Investigating Polypropylene Use in High-Capacity Wastewater Containers

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polypropylene in Wastewater: Background and Objectives

Polypropylene has emerged as a significant material in the field of wastewater management, particularly in the context of high-capacity containers. This synthetic thermoplastic polymer, first synthesized in 1951, has since revolutionized various industries due to its unique properties. In the realm of wastewater treatment and storage, polypropylene's characteristics make it an ideal candidate for constructing large-scale containers.

The evolution of wastewater management technologies has led to an increased demand for materials that can withstand harsh chemical environments while maintaining structural integrity. Polypropylene's resistance to a wide range of chemicals, coupled with its high tensile strength and low density, positions it as a superior alternative to traditional materials like concrete or metal in many wastewater applications.

The primary objective of investigating polypropylene use in high-capacity wastewater containers is to optimize the design, durability, and efficiency of these critical infrastructure components. This research aims to address the growing global challenges in water resource management, particularly in urban areas experiencing rapid population growth and industrial expansion.

One of the key drivers behind this technological exploration is the need for sustainable and cost-effective solutions in wastewater treatment facilities. Polypropylene containers offer potential advantages in terms of reduced transportation costs, easier installation, and lower maintenance requirements compared to their heavier counterparts.

Furthermore, the investigation into polypropylene's application in this field is closely tied to advancements in polymer science and manufacturing techniques. Recent developments in material engineering have led to enhanced grades of polypropylene with improved mechanical properties and chemical resistance, opening new possibilities for its use in more demanding wastewater environments.

The scope of this research extends beyond mere material selection. It encompasses a holistic approach to container design, including considerations for structural integrity, leak prevention, and long-term performance under varying environmental conditions. Additionally, the study aims to explore the potential for incorporating smart technologies into polypropylene containers, such as integrated sensors for real-time monitoring of wastewater parameters.

As environmental regulations become increasingly stringent, there is a growing emphasis on the lifecycle assessment of materials used in wastewater infrastructure. This investigation, therefore, also seeks to evaluate the environmental impact of polypropylene containers, from production to end-of-life disposal or recycling, ensuring alignment with sustainability goals.

The evolution of wastewater management technologies has led to an increased demand for materials that can withstand harsh chemical environments while maintaining structural integrity. Polypropylene's resistance to a wide range of chemicals, coupled with its high tensile strength and low density, positions it as a superior alternative to traditional materials like concrete or metal in many wastewater applications.

The primary objective of investigating polypropylene use in high-capacity wastewater containers is to optimize the design, durability, and efficiency of these critical infrastructure components. This research aims to address the growing global challenges in water resource management, particularly in urban areas experiencing rapid population growth and industrial expansion.

One of the key drivers behind this technological exploration is the need for sustainable and cost-effective solutions in wastewater treatment facilities. Polypropylene containers offer potential advantages in terms of reduced transportation costs, easier installation, and lower maintenance requirements compared to their heavier counterparts.

Furthermore, the investigation into polypropylene's application in this field is closely tied to advancements in polymer science and manufacturing techniques. Recent developments in material engineering have led to enhanced grades of polypropylene with improved mechanical properties and chemical resistance, opening new possibilities for its use in more demanding wastewater environments.

The scope of this research extends beyond mere material selection. It encompasses a holistic approach to container design, including considerations for structural integrity, leak prevention, and long-term performance under varying environmental conditions. Additionally, the study aims to explore the potential for incorporating smart technologies into polypropylene containers, such as integrated sensors for real-time monitoring of wastewater parameters.

As environmental regulations become increasingly stringent, there is a growing emphasis on the lifecycle assessment of materials used in wastewater infrastructure. This investigation, therefore, also seeks to evaluate the environmental impact of polypropylene containers, from production to end-of-life disposal or recycling, ensuring alignment with sustainability goals.

Market Analysis for High-Capacity Wastewater Containers

The market for high-capacity wastewater containers is experiencing significant growth, driven by increasing urbanization, industrial expansion, and stricter environmental regulations. These containers play a crucial role in managing and treating large volumes of wastewater from various sources, including municipal sewage systems, industrial processes, and agricultural operations.

The global wastewater treatment market, which encompasses high-capacity containers, is projected to grow steadily over the next decade. This growth is fueled by the rising demand for clean water, especially in developing countries, and the need to upgrade aging water infrastructure in developed nations. The Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization and urban development.

Polypropylene has emerged as a preferred material for high-capacity wastewater containers due to its excellent chemical resistance, durability, and cost-effectiveness. The market for polypropylene-based containers is expanding as industries and municipalities seek more efficient and long-lasting solutions for wastewater management.

Key market drivers include stringent environmental regulations, increasing awareness of water scarcity, and the need for sustainable water management practices. Governments worldwide are implementing policies that mandate proper wastewater treatment, creating a strong demand for high-capacity containers. Additionally, the growing focus on circular economy principles is pushing industries to adopt more efficient water treatment and recycling systems.

The industrial sector, particularly chemical, petrochemical, and food processing industries, represents a significant market segment for high-capacity wastewater containers. These industries generate large volumes of wastewater that require specialized treatment and storage solutions. The municipal sector is another major consumer, driven by the need to upgrade and expand urban wastewater treatment facilities.

Market challenges include high initial investment costs for large-scale wastewater treatment systems and the complexity of integrating new technologies with existing infrastructure. However, these challenges also present opportunities for innovation in container design and materials, potentially leading to more cost-effective and efficient solutions.

The market is characterized by a mix of established players and new entrants, with ongoing research and development efforts focused on improving container performance, reducing costs, and enhancing sustainability. Collaborations between material suppliers, container manufacturers, and wastewater treatment companies are becoming more common, driving innovation and market growth.

The global wastewater treatment market, which encompasses high-capacity containers, is projected to grow steadily over the next decade. This growth is fueled by the rising demand for clean water, especially in developing countries, and the need to upgrade aging water infrastructure in developed nations. The Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization and urban development.

Polypropylene has emerged as a preferred material for high-capacity wastewater containers due to its excellent chemical resistance, durability, and cost-effectiveness. The market for polypropylene-based containers is expanding as industries and municipalities seek more efficient and long-lasting solutions for wastewater management.

Key market drivers include stringent environmental regulations, increasing awareness of water scarcity, and the need for sustainable water management practices. Governments worldwide are implementing policies that mandate proper wastewater treatment, creating a strong demand for high-capacity containers. Additionally, the growing focus on circular economy principles is pushing industries to adopt more efficient water treatment and recycling systems.

The industrial sector, particularly chemical, petrochemical, and food processing industries, represents a significant market segment for high-capacity wastewater containers. These industries generate large volumes of wastewater that require specialized treatment and storage solutions. The municipal sector is another major consumer, driven by the need to upgrade and expand urban wastewater treatment facilities.

Market challenges include high initial investment costs for large-scale wastewater treatment systems and the complexity of integrating new technologies with existing infrastructure. However, these challenges also present opportunities for innovation in container design and materials, potentially leading to more cost-effective and efficient solutions.

The market is characterized by a mix of established players and new entrants, with ongoing research and development efforts focused on improving container performance, reducing costs, and enhancing sustainability. Collaborations between material suppliers, container manufacturers, and wastewater treatment companies are becoming more common, driving innovation and market growth.

Current Challenges in Wastewater Container Materials

The current challenges in wastewater container materials, particularly for high-capacity applications, are multifaceted and require careful consideration. Traditional materials such as concrete and steel have long been used for wastewater storage, but they present significant limitations in terms of durability, weight, and cost-effectiveness. Concrete structures are prone to cracking and degradation over time, especially when exposed to corrosive wastewater components. Steel containers, while robust, are susceptible to rust and corrosion, leading to potential leaks and contamination risks.

The increasing demand for large-scale wastewater management solutions has highlighted the need for alternative materials that can withstand harsh chemical environments while maintaining structural integrity. Polypropylene (PP) has emerged as a promising candidate due to its excellent chemical resistance and relatively low cost. However, the use of PP in high-capacity wastewater containers faces several challenges that need to be addressed.

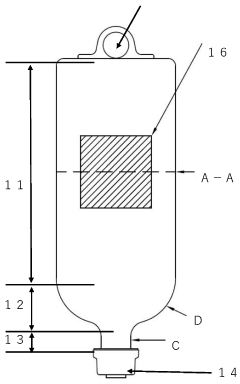

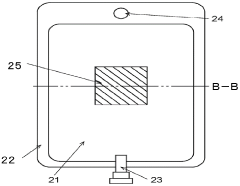

One of the primary concerns is the long-term structural stability of PP containers when subjected to high hydrostatic pressures. Large volumes of wastewater exert significant forces on container walls, potentially leading to deformation or failure over time. This issue is particularly pronounced in underground installations where soil pressure adds to the overall stress on the container.

Another challenge lies in ensuring the chemical compatibility of PP with various wastewater compositions. While PP generally exhibits good resistance to many chemicals, certain industrial effluents may contain compounds that can degrade the polymer structure over extended periods. This necessitates thorough testing and possibly the development of specialized PP formulations to enhance chemical resistance.

The thermal expansion characteristics of PP also present a challenge in wastewater container design. Fluctuations in temperature can cause significant dimensional changes, potentially leading to stress on joints and connections. This is especially problematic in regions with extreme temperature variations, where thermal cycling can accelerate material fatigue.

Furthermore, the joining and sealing of large PP components pose technical difficulties. Traditional welding techniques may not be suitable for creating reliable, long-lasting joints in high-capacity containers. Developing effective methods for assembling and sealing PP sections without compromising structural integrity or introducing potential leak points is crucial.

Lastly, there are concerns regarding the environmental impact and end-of-life management of large PP wastewater containers. While PP is recyclable, the size and contamination of these containers make recycling processes complex and potentially costly. Addressing these sustainability issues is essential for the widespread adoption of PP in wastewater management infrastructure.

The increasing demand for large-scale wastewater management solutions has highlighted the need for alternative materials that can withstand harsh chemical environments while maintaining structural integrity. Polypropylene (PP) has emerged as a promising candidate due to its excellent chemical resistance and relatively low cost. However, the use of PP in high-capacity wastewater containers faces several challenges that need to be addressed.

One of the primary concerns is the long-term structural stability of PP containers when subjected to high hydrostatic pressures. Large volumes of wastewater exert significant forces on container walls, potentially leading to deformation or failure over time. This issue is particularly pronounced in underground installations where soil pressure adds to the overall stress on the container.

Another challenge lies in ensuring the chemical compatibility of PP with various wastewater compositions. While PP generally exhibits good resistance to many chemicals, certain industrial effluents may contain compounds that can degrade the polymer structure over extended periods. This necessitates thorough testing and possibly the development of specialized PP formulations to enhance chemical resistance.

The thermal expansion characteristics of PP also present a challenge in wastewater container design. Fluctuations in temperature can cause significant dimensional changes, potentially leading to stress on joints and connections. This is especially problematic in regions with extreme temperature variations, where thermal cycling can accelerate material fatigue.

Furthermore, the joining and sealing of large PP components pose technical difficulties. Traditional welding techniques may not be suitable for creating reliable, long-lasting joints in high-capacity containers. Developing effective methods for assembling and sealing PP sections without compromising structural integrity or introducing potential leak points is crucial.

Lastly, there are concerns regarding the environmental impact and end-of-life management of large PP wastewater containers. While PP is recyclable, the size and contamination of these containers make recycling processes complex and potentially costly. Addressing these sustainability issues is essential for the widespread adoption of PP in wastewater management infrastructure.

Existing Polypropylene Solutions for Wastewater Containers

01 Polypropylene production capacity enhancement

Various methods and systems are employed to increase polypropylene production capacity. These include optimizing reactor designs, improving catalyst systems, and enhancing process control mechanisms. Such advancements allow for higher throughput and more efficient use of resources in polypropylene manufacturing facilities.- Polypropylene production capacity enhancement: Various methods and systems are employed to increase polypropylene production capacity. These include optimizing reactor designs, improving catalyst systems, and enhancing process control mechanisms. Advanced technologies are implemented to maximize efficiency and output in polypropylene manufacturing facilities.

- Polypropylene storage and handling systems: Innovative storage and handling systems are developed to manage increased polypropylene production capacity. These systems include advanced silos, conveying equipment, and packaging solutions designed to handle large volumes of polypropylene efficiently and safely.

- Polypropylene grade diversification: To meet diverse market demands, manufacturers are expanding their capacity to produce various grades of polypropylene. This includes developing specialized reactor systems and post-production modification techniques to create a wide range of polypropylene grades with different properties and applications.

- Recycling and sustainability in polypropylene production: Efforts to increase polypropylene capacity include integrating recycling technologies and sustainable practices. This involves developing processes for efficiently recycling polypropylene waste and incorporating recycled content into new production, thereby expanding overall capacity while reducing environmental impact.

- Process optimization for increased polypropylene capacity: Advanced process optimization techniques are employed to enhance polypropylene production capacity. These include implementing sophisticated control systems, utilizing data analytics for predictive maintenance, and developing novel reactor designs that improve polymerization efficiency and product quality.

02 Innovative reactor designs for polypropylene synthesis

Novel reactor configurations are developed to improve polypropylene production capacity. These designs focus on factors such as heat transfer, mixing efficiency, and residence time distribution. Advanced reactor technologies enable better control over polymerization conditions, resulting in increased productivity and product quality.Expand Specific Solutions03 Catalyst systems for enhanced polypropylene yield

Advanced catalyst systems are developed to boost polypropylene production capacity. These catalysts offer improved activity, selectivity, and stability, leading to higher polymer yields and reduced production costs. Innovations in catalyst technology contribute significantly to increasing overall plant capacity.Expand Specific Solutions04 Process optimization techniques for polypropylene manufacturing

Various process optimization techniques are implemented to maximize polypropylene production capacity. These include improved feed purification methods, enhanced polymerization control strategies, and efficient product recovery systems. Such optimizations result in increased throughput and reduced downtime in manufacturing facilities.Expand Specific Solutions05 Modular and scalable polypropylene production units

Modular and scalable production units are designed to facilitate capacity expansion in polypropylene manufacturing. These systems allow for flexible capacity adjustment and rapid deployment of additional production capabilities. Such modular approaches enable manufacturers to respond quickly to market demands and optimize their production capacity.Expand Specific Solutions

Key Players in Polypropylene and Container Manufacturing

The market for high-capacity wastewater containers using polypropylene is in a growth phase, driven by increasing environmental regulations and water management needs. The global market size is estimated to be in the billions, with steady annual growth. Technologically, the field is moderately mature, with ongoing innovations in material properties and design. Key players like SABIC, Borealis, and ExxonMobil Chemical are leading research and development efforts, focusing on improving durability, chemical resistance, and sustainability of polypropylene-based solutions. Emerging companies such as Prime Polymer and TOPAS Advanced Polymers are also contributing to advancements in this sector, indicating a competitive and dynamic market landscape.

SABIC Global Technologies BV

Technical Solution: SABIC has developed advanced polypropylene (PP) grades specifically designed for high-capacity wastewater containers. Their SABIC® PP compounds offer excellent chemical resistance and durability, crucial for wastewater applications. The company's proprietary technology allows for the production of PP with enhanced impact strength and environmental stress crack resistance (ESCR), addressing key challenges in wastewater container manufacturing[1]. SABIC's PP grades also incorporate additives that improve long-term performance under harsh conditions, including UV stabilizers and antioxidants, ensuring container longevity[2]. Additionally, SABIC has implemented a sustainable approach, incorporating recycled content into their PP formulations without compromising performance, aligning with circular economy principles[3].

Strengths: Superior chemical resistance, high impact strength, and excellent ESCR. Sustainable formulations with recycled content. Weaknesses: Potentially higher cost compared to standard PP grades, may require specialized processing equipment.

Borealis AG

Technical Solution: Borealis AG has pioneered the development of Borstar® technology for polypropylene production, which is particularly suitable for high-capacity wastewater containers. This technology enables the creation of bimodal PP with a unique balance of stiffness and impact resistance[1]. For wastewater applications, Borealis offers PP grades with enhanced chemical resistance and long-term hydrostatic strength, crucial for containing corrosive effluents[2]. Their PP compounds also feature advanced stabilization packages to prevent degradation from prolonged exposure to wastewater contaminants and environmental factors. Borealis has further innovated by introducing Borcycle™, a portfolio of recycled PP compounds, allowing for more sustainable wastewater container production without compromising on performance[3].

Strengths: Bimodal PP technology offering superior mechanical properties, excellent chemical resistance, and options for recycled content. Weaknesses: May require specific processing conditions, potentially limiting manufacturing flexibility.

Innovations in Polypropylene for Wastewater Applications

Polypropylene containers having a barrier layer for the packaging, storage and preservation of foods

PatentWO2008006524A1

Innovation

- Transparent polypropylene containers with a barrier layer are developed, featuring a propylene homopolymer or copolymer with specific mechanical properties and low permeability to oxygen and water vapor, ensuring extended food storage and handling while maintaining transparency and economic production.

container

PatentActiveIN202017044900A

Innovation

- A container composed of a specific resin composition containing 57-75% propylene resin, 10-25% ethylene resin, and 10-18% propylene elastomer resin, optimized for melt flow rate, density, hardness, and glass transition temperature, ensuring heat resistance, transparency, and impact resistance while preventing deformation and blocking during high-temperature sterilization.

Environmental Impact and Sustainability Considerations

The use of polypropylene in high-capacity wastewater containers presents significant environmental and sustainability considerations that must be carefully evaluated. Polypropylene, a thermoplastic polymer, offers several advantages in this application, including its durability, chemical resistance, and recyclability. However, its production and disposal also raise important environmental concerns.

From a production standpoint, polypropylene is derived from petroleum, a non-renewable resource. The extraction and refining processes associated with petroleum contribute to greenhouse gas emissions and other environmental impacts. However, compared to alternative materials like steel or concrete, polypropylene production generally requires less energy and results in lower carbon emissions over its lifecycle.

In terms of durability and longevity, polypropylene containers can withstand harsh chemical environments and resist corrosion, potentially leading to extended service life. This longevity can reduce the need for frequent replacements, thereby minimizing waste generation and resource consumption in the long term. Additionally, the lightweight nature of polypropylene compared to traditional materials can result in reduced transportation-related emissions during distribution and installation.

Recyclability is a key sustainability advantage of polypropylene. At the end of their useful life, polypropylene wastewater containers can be recycled into new products, reducing the demand for virgin materials and minimizing waste sent to landfills. However, the effectiveness of recycling depends on the availability and efficiency of local recycling infrastructure, as well as the proper separation and collection of these containers.

The potential for chemical leaching is an important environmental consideration. While polypropylene is generally considered chemically stable, there is a risk of additives or degradation products leaching into the wastewater, potentially impacting water quality and ecosystems. Rigorous testing and quality control measures are essential to mitigate this risk.

From a broader sustainability perspective, the use of polypropylene in wastewater containers aligns with principles of circular economy and resource efficiency. By choosing a material that is both durable and recyclable, the overall environmental footprint of wastewater management systems can be reduced. However, this requires a comprehensive approach that considers the entire lifecycle of the containers, from production to disposal or recycling.

In conclusion, while polypropylene offers several environmental and sustainability benefits for high-capacity wastewater containers, its use must be carefully managed to maximize these advantages and minimize potential negative impacts. Ongoing research and development in bio-based alternatives and improved recycling technologies may further enhance the sustainability profile of polypropylene in this application.

From a production standpoint, polypropylene is derived from petroleum, a non-renewable resource. The extraction and refining processes associated with petroleum contribute to greenhouse gas emissions and other environmental impacts. However, compared to alternative materials like steel or concrete, polypropylene production generally requires less energy and results in lower carbon emissions over its lifecycle.

In terms of durability and longevity, polypropylene containers can withstand harsh chemical environments and resist corrosion, potentially leading to extended service life. This longevity can reduce the need for frequent replacements, thereby minimizing waste generation and resource consumption in the long term. Additionally, the lightweight nature of polypropylene compared to traditional materials can result in reduced transportation-related emissions during distribution and installation.

Recyclability is a key sustainability advantage of polypropylene. At the end of their useful life, polypropylene wastewater containers can be recycled into new products, reducing the demand for virgin materials and minimizing waste sent to landfills. However, the effectiveness of recycling depends on the availability and efficiency of local recycling infrastructure, as well as the proper separation and collection of these containers.

The potential for chemical leaching is an important environmental consideration. While polypropylene is generally considered chemically stable, there is a risk of additives or degradation products leaching into the wastewater, potentially impacting water quality and ecosystems. Rigorous testing and quality control measures are essential to mitigate this risk.

From a broader sustainability perspective, the use of polypropylene in wastewater containers aligns with principles of circular economy and resource efficiency. By choosing a material that is both durable and recyclable, the overall environmental footprint of wastewater management systems can be reduced. However, this requires a comprehensive approach that considers the entire lifecycle of the containers, from production to disposal or recycling.

In conclusion, while polypropylene offers several environmental and sustainability benefits for high-capacity wastewater containers, its use must be carefully managed to maximize these advantages and minimize potential negative impacts. Ongoing research and development in bio-based alternatives and improved recycling technologies may further enhance the sustainability profile of polypropylene in this application.

Regulatory Framework for Wastewater Container Materials

The regulatory framework governing wastewater container materials plays a crucial role in ensuring the safety, durability, and environmental compliance of high-capacity wastewater containers. For polypropylene use in such applications, several key regulations and standards must be considered.

In the United States, the Environmental Protection Agency (EPA) sets forth guidelines for wastewater management under the Clean Water Act. While not specifically addressing container materials, these regulations influence the design and material selection process. The EPA's focus on preventing contamination and ensuring proper treatment of wastewater indirectly impacts the requirements for container materials.

The American National Standards Institute (ANSI) and the American Society for Testing and Materials (ASTM) provide specific standards for plastic materials used in wastewater applications. ASTM D3350 outlines the standard specification for polyethylene plastics pipe and fittings materials, which can be applied to polypropylene in similar contexts. This standard addresses physical properties, chemical resistance, and long-term performance characteristics.

The National Sanitation Foundation (NSF) International has developed NSF/ANSI 61, which sets health effects criteria for water system components. Although primarily focused on drinking water systems, this standard is often referenced for wastewater applications to ensure materials do not leach harmful substances.

In the European Union, the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation impacts the use of polypropylene in wastewater containers. REACH requires manufacturers to register chemicals and demonstrate their safe use, which includes assessing potential environmental impacts.

The International Organization for Standardization (ISO) provides several relevant standards, including ISO 15874 for polypropylene piping systems for hot and cold water installations. While not specific to wastewater containers, these standards offer guidance on material properties and testing methods applicable to high-capacity containers.

Many countries have adopted or adapted these international standards into their national regulatory frameworks. For instance, in Australia, the Water Services Association of Australia (WSAA) provides guidelines that incorporate elements from international standards while addressing local environmental conditions and regulatory requirements.

Compliance with these regulations and standards typically involves rigorous testing procedures. These may include chemical resistance tests, stress crack resistance evaluations, and long-term hydrostatic strength assessments. Manufacturers must demonstrate that polypropylene containers can maintain their integrity under various environmental conditions and chemical exposures typical in wastewater applications.

As environmental concerns grow, regulations are evolving to address the entire lifecycle of wastewater containers. This includes considerations for recyclability and end-of-life disposal. The European Union's Waste Framework Directive, for example, promotes the recycling of plastics and sets targets for material recovery, which indirectly influences the design and material selection for wastewater containers.

In the United States, the Environmental Protection Agency (EPA) sets forth guidelines for wastewater management under the Clean Water Act. While not specifically addressing container materials, these regulations influence the design and material selection process. The EPA's focus on preventing contamination and ensuring proper treatment of wastewater indirectly impacts the requirements for container materials.

The American National Standards Institute (ANSI) and the American Society for Testing and Materials (ASTM) provide specific standards for plastic materials used in wastewater applications. ASTM D3350 outlines the standard specification for polyethylene plastics pipe and fittings materials, which can be applied to polypropylene in similar contexts. This standard addresses physical properties, chemical resistance, and long-term performance characteristics.

The National Sanitation Foundation (NSF) International has developed NSF/ANSI 61, which sets health effects criteria for water system components. Although primarily focused on drinking water systems, this standard is often referenced for wastewater applications to ensure materials do not leach harmful substances.

In the European Union, the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation impacts the use of polypropylene in wastewater containers. REACH requires manufacturers to register chemicals and demonstrate their safe use, which includes assessing potential environmental impacts.

The International Organization for Standardization (ISO) provides several relevant standards, including ISO 15874 for polypropylene piping systems for hot and cold water installations. While not specific to wastewater containers, these standards offer guidance on material properties and testing methods applicable to high-capacity containers.

Many countries have adopted or adapted these international standards into their national regulatory frameworks. For instance, in Australia, the Water Services Association of Australia (WSAA) provides guidelines that incorporate elements from international standards while addressing local environmental conditions and regulatory requirements.

Compliance with these regulations and standards typically involves rigorous testing procedures. These may include chemical resistance tests, stress crack resistance evaluations, and long-term hydrostatic strength assessments. Manufacturers must demonstrate that polypropylene containers can maintain their integrity under various environmental conditions and chemical exposures typical in wastewater applications.

As environmental concerns grow, regulations are evolving to address the entire lifecycle of wastewater containers. This includes considerations for recyclability and end-of-life disposal. The European Union's Waste Framework Directive, for example, promotes the recycling of plastics and sets targets for material recovery, which indirectly influences the design and material selection for wastewater containers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!