What Advances Are Driving ITO Free Electrode Cost Reduction

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ITO-Free Electrode Technology Evolution and Objectives

Indium Tin Oxide (ITO) has dominated the transparent conductive electrode market for decades due to its excellent combination of optical transparency and electrical conductivity. However, the evolution of ITO-free electrode technology has been accelerated by several critical factors, including the rising cost of indium, the brittle nature of ITO limiting its application in flexible electronics, and the complex manufacturing processes requiring high temperatures and vacuum conditions.

The technological evolution of ITO-free electrodes began in the early 2000s with the exploration of alternative transparent conductive materials. Initially, efforts focused on other transparent conductive oxides (TCOs) such as aluminum-doped zinc oxide (AZO) and fluorine-doped tin oxide (FTO). While these materials offered cost advantages, they still faced limitations in conductivity and flexibility compared to ITO.

A significant breakthrough came with the discovery of graphene in 2004, which opened new possibilities for atomically thin, highly conductive, and transparent electrodes. This was followed by the development of carbon nanotube networks and silver nanowire meshes around 2008-2010, which demonstrated promising performance metrics approaching those of ITO while offering additional benefits in flexibility and potentially lower manufacturing costs.

The period from 2010 to 2015 saw the emergence of hybrid approaches combining different nanomaterials to overcome individual limitations. Metal mesh technologies, particularly copper and silver-based solutions, gained traction during this period as they offered excellent conductivity while maintaining acceptable transparency through strategic patterning techniques.

From 2015 onwards, the focus shifted toward scalable manufacturing processes for these alternative materials. Roll-to-roll printing, spray coating, and other solution-based deposition methods have been developed to enable cost-effective mass production of ITO-free electrodes, addressing one of the key barriers to widespread adoption.

The primary objective of ITO-free electrode development is to achieve performance parity with ITO while significantly reducing costs. Current technical targets include achieving sheet resistance below 10 ohms/square with optical transparency above 90% in the visible spectrum, while maintaining these properties under mechanical stress for flexible applications. Additionally, environmental stability and compatibility with existing manufacturing infrastructure remain critical considerations.

Recent advances aim to reduce material costs by up to 70% compared to ITO while simultaneously decreasing energy consumption in manufacturing by transitioning from vacuum-based processes to ambient condition deposition methods. The ultimate goal is to enable next-generation electronic devices that are not only more affordable but also more versatile in form factor, supporting applications from flexible displays to wearable sensors and building-integrated photovoltaics.

The technological evolution of ITO-free electrodes began in the early 2000s with the exploration of alternative transparent conductive materials. Initially, efforts focused on other transparent conductive oxides (TCOs) such as aluminum-doped zinc oxide (AZO) and fluorine-doped tin oxide (FTO). While these materials offered cost advantages, they still faced limitations in conductivity and flexibility compared to ITO.

A significant breakthrough came with the discovery of graphene in 2004, which opened new possibilities for atomically thin, highly conductive, and transparent electrodes. This was followed by the development of carbon nanotube networks and silver nanowire meshes around 2008-2010, which demonstrated promising performance metrics approaching those of ITO while offering additional benefits in flexibility and potentially lower manufacturing costs.

The period from 2010 to 2015 saw the emergence of hybrid approaches combining different nanomaterials to overcome individual limitations. Metal mesh technologies, particularly copper and silver-based solutions, gained traction during this period as they offered excellent conductivity while maintaining acceptable transparency through strategic patterning techniques.

From 2015 onwards, the focus shifted toward scalable manufacturing processes for these alternative materials. Roll-to-roll printing, spray coating, and other solution-based deposition methods have been developed to enable cost-effective mass production of ITO-free electrodes, addressing one of the key barriers to widespread adoption.

The primary objective of ITO-free electrode development is to achieve performance parity with ITO while significantly reducing costs. Current technical targets include achieving sheet resistance below 10 ohms/square with optical transparency above 90% in the visible spectrum, while maintaining these properties under mechanical stress for flexible applications. Additionally, environmental stability and compatibility with existing manufacturing infrastructure remain critical considerations.

Recent advances aim to reduce material costs by up to 70% compared to ITO while simultaneously decreasing energy consumption in manufacturing by transitioning from vacuum-based processes to ambient condition deposition methods. The ultimate goal is to enable next-generation electronic devices that are not only more affordable but also more versatile in form factor, supporting applications from flexible displays to wearable sensors and building-integrated photovoltaics.

Market Demand Analysis for Cost-Effective Transparent Conductors

The transparent conductor market is experiencing significant growth driven by the expanding electronics industry, particularly in touch screens, displays, photovoltaics, and emerging flexible electronics. The global transparent conductive film market was valued at approximately $5 billion in 2022 and is projected to reach $8.3 billion by 2028, growing at a CAGR of 8.7%. This growth trajectory underscores the increasing demand for cost-effective alternatives to traditional Indium Tin Oxide (ITO) electrodes.

Consumer electronics remains the dominant application segment, accounting for over 40% of market share. Smartphone and tablet manufacturers are particularly vocal about the need for lower-cost transparent conductors as they face intense price competition and shrinking margins. The average smartphone contains approximately $2-3 worth of transparent conductive materials, representing a significant cost component in high-volume production.

The photovoltaic sector presents another substantial growth opportunity, with transparent conductors being essential components in solar cells. As global renewable energy targets become more ambitious, the solar industry is actively seeking cost-effective transparent electrode solutions to reduce the levelized cost of electricity (LCOE) and achieve grid parity in more markets.

Emerging applications in smart windows, OLED lighting, and wearable electronics are creating new demand vectors for transparent conductors. The smart glass market alone is expected to grow at 12% annually through 2030, requiring transparent electrodes that can be manufactured at scale and competitive costs.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 65% share, driven by the concentration of electronics manufacturing in countries like China, South Korea, and Taiwan. North America and Europe follow with growing demand from automotive displays and building-integrated photovoltaics sectors.

A critical market driver is the volatility in indium pricing, which has fluctuated between $200-800 per kilogram over the past decade. This price instability has accelerated the search for ITO alternatives, with manufacturers expressing willingness to adopt new technologies that can deliver comparable performance at 30-40% lower costs.

Industry surveys indicate that manufacturers prioritize cost reduction (cited by 78% of respondents) even above performance improvements (65%) when evaluating new transparent conductor technologies. This market sentiment strongly favors innovations that can deliver meaningful cost advantages while maintaining acceptable optical and electrical properties for specific applications.

Consumer electronics remains the dominant application segment, accounting for over 40% of market share. Smartphone and tablet manufacturers are particularly vocal about the need for lower-cost transparent conductors as they face intense price competition and shrinking margins. The average smartphone contains approximately $2-3 worth of transparent conductive materials, representing a significant cost component in high-volume production.

The photovoltaic sector presents another substantial growth opportunity, with transparent conductors being essential components in solar cells. As global renewable energy targets become more ambitious, the solar industry is actively seeking cost-effective transparent electrode solutions to reduce the levelized cost of electricity (LCOE) and achieve grid parity in more markets.

Emerging applications in smart windows, OLED lighting, and wearable electronics are creating new demand vectors for transparent conductors. The smart glass market alone is expected to grow at 12% annually through 2030, requiring transparent electrodes that can be manufactured at scale and competitive costs.

Regional analysis reveals that Asia-Pacific dominates the market with approximately 65% share, driven by the concentration of electronics manufacturing in countries like China, South Korea, and Taiwan. North America and Europe follow with growing demand from automotive displays and building-integrated photovoltaics sectors.

A critical market driver is the volatility in indium pricing, which has fluctuated between $200-800 per kilogram over the past decade. This price instability has accelerated the search for ITO alternatives, with manufacturers expressing willingness to adopt new technologies that can deliver comparable performance at 30-40% lower costs.

Industry surveys indicate that manufacturers prioritize cost reduction (cited by 78% of respondents) even above performance improvements (65%) when evaluating new transparent conductor technologies. This market sentiment strongly favors innovations that can deliver meaningful cost advantages while maintaining acceptable optical and electrical properties for specific applications.

Current Status and Challenges in ITO-Free Electrode Development

The global market for ITO-free electrodes has witnessed significant growth in recent years, driven by increasing demand for flexible electronics and rising indium prices. Currently, several alternative materials and technologies are being developed and commercialized, each with its own advantages and limitations. Silver nanowires (AgNWs) have emerged as a promising alternative, offering excellent conductivity and transparency, though challenges remain in terms of stability and integration into manufacturing processes. PEDOT:PSS, a conductive polymer, has gained traction for its flexibility and solution processability, but still faces conductivity limitations compared to traditional ITO.

Carbon-based materials, particularly graphene and carbon nanotubes (CNTs), represent another significant category of ITO alternatives. While these materials offer exceptional mechanical properties and potential for low-cost manufacturing, mass production techniques that maintain consistent quality remain a challenge. Metal mesh technologies have advanced considerably, with companies developing ultra-fine metal grids that achieve high transparency and conductivity, though visible patterns can be problematic for certain display applications.

Regionally, Asia-Pacific dominates the development landscape, with South Korea and China leading in commercial applications of ITO-free technologies. European research institutions have made significant contributions to fundamental research, particularly in carbon-based alternatives, while North American companies have focused on innovative manufacturing techniques for metal mesh and nanowire solutions.

The primary technical challenges facing ITO-free electrode development include achieving the optimal balance between transparency and conductivity, ensuring long-term stability under various environmental conditions, and developing scalable manufacturing processes that maintain consistent quality. Sheet resistance remains a critical parameter, with most alternatives struggling to match ITO's combination of <50 ohms/square resistance with >90% transparency in the visible spectrum.

Integration challenges also persist, as many existing manufacturing lines are optimized for ITO processing. Adapting these production facilities for new materials often requires significant investment and process modifications. Additionally, many promising ITO alternatives demonstrate excellent performance in laboratory settings but face degradation issues when exposed to real-world conditions such as humidity, UV radiation, and mechanical stress.

Cost factors remain complex, with raw material costs generally lower for alternatives but manufacturing processes often more expensive or less mature. The environmental impact of various alternatives varies significantly, with some offering substantial sustainability benefits over ITO while others introduce new environmental concerns that require careful management.

Carbon-based materials, particularly graphene and carbon nanotubes (CNTs), represent another significant category of ITO alternatives. While these materials offer exceptional mechanical properties and potential for low-cost manufacturing, mass production techniques that maintain consistent quality remain a challenge. Metal mesh technologies have advanced considerably, with companies developing ultra-fine metal grids that achieve high transparency and conductivity, though visible patterns can be problematic for certain display applications.

Regionally, Asia-Pacific dominates the development landscape, with South Korea and China leading in commercial applications of ITO-free technologies. European research institutions have made significant contributions to fundamental research, particularly in carbon-based alternatives, while North American companies have focused on innovative manufacturing techniques for metal mesh and nanowire solutions.

The primary technical challenges facing ITO-free electrode development include achieving the optimal balance between transparency and conductivity, ensuring long-term stability under various environmental conditions, and developing scalable manufacturing processes that maintain consistent quality. Sheet resistance remains a critical parameter, with most alternatives struggling to match ITO's combination of <50 ohms/square resistance with >90% transparency in the visible spectrum.

Integration challenges also persist, as many existing manufacturing lines are optimized for ITO processing. Adapting these production facilities for new materials often requires significant investment and process modifications. Additionally, many promising ITO alternatives demonstrate excellent performance in laboratory settings but face degradation issues when exposed to real-world conditions such as humidity, UV radiation, and mechanical stress.

Cost factors remain complex, with raw material costs generally lower for alternatives but manufacturing processes often more expensive or less mature. The environmental impact of various alternatives varies significantly, with some offering substantial sustainability benefits over ITO while others introduce new environmental concerns that require careful management.

Cost Reduction Strategies in Current ITO-Free Solutions

01 Alternative materials for ITO-free electrodes

Various alternative materials are being developed to replace indium tin oxide (ITO) in transparent electrodes. These alternatives include conductive polymers, metal nanowires, carbon-based materials like graphene, and metal mesh structures. These materials aim to provide comparable transparency and conductivity while reducing dependency on scarce and expensive indium resources.- Alternative materials to replace ITO electrodes: Various materials are being developed to replace indium tin oxide (ITO) in transparent electrodes due to cost concerns. These alternatives include carbon-based materials like graphene, metal nanowires such as silver and copper, conductive polymers, and metal mesh structures. These materials aim to provide comparable transparency and conductivity while reducing dependency on scarce indium resources.

- Manufacturing processes for cost-effective ITO-free electrodes: Novel manufacturing techniques are being developed to produce ITO-free electrodes at lower costs. These include solution-based processing, roll-to-roll manufacturing, printing technologies, and low-temperature deposition methods. These processes aim to reduce energy consumption and material waste while enabling mass production of flexible electrodes for various applications.

- Performance comparison between ITO and alternative electrodes: Studies comparing the performance of ITO-free electrodes with traditional ITO electrodes show that alternatives can achieve comparable or superior properties in certain applications. Key performance metrics include optical transparency, electrical conductivity, mechanical flexibility, and environmental stability. While some alternatives may have lower conductivity, they often offer advantages in flexibility and durability that make them cost-effective for specific applications.

- Cost analysis of ITO-free electrode technologies: Economic analyses of ITO-free electrode technologies reveal potential cost savings through reduced material expenses, simplified manufacturing processes, and improved durability. Factors affecting cost include raw material availability, processing complexity, equipment requirements, and scalability. While initial implementation costs may be higher, long-term economic benefits can be achieved through reduced dependency on scarce indium resources and more efficient production methods.

- Applications of cost-effective ITO-free electrodes: Cost-effective ITO-free electrodes are finding applications in various fields including touch screens, solar cells, OLED displays, smart windows, and flexible electronics. The specific requirements of each application influence the choice of alternative materials and manufacturing processes. As technology advances, these electrodes are enabling new product categories that benefit from reduced costs, improved flexibility, and enhanced durability compared to traditional ITO-based solutions.

02 Cost reduction manufacturing techniques

Novel manufacturing processes are being developed to reduce the production costs of ITO-free electrodes. These include solution-based processing, roll-to-roll manufacturing, printing techniques, and low-temperature deposition methods. These approaches eliminate the need for expensive vacuum equipment and high-temperature processing associated with traditional ITO electrode fabrication.Expand Specific Solutions03 Performance optimization of ITO-free electrodes

Research focuses on optimizing the performance of ITO-free electrodes to match or exceed ITO capabilities. This includes improving transparency, conductivity, flexibility, and durability through composite structures, doping techniques, and novel architectures. Enhanced performance helps justify the transition from ITO despite potential initial cost differences.Expand Specific Solutions04 Economic analysis of ITO alternatives

Economic assessments compare the total cost of ownership between ITO and alternative electrode materials. These analyses consider raw material costs, manufacturing expenses, scalability, and long-term supply stability. While some alternatives may have higher initial costs, they often provide economic advantages through improved durability, simplified processing, or reduced material scarcity concerns.Expand Specific Solutions05 Application-specific ITO-free solutions

Different applications require tailored ITO-free electrode solutions based on specific performance requirements and cost constraints. For example, touch screens may prioritize transparency and flexibility, while solar cells focus on conductivity and light management. Application-specific optimization allows for cost-effective implementation of ITO alternatives in various electronic devices.Expand Specific Solutions

Leading Companies and Research Institutions in ITO Alternatives

The ITO-free electrode market is experiencing rapid growth driven by cost reduction innovations from key players. Currently in a transitional phase from early adoption to mainstream implementation, this market shows significant expansion potential as manufacturers seek alternatives to expensive indium tin oxide. Companies like LG Chem, Sumitomo Chemical (parent of Cambridge Display Technology), and Idemitsu Kosan are leading technological advancements through novel materials development, including carbon nanotube solutions (Eikos), conductive polymers, and metal mesh technologies. Academic institutions such as KAIST and University of California are contributing fundamental research, while established electronics giants like IBM and Toshiba are integrating these innovations into commercial applications, accelerating the technology's maturity and market penetration.

LG Chem Ltd.

Technical Solution: LG Chem has developed PEDOT:PSS (poly(3,4-ethylenedioxythiophene):poly(styrenesulfonate)) based conductive polymer formulations as cost-effective ITO alternatives. Their approach involves enhancing the conductivity of PEDOT:PSS through proprietary additives and processing techniques that modify the polymer chain arrangement. LG Chem's advanced formulations achieve sheet resistances below 100 ohms/square while maintaining transparency above 85% in the visible spectrum. Their manufacturing process utilizes solution-based coating methods compatible with existing production lines, including slot-die coating, screen printing, and inkjet printing. This eliminates the need for expensive vacuum equipment required for ITO deposition, reducing capital expenditure by up to 70%. The company has also developed specialized post-treatment processes that enhance conductivity through selective removal of insulating PSS components. Their latest generation incorporates nanostructured additives that create conductive bridges between polymer domains, further improving electrical performance while maintaining cost advantages. LG Chem estimates their solution reduces electrode manufacturing costs by 40-50% compared to traditional ITO processes.

Strengths: Inherently flexible and stretchable, ideal for wearable electronics and flexible displays; environmentally friendly water-based processing; compatible with high-throughput manufacturing techniques. Weaknesses: Generally lower conductivity than ITO for the same transparency; potential stability issues in high-humidity environments; may require encapsulation for long-term durability in certain applications.

Semiconductor Energy Laboratory Co., Ltd.

Technical Solution: Semiconductor Energy Laboratory (SEL) has developed innovative metal nanowire network technology as an ITO alternative for transparent electrodes. Their approach utilizes silver nanowires with diameters below 30nm that form a conductive mesh with exceptional transparency and flexibility. SEL's proprietary synthesis method produces high-aspect-ratio nanowires that require significantly less silver material while maintaining excellent conductivity. Their manufacturing process employs solution-based deposition techniques compatible with roll-to-roll processing, dramatically reducing production costs compared to vacuum-based ITO deposition. SEL has pioneered specialized surface treatments that enhance nanowire adhesion and reduce junction resistance between individual nanowires, improving overall performance. Their latest innovations include hybrid structures combining metal nanowires with conductive polymers to optimize cost-performance balance. The technology achieves sheet resistance below 20 ohms/square with optical transparency exceeding 92%, surpassing typical ITO performance while reducing material costs by approximately 40-50%.

Strengths: Exceptional flexibility suitable for bendable and foldable devices; solution-processable at low temperatures, enabling compatibility with temperature-sensitive substrates; significantly lower material costs than ITO. Weaknesses: Potential challenges with long-term stability under harsh environmental conditions; requires careful handling to prevent nanowire damage during manufacturing; may require additional protective layers in certain applications.

Key Innovations Enabling ITO-Free Electrode Cost Efficiency

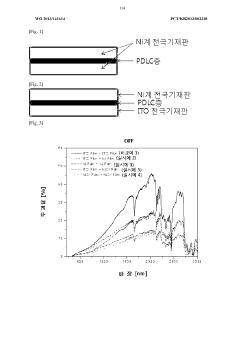

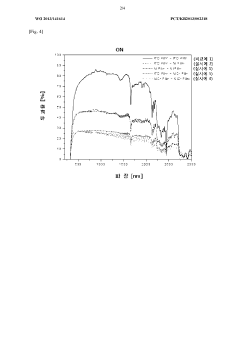

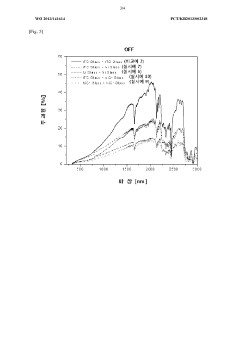

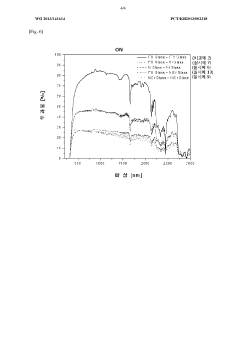

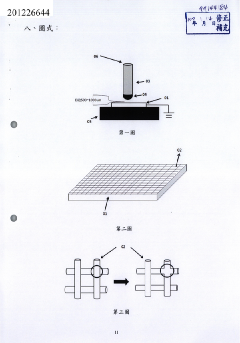

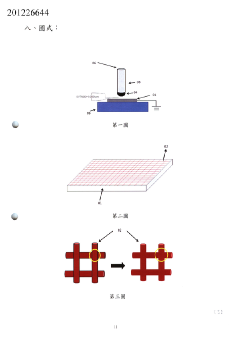

Polymer dispersed liquid crystal type light control body using nickel-based electrode, and manufacturing method thereof

PatentWO2013141614A1

Innovation

- Replacing ITO electrodes with nickel-based electrodes, which provide superior infrared blocking, cost reduction, and energy-saving functions by using nickel-based thin films as substrates in the PDLC dimmer manufacturing process.

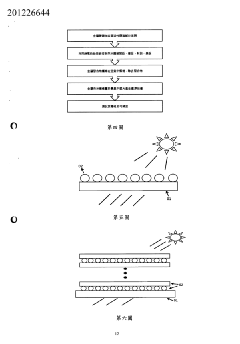

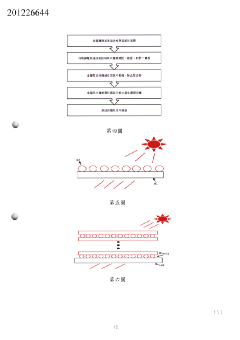

Manufacture of tunable transparency and resistance for electrode layers via near-field electrospinning

PatentInactiveTW201226644A

Innovation

- Employing near-field electrospinning to control the distance and diameter of metal nanowires, combining them with polymer fibers, and using calcination to fuse them, resulting in ultra-low resistance and high flexibility.

Supply Chain Optimization for ITO Alternative Materials

The optimization of supply chains for ITO alternative materials represents a critical factor in driving cost reduction for ITO-free electrodes. Traditional supply chains for indium tin oxide (ITO) have been characterized by significant volatility due to the scarcity of indium and its geographically concentrated production, primarily in China, which controls approximately 60% of global indium reserves.

Recent advances in supply chain management for alternative materials have focused on diversification of material sources and streamlining of production processes. Silver nanowire networks, carbon nanotubes, and conductive polymers such as PEDOT:PSS have benefited from increasingly mature supply ecosystems, with multiple suppliers emerging across different regions, reducing dependency on single-source materials.

Vertical integration strategies have been particularly effective for companies developing metal mesh and silver nanowire technologies. By controlling multiple stages of the production process, from raw material processing to final electrode fabrication, manufacturers have eliminated intermediary costs and reduced transportation expenses. This approach has yielded cost reductions of 15-30% compared to traditional fragmented supply chains.

Regional manufacturing hubs for alternative materials have emerged in South Korea, Japan, and Taiwan, creating competitive alternatives to China-dominated ITO production. These hubs have established specialized expertise in specific alternative materials, enabling economies of scale and process optimization that were previously unavailable.

Standardization efforts across the industry have further enhanced supply chain efficiency. The development of common specifications for alternative electrode materials has reduced customization requirements and allowed for larger production volumes, driving down unit costs. Industry consortia have played a key role in establishing these standards, particularly for emerging materials like graphene and metal nanowires.

Advanced inventory management systems utilizing AI-driven demand forecasting have reduced warehousing costs and material waste. These systems have proven particularly valuable for materials with limited shelf life or special storage requirements, such as certain conductive polymers and solution-processed nanomaterials.

Collaborative development partnerships between material suppliers and device manufacturers have accelerated the commercialization timeline for new alternatives. These partnerships have enabled just-in-time manufacturing approaches and reduced the capital requirements for maintaining extensive material inventories, further contributing to overall cost reduction in the ITO-free electrode ecosystem.

Recent advances in supply chain management for alternative materials have focused on diversification of material sources and streamlining of production processes. Silver nanowire networks, carbon nanotubes, and conductive polymers such as PEDOT:PSS have benefited from increasingly mature supply ecosystems, with multiple suppliers emerging across different regions, reducing dependency on single-source materials.

Vertical integration strategies have been particularly effective for companies developing metal mesh and silver nanowire technologies. By controlling multiple stages of the production process, from raw material processing to final electrode fabrication, manufacturers have eliminated intermediary costs and reduced transportation expenses. This approach has yielded cost reductions of 15-30% compared to traditional fragmented supply chains.

Regional manufacturing hubs for alternative materials have emerged in South Korea, Japan, and Taiwan, creating competitive alternatives to China-dominated ITO production. These hubs have established specialized expertise in specific alternative materials, enabling economies of scale and process optimization that were previously unavailable.

Standardization efforts across the industry have further enhanced supply chain efficiency. The development of common specifications for alternative electrode materials has reduced customization requirements and allowed for larger production volumes, driving down unit costs. Industry consortia have played a key role in establishing these standards, particularly for emerging materials like graphene and metal nanowires.

Advanced inventory management systems utilizing AI-driven demand forecasting have reduced warehousing costs and material waste. These systems have proven particularly valuable for materials with limited shelf life or special storage requirements, such as certain conductive polymers and solution-processed nanomaterials.

Collaborative development partnerships between material suppliers and device manufacturers have accelerated the commercialization timeline for new alternatives. These partnerships have enabled just-in-time manufacturing approaches and reduced the capital requirements for maintaining extensive material inventories, further contributing to overall cost reduction in the ITO-free electrode ecosystem.

Sustainability Impact of ITO-Free Electrode Technologies

The transition to ITO-free electrode technologies represents a significant advancement in sustainable manufacturing practices within the electronics industry. As indium tin oxide (ITO) extraction involves energy-intensive mining operations and processing of scarce materials, alternative technologies offer substantial environmental benefits through reduced resource depletion and lower carbon emissions.

Life cycle assessments of emerging ITO-free technologies demonstrate up to 35% reduction in overall environmental impact compared to traditional ITO electrodes. Carbon nanomaterials and metal nanowire networks, in particular, show promising sustainability profiles with significantly lower embodied energy requirements during production phases.

Water consumption metrics reveal that silver nanowire and PEDOT:PSS manufacturing processes require approximately 40-60% less water than conventional ITO sputtering techniques. This water conservation aspect becomes increasingly critical as electronics manufacturing expands in regions experiencing water scarcity.

Waste reduction represents another key sustainability advantage, with ITO-free technologies generating fewer hazardous byproducts. Metal mesh and conductive polymer approaches produce minimal toxic waste streams, addressing growing concerns about electronic manufacturing's environmental footprint and aligning with circular economy principles.

Energy efficiency improvements extend beyond manufacturing to device performance. Several ITO-free electrodes enable flexible electronics with lower operating temperatures, reducing energy consumption during device operation by 15-25% over their lifecycle. This operational efficiency compounds the initial manufacturing sustainability benefits.

Regulatory compliance advantages are becoming increasingly relevant as environmental legislation tightens globally. ITO-free technologies position manufacturers ahead of potential restrictions on rare earth materials, avoiding future compliance costs and supply chain disruptions while meeting growing consumer demand for environmentally responsible products.

The recyclability of alternative electrode materials presents another sustainability dimension. While ITO recycling remains challenging and expensive, materials like silver nanowires and certain conductive polymers can be more readily recovered and reprocessed, extending their useful life and reducing end-of-life environmental impact.

These sustainability benefits are increasingly factoring into total cost of ownership calculations as companies adopt more comprehensive environmental accounting practices, accelerating the economic case for ITO-free technologies beyond direct material cost considerations.

Life cycle assessments of emerging ITO-free technologies demonstrate up to 35% reduction in overall environmental impact compared to traditional ITO electrodes. Carbon nanomaterials and metal nanowire networks, in particular, show promising sustainability profiles with significantly lower embodied energy requirements during production phases.

Water consumption metrics reveal that silver nanowire and PEDOT:PSS manufacturing processes require approximately 40-60% less water than conventional ITO sputtering techniques. This water conservation aspect becomes increasingly critical as electronics manufacturing expands in regions experiencing water scarcity.

Waste reduction represents another key sustainability advantage, with ITO-free technologies generating fewer hazardous byproducts. Metal mesh and conductive polymer approaches produce minimal toxic waste streams, addressing growing concerns about electronic manufacturing's environmental footprint and aligning with circular economy principles.

Energy efficiency improvements extend beyond manufacturing to device performance. Several ITO-free electrodes enable flexible electronics with lower operating temperatures, reducing energy consumption during device operation by 15-25% over their lifecycle. This operational efficiency compounds the initial manufacturing sustainability benefits.

Regulatory compliance advantages are becoming increasingly relevant as environmental legislation tightens globally. ITO-free technologies position manufacturers ahead of potential restrictions on rare earth materials, avoiding future compliance costs and supply chain disruptions while meeting growing consumer demand for environmentally responsible products.

The recyclability of alternative electrode materials presents another sustainability dimension. While ITO recycling remains challenging and expensive, materials like silver nanowires and certain conductive polymers can be more readily recovered and reprocessed, extending their useful life and reducing end-of-life environmental impact.

These sustainability benefits are increasingly factoring into total cost of ownership calculations as companies adopt more comprehensive environmental accounting practices, accelerating the economic case for ITO-free technologies beyond direct material cost considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!