumption, but the Asia-Pacific region is experiencing the fastest growth. Countries like China and India are not only major consumers but also key producers of polypropylene and PPE, influencing global supply chains and market dynamics.

The market demand for polypropylene in PPE is also driven by its sustainability advantages. As environmental concerns gain prominence, the recyclability of polypropylene positions it favorably against other materials. This aligns with the growing trend of sustainable and circular economy practices in the PPE industry.

Looking ahead, the market demand for polypropylene in PPE is expected to stabilize but remain significantly higher than pre-pandemic levels. Factors such as ongoing healthcare needs, industrial safety requirements, and the potential for future public health emergencies will continue to support demand. Innovation in polypropylene formulations and PPE design is likely to further expand market opportunities, addressing evolving user needs and regulatory standards.

Polypropylene Challenges

Despite its widespread use in personal protective equipment (PPE), polypropylene faces several challenges that impact its effectiveness and sustainability in this critical application. One of the primary concerns is the material's limited breathability, which can lead to discomfort and reduced wear time for users, particularly in high-temperature or humid environments. This issue is especially pronounced in face masks and protective suits, where prolonged use can result in moisture buildup and potential skin irritation.

Another significant challenge is polypropylene's susceptibility to degradation when exposed to certain environmental factors. Ultraviolet (UV) radiation from sunlight can cause the material to break down over time, potentially compromising its protective properties. This degradation can lead to a reduction in the lifespan of PPE items, necessitating more frequent replacements and increasing overall costs for healthcare systems and other industries reliant on protective gear.

The hydrophobic nature of polypropylene, while beneficial for repelling liquids, presents challenges in incorporating antimicrobial properties. As pathogens can survive on surfaces for extended periods, enhancing polypropylene's ability to neutralize microorganisms without compromising its other protective qualities remains an ongoing area of research and development.

Polypropylene's performance in filtration applications, particularly in N95 respirators, faces challenges in balancing high filtration efficiency with low breathing resistance. Achieving the optimal balance between these two factors is crucial for ensuring both protection and user comfort, especially during prolonged wear in healthcare settings.

From a sustainability perspective, the widespread use of polypropylene in single-use PPE items contributes significantly to plastic waste. The material's resistance to degradation, while beneficial for protection, becomes problematic in waste management. Developing eco-friendly alternatives or improving recycling processes for polypropylene-based PPE is a pressing challenge that intersects environmental concerns with public health needs.

Additionally, the scalability of polypropylene production to meet sudden surges in demand, as witnessed during the COVID-19 pandemic, highlights vulnerabilities in the supply chain. Ensuring a stable and flexible production capacity that can rapidly respond to global health crises without compromising quality or increasing costs remains a complex challenge for manufacturers and policymakers alike.

Another significant challenge is polypropylene's susceptibility to degradation when exposed to certain environmental factors. Ultraviolet (UV) radiation from sunlight can cause the material to break down over time, potentially compromising its protective properties. This degradation can lead to a reduction in the lifespan of PPE items, necessitating more frequent replacements and increasing overall costs for healthcare systems and other industries reliant on protective gear.

The hydrophobic nature of polypropylene, while beneficial for repelling liquids, presents challenges in incorporating antimicrobial properties. As pathogens can survive on surfaces for extended periods, enhancing polypropylene's ability to neutralize microorganisms without compromising its other protective qualities remains an ongoing area of research and development.

Polypropylene's performance in filtration applications, particularly in N95 respirators, faces challenges in balancing high filtration efficiency with low breathing resistance. Achieving the optimal balance between these two factors is crucial for ensuring both protection and user comfort, especially during prolonged wear in healthcare settings.

From a sustainability perspective, the widespread use of polypropylene in single-use PPE items contributes significantly to plastic waste. The material's resistance to degradation, while beneficial for protection, becomes problematic in waste management. Developing eco-friendly alternatives or improving recycling processes for polypropylene-based PPE is a pressing challenge that intersects environmental concerns with public health needs.

Additionally, the scalability of polypropylene production to meet sudden surges in demand, as witnessed during the COVID-19 pandemic, highlights vulnerabilities in the supply chain. Ensuring a stable and flexible production capacity that can rapidly respond to global health crises without compromising quality or increasing costs remains a complex challenge for manufacturers and policymakers alike.

Current PP-based Solutions

01 Polypropylene synthesis and production methods

Various methods for synthesizing and producing polypropylene, including polymerization techniques, catalyst systems, and process improvements to enhance yield and quality of the resulting polymer.- Polypropylene composition and manufacturing: Various methods and compositions for producing polypropylene with specific properties are described. These include techniques for improving the mechanical strength, thermal stability, and processability of polypropylene. The compositions may involve blending polypropylene with other polymers or additives to enhance its performance characteristics.

- Polypropylene applications in packaging: Polypropylene is widely used in packaging applications due to its versatility and favorable properties. Innovations in this area include the development of polypropylene films with improved barrier properties, heat-sealability, and printability. These advancements enhance the material's suitability for food packaging, consumer goods packaging, and industrial applications.

- Polypropylene in fiber and textile applications: The use of polypropylene in fiber and textile applications is explored, with developments focusing on improving the material's properties for these purposes. This includes methods for enhancing the dyeability of polypropylene fibers, increasing their strength and durability, and developing specialized finishes for specific textile applications.

- Polypropylene modifications and additives: Various modifications and additives for polypropylene are described to enhance its properties and expand its range of applications. These include the incorporation of nanoparticles, compatibilizers, and other functional additives to improve mechanical properties, flame retardancy, and UV resistance. Methods for grafting and copolymerization are also explored to create specialized polypropylene variants.

- Recycling and sustainability of polypropylene: Advancements in the recycling and sustainability of polypropylene are discussed, including methods for improving the recyclability of polypropylene products, developing bio-based polypropylene alternatives, and enhancing the material's overall environmental profile. These innovations aim to address growing concerns about plastic waste and promote a more circular economy for polypropylene materials.

02 Polypropylene compositions and blends

Development of polypropylene compositions and blends with other materials to enhance specific properties such as strength, flexibility, or heat resistance for various applications.Expand Specific Solutions03 Polypropylene fiber and film production

Techniques for manufacturing polypropylene fibers and films, including extrusion processes, orientation methods, and surface treatments to improve performance characteristics.Expand Specific Solutions04 Polypropylene modification and functionalization

Methods for modifying and functionalizing polypropylene to improve its properties or compatibility with other materials, such as grafting, crosslinking, or adding specific functional groups.Expand Specific Solutions05 Polypropylene recycling and sustainability

Innovations in polypropylene recycling processes, including mechanical and chemical recycling methods, as well as the development of more sustainable and biodegradable polypropylene-based materials.Expand Specific Solutions

Key PPE Manufacturers

The market for polypropylene in personal protective equipment (PPE) is experiencing rapid growth, driven by increased demand for safety gear across various industries. The industry is in an expansion phase, with the global PPE market expected to reach significant size in the coming years. Technologically, polypropylene applications in PPE are relatively mature, with ongoing innovations focused on enhancing performance and sustainability. Key players like ExxonMobil Chemical, Dow Global Technologies, and SABIC Global Technologies are leading research and development efforts, while companies such as DuPont Safety & Construction and Borealis AG are expanding their product portfolios. Chinese firms like Sinopec and emerging players are also gaining market share, intensifying competition in this dynamic sector.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced polypropylene (PP) materials for personal protective equipment (PPE). Their research focuses on enhancing PP's properties for improved barrier protection and comfort. They have introduced a high-melt strength PP grade specifically designed for meltblown nonwoven fabrics used in face masks and protective clothing[1]. This grade offers superior filtration efficiency and breathability. Sinopec has also developed a spunbond PP grade with improved tensile strength and elongation, suitable for the outer layers of medical protective suits[2]. Their PP materials incorporate additives for enhanced UV resistance and antistatic properties, extending the lifespan and functionality of PPE[3].

Strengths: Large-scale production capabilities, integrated supply chain, and strong R&D resources. Weaknesses: Potential over-reliance on domestic market, and challenges in global market expansion.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil Chemical has developed specialized polypropylene grades for PPE applications. Their VistamaxxTM performance polymers are used to enhance the elasticity and comfort of face masks and protective garments[4]. These polymers are designed to improve the fit and seal of face masks while maintaining breathability. ExxonMobil has also introduced metallocene PP grades with enhanced melt strength and spinnability, suitable for producing high-quality meltblown nonwovens for filtration layers in PPE[5]. Their research extends to developing PP compounds with antimicrobial properties, incorporating additives that inhibit bacterial growth on PPE surfaces[6].

Strengths: Global presence, extensive R&D capabilities, and diverse product portfolio. Weaknesses: Higher production costs compared to some competitors, and potential environmental concerns associated with fossil fuel-based materials.

Polypropylene Innovations

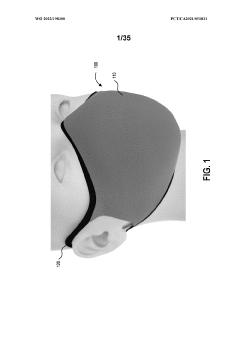

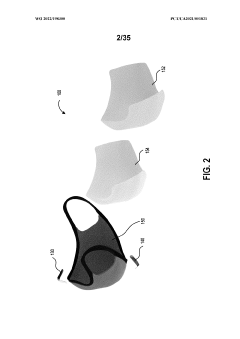

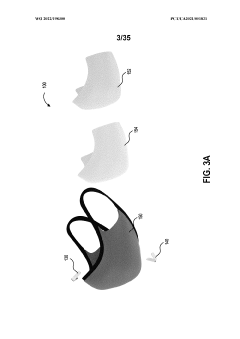

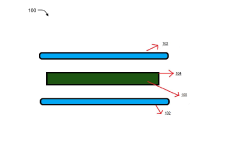

Filtration garments

PatentWO2022198300A1

Innovation

- The development of filtration garments with a multilayer knit structure comprising an outer hydrophobic textile, an inner natural fiber textile, and an interconnecting structure of nylon-wrapped synthetic elastane fibers, which maintains filtration efficiency and breathability even after multiple wash cycles, using materials like super-hydrophobic polyester and cotton with optimized stitch lengths and porosity.

Personal protective equipment (PPE) with cooling effect

PatentPendingIN202311058080A

Innovation

- A PPE kit composed of polypropylene fibers with integrated cooling gel bladders and a motor for gel movement, providing a prolonged cooling effect and improved ventilation, allowing for unrestricted mobility and storage in refrigeration units.

Regulatory Framework

The regulatory framework surrounding polypropylene's use in personal protective equipment (PPE) is complex and multifaceted, involving various international, national, and industry-specific standards. At the global level, the World Health Organization (WHO) provides guidelines for PPE manufacturing and usage, which many countries incorporate into their regulatory frameworks.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of PPE as medical devices. The FDA has established specific requirements for polypropylene-based PPE, including performance standards, labeling requirements, and quality control measures. Additionally, the Occupational Safety and Health Administration (OSHA) sets standards for workplace safety, which include specifications for PPE made from polypropylene.

The European Union has implemented the Personal Protective Equipment Regulation (EU) 2016/425, which outlines essential health and safety requirements for PPE. This regulation includes specific provisions for polypropylene-based products, addressing aspects such as material safety, durability, and performance under various conditions.

In Asia, countries like China and Japan have their own regulatory bodies and standards for PPE. China's National Medical Products Administration (NMPA) and Japan's Ministry of Health, Labour and Welfare (MHLW) have established guidelines for polypropylene-based PPE, focusing on quality control and safety assurance.

International standards organizations, such as the International Organization for Standardization (ISO) and ASTM International, play a crucial role in setting global benchmarks for PPE. These standards often serve as references for national regulations and industry practices, ensuring consistency and quality across borders.

The regulatory landscape also addresses environmental concerns related to polypropylene use in PPE. Many countries have implemented regulations on the disposal and recycling of PPE, considering the material's environmental impact. These regulations aim to balance the need for effective protection with sustainability goals.

As the COVID-19 pandemic has highlighted the critical importance of PPE, regulatory bodies worldwide have been adapting their frameworks to address emerging challenges. This includes expedited approval processes for new polypropylene-based PPE designs, increased scrutiny of supply chains, and enhanced quality control measures to combat counterfeit products.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of PPE as medical devices. The FDA has established specific requirements for polypropylene-based PPE, including performance standards, labeling requirements, and quality control measures. Additionally, the Occupational Safety and Health Administration (OSHA) sets standards for workplace safety, which include specifications for PPE made from polypropylene.

The European Union has implemented the Personal Protective Equipment Regulation (EU) 2016/425, which outlines essential health and safety requirements for PPE. This regulation includes specific provisions for polypropylene-based products, addressing aspects such as material safety, durability, and performance under various conditions.

In Asia, countries like China and Japan have their own regulatory bodies and standards for PPE. China's National Medical Products Administration (NMPA) and Japan's Ministry of Health, Labour and Welfare (MHLW) have established guidelines for polypropylene-based PPE, focusing on quality control and safety assurance.

International standards organizations, such as the International Organization for Standardization (ISO) and ASTM International, play a crucial role in setting global benchmarks for PPE. These standards often serve as references for national regulations and industry practices, ensuring consistency and quality across borders.

The regulatory landscape also addresses environmental concerns related to polypropylene use in PPE. Many countries have implemented regulations on the disposal and recycling of PPE, considering the material's environmental impact. These regulations aim to balance the need for effective protection with sustainability goals.

As the COVID-19 pandemic has highlighted the critical importance of PPE, regulatory bodies worldwide have been adapting their frameworks to address emerging challenges. This includes expedited approval processes for new polypropylene-based PPE designs, increased scrutiny of supply chains, and enhanced quality control measures to combat counterfeit products.

Environmental Impact

The environmental impact of polypropylene in personal protective equipment (PPE) is a critical consideration in the ongoing efforts to balance safety requirements with sustainability goals. Polypropylene, a widely used material in PPE production, offers excellent protective properties but also presents significant environmental challenges throughout its lifecycle.

The production of polypropylene for PPE contributes to greenhouse gas emissions and resource depletion. The polymer is derived from fossil fuels, primarily natural gas and crude oil, which are non-renewable resources. The extraction and refining processes associated with these raw materials result in substantial carbon emissions and energy consumption. Additionally, the manufacturing of polypropylene involves energy-intensive processes, further increasing its carbon footprint.

During the use phase, polypropylene-based PPE provides essential protection for healthcare workers and other professionals. However, the disposable nature of many PPE items leads to rapid turnover and significant waste generation. The COVID-19 pandemic has exacerbated this issue, with millions of single-use masks and other protective gear being discarded daily worldwide.

The end-of-life management of polypropylene PPE poses substantial environmental challenges. Most PPE items are not recyclable due to contamination concerns and the complexity of mixed materials used in their construction. Consequently, the majority of used PPE ends up in landfills or incinerators. In landfills, polypropylene can take hundreds of years to decompose, contributing to long-term environmental pollution. Incineration, while reducing waste volume, releases harmful emissions and greenhouse gases.

Improper disposal of PPE has led to increased plastic pollution in terrestrial and aquatic ecosystems. Discarded masks and gloves have been found in alarming quantities in natural environments, posing threats to wildlife through entanglement and ingestion. The breakdown of polypropylene into microplastics further compounds the problem, as these particles can enter food chains and potentially impact human health.

Efforts to mitigate the environmental impact of polypropylene in PPE are ongoing. Research into biodegradable alternatives and more sustainable production methods is gaining momentum. Some initiatives focus on developing reusable PPE to reduce waste generation, while others explore advanced recycling technologies to process contaminated polypropylene waste. However, these solutions must be carefully balanced with the primary function of PPE in ensuring user safety and protection.

The production of polypropylene for PPE contributes to greenhouse gas emissions and resource depletion. The polymer is derived from fossil fuels, primarily natural gas and crude oil, which are non-renewable resources. The extraction and refining processes associated with these raw materials result in substantial carbon emissions and energy consumption. Additionally, the manufacturing of polypropylene involves energy-intensive processes, further increasing its carbon footprint.

During the use phase, polypropylene-based PPE provides essential protection for healthcare workers and other professionals. However, the disposable nature of many PPE items leads to rapid turnover and significant waste generation. The COVID-19 pandemic has exacerbated this issue, with millions of single-use masks and other protective gear being discarded daily worldwide.

The end-of-life management of polypropylene PPE poses substantial environmental challenges. Most PPE items are not recyclable due to contamination concerns and the complexity of mixed materials used in their construction. Consequently, the majority of used PPE ends up in landfills or incinerators. In landfills, polypropylene can take hundreds of years to decompose, contributing to long-term environmental pollution. Incineration, while reducing waste volume, releases harmful emissions and greenhouse gases.

Improper disposal of PPE has led to increased plastic pollution in terrestrial and aquatic ecosystems. Discarded masks and gloves have been found in alarming quantities in natural environments, posing threats to wildlife through entanglement and ingestion. The breakdown of polypropylene into microplastics further compounds the problem, as these particles can enter food chains and potentially impact human health.

Efforts to mitigate the environmental impact of polypropylene in PPE are ongoing. Research into biodegradable alternatives and more sustainable production methods is gaining momentum. Some initiatives focus on developing reusable PPE to reduce waste generation, while others explore advanced recycling technologies to process contaminated polypropylene waste. However, these solutions must be carefully balanced with the primary function of PPE in ensuring user safety and protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!