ITO Free Electrode: The Role of Carbon Nanotubes

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CNT Electrode Technology Background and Objectives

Carbon nanotubes (CNTs) have emerged as a revolutionary material in the field of transparent conductive electrodes (TCEs), offering a promising alternative to the industry-standard indium tin oxide (ITO). The evolution of CNT electrode technology can be traced back to the early 2000s when researchers began exploring carbon-based materials as potential replacements for ITO due to concerns about indium scarcity and the brittle nature of ITO films. Over the past two decades, significant advancements in CNT synthesis, purification, and deposition techniques have transformed these materials from laboratory curiosities to commercially viable electrode materials.

The technological trajectory of CNT electrodes has been characterized by continuous improvements in conductivity, transparency, and mechanical flexibility. Early CNT electrodes suffered from high sheet resistance and limited optical transparency, making them unsuitable for many applications. However, innovations in CNT alignment, network formation, and post-treatment processes have dramatically enhanced their performance metrics, bringing them closer to or even surpassing ITO in specific applications.

Current market trends indicate a growing demand for flexible, stretchable, and durable electrodes in emerging technologies such as wearable electronics, foldable displays, and photovoltaics. This shift is driving the exploration of ITO alternatives, with CNT electrodes positioned as a leading candidate due to their exceptional mechanical properties and tunable optoelectronic characteristics.

The primary technical objectives for CNT electrode development include achieving sheet resistance below 50 ohms/square at 90% transparency, enhancing environmental stability, developing scalable and cost-effective manufacturing processes, and ensuring compatibility with existing device architectures. These targets are essential for enabling CNT electrodes to compete effectively with ITO in mainstream applications while opening new possibilities in flexible electronics.

Recent breakthroughs in CNT sorting techniques, hybrid structures combining CNTs with other nanomaterials, and novel doping strategies have accelerated progress toward these objectives. Particularly promising are approaches that leverage the synergistic effects of CNTs with graphene, metal nanowires, or conductive polymers to overcome the inherent limitations of single-material systems.

Looking forward, the technology roadmap for CNT electrodes focuses on addressing remaining challenges in uniformity, scalability, and integration while exploiting unique advantages such as stretchability, solution processability, and compatibility with roll-to-roll manufacturing. The ultimate goal is to establish CNT-based electrodes as a versatile platform technology that can not only replace ITO in conventional applications but also enable next-generation devices with unprecedented form factors and functionalities.

The technological trajectory of CNT electrodes has been characterized by continuous improvements in conductivity, transparency, and mechanical flexibility. Early CNT electrodes suffered from high sheet resistance and limited optical transparency, making them unsuitable for many applications. However, innovations in CNT alignment, network formation, and post-treatment processes have dramatically enhanced their performance metrics, bringing them closer to or even surpassing ITO in specific applications.

Current market trends indicate a growing demand for flexible, stretchable, and durable electrodes in emerging technologies such as wearable electronics, foldable displays, and photovoltaics. This shift is driving the exploration of ITO alternatives, with CNT electrodes positioned as a leading candidate due to their exceptional mechanical properties and tunable optoelectronic characteristics.

The primary technical objectives for CNT electrode development include achieving sheet resistance below 50 ohms/square at 90% transparency, enhancing environmental stability, developing scalable and cost-effective manufacturing processes, and ensuring compatibility with existing device architectures. These targets are essential for enabling CNT electrodes to compete effectively with ITO in mainstream applications while opening new possibilities in flexible electronics.

Recent breakthroughs in CNT sorting techniques, hybrid structures combining CNTs with other nanomaterials, and novel doping strategies have accelerated progress toward these objectives. Particularly promising are approaches that leverage the synergistic effects of CNTs with graphene, metal nanowires, or conductive polymers to overcome the inherent limitations of single-material systems.

Looking forward, the technology roadmap for CNT electrodes focuses on addressing remaining challenges in uniformity, scalability, and integration while exploiting unique advantages such as stretchability, solution processability, and compatibility with roll-to-roll manufacturing. The ultimate goal is to establish CNT-based electrodes as a versatile platform technology that can not only replace ITO in conventional applications but also enable next-generation devices with unprecedented form factors and functionalities.

Market Analysis for ITO-Free Transparent Conductors

The transparent conductor market is experiencing significant transformation as alternatives to Indium Tin Oxide (ITO) gain traction. The global transparent conductive film market was valued at approximately $6.9 billion in 2022 and is projected to reach $12.5 billion by 2028, growing at a CAGR of 10.4%. This growth is primarily driven by increasing demand for touchscreens, displays, photovoltaics, and emerging flexible electronics applications.

ITO has traditionally dominated this market with over 80% market share due to its excellent combination of optical transparency and electrical conductivity. However, several market factors are accelerating the shift toward ITO-free alternatives, particularly carbon nanotube (CNT) based solutions. The rising cost of indium, classified as a critical raw material with supply constraints primarily from China (which controls about 60% of global production), has created price volatility and supply chain vulnerabilities for manufacturers.

The consumer electronics segment represents the largest application area, accounting for approximately 45% of the transparent conductor market. Smartphone and tablet manufacturers are increasingly seeking ITO alternatives that can enable next-generation flexible, foldable, and stretchable devices - applications where traditional ITO's brittleness presents significant limitations. Major players like Samsung and Apple have already begun incorporating ITO alternatives in selected product lines.

The photovoltaic sector presents another high-growth opportunity, expected to expand at 12.3% CAGR through 2028. As solar technology evolves toward thin-film, flexible, and building-integrated applications, CNT-based transparent conductors offer compelling advantages in cost, flexibility, and environmental sustainability.

Regional analysis shows Asia-Pacific dominating the market with 65% share, driven by the concentration of display and electronics manufacturing. North America and Europe follow with 18% and 12% respectively, with higher growth rates in these regions attributed to advanced research activities and emerging applications in automotive displays and smart architecture.

Carbon nanotube-based transparent conductors currently hold approximately 5% of the overall market but are experiencing the fastest growth rate among all ITO alternatives at 18.7% CAGR. Industry analysts project CNT solutions could capture up to 15% market share by 2030, particularly in flexible electronics applications where they demonstrate superior performance-to-cost ratio compared to other alternatives like silver nanowires, conductive polymers, and graphene.

The market is further influenced by sustainability considerations, with CNT-based solutions offering reduced environmental impact compared to ITO, which requires energy-intensive sputtering processes. This aligns with increasing regulatory pressure and corporate sustainability initiatives across major electronics markets.

ITO has traditionally dominated this market with over 80% market share due to its excellent combination of optical transparency and electrical conductivity. However, several market factors are accelerating the shift toward ITO-free alternatives, particularly carbon nanotube (CNT) based solutions. The rising cost of indium, classified as a critical raw material with supply constraints primarily from China (which controls about 60% of global production), has created price volatility and supply chain vulnerabilities for manufacturers.

The consumer electronics segment represents the largest application area, accounting for approximately 45% of the transparent conductor market. Smartphone and tablet manufacturers are increasingly seeking ITO alternatives that can enable next-generation flexible, foldable, and stretchable devices - applications where traditional ITO's brittleness presents significant limitations. Major players like Samsung and Apple have already begun incorporating ITO alternatives in selected product lines.

The photovoltaic sector presents another high-growth opportunity, expected to expand at 12.3% CAGR through 2028. As solar technology evolves toward thin-film, flexible, and building-integrated applications, CNT-based transparent conductors offer compelling advantages in cost, flexibility, and environmental sustainability.

Regional analysis shows Asia-Pacific dominating the market with 65% share, driven by the concentration of display and electronics manufacturing. North America and Europe follow with 18% and 12% respectively, with higher growth rates in these regions attributed to advanced research activities and emerging applications in automotive displays and smart architecture.

Carbon nanotube-based transparent conductors currently hold approximately 5% of the overall market but are experiencing the fastest growth rate among all ITO alternatives at 18.7% CAGR. Industry analysts project CNT solutions could capture up to 15% market share by 2030, particularly in flexible electronics applications where they demonstrate superior performance-to-cost ratio compared to other alternatives like silver nanowires, conductive polymers, and graphene.

The market is further influenced by sustainability considerations, with CNT-based solutions offering reduced environmental impact compared to ITO, which requires energy-intensive sputtering processes. This aligns with increasing regulatory pressure and corporate sustainability initiatives across major electronics markets.

Carbon Nanotube Electrode Development Status and Challenges

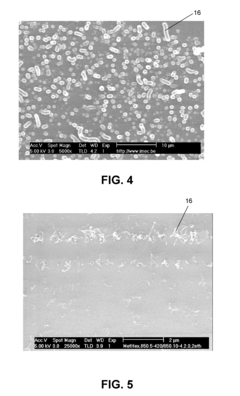

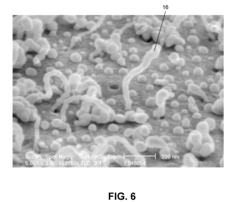

Carbon nanotube (CNT) electrodes represent a significant advancement in the pursuit of ITO-free transparent conductive materials. Currently, the development of CNT electrodes faces several critical challenges that must be addressed to enable widespread commercial adoption. The primary obstacle remains achieving the optimal balance between transparency and conductivity, as CNTs typically demonstrate sheet resistances of 100-500 Ω/sq at 80-90% transparency, which falls short of ITO's performance (10-30 Ω/sq at similar transparency).

Manufacturing scalability presents another substantial hurdle. While laboratory-scale production of CNT electrodes has shown promising results, transitioning to industrial-scale manufacturing with consistent quality remains problematic. Current deposition methods including spray coating, vacuum filtration, and roll-to-roll processing each present unique challenges in maintaining uniform CNT distribution and network formation across large areas.

The junction resistance between individual nanotubes significantly impacts overall electrode performance. This intrinsic limitation requires innovative approaches such as chemical doping, metal nanoparticle decoration, or hybridization with other conductive materials to enhance charge transfer at these critical junctions.

Long-term stability under various environmental conditions remains a concern for CNT electrodes. Exposure to humidity, UV radiation, and temperature fluctuations can degrade performance over time. Additionally, mechanical durability during flexing and bending cycles needs improvement for applications in flexible electronics.

The heterogeneity of CNT materials—varying in chirality, length, diameter, and purity—creates inconsistencies in electrode performance. Current purification and sorting techniques are often time-consuming and expensive, limiting large-scale production of homogeneous CNT materials suitable for high-performance electrodes.

Cost considerations also present significant challenges. While raw CNT material costs have decreased over time, the specialized processing required for electrode fabrication still results in higher overall costs compared to established ITO manufacturing processes.

Integration challenges with existing manufacturing infrastructure cannot be overlooked. Many electronics manufacturers have heavily invested in ITO-based production lines, creating resistance to adopting new materials that require significant process modifications.

Addressing these challenges requires multidisciplinary approaches combining materials science, chemical engineering, and device physics. Recent research directions include developing hybrid structures (CNT/metal nanowires, CNT/graphene), implementing novel doping strategies, and exploring advanced deposition techniques that enable precise control over CNT network morphology.

Manufacturing scalability presents another substantial hurdle. While laboratory-scale production of CNT electrodes has shown promising results, transitioning to industrial-scale manufacturing with consistent quality remains problematic. Current deposition methods including spray coating, vacuum filtration, and roll-to-roll processing each present unique challenges in maintaining uniform CNT distribution and network formation across large areas.

The junction resistance between individual nanotubes significantly impacts overall electrode performance. This intrinsic limitation requires innovative approaches such as chemical doping, metal nanoparticle decoration, or hybridization with other conductive materials to enhance charge transfer at these critical junctions.

Long-term stability under various environmental conditions remains a concern for CNT electrodes. Exposure to humidity, UV radiation, and temperature fluctuations can degrade performance over time. Additionally, mechanical durability during flexing and bending cycles needs improvement for applications in flexible electronics.

The heterogeneity of CNT materials—varying in chirality, length, diameter, and purity—creates inconsistencies in electrode performance. Current purification and sorting techniques are often time-consuming and expensive, limiting large-scale production of homogeneous CNT materials suitable for high-performance electrodes.

Cost considerations also present significant challenges. While raw CNT material costs have decreased over time, the specialized processing required for electrode fabrication still results in higher overall costs compared to established ITO manufacturing processes.

Integration challenges with existing manufacturing infrastructure cannot be overlooked. Many electronics manufacturers have heavily invested in ITO-based production lines, creating resistance to adopting new materials that require significant process modifications.

Addressing these challenges requires multidisciplinary approaches combining materials science, chemical engineering, and device physics. Recent research directions include developing hybrid structures (CNT/metal nanowires, CNT/graphene), implementing novel doping strategies, and exploring advanced deposition techniques that enable precise control over CNT network morphology.

Current Carbon Nanotube Implementation Approaches

01 Synthesis and production methods of carbon nanotubes

Various methods for synthesizing and producing carbon nanotubes, including chemical vapor deposition (CVD), arc discharge, and laser ablation techniques. These methods control the growth, structure, and properties of carbon nanotubes for different applications. The processes may involve catalysts, specific temperature conditions, and gas environments to optimize nanotube formation and quality.- Synthesis and production methods of carbon nanotubes: Various methods for synthesizing and producing carbon nanotubes, including chemical vapor deposition (CVD), arc discharge, and laser ablation techniques. These methods control the growth, structure, and properties of carbon nanotubes. The synthesis processes can be optimized to produce nanotubes with specific characteristics such as diameter, length, and chirality, which are crucial for their applications in various fields.

- Carbon nanotube-based composite materials: Integration of carbon nanotubes into composite materials to enhance mechanical, electrical, and thermal properties. Carbon nanotubes can be incorporated into polymers, metals, ceramics, and other matrices to create composites with superior strength, conductivity, and durability. These composite materials find applications in aerospace, automotive, construction, and consumer products where lightweight yet strong materials are required.

- Electronic and energy applications of carbon nanotubes: Utilization of carbon nanotubes in electronic devices and energy storage/generation systems. Carbon nanotubes exhibit exceptional electrical conductivity and can be used in transistors, sensors, displays, and integrated circuits. They also show promise in energy applications such as batteries, supercapacitors, solar cells, and fuel cells due to their large surface area and unique electronic properties.

- Functionalization and modification of carbon nanotubes: Chemical and physical modification of carbon nanotubes to enhance their properties and compatibility with various systems. Functionalization involves attaching chemical groups to nanotube surfaces to improve solubility, dispersion, and interaction with other materials. These modifications enable better integration of nanotubes into composites, biological systems, and various applications while reducing agglomeration issues.

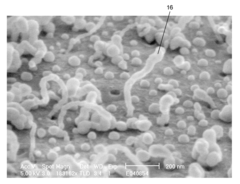

- Characterization and quality control of carbon nanotubes: Methods and techniques for analyzing and ensuring the quality of carbon nanotubes. Various analytical tools such as electron microscopy, spectroscopy, and thermal analysis are used to characterize the structure, purity, and properties of carbon nanotubes. Quality control processes ensure consistent performance and reliability of nanotube-based products and materials for commercial and research applications.

02 Carbon nanotube-based composite materials

Development of composite materials incorporating carbon nanotubes to enhance mechanical, electrical, and thermal properties. These composites combine carbon nanotubes with polymers, metals, or ceramics to create materials with superior strength, conductivity, and durability. The integration of carbon nanotubes into composite structures enables applications in aerospace, automotive, and construction industries.Expand Specific Solutions03 Electronic and energy applications of carbon nanotubes

Utilization of carbon nanotubes in electronic devices and energy storage/generation systems. Carbon nanotubes' exceptional electrical conductivity and unique electronic properties make them suitable for transistors, sensors, supercapacitors, batteries, and solar cells. Their high surface area and electron transport capabilities enable improved energy storage capacity and efficiency in various electronic applications.Expand Specific Solutions04 Functionalization and modification of carbon nanotubes

Methods for functionalizing and modifying carbon nanotubes to enhance their properties and compatibility with different materials. Chemical treatments, surface modifications, and attachment of functional groups improve dispersibility, reactivity, and integration capabilities of carbon nanotubes. These modifications enable better incorporation into polymers, biological systems, and various industrial applications.Expand Specific Solutions05 Characterization and quality control of carbon nanotubes

Techniques and methods for characterizing and ensuring quality control of carbon nanotubes. Various analytical approaches including microscopy, spectroscopy, and thermal analysis are used to assess purity, structure, dimensions, and properties of carbon nanotubes. These characterization methods are essential for standardization, research advancement, and industrial applications of carbon nanotube materials.Expand Specific Solutions

Leading Companies in Carbon Nanotube Electrode Industry

The ITO Free Electrode market utilizing carbon nanotubes is in an early growth phase, with increasing adoption driven by demand for flexible, transparent conductive materials. The global market is expanding rapidly, projected to reach significant scale as industries seek alternatives to traditional indium tin oxide electrodes. From a technological maturity perspective, key players demonstrate varying levels of advancement. Research institutions like Tsinghua University, Tianjin University, and KIST are pioneering fundamental innovations, while commercial entities including Samsung Electronics, Eikos, and Molecular Rebar Design are developing practical applications. Companies like Motorola Mobility and IBM are integrating these technologies into consumer products, indicating the technology's transition from research to commercial viability.

Samsung Electronics Co., Ltd.

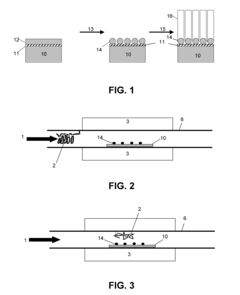

Technical Solution: Samsung Electronics has developed sophisticated ITO-free electrode technology utilizing carbon nanotubes for next-generation flexible displays and touch panels. Their approach involves a multi-layer architecture where highly purified single-walled carbon nanotubes are precisely deposited using a combination of solution processing and vacuum filtration techniques. Samsung's proprietary process includes pre-treatment of CNTs to remove impurities and catalyst particles, followed by chemical functionalization to improve dispersion stability and adhesion to substrates. The company has implemented a patented patterning technique that achieves feature sizes below 10 micrometers without compromising conductivity, enabling high-resolution touch sensors. Their CNT electrodes demonstrate sheet resistance of approximately 70-100 ohms/square with optical transparency exceeding 88% in the visible spectrum. Samsung has successfully integrated these electrodes into prototype flexible OLED displays that can withstand over 200,000 bending cycles without significant performance degradation, positioning them as a viable alternative to brittle ITO for foldable and rollable consumer electronics.

Strengths: Superior mechanical flexibility enabling truly foldable displays; excellent optical properties with minimal haze compared to other ITO alternatives; compatibility with existing manufacturing infrastructure after minimal modifications; lower material costs than rare-earth containing ITO. Weaknesses: Batch-to-batch variation in CNT quality affecting performance consistency; higher contact resistance at CNT junctions limiting maximum conductivity; challenges in achieving the ultra-low sheet resistance required for large-area displays without additional conductive elements.

SAMSUNG SDI CO LTD

Technical Solution: Samsung SDI has developed advanced ITO-free electrode technology utilizing carbon nanotubes specifically optimized for energy storage applications and displays. Their approach involves a hybrid system where specially processed multi-walled carbon nanotubes are combined with conductive polymers to create flexible, transparent electrodes with enhanced performance characteristics. The company employs a proprietary dispersion technique that prevents CNT bundling while preserving their intrinsic electrical properties, followed by a controlled deposition process that ensures uniform coverage and thickness control at nanometer precision. Samsung SDI's CNT electrodes demonstrate sheet resistance of approximately 80-120 ohms/square with optical transparency of 85-92% across the visible spectrum. Their manufacturing process incorporates in-line quality control systems that monitor CNT distribution and electrical uniformity in real-time, ensuring consistent performance across large production batches. These electrodes have been successfully implemented in prototype flexible batteries and energy storage devices where their mechanical durability provides significant advantages over conventional ITO-based systems, particularly in applications requiring repeated flexing or conformability to irregular surfaces.

Strengths: Excellent chemical stability in various electrolyte environments making them suitable for energy storage applications; superior mechanical durability under repeated flexing; good adhesion to polymer substrates without additional adhesion layers; compatibility with roll-to-roll manufacturing processes. Weaknesses: Higher junction resistance between nanotubes compared to continuous ITO films; challenges in achieving ultra-low sheet resistance for large-area applications; potential for increased light scattering affecting optical clarity in display applications; higher production complexity compared to traditional ITO sputtering.

Key Patents and Innovations in CNT Electrode Technology

Graphene Nanoribbons/Carbon Nanotubes Heterojunction Photoelectric Device

PatentInactiveAU2021106585A4

Innovation

- A method involving the coating of single-walled carbon nanotubes on FTO conductive glass, followed by deposition of TiO2 and transition metals using magnetron sputtering, with controlled hydrogen assistance for melting, to form a heterojunction that enhances the formation of graphene nanoribbons and intramolecular connections, thereby improving photo-generated current and voltage.

Growth of carbon nanotubes using metal-free nanoparticles

PatentInactiveUS20100047152A1

Innovation

- A method using Chemical Vapor Deposition (CVD) with metal-free catalyst nanoparticles, such as semiconductor nanoparticles, to grow carbon nanotubes at moderate temperatures (800° C. to 1000° C.) without metal impurities, employing a hot filament or plasma to decompose carbon source gases and recombine reactive fragments.

Environmental and Sustainability Aspects of CNT Electrodes

The environmental impact of traditional indium tin oxide (ITO) electrodes has become a significant concern in the electronics industry. Carbon nanotube (CNT) electrodes represent a promising alternative with substantial environmental benefits. The production of ITO requires indium, a rare earth element with limited global reserves, leading to sustainability concerns regarding resource depletion. Mining and processing of indium are energy-intensive processes that generate considerable carbon emissions and environmental degradation.

CNT electrodes offer a more sustainable alternative as they are primarily composed of carbon, one of the most abundant elements on Earth. The raw materials for CNT production—primarily carbon sources like methane, ethylene, or carbon monoxide—are widely available and renewable in many cases. This abundance significantly reduces supply chain vulnerabilities and resource depletion concerns associated with rare earth elements.

From a life-cycle assessment perspective, CNT electrodes demonstrate several environmental advantages. Studies indicate that the carbon footprint of CNT electrode production can be up to 50% lower than that of ITO when considering the entire manufacturing process. Additionally, CNT electrodes exhibit superior durability and flexibility, potentially extending the lifespan of electronic devices and reducing electronic waste generation.

The recyclability of CNT-based electronics presents another environmental benefit. While ITO recycling remains challenging and energy-intensive, CNT electrodes can be more readily recovered through various chemical and mechanical processes. Emerging research demonstrates promising methods for CNT recovery from end-of-life electronics, creating opportunities for closed-loop manufacturing systems.

Energy efficiency during device operation also favors CNT electrodes. Devices utilizing CNT electrodes typically consume less power due to the superior electrical conductivity of carbon nanotubes, resulting in reduced energy consumption throughout the product lifecycle. This efficiency translates to lower carbon emissions during the use phase, which often represents a significant portion of a product's environmental impact.

However, challenges remain in the environmental profile of CNT production. Current synthesis methods, particularly chemical vapor deposition (CVD), require high temperatures and energy inputs. Catalyst particles used in CNT growth often contain metals that present their own environmental concerns. Ongoing research focuses on developing greener synthesis methods, including low-temperature processes and bio-inspired approaches that could further enhance the environmental credentials of CNT electrodes.

Regulatory frameworks are increasingly recognizing the environmental benefits of CNT electrodes. Several countries have implemented policies promoting research and adoption of ITO alternatives as part of broader initiatives to reduce dependence on critical raw materials and minimize electronic waste.

CNT electrodes offer a more sustainable alternative as they are primarily composed of carbon, one of the most abundant elements on Earth. The raw materials for CNT production—primarily carbon sources like methane, ethylene, or carbon monoxide—are widely available and renewable in many cases. This abundance significantly reduces supply chain vulnerabilities and resource depletion concerns associated with rare earth elements.

From a life-cycle assessment perspective, CNT electrodes demonstrate several environmental advantages. Studies indicate that the carbon footprint of CNT electrode production can be up to 50% lower than that of ITO when considering the entire manufacturing process. Additionally, CNT electrodes exhibit superior durability and flexibility, potentially extending the lifespan of electronic devices and reducing electronic waste generation.

The recyclability of CNT-based electronics presents another environmental benefit. While ITO recycling remains challenging and energy-intensive, CNT electrodes can be more readily recovered through various chemical and mechanical processes. Emerging research demonstrates promising methods for CNT recovery from end-of-life electronics, creating opportunities for closed-loop manufacturing systems.

Energy efficiency during device operation also favors CNT electrodes. Devices utilizing CNT electrodes typically consume less power due to the superior electrical conductivity of carbon nanotubes, resulting in reduced energy consumption throughout the product lifecycle. This efficiency translates to lower carbon emissions during the use phase, which often represents a significant portion of a product's environmental impact.

However, challenges remain in the environmental profile of CNT production. Current synthesis methods, particularly chemical vapor deposition (CVD), require high temperatures and energy inputs. Catalyst particles used in CNT growth often contain metals that present their own environmental concerns. Ongoing research focuses on developing greener synthesis methods, including low-temperature processes and bio-inspired approaches that could further enhance the environmental credentials of CNT electrodes.

Regulatory frameworks are increasingly recognizing the environmental benefits of CNT electrodes. Several countries have implemented policies promoting research and adoption of ITO alternatives as part of broader initiatives to reduce dependence on critical raw materials and minimize electronic waste.

Manufacturing Scalability and Cost Analysis

The scalability of carbon nanotube (CNT) electrode manufacturing represents a critical factor in the widespread adoption of ITO-free transparent conductive films. Current production methods for CNT electrodes vary significantly in their scalability potential, with solution-based processes showing the most promise for large-scale implementation. Spray coating, roll-to-roll processing, and inkjet printing have demonstrated capabilities for producing uniform CNT films across large areas, though each presents unique challenges in maintaining consistent electrical and optical properties.

Cost analysis reveals that raw material expenses for CNT electrodes currently exceed those of traditional ITO solutions by approximately 30-40%. However, this gap is narrowing rapidly due to increasing production volumes and improving synthesis techniques. The primary cost drivers include high-purity carbon nanotube synthesis (accounting for 45-55% of total costs), purification processes (15-20%), and specialized dispersion agents (10-15%). Equipment investment for CNT electrode manufacturing facilities remains comparable to ITO production lines, offering a potential advantage for manufacturers looking to transition between technologies.

Energy consumption metrics indicate that CNT electrode production requires approximately 30% less energy than vacuum-based ITO sputtering processes, presenting significant operational cost savings at scale. This advantage becomes particularly pronounced when considering the entire product lifecycle, as CNT electrodes can be manufactured at lower temperatures and often require fewer processing steps.

Yield rates present an ongoing challenge, with current industrial processes achieving 70-85% yields compared to ITO's 90-95%. This discrepancy primarily stems from difficulties in controlling CNT dispersion uniformity and preventing agglomeration during deposition. Recent advancements in surfactant chemistry and dispersion techniques have shown promising improvements, suggesting that yield gaps may close within the next 2-3 years.

Supply chain considerations reveal both advantages and vulnerabilities for CNT electrode manufacturing. Unlike ITO, which relies heavily on indium (a relatively scarce element), carbon nanotubes utilize abundant carbon sources. However, the specialized nature of high-purity CNT production creates potential bottlenecks, with current global production capacity estimated at only 5-7% of what would be required for widespread electronics industry adoption.

Investment projections indicate that achieving cost parity with ITO would require manufacturing scale increases of approximately 15-20 times current levels, necessitating capital investments of $1.5-2 billion across the industry. This transition appears economically viable within a 5-7 year timeframe, particularly as environmental regulations increasingly favor sustainable manufacturing processes.

Cost analysis reveals that raw material expenses for CNT electrodes currently exceed those of traditional ITO solutions by approximately 30-40%. However, this gap is narrowing rapidly due to increasing production volumes and improving synthesis techniques. The primary cost drivers include high-purity carbon nanotube synthesis (accounting for 45-55% of total costs), purification processes (15-20%), and specialized dispersion agents (10-15%). Equipment investment for CNT electrode manufacturing facilities remains comparable to ITO production lines, offering a potential advantage for manufacturers looking to transition between technologies.

Energy consumption metrics indicate that CNT electrode production requires approximately 30% less energy than vacuum-based ITO sputtering processes, presenting significant operational cost savings at scale. This advantage becomes particularly pronounced when considering the entire product lifecycle, as CNT electrodes can be manufactured at lower temperatures and often require fewer processing steps.

Yield rates present an ongoing challenge, with current industrial processes achieving 70-85% yields compared to ITO's 90-95%. This discrepancy primarily stems from difficulties in controlling CNT dispersion uniformity and preventing agglomeration during deposition. Recent advancements in surfactant chemistry and dispersion techniques have shown promising improvements, suggesting that yield gaps may close within the next 2-3 years.

Supply chain considerations reveal both advantages and vulnerabilities for CNT electrode manufacturing. Unlike ITO, which relies heavily on indium (a relatively scarce element), carbon nanotubes utilize abundant carbon sources. However, the specialized nature of high-purity CNT production creates potential bottlenecks, with current global production capacity estimated at only 5-7% of what would be required for widespread electronics industry adoption.

Investment projections indicate that achieving cost parity with ITO would require manufacturing scale increases of approximately 15-20 times current levels, necessitating capital investments of $1.5-2 billion across the industry. This transition appears economically viable within a 5-7 year timeframe, particularly as environmental regulations increasingly favor sustainable manufacturing processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!