Investigating Stretch Blow Molding for Polypropylene Bottle Designs

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PP Bottle SBM Background

Stretch blow molding (SBM) is a manufacturing process widely used in the production of plastic bottles and containers. Traditionally, this technique has been primarily associated with polyethylene terephthalate (PET) due to its excellent stretch properties and clarity. However, the application of SBM to polypropylene (PP) bottle designs represents an emerging area of interest in the packaging industry.

The exploration of PP in SBM processes stems from the material's unique properties and potential advantages. Polypropylene offers excellent chemical resistance, high temperature tolerance, and good barrier properties against moisture. These characteristics make PP an attractive alternative for certain packaging applications, particularly in the food, beverage, and personal care industries.

The history of SBM for PP bottles can be traced back to the early 2000s when researchers and manufacturers began investigating the feasibility of using PP in this process. Initial challenges included achieving uniform wall thickness distribution and overcoming PP's lower melt strength compared to PET. Over the years, advancements in material science and processing technologies have gradually improved the viability of PP in SBM applications.

One of the key drivers for investigating PP in SBM is the growing demand for more sustainable packaging solutions. PP is recyclable and has a lower carbon footprint compared to some other plastics, aligning with increasing environmental concerns and regulations. Additionally, the potential for lightweighting PP bottles through SBM techniques offers further sustainability benefits and cost savings in transportation and material usage.

The technical objectives of researching SBM for PP bottle designs are multifaceted. These include optimizing the preform design to achieve desired bottle properties, developing suitable processing parameters to ensure uniform material distribution, and enhancing the overall quality and performance of PP bottles produced through SBM. Researchers are also focusing on improving the clarity of PP bottles to compete with the transparency of PET, which has been a significant barrier to wider adoption in certain markets.

As the packaging industry continues to evolve, the investigation of SBM for PP bottle designs represents a convergence of material science, process engineering, and market demands. This research area holds promise for expanding the application range of PP in packaging, potentially offering new solutions that balance performance, cost-effectiveness, and environmental considerations.

The exploration of PP in SBM processes stems from the material's unique properties and potential advantages. Polypropylene offers excellent chemical resistance, high temperature tolerance, and good barrier properties against moisture. These characteristics make PP an attractive alternative for certain packaging applications, particularly in the food, beverage, and personal care industries.

The history of SBM for PP bottles can be traced back to the early 2000s when researchers and manufacturers began investigating the feasibility of using PP in this process. Initial challenges included achieving uniform wall thickness distribution and overcoming PP's lower melt strength compared to PET. Over the years, advancements in material science and processing technologies have gradually improved the viability of PP in SBM applications.

One of the key drivers for investigating PP in SBM is the growing demand for more sustainable packaging solutions. PP is recyclable and has a lower carbon footprint compared to some other plastics, aligning with increasing environmental concerns and regulations. Additionally, the potential for lightweighting PP bottles through SBM techniques offers further sustainability benefits and cost savings in transportation and material usage.

The technical objectives of researching SBM for PP bottle designs are multifaceted. These include optimizing the preform design to achieve desired bottle properties, developing suitable processing parameters to ensure uniform material distribution, and enhancing the overall quality and performance of PP bottles produced through SBM. Researchers are also focusing on improving the clarity of PP bottles to compete with the transparency of PET, which has been a significant barrier to wider adoption in certain markets.

As the packaging industry continues to evolve, the investigation of SBM for PP bottle designs represents a convergence of material science, process engineering, and market demands. This research area holds promise for expanding the application range of PP in packaging, potentially offering new solutions that balance performance, cost-effectiveness, and environmental considerations.

Market Demand Analysis

The market demand for polypropylene bottles produced through stretch blow molding has been steadily increasing in recent years, driven by several key factors. The packaging industry, particularly for food and beverages, has shown a growing preference for polypropylene due to its excellent barrier properties, chemical resistance, and recyclability. This shift is largely attributed to the increasing consumer awareness of environmental issues and the push for more sustainable packaging solutions.

In the beverage sector, polypropylene bottles are gaining traction as an alternative to traditional PET bottles. The market for carbonated soft drinks, juices, and dairy products is experiencing a notable transition towards polypropylene packaging. This trend is supported by the material's ability to withstand high-temperature filling processes and its superior hot-fill performance compared to PET.

The personal care and household products industries are also contributing significantly to the demand for polypropylene bottles. These sectors value the material's moisture barrier properties and its resistance to chemicals, making it ideal for products such as shampoos, lotions, and cleaning agents. The cosmetics industry, in particular, has shown increased interest in polypropylene packaging due to its clarity and aesthetic appeal when properly processed.

Market analysis indicates that the global polypropylene bottle market is expected to grow at a compound annual growth rate (CAGR) of over 5% in the next five years. This growth is primarily fueled by the Asia-Pacific region, where rapid industrialization and changing consumer lifestyles are driving demand for packaged goods. North America and Europe are also significant contributors to market growth, with a focus on sustainable and recyclable packaging solutions.

The automotive and industrial sectors are emerging as potential growth areas for polypropylene bottles produced through stretch blow molding. These industries are exploring the use of polypropylene containers for fluids, chemicals, and small parts storage due to the material's durability and cost-effectiveness.

However, the market faces challenges in terms of processing difficulties associated with stretch blow molding polypropylene. The material's narrow processing window and lower strain hardening properties compared to PET require specialized equipment and expertise. This has led to increased research and development efforts to optimize the stretch blow molding process for polypropylene, creating opportunities for equipment manufacturers and material suppliers.

In conclusion, the market demand for polypropylene bottles produced through stretch blow molding is robust and diversifying. The packaging industry's shift towards more sustainable materials, coupled with polypropylene's unique properties, is driving adoption across various sectors. As processing technologies continue to improve, the market is poised for further expansion, presenting significant opportunities for manufacturers and innovators in the field.

In the beverage sector, polypropylene bottles are gaining traction as an alternative to traditional PET bottles. The market for carbonated soft drinks, juices, and dairy products is experiencing a notable transition towards polypropylene packaging. This trend is supported by the material's ability to withstand high-temperature filling processes and its superior hot-fill performance compared to PET.

The personal care and household products industries are also contributing significantly to the demand for polypropylene bottles. These sectors value the material's moisture barrier properties and its resistance to chemicals, making it ideal for products such as shampoos, lotions, and cleaning agents. The cosmetics industry, in particular, has shown increased interest in polypropylene packaging due to its clarity and aesthetic appeal when properly processed.

Market analysis indicates that the global polypropylene bottle market is expected to grow at a compound annual growth rate (CAGR) of over 5% in the next five years. This growth is primarily fueled by the Asia-Pacific region, where rapid industrialization and changing consumer lifestyles are driving demand for packaged goods. North America and Europe are also significant contributors to market growth, with a focus on sustainable and recyclable packaging solutions.

The automotive and industrial sectors are emerging as potential growth areas for polypropylene bottles produced through stretch blow molding. These industries are exploring the use of polypropylene containers for fluids, chemicals, and small parts storage due to the material's durability and cost-effectiveness.

However, the market faces challenges in terms of processing difficulties associated with stretch blow molding polypropylene. The material's narrow processing window and lower strain hardening properties compared to PET require specialized equipment and expertise. This has led to increased research and development efforts to optimize the stretch blow molding process for polypropylene, creating opportunities for equipment manufacturers and material suppliers.

In conclusion, the market demand for polypropylene bottles produced through stretch blow molding is robust and diversifying. The packaging industry's shift towards more sustainable materials, coupled with polypropylene's unique properties, is driving adoption across various sectors. As processing technologies continue to improve, the market is poised for further expansion, presenting significant opportunities for manufacturers and innovators in the field.

SBM Tech Challenges

Stretch blow molding (SBM) for polypropylene (PP) bottle designs presents several significant technical challenges that researchers and manufacturers must overcome. One of the primary obstacles is the narrow processing window for PP compared to more commonly used materials like PET. PP requires precise temperature control during the preform heating stage to achieve uniform material distribution in the final product.

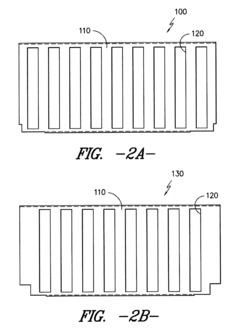

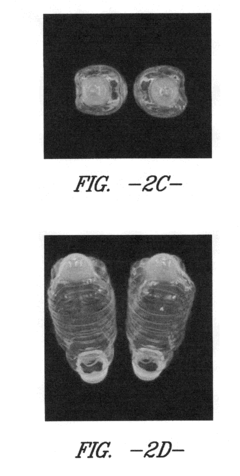

The crystallization behavior of PP adds another layer of complexity to the SBM process. Unlike PET, which remains amorphous during stretching, PP tends to crystallize rapidly under strain. This characteristic can lead to uneven wall thickness and reduced optical clarity in the finished bottles. Controlling the crystallization rate and distribution is crucial for producing high-quality PP bottles through SBM.

Material selection and formulation pose additional challenges. Standard PP grades often lack the melt strength and strain hardening properties necessary for successful SBM processing. Developing specialized PP grades with enhanced rheological properties, such as high melt strength and improved strain hardening behavior, is essential for achieving optimal bottle performance and processability.

The biaxial orientation of PP during the SBM process is another area of concern. Achieving the desired molecular orientation to improve mechanical properties and barrier performance is more difficult with PP than with PET. The orientation process must be carefully controlled to balance the material's strength, flexibility, and barrier properties in the final product.

Thermal stability during the blowing stage is a critical factor that affects the success of PP SBM. PP has a lower heat capacity and thermal conductivity compared to PET, which can result in uneven heating and cooling during the process. This can lead to inconsistencies in wall thickness and overall bottle quality. Developing advanced heating and cooling strategies is necessary to maintain uniform temperature distribution throughout the preform and during the blowing stage.

Barrier properties are another significant challenge in PP bottle production. PP inherently has lower gas barrier properties compared to PET, which can limit its use in certain applications, particularly for carbonated beverages or oxygen-sensitive products. Enhancing the barrier performance of PP bottles without compromising other desirable properties requires innovative approaches, such as multilayer structures or the incorporation of nanocomposites.

Addressing these technical challenges requires a multidisciplinary approach, combining expertise in polymer science, process engineering, and material characterization. Overcoming these hurdles will be crucial for expanding the use of PP in SBM applications and potentially offering a more sustainable alternative to PET in certain market segments.

The crystallization behavior of PP adds another layer of complexity to the SBM process. Unlike PET, which remains amorphous during stretching, PP tends to crystallize rapidly under strain. This characteristic can lead to uneven wall thickness and reduced optical clarity in the finished bottles. Controlling the crystallization rate and distribution is crucial for producing high-quality PP bottles through SBM.

Material selection and formulation pose additional challenges. Standard PP grades often lack the melt strength and strain hardening properties necessary for successful SBM processing. Developing specialized PP grades with enhanced rheological properties, such as high melt strength and improved strain hardening behavior, is essential for achieving optimal bottle performance and processability.

The biaxial orientation of PP during the SBM process is another area of concern. Achieving the desired molecular orientation to improve mechanical properties and barrier performance is more difficult with PP than with PET. The orientation process must be carefully controlled to balance the material's strength, flexibility, and barrier properties in the final product.

Thermal stability during the blowing stage is a critical factor that affects the success of PP SBM. PP has a lower heat capacity and thermal conductivity compared to PET, which can result in uneven heating and cooling during the process. This can lead to inconsistencies in wall thickness and overall bottle quality. Developing advanced heating and cooling strategies is necessary to maintain uniform temperature distribution throughout the preform and during the blowing stage.

Barrier properties are another significant challenge in PP bottle production. PP inherently has lower gas barrier properties compared to PET, which can limit its use in certain applications, particularly for carbonated beverages or oxygen-sensitive products. Enhancing the barrier performance of PP bottles without compromising other desirable properties requires innovative approaches, such as multilayer structures or the incorporation of nanocomposites.

Addressing these technical challenges requires a multidisciplinary approach, combining expertise in polymer science, process engineering, and material characterization. Overcoming these hurdles will be crucial for expanding the use of PP in SBM applications and potentially offering a more sustainable alternative to PET in certain market segments.

Current SBM Solutions

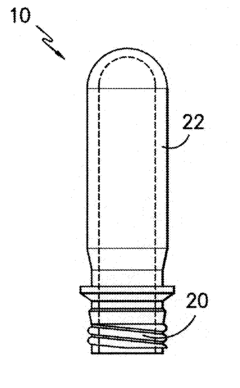

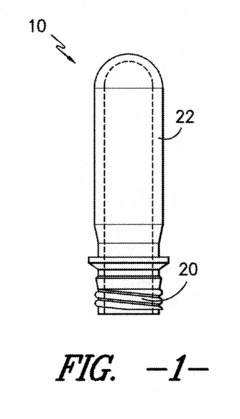

01 Preform design for stretch blow molding

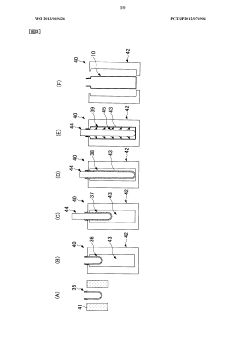

The design of the preform is crucial in stretch blow molding. Factors such as wall thickness distribution, shape, and size of the preform affect the final bottle properties. Optimizing preform design can improve material distribution, enhance bottle strength, and reduce material usage.- Preform design for stretch blow molding: The design of the preform is crucial in stretch blow molding. Factors such as wall thickness distribution, shape, and size of the preform affect the final bottle properties. Optimizing preform design can improve material distribution, enhance bottle strength, and reduce material usage.

- Temperature control during stretch blow molding: Proper temperature control throughout the stretch blow molding process is essential for achieving desired bottle properties. This includes preform heating, mold temperature regulation, and cooling strategies. Precise temperature management can improve material distribution, reduce cycle times, and enhance bottle quality.

- Mold design and features: The design of the mold used in stretch blow molding significantly impacts the final bottle characteristics. Features such as mold cavity shape, venting systems, and cooling channels influence bottle formation, surface finish, and cycle times. Innovative mold designs can improve bottle quality and production efficiency.

- Process parameters optimization: Optimizing various process parameters is crucial for successful stretch blow molding. This includes factors such as stretching speed, blowing pressure, and timing sequences. Fine-tuning these parameters can improve material distribution, enhance bottle properties, and increase production efficiency.

- Bottle design features for improved performance: Incorporating specific design features in the bottle can enhance its performance and functionality. This may include reinforcement structures, grip designs, or specialized neck finishes. These features can improve bottle strength, ergonomics, and overall user experience while maintaining efficient production.

02 Temperature control during stretch blow molding

Precise temperature control during the stretch blow molding process is essential for achieving desired bottle properties. This includes preform heating, mold temperature management, and cooling strategies. Proper temperature control can improve material distribution, enhance clarity, and optimize bottle performance.Expand Specific Solutions03 Mold design for stretch blow molding

The design of the mold plays a significant role in determining the final bottle shape and properties. Considerations include mold cavity shape, venting systems, and cooling channels. Innovative mold designs can improve bottle quality, reduce cycle times, and enhance production efficiency.Expand Specific Solutions04 Process parameters optimization

Optimizing process parameters such as stretch ratios, blow pressure, and timing is crucial for producing high-quality bottles. Fine-tuning these parameters can improve material distribution, enhance bottle strength, and minimize defects. Advanced control systems and simulation tools can aid in process optimization.Expand Specific Solutions05 Innovative bottle designs for specific applications

Developing innovative bottle designs for specific applications, such as hot-fill bottles, lightweight containers, or bottles with complex shapes. These designs may incorporate features like vacuum panels, reinforcing structures, or unique aesthetic elements to meet specific market demands or functional requirements.Expand Specific Solutions

Key Industry Players

The stretch blow molding market for polypropylene bottle designs is in a growth phase, driven by increasing demand for lightweight, durable packaging solutions. The global market size is expanding, with key players like Total Petrochemicals & Refining USA, Basell Polyolefine GmbH, and ALPLA Werke Alwin Lehner GmbH & Co. KG leading innovation. Technological maturity varies, with companies like ExxonMobil Chemical Patents and BASF Corp. advancing material properties, while Sidel Participations SAS and SMI SpA focus on machinery improvements. The industry is seeing a shift towards more sustainable and cost-effective solutions, with NatureWorks LLC exploring bio-based alternatives, indicating a dynamic and competitive landscape.

Total Petrochemicals & Refining USA, Inc.

Technical Solution: Total Petrochemicals has developed a specialized polypropylene (PP) grade for stretch blow molding applications. Their PP grade exhibits enhanced melt strength and strain hardening behavior, crucial for successful stretch blow molding. The company utilizes a proprietary catalyst system and polymerization process to achieve a controlled molecular weight distribution and long-chain branching in the PP structure[1]. This results in improved processability and better bottle performance. Total's PP grade demonstrates excellent clarity, impact resistance, and barrier properties, making it suitable for various bottle designs[2]. The company has also implemented advanced thermal management techniques during the stretch blow molding process to optimize material distribution and achieve uniform wall thickness[3].

Strengths: Excellent melt strength, improved processability, and enhanced bottle performance. Weaknesses: May require specialized equipment for optimal processing, potentially higher material cost compared to standard PP grades.

Toyo Seikan Co., Ltd.

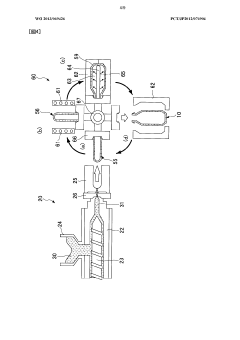

Technical Solution: Toyo Seikan has developed a multi-layer stretch blow molding technology for PP bottles. Their approach involves co-extruding multiple layers of PP with different properties to achieve optimal performance. The inner layer is designed for chemical resistance and product compatibility, while the outer layer focuses on impact resistance and aesthetics. A tie layer is used to ensure strong adhesion between the layers[4]. Toyo Seikan's process incorporates a controlled preform heating system that allows for precise temperature control of each layer during stretching. This results in improved material distribution and reduced thickness variations. The company has also implemented a novel air pressure control system during the blowing phase to achieve complex bottle shapes while maintaining structural integrity[5].

Strengths: Excellent barrier properties, customizable performance, and ability to create complex bottle designs. Weaknesses: Higher production complexity and potentially increased manufacturing costs.

Core PP SBM Innovations

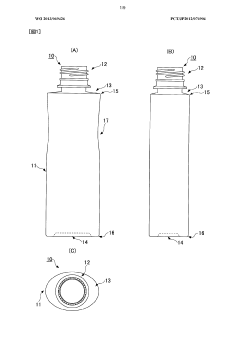

Container manufacturing method and container

PatentWO2013069426A1

Innovation

- A manufacturing method involving injection stretch blow molding, where the polypropylene resin composition is cooled to a temperature below its crystallization temperature in the injection mold and then stretch blow molded, optimizing the cooling process to enhance transparency and maintain strength.

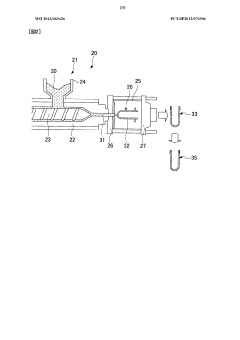

Stretch-blow molded polypropylene article

PatentInactiveUS20080038500A1

Innovation

- A two-stage process involving precise control of preform temperature uniformity through optimized reflector design in the reheat oven, ensuring a temperature delta of no more than 10°C around the circumference, combined with high-speed stretch blow molding to produce polypropylene bottles with minimal wall thickness variation.

Material Properties

Polypropylene (PP) is a versatile thermoplastic polymer widely used in various applications, including bottle manufacturing. When considering stretch blow molding for PP bottle designs, understanding the material properties is crucial for optimizing the production process and ensuring the final product's quality.

PP exhibits a unique combination of properties that make it suitable for bottle production. It has a relatively low density, ranging from 0.895 to 0.92 g/cm³, which contributes to lightweight bottle designs. This characteristic is particularly advantageous for reducing transportation costs and improving overall sustainability. Additionally, PP possesses excellent chemical resistance, making it ideal for packaging a wide range of products, including household chemicals, personal care items, and certain food products.

The mechanical properties of PP are essential considerations in stretch blow molding. PP has a moderate tensile strength, typically ranging from 30 to 40 MPa, which provides sufficient durability for bottle applications. Its elongation at break can vary from 100% to 600%, depending on the specific grade and processing conditions. This high elongation capability is crucial for the stretching phase of the blow molding process, allowing for significant material deformation without failure.

Thermal properties play a significant role in the stretch blow molding of PP bottles. The material's melting point, approximately 160-165°C, influences the processing temperature range. The relatively high crystallinity of PP, which can reach up to 65%, affects its thermal behavior during cooling and solidification. This crystallinity contributes to the material's stiffness and barrier properties but can also impact the clarity of the final product.

PP's low thermal conductivity, around 0.22 W/(m·K), affects the heating and cooling rates during the molding process. This property necessitates careful temperature control to ensure uniform heating of the preform and efficient cooling of the blown bottle. The material's specific heat capacity, approximately 1.9 kJ/(kg·K), also influences the energy requirements for processing.

The rheological properties of PP are critical for successful stretch blow molding. The material's melt flow index (MFI), typically ranging from 2 to 35 g/10 min for bottle-grade PP, affects its processability. A lower MFI generally indicates higher molecular weight and better stretch properties, which can be advantageous for achieving the desired bottle shape and wall thickness distribution.

Understanding these material properties is essential for optimizing the stretch blow molding process parameters, such as preform design, heating profile, stretching ratio, and blowing pressure. By carefully considering these properties, manufacturers can develop PP bottle designs that meet performance requirements while maximizing production efficiency and product quality.

PP exhibits a unique combination of properties that make it suitable for bottle production. It has a relatively low density, ranging from 0.895 to 0.92 g/cm³, which contributes to lightweight bottle designs. This characteristic is particularly advantageous for reducing transportation costs and improving overall sustainability. Additionally, PP possesses excellent chemical resistance, making it ideal for packaging a wide range of products, including household chemicals, personal care items, and certain food products.

The mechanical properties of PP are essential considerations in stretch blow molding. PP has a moderate tensile strength, typically ranging from 30 to 40 MPa, which provides sufficient durability for bottle applications. Its elongation at break can vary from 100% to 600%, depending on the specific grade and processing conditions. This high elongation capability is crucial for the stretching phase of the blow molding process, allowing for significant material deformation without failure.

Thermal properties play a significant role in the stretch blow molding of PP bottles. The material's melting point, approximately 160-165°C, influences the processing temperature range. The relatively high crystallinity of PP, which can reach up to 65%, affects its thermal behavior during cooling and solidification. This crystallinity contributes to the material's stiffness and barrier properties but can also impact the clarity of the final product.

PP's low thermal conductivity, around 0.22 W/(m·K), affects the heating and cooling rates during the molding process. This property necessitates careful temperature control to ensure uniform heating of the preform and efficient cooling of the blown bottle. The material's specific heat capacity, approximately 1.9 kJ/(kg·K), also influences the energy requirements for processing.

The rheological properties of PP are critical for successful stretch blow molding. The material's melt flow index (MFI), typically ranging from 2 to 35 g/10 min for bottle-grade PP, affects its processability. A lower MFI generally indicates higher molecular weight and better stretch properties, which can be advantageous for achieving the desired bottle shape and wall thickness distribution.

Understanding these material properties is essential for optimizing the stretch blow molding process parameters, such as preform design, heating profile, stretching ratio, and blowing pressure. By carefully considering these properties, manufacturers can develop PP bottle designs that meet performance requirements while maximizing production efficiency and product quality.

Sustainability Aspects

Sustainability has become a critical consideration in the development of packaging solutions, including polypropylene (PP) bottles produced through stretch blow molding. The environmental impact of plastic packaging has led to increased scrutiny and demand for more sustainable alternatives. In the context of PP bottle designs, several sustainability aspects must be addressed to ensure the long-term viability and eco-friendliness of the product.

One of the primary sustainability concerns is the recyclability of PP bottles. While polypropylene is a recyclable material, the efficiency of recycling processes and the availability of recycling infrastructure vary significantly across regions. Improving the recyclability of PP bottles involves optimizing the design for easy separation of components, minimizing the use of additives that may hinder recycling, and ensuring compatibility with existing recycling streams.

The use of recycled content in PP bottle production is another crucial aspect of sustainability. Incorporating post-consumer recycled (PCR) polypropylene into new bottles can significantly reduce the environmental footprint of the packaging. However, challenges such as maintaining material properties and meeting food-contact regulations must be addressed when using recycled content in stretch blow molded PP bottles.

Weight reduction is a key strategy for improving the sustainability of PP bottle designs. By optimizing the bottle's structure and wall thickness distribution through advanced stretch blow molding techniques, manufacturers can reduce the amount of material used without compromising performance. This not only conserves resources but also reduces transportation-related emissions throughout the supply chain.

The potential for bio-based or biodegradable alternatives to traditional polypropylene is an area of growing interest. While fully bio-based PP is not yet commercially viable, partially bio-based options are being explored. Additionally, the development of biodegradable additives that can enhance the environmental breakdown of PP bottles without compromising recyclability is an active area of research.

Energy efficiency in the stretch blow molding process itself is another important sustainability consideration. Innovations in machine design, process optimization, and the use of renewable energy sources can significantly reduce the carbon footprint associated with PP bottle production. This includes improvements in heating systems, air compression efficiency, and overall cycle time reduction.

Lastly, the end-of-life management of PP bottles plays a crucial role in their overall sustainability profile. Designing bottles for easy disassembly, promoting consumer education on proper disposal, and supporting the development of advanced recycling technologies are all essential components of a comprehensive sustainability strategy for PP bottle designs produced through stretch blow molding.

One of the primary sustainability concerns is the recyclability of PP bottles. While polypropylene is a recyclable material, the efficiency of recycling processes and the availability of recycling infrastructure vary significantly across regions. Improving the recyclability of PP bottles involves optimizing the design for easy separation of components, minimizing the use of additives that may hinder recycling, and ensuring compatibility with existing recycling streams.

The use of recycled content in PP bottle production is another crucial aspect of sustainability. Incorporating post-consumer recycled (PCR) polypropylene into new bottles can significantly reduce the environmental footprint of the packaging. However, challenges such as maintaining material properties and meeting food-contact regulations must be addressed when using recycled content in stretch blow molded PP bottles.

Weight reduction is a key strategy for improving the sustainability of PP bottle designs. By optimizing the bottle's structure and wall thickness distribution through advanced stretch blow molding techniques, manufacturers can reduce the amount of material used without compromising performance. This not only conserves resources but also reduces transportation-related emissions throughout the supply chain.

The potential for bio-based or biodegradable alternatives to traditional polypropylene is an area of growing interest. While fully bio-based PP is not yet commercially viable, partially bio-based options are being explored. Additionally, the development of biodegradable additives that can enhance the environmental breakdown of PP bottles without compromising recyclability is an active area of research.

Energy efficiency in the stretch blow molding process itself is another important sustainability consideration. Innovations in machine design, process optimization, and the use of renewable energy sources can significantly reduce the carbon footprint associated with PP bottle production. This includes improvements in heating systems, air compression efficiency, and overall cycle time reduction.

Lastly, the end-of-life management of PP bottles plays a crucial role in their overall sustainability profile. Designing bottles for easy disassembly, promoting consumer education on proper disposal, and supporting the development of advanced recycling technologies are all essential components of a comprehensive sustainability strategy for PP bottle designs produced through stretch blow molding.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!