ITO Free Electrode: Applications in Smart Windows

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ITO-Free Electrode Technology Background and Objectives

Transparent conductive electrodes (TCEs) have been a cornerstone in optoelectronic devices for decades, with indium tin oxide (ITO) dominating the market since the 1950s. ITO's unique combination of high optical transparency and electrical conductivity has made it the standard material for applications ranging from touch screens to solar cells. However, the growing demand for flexible electronics, coupled with indium's scarcity and rising costs, has intensified the search for alternative materials in recent years.

The evolution of ITO-free electrode technology has been driven by several factors. Initially, research focused on addressing ITO's brittleness, which limits its application in flexible devices. Subsequently, concerns about indium supply constraints emerged, as indium is classified as a critical raw material with limited global reserves. The development trajectory has accelerated in the past decade, with significant breakthroughs in nanomaterials science enabling viable alternatives.

Smart windows represent a particularly promising application area for ITO-free electrodes. These advanced glazing systems can dynamically control light transmission and heat flow, potentially reducing building energy consumption by 20-40%. The global smart window market is projected to reach $8.5 billion by 2026, with a compound annual growth rate exceeding 15%, highlighting the significant commercial opportunity.

The primary technical objectives for ITO-free electrodes in smart window applications include achieving comparable or superior performance to ITO in terms of transparency (>90% in the visible spectrum) and sheet resistance (<10 Ω/sq), while offering additional benefits such as mechanical flexibility, reduced production costs, and environmental sustainability. Durability under varying environmental conditions is particularly critical for smart window applications, with expected lifespans of 20+ years.

Current research is focused on several promising alternative materials, including silver nanowire networks, carbon-based materials (graphene, carbon nanotubes), conductive polymers (PEDOT:PSS), and metal mesh structures. Each offers distinct advantages and challenges in terms of optical, electrical, and mechanical properties. The integration of these materials into existing manufacturing processes represents a significant technical hurdle that must be overcome for widespread commercial adoption.

The ultimate goal of ITO-free electrode development for smart windows is to enable a new generation of energy-efficient, cost-effective, and environmentally sustainable building components that can be deployed at scale in both new construction and retrofitting applications. Success in this domain could significantly impact global energy consumption patterns and accelerate the transition toward more sustainable built environments.

The evolution of ITO-free electrode technology has been driven by several factors. Initially, research focused on addressing ITO's brittleness, which limits its application in flexible devices. Subsequently, concerns about indium supply constraints emerged, as indium is classified as a critical raw material with limited global reserves. The development trajectory has accelerated in the past decade, with significant breakthroughs in nanomaterials science enabling viable alternatives.

Smart windows represent a particularly promising application area for ITO-free electrodes. These advanced glazing systems can dynamically control light transmission and heat flow, potentially reducing building energy consumption by 20-40%. The global smart window market is projected to reach $8.5 billion by 2026, with a compound annual growth rate exceeding 15%, highlighting the significant commercial opportunity.

The primary technical objectives for ITO-free electrodes in smart window applications include achieving comparable or superior performance to ITO in terms of transparency (>90% in the visible spectrum) and sheet resistance (<10 Ω/sq), while offering additional benefits such as mechanical flexibility, reduced production costs, and environmental sustainability. Durability under varying environmental conditions is particularly critical for smart window applications, with expected lifespans of 20+ years.

Current research is focused on several promising alternative materials, including silver nanowire networks, carbon-based materials (graphene, carbon nanotubes), conductive polymers (PEDOT:PSS), and metal mesh structures. Each offers distinct advantages and challenges in terms of optical, electrical, and mechanical properties. The integration of these materials into existing manufacturing processes represents a significant technical hurdle that must be overcome for widespread commercial adoption.

The ultimate goal of ITO-free electrode development for smart windows is to enable a new generation of energy-efficient, cost-effective, and environmentally sustainable building components that can be deployed at scale in both new construction and retrofitting applications. Success in this domain could significantly impact global energy consumption patterns and accelerate the transition toward more sustainable built environments.

Smart Window Market Analysis and Growth Potential

The global smart window market is experiencing robust growth, driven by increasing demand for energy-efficient building solutions and technological advancements in materials science. Currently valued at approximately 5.8 billion USD in 2023, the market is projected to reach 10.3 billion USD by 2028, representing a compound annual growth rate (CAGR) of 12.2%. This significant expansion reflects the growing adoption of smart windows across various sectors, particularly in commercial buildings, residential construction, and automotive applications.

The commercial building segment dominates the market share, accounting for nearly 45% of total demand. This is primarily due to the increasing focus on green building certifications such as LEED and BREEAM, which award points for energy-efficient façade solutions. Smart windows with ITO-free electrodes are particularly attractive in this segment as they offer superior energy savings while meeting sustainability requirements.

Geographically, North America leads the market with approximately 38% share, followed by Europe at 31% and Asia-Pacific at 24%. The Asia-Pacific region, however, is expected to witness the fastest growth rate of 15.7% annually through 2028, driven by rapid urbanization, increasing construction activities, and growing environmental awareness in countries like China, Japan, and South Korea.

The residential sector represents an emerging opportunity, currently accounting for about 22% of the market but growing at 14.3% annually. Homeowners are increasingly recognizing the benefits of smart windows in reducing energy costs and enhancing comfort, particularly as prices become more accessible to mainstream consumers.

Key market drivers include stringent building energy codes, rising energy costs, and increasing awareness of the environmental impact of buildings. The European Union's Energy Performance of Buildings Directive and similar regulations worldwide are creating regulatory tailwinds for smart window adoption. Additionally, the growing focus on occupant comfort and productivity in commercial spaces is driving demand for dynamic glazing solutions.

The automotive sector represents another significant growth avenue, particularly for premium vehicles where smart windows are increasingly being incorporated as standard features. This segment is expected to grow at 13.8% annually, reaching 1.8 billion USD by 2028.

ITO-free electrode technology specifically addresses several market pain points, including cost barriers and sustainability concerns associated with traditional smart windows. By eliminating the need for scarce indium, this technology has the potential to reduce manufacturing costs by 15-20% while improving environmental credentials, thereby accelerating market penetration across all segments.

The commercial building segment dominates the market share, accounting for nearly 45% of total demand. This is primarily due to the increasing focus on green building certifications such as LEED and BREEAM, which award points for energy-efficient façade solutions. Smart windows with ITO-free electrodes are particularly attractive in this segment as they offer superior energy savings while meeting sustainability requirements.

Geographically, North America leads the market with approximately 38% share, followed by Europe at 31% and Asia-Pacific at 24%. The Asia-Pacific region, however, is expected to witness the fastest growth rate of 15.7% annually through 2028, driven by rapid urbanization, increasing construction activities, and growing environmental awareness in countries like China, Japan, and South Korea.

The residential sector represents an emerging opportunity, currently accounting for about 22% of the market but growing at 14.3% annually. Homeowners are increasingly recognizing the benefits of smart windows in reducing energy costs and enhancing comfort, particularly as prices become more accessible to mainstream consumers.

Key market drivers include stringent building energy codes, rising energy costs, and increasing awareness of the environmental impact of buildings. The European Union's Energy Performance of Buildings Directive and similar regulations worldwide are creating regulatory tailwinds for smart window adoption. Additionally, the growing focus on occupant comfort and productivity in commercial spaces is driving demand for dynamic glazing solutions.

The automotive sector represents another significant growth avenue, particularly for premium vehicles where smart windows are increasingly being incorporated as standard features. This segment is expected to grow at 13.8% annually, reaching 1.8 billion USD by 2028.

ITO-free electrode technology specifically addresses several market pain points, including cost barriers and sustainability concerns associated with traditional smart windows. By eliminating the need for scarce indium, this technology has the potential to reduce manufacturing costs by 15-20% while improving environmental credentials, thereby accelerating market penetration across all segments.

Current Status and Technical Barriers of ITO-Free Electrodes

The global market for ITO-free electrodes has witnessed significant growth in recent years, particularly in smart window applications. Currently, several alternative materials have emerged as potential replacements for the conventional Indium Tin Oxide (ITO) electrodes. Among these, metal nanowires (particularly silver nanowires), conductive polymers (PEDOT:PSS), carbon-based materials (graphene and carbon nanotubes), and metal meshes represent the most promising candidates.

Silver nanowires have achieved commercial implementation in some smart window products, demonstrating optical transmittance exceeding 90% and sheet resistance below 20 ohms/square. However, their long-term stability remains a concern, with oxidation and mechanical durability presenting significant challenges in real-world applications. PEDOT:PSS offers excellent flexibility but suffers from relatively higher sheet resistance (typically 100-200 ohms/square) compared to ITO, limiting its application in larger-area smart windows.

Graphene-based electrodes show exceptional theoretical properties but face substantial manufacturing barriers at scale. Current production methods struggle to produce large-area, defect-free graphene films with consistent electrical properties. Carbon nanotubes offer better scalability but encounter challenges in achieving uniform dispersion and network formation across large surfaces.

The geographical distribution of ITO-free electrode technology development shows concentration in East Asia (particularly Japan, South Korea, and China), North America, and Western Europe. Chinese manufacturers have made significant progress in silver nanowire production, while European research institutions lead in conductive polymer development. North American companies have focused primarily on carbon-based alternatives and hybrid solutions.

Key technical barriers preventing widespread adoption include scalability limitations, cost-effectiveness challenges, and performance trade-offs. Most alternative materials struggle to simultaneously achieve the optical transparency, electrical conductivity, and mechanical durability that ITO provides. Manufacturing processes for alternatives often require specialized equipment or precise control parameters that increase production costs significantly.

Environmental stability represents another critical challenge, with many ITO alternatives demonstrating sensitivity to moisture, oxygen, or UV exposure. This necessitates additional encapsulation layers, further complicating device architecture and manufacturing processes. Integration challenges also persist, as existing smart window production lines are optimized for ITO-based systems, requiring significant retooling for alternative electrode materials.

Despite these challenges, recent advancements in hybrid systems combining multiple materials (such as metal nanowire/PEDOT:PSS composites) show promise in overcoming individual material limitations, potentially offering a viable path forward for commercial implementation in next-generation smart windows.

Silver nanowires have achieved commercial implementation in some smart window products, demonstrating optical transmittance exceeding 90% and sheet resistance below 20 ohms/square. However, their long-term stability remains a concern, with oxidation and mechanical durability presenting significant challenges in real-world applications. PEDOT:PSS offers excellent flexibility but suffers from relatively higher sheet resistance (typically 100-200 ohms/square) compared to ITO, limiting its application in larger-area smart windows.

Graphene-based electrodes show exceptional theoretical properties but face substantial manufacturing barriers at scale. Current production methods struggle to produce large-area, defect-free graphene films with consistent electrical properties. Carbon nanotubes offer better scalability but encounter challenges in achieving uniform dispersion and network formation across large surfaces.

The geographical distribution of ITO-free electrode technology development shows concentration in East Asia (particularly Japan, South Korea, and China), North America, and Western Europe. Chinese manufacturers have made significant progress in silver nanowire production, while European research institutions lead in conductive polymer development. North American companies have focused primarily on carbon-based alternatives and hybrid solutions.

Key technical barriers preventing widespread adoption include scalability limitations, cost-effectiveness challenges, and performance trade-offs. Most alternative materials struggle to simultaneously achieve the optical transparency, electrical conductivity, and mechanical durability that ITO provides. Manufacturing processes for alternatives often require specialized equipment or precise control parameters that increase production costs significantly.

Environmental stability represents another critical challenge, with many ITO alternatives demonstrating sensitivity to moisture, oxygen, or UV exposure. This necessitates additional encapsulation layers, further complicating device architecture and manufacturing processes. Integration challenges also persist, as existing smart window production lines are optimized for ITO-based systems, requiring significant retooling for alternative electrode materials.

Despite these challenges, recent advancements in hybrid systems combining multiple materials (such as metal nanowire/PEDOT:PSS composites) show promise in overcoming individual material limitations, potentially offering a viable path forward for commercial implementation in next-generation smart windows.

Current ITO-Free Solutions for Smart Window Applications

01 Carbon-based materials as ITO alternatives

Carbon-based materials such as graphene, carbon nanotubes (CNTs), and carbon composites are being used as alternatives to ITO for transparent electrodes. These materials offer high conductivity, flexibility, and optical transparency while avoiding the brittleness and scarcity issues associated with indium. Carbon-based electrodes can be fabricated through various deposition methods and can be integrated into flexible electronic devices.- Carbon-based ITO alternatives: Carbon-based materials such as graphene, carbon nanotubes (CNTs), and carbon composites are being used as alternatives to ITO for transparent electrodes. These materials offer advantages including flexibility, durability, and comparable conductivity while avoiding the scarcity and brittleness issues associated with indium. Carbon-based electrodes can be fabricated through various deposition methods and can be integrated into flexible electronic devices.

- Metal nanowire electrodes: Metal nanowires, particularly silver nanowires, are being developed as ITO-free electrode materials. These nanowires form conductive networks that maintain high transparency while providing excellent electrical conductivity. The fabrication typically involves solution processing methods that are more cost-effective than traditional ITO deposition. These electrodes demonstrate superior flexibility and can be used in bendable displays, touch panels, and photovoltaic devices.

- Conductive polymer electrodes: Conductive polymers such as PEDOT:PSS and polyaniline are being utilized as organic alternatives to ITO. These materials can be solution-processed at low temperatures, making them compatible with flexible substrates and roll-to-roll manufacturing. While traditionally less conductive than ITO, recent advancements in doping and processing have significantly improved their performance. These polymer electrodes are particularly suitable for organic electronics and can be combined with other materials to enhance conductivity.

- Metal mesh and grid electrodes: Metal mesh or grid structures are being implemented as ITO replacements, featuring patterned metal lines that are thin enough to maintain transparency while providing electrical conductivity. These can be fabricated using various techniques including photolithography, printing, and laser patterning. The mesh design allows for optimization of the trade-off between transparency and conductivity. These electrodes demonstrate excellent mechanical flexibility and can be manufactured at lower costs compared to ITO.

- Metal oxide composites: Alternative metal oxide composites that don't contain indium are being developed as ITO replacements. These include materials such as aluminum-doped zinc oxide (AZO), fluorine-doped tin oxide (FTO), and various other doped metal oxides. These materials aim to provide similar optical and electrical properties to ITO while using more abundant elements. The fabrication methods include sputtering, sol-gel processes, and chemical vapor deposition, with ongoing research focused on improving their stability and conductivity.

02 Metal nanowire networks for transparent electrodes

Metal nanowire networks, particularly those made from silver, copper, or gold, provide an effective ITO-free electrode solution. These nanowires form conductive meshes that maintain high transparency while achieving excellent electrical conductivity. The fabrication typically involves solution processing methods such as spray coating or printing, making them cost-effective alternatives. These electrodes demonstrate superior mechanical flexibility compared to ITO, making them suitable for flexible display and touch panel applications.Expand Specific Solutions03 Conductive polymers as flexible electrode materials

Conductive polymers such as PEDOT:PSS, polyaniline, and polythiophene derivatives are being developed as ITO-free electrode materials. These organic materials offer advantages including solution processability, mechanical flexibility, and compatibility with roll-to-roll manufacturing. While traditionally less conductive than ITO, recent advancements in doping and formulation have significantly improved their conductivity while maintaining high transparency, making them viable alternatives for flexible electronics and optoelectronic devices.Expand Specific Solutions04 Metal oxide alternatives to ITO

Alternative metal oxide materials are being developed to replace ITO while maintaining similar optical and electrical properties. These include aluminum-doped zinc oxide (AZO), fluorine-doped tin oxide (FTO), and gallium-doped zinc oxide (GZO). These materials offer comparable transparency and conductivity to ITO but utilize more abundant elements, potentially reducing costs. Various deposition techniques including sputtering, chemical vapor deposition, and sol-gel methods are used to create these alternative transparent conductive oxide films.Expand Specific Solutions05 Hybrid and composite electrode structures

Hybrid and composite electrode structures combine multiple materials to achieve superior performance compared to single-material electrodes. These may include metal grid/mesh structures combined with conductive polymers, metal nanowires embedded in transparent matrices, or multilayer structures of different conductive materials. Such hybrid approaches can overcome the limitations of individual materials, offering optimized combinations of transparency, conductivity, flexibility, and cost-effectiveness for various applications including displays, solar cells, and touch panels.Expand Specific Solutions

Leading Companies and Research Institutions in ITO Alternatives

The ITO Free Electrode market for smart windows is currently in an early growth phase, characterized by increasing R&D investments and emerging commercial applications. The global market size is projected to expand significantly as energy-efficient building solutions gain traction, with estimates suggesting a compound annual growth rate exceeding 15% through 2030. Technologically, the field shows moderate maturity with several key players advancing different approaches. Samsung Display, LG Chem, and Eastman Kodak lead commercial development with established intellectual property portfolios, while research institutions like Harbin Institute of Technology and National Institute for Materials Science provide fundamental innovations. TDK Corp and Corning Precision Materials are leveraging their materials expertise to develop specialized electrode solutions, positioning themselves as critical component suppliers in this evolving ecosystem.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed advanced ITO-free electrode technology for smart windows using metal mesh structures. Their approach utilizes ultra-thin silver nanowire networks that achieve over 90% transparency while maintaining conductivity comparable to traditional ITO. Samsung's solution incorporates a proprietary polymer matrix that encapsulates the nanowires, enhancing durability against environmental factors and repeated switching cycles. The company has integrated this technology with their electrochromic and PDLC (Polymer Dispersed Liquid Crystal) smart window systems, enabling precise control of light transmission and energy efficiency. Their manufacturing process employs roll-to-roll techniques that significantly reduce production costs compared to vacuum-based ITO deposition methods, making large-area smart windows economically viable for commercial applications.

Strengths: Superior flexibility allowing application on curved surfaces; cost-effective large-area production capability; excellent optical transparency with minimal haze. Weaknesses: Potential long-term stability issues in extreme weather conditions; higher sheet resistance compared to some competing technologies; requires specialized handling during installation.

LG Chem Ltd.

Technical Solution: LG Chem has developed a sophisticated ITO-free electrode technology for smart windows utilizing their proprietary conductive polymer composites. Their approach combines PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) with silver nanowires in a multilayer structure that achieves sheet resistance of approximately 25 ohms/square while maintaining transparency above 85%. LG's manufacturing process employs solution-based coating techniques compatible with existing glass production lines, significantly reducing implementation costs. For smart window applications, LG Chem has integrated this electrode technology with their advanced electrochromic materials, creating a system capable of modulating visible light transmission from 75% to below 10% with switching times under 4 minutes. Their smart window solution incorporates a specialized ion storage layer that enhances cycling stability, demonstrating less than 5% performance degradation after 50,000 switching cycles. The system operates at low voltages (1-3V) and consumes minimal power (approximately 0.05 W/m² during transitions), making it highly energy efficient for building applications. LG Chem has successfully implemented this technology in commercial projects, demonstrating energy savings of 20-25% in cooling costs compared to conventional glazing.

Strengths: Excellent compatibility with existing manufacturing infrastructure; superior cycling stability for long-term applications; low power consumption ideal for energy-efficient buildings. Weaknesses: Slightly lower transparency compared to some competing technologies; potential degradation under extreme UV exposure; limited color neutrality in darkened states.

Key Patents and Innovations in Alternative Transparent Conductors

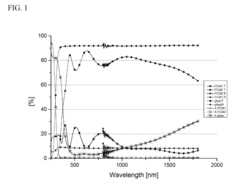

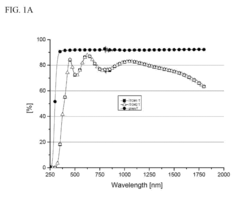

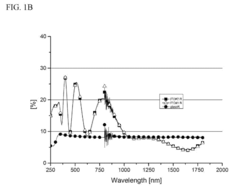

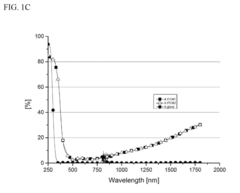

Indium Tin Oxide Thin Films With Both Near-Infrared Transparency and Excellent Resistivity

PatentActiveUS20170306470A1

Innovation

- A low-energy sputter deposition process is used to produce an ITO film with a low carrier concentration and high carrier mobility, achieved by using a 90:10 In2O3:SnO2 target with argon as the sputter gas, optimizing power and pressure to achieve a 350 nm thickness, resulting in high near-IR transparency and low resistivity.

Environmental Impact and Sustainability Assessment

The environmental impact of ITO (Indium Tin Oxide) free electrodes in smart window applications represents a significant advancement in sustainable building technology. Traditional ITO-based electrodes rely on indium, a rare earth element with limited global reserves and environmentally problematic extraction processes. Mining operations for indium generate substantial carbon emissions, contribute to habitat destruction, and often involve toxic chemicals that contaminate local water sources and soil.

ITO-free alternatives significantly reduce these environmental burdens by utilizing more abundant materials such as silver nanowires, carbon nanotubes, graphene, and conductive polymers. Life cycle assessments indicate that these alternatives can reduce the carbon footprint of smart window production by 30-45% compared to conventional ITO-based systems. The elimination of indium dependency also addresses critical supply chain vulnerabilities and reduces the geopolitical tensions associated with rare earth element procurement.

From a manufacturing perspective, many ITO-free electrode technologies employ solution-based processing methods that consume less energy and generate fewer hazardous byproducts than the vacuum deposition techniques required for ITO. These more efficient production processes translate to approximately 25% lower embodied energy in the final product, contributing to overall building sustainability metrics.

In operational contexts, smart windows incorporating ITO-free electrodes maintain the energy-saving benefits of traditional electrochromic systems while potentially offering enhanced durability. This longevity factor is crucial for sustainability assessments, as extended product lifecycles significantly reduce waste generation and resource consumption associated with replacement and maintenance.

The end-of-life considerations also favor ITO-free technologies. While recycling infrastructure for these newer materials remains under development, the absence of rare earth elements simplifies potential recovery processes. Several ITO-free electrode materials show promising recyclability characteristics, with laboratory studies demonstrating material recovery rates exceeding 80% for certain carbon-based and polymer systems.

Regulatory frameworks increasingly recognize these environmental advantages, with several green building certification programs now awarding additional points for ITO-free smart window implementations. This regulatory support accelerates market adoption and further incentivizes research into even more sustainable electrode materials and manufacturing processes, creating a positive feedback loop for environmental innovation in the smart building sector.

ITO-free alternatives significantly reduce these environmental burdens by utilizing more abundant materials such as silver nanowires, carbon nanotubes, graphene, and conductive polymers. Life cycle assessments indicate that these alternatives can reduce the carbon footprint of smart window production by 30-45% compared to conventional ITO-based systems. The elimination of indium dependency also addresses critical supply chain vulnerabilities and reduces the geopolitical tensions associated with rare earth element procurement.

From a manufacturing perspective, many ITO-free electrode technologies employ solution-based processing methods that consume less energy and generate fewer hazardous byproducts than the vacuum deposition techniques required for ITO. These more efficient production processes translate to approximately 25% lower embodied energy in the final product, contributing to overall building sustainability metrics.

In operational contexts, smart windows incorporating ITO-free electrodes maintain the energy-saving benefits of traditional electrochromic systems while potentially offering enhanced durability. This longevity factor is crucial for sustainability assessments, as extended product lifecycles significantly reduce waste generation and resource consumption associated with replacement and maintenance.

The end-of-life considerations also favor ITO-free technologies. While recycling infrastructure for these newer materials remains under development, the absence of rare earth elements simplifies potential recovery processes. Several ITO-free electrode materials show promising recyclability characteristics, with laboratory studies demonstrating material recovery rates exceeding 80% for certain carbon-based and polymer systems.

Regulatory frameworks increasingly recognize these environmental advantages, with several green building certification programs now awarding additional points for ITO-free smart window implementations. This regulatory support accelerates market adoption and further incentivizes research into even more sustainable electrode materials and manufacturing processes, creating a positive feedback loop for environmental innovation in the smart building sector.

Manufacturing Scalability and Cost Analysis

The scalability of ITO-free electrode manufacturing processes represents a critical factor in the widespread adoption of smart window technologies. Current production methods for traditional ITO-based electrodes involve high-temperature vacuum deposition techniques that require significant capital investment and energy consumption. In contrast, several ITO-free alternatives offer potentially more scalable manufacturing routes. Silver nanowire networks can be deposited using solution-based processes such as roll-to-roll printing, spray coating, or slot-die coating, which are compatible with high-throughput production lines.

PEDOT:PSS conductive polymers present another scalable alternative, as they can be applied using conventional coating methods at ambient temperatures. However, challenges remain in achieving uniform electrical properties across large surface areas, particularly for window applications exceeding one square meter. The stability of these materials in industrial manufacturing environments also requires further optimization to ensure consistent performance.

From a cost perspective, ITO-free electrodes offer significant advantages. ITO production relies on indium, a relatively scarce element with volatile pricing that has seen increases of up to 900% during supply shortages. Analysis indicates that material costs for silver nanowire electrodes can be 40-60% lower than ITO when produced at scale, though this advantage diminishes at lower production volumes due to higher process development costs.

Carbon-based alternatives such as graphene and carbon nanotubes present the most economically attractive long-term solution, with raw material costs potentially 70-85% lower than ITO. However, current manufacturing yields and quality control issues offset these theoretical cost advantages. Industry projections suggest that as production volumes increase, manufacturing costs for graphene-based electrodes could decrease by approximately 30% annually over the next five years.

Equipment investment requirements also differ significantly between technologies. ITO sputtering systems typically require capital expenditures of $2-5 million for production-scale equipment, while roll-to-roll printing systems for alternative electrodes can be established for $0.8-1.5 million. This lower barrier to entry may accelerate adoption among smaller manufacturers and facilitate more distributed production models.

Energy consumption analysis reveals that ITO-free manufacturing processes typically consume 40-60% less energy than vacuum-based ITO deposition, translating to both cost savings and reduced environmental impact. This factor becomes increasingly significant as environmental regulations and carbon pricing mechanisms evolve globally.

PEDOT:PSS conductive polymers present another scalable alternative, as they can be applied using conventional coating methods at ambient temperatures. However, challenges remain in achieving uniform electrical properties across large surface areas, particularly for window applications exceeding one square meter. The stability of these materials in industrial manufacturing environments also requires further optimization to ensure consistent performance.

From a cost perspective, ITO-free electrodes offer significant advantages. ITO production relies on indium, a relatively scarce element with volatile pricing that has seen increases of up to 900% during supply shortages. Analysis indicates that material costs for silver nanowire electrodes can be 40-60% lower than ITO when produced at scale, though this advantage diminishes at lower production volumes due to higher process development costs.

Carbon-based alternatives such as graphene and carbon nanotubes present the most economically attractive long-term solution, with raw material costs potentially 70-85% lower than ITO. However, current manufacturing yields and quality control issues offset these theoretical cost advantages. Industry projections suggest that as production volumes increase, manufacturing costs for graphene-based electrodes could decrease by approximately 30% annually over the next five years.

Equipment investment requirements also differ significantly between technologies. ITO sputtering systems typically require capital expenditures of $2-5 million for production-scale equipment, while roll-to-roll printing systems for alternative electrodes can be established for $0.8-1.5 million. This lower barrier to entry may accelerate adoption among smaller manufacturers and facilitate more distributed production models.

Energy consumption analysis reveals that ITO-free manufacturing processes typically consume 40-60% less energy than vacuum-based ITO deposition, translating to both cost savings and reduced environmental impact. This factor becomes increasingly significant as environmental regulations and carbon pricing mechanisms evolve globally.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!