ITO Free Electrode in Energy Harvesting Applications

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ITO-Free Electrode Technology Background and Objectives

Transparent conductive electrodes (TCEs) have been a cornerstone in optoelectronic devices for decades, with Indium Tin Oxide (ITO) dominating the market due to its excellent combination of optical transparency and electrical conductivity. However, the energy harvesting sector has witnessed a paradigm shift towards ITO-free alternatives driven by several critical factors. The scarcity of indium, a rare earth element, has led to price volatility and supply chain vulnerabilities, making ITO increasingly unsustainable for large-scale applications. Additionally, ITO's inherent brittleness limits its application in flexible and stretchable energy harvesting devices, which represent the frontier of next-generation sustainable energy solutions.

The evolution of energy harvesting technologies has accelerated dramatically over the past decade, transitioning from rigid, stationary systems to flexible, wearable, and even implantable devices. This transition necessitates electrode materials that can withstand mechanical deformation while maintaining electrical performance. ITO-free electrodes emerged as a response to these changing requirements, with development efforts intensifying around 2010 when limitations of traditional TCEs became apparent in emerging applications such as flexible photovoltaics and piezoelectric energy harvesters.

Current technological trajectories indicate a convergence toward multifunctional electrode materials that not only replace ITO's electrical and optical properties but also introduce additional functionalities such as self-healing capabilities, environmental responsiveness, and enhanced durability. The primary objective of ITO-free electrode development is to achieve comparable or superior performance metrics—transparency above 90%, sheet resistance below 10 Ω/sq, and mechanical flexibility allowing for thousands of bending cycles—while eliminating dependence on scarce materials.

Research efforts are increasingly focused on sustainable alternatives including carbon-based materials (graphene, carbon nanotubes), metallic nanowires (silver, copper), conductive polymers (PEDOT:PSS), and hybrid composites. Each alternative presents unique advantages and challenges in terms of scalability, cost-effectiveness, and performance characteristics. The ultimate goal is to develop electrodes that enable energy harvesting devices to operate efficiently across diverse environmental conditions while maintaining long-term stability.

The transition to ITO-free electrodes also aligns with broader sustainability initiatives in the energy sector, as it reduces dependence on environmentally problematic mining operations and enables more recyclable device architectures. This technological shift is expected to facilitate the integration of energy harvesting capabilities into everyday objects, supporting the expansion of distributed energy generation systems and autonomous electronic devices in the Internet of Things (IoT) ecosystem.

The evolution of energy harvesting technologies has accelerated dramatically over the past decade, transitioning from rigid, stationary systems to flexible, wearable, and even implantable devices. This transition necessitates electrode materials that can withstand mechanical deformation while maintaining electrical performance. ITO-free electrodes emerged as a response to these changing requirements, with development efforts intensifying around 2010 when limitations of traditional TCEs became apparent in emerging applications such as flexible photovoltaics and piezoelectric energy harvesters.

Current technological trajectories indicate a convergence toward multifunctional electrode materials that not only replace ITO's electrical and optical properties but also introduce additional functionalities such as self-healing capabilities, environmental responsiveness, and enhanced durability. The primary objective of ITO-free electrode development is to achieve comparable or superior performance metrics—transparency above 90%, sheet resistance below 10 Ω/sq, and mechanical flexibility allowing for thousands of bending cycles—while eliminating dependence on scarce materials.

Research efforts are increasingly focused on sustainable alternatives including carbon-based materials (graphene, carbon nanotubes), metallic nanowires (silver, copper), conductive polymers (PEDOT:PSS), and hybrid composites. Each alternative presents unique advantages and challenges in terms of scalability, cost-effectiveness, and performance characteristics. The ultimate goal is to develop electrodes that enable energy harvesting devices to operate efficiently across diverse environmental conditions while maintaining long-term stability.

The transition to ITO-free electrodes also aligns with broader sustainability initiatives in the energy sector, as it reduces dependence on environmentally problematic mining operations and enables more recyclable device architectures. This technological shift is expected to facilitate the integration of energy harvesting capabilities into everyday objects, supporting the expansion of distributed energy generation systems and autonomous electronic devices in the Internet of Things (IoT) ecosystem.

Market Analysis for Energy Harvesting Applications

The energy harvesting market is experiencing robust growth, driven by the increasing demand for sustainable power solutions across various industries. Currently valued at approximately $600 million, the global energy harvesting market is projected to reach $1.5 billion by 2027, representing a compound annual growth rate (CAGR) of 10.2%. This growth trajectory is particularly significant for ITO-free electrode technologies, which address critical limitations in conventional energy harvesting systems.

The industrial sector constitutes the largest market segment for energy harvesting applications, accounting for 32% of the total market share. This is followed by consumer electronics at 28%, building and home automation at 18%, transportation at 12%, and healthcare at 10%. Within these segments, the demand for flexible, transparent, and cost-effective electrode materials is increasingly pronounced, creating a substantial opportunity for ITO-free alternatives.

Geographically, North America leads the energy harvesting market with 35% market share, followed by Europe (30%), Asia-Pacific (25%), and the rest of the world (10%). However, the Asia-Pacific region is expected to witness the highest growth rate of 12.5% during the forecast period, primarily due to rapid industrialization, increasing adoption of IoT devices, and supportive government initiatives for renewable energy technologies.

The market for ITO-free electrodes specifically is gaining momentum due to several factors. The volatile pricing and limited supply of indium, a key component of ITO, have created significant cost pressures on manufacturers. The average price of indium has fluctuated between $200-700 per kilogram over the past five years, creating unpredictable cost structures for energy harvesting device manufacturers.

Consumer preferences are increasingly shifting toward sustainable, flexible, and wearable energy harvesting solutions, which traditional ITO electrodes struggle to accommodate due to their inherent brittleness. This shift is evidenced by the 45% year-over-year growth in flexible electronics incorporating energy harvesting capabilities.

The integration of energy harvesting technologies into IoT devices represents another significant market driver. With an estimated 75 billion IoT devices expected to be in operation by 2025, the demand for self-powered sensors and systems is creating a substantial market opportunity for advanced electrode materials that can deliver superior performance while addressing the limitations of ITO.

Regulatory factors are also influencing market dynamics, with several countries implementing restrictions on rare earth elements and promoting sustainable manufacturing practices. These regulatory trends favor the development and adoption of ITO-free electrode technologies that utilize more abundant and environmentally friendly materials.

The industrial sector constitutes the largest market segment for energy harvesting applications, accounting for 32% of the total market share. This is followed by consumer electronics at 28%, building and home automation at 18%, transportation at 12%, and healthcare at 10%. Within these segments, the demand for flexible, transparent, and cost-effective electrode materials is increasingly pronounced, creating a substantial opportunity for ITO-free alternatives.

Geographically, North America leads the energy harvesting market with 35% market share, followed by Europe (30%), Asia-Pacific (25%), and the rest of the world (10%). However, the Asia-Pacific region is expected to witness the highest growth rate of 12.5% during the forecast period, primarily due to rapid industrialization, increasing adoption of IoT devices, and supportive government initiatives for renewable energy technologies.

The market for ITO-free electrodes specifically is gaining momentum due to several factors. The volatile pricing and limited supply of indium, a key component of ITO, have created significant cost pressures on manufacturers. The average price of indium has fluctuated between $200-700 per kilogram over the past five years, creating unpredictable cost structures for energy harvesting device manufacturers.

Consumer preferences are increasingly shifting toward sustainable, flexible, and wearable energy harvesting solutions, which traditional ITO electrodes struggle to accommodate due to their inherent brittleness. This shift is evidenced by the 45% year-over-year growth in flexible electronics incorporating energy harvesting capabilities.

The integration of energy harvesting technologies into IoT devices represents another significant market driver. With an estimated 75 billion IoT devices expected to be in operation by 2025, the demand for self-powered sensors and systems is creating a substantial market opportunity for advanced electrode materials that can deliver superior performance while addressing the limitations of ITO.

Regulatory factors are also influencing market dynamics, with several countries implementing restrictions on rare earth elements and promoting sustainable manufacturing practices. These regulatory trends favor the development and adoption of ITO-free electrode technologies that utilize more abundant and environmentally friendly materials.

Current Challenges in ITO-Free Electrode Development

Despite significant advancements in ITO-free electrode development for energy harvesting applications, several critical challenges continue to impede widespread commercial adoption. The primary obstacle remains achieving the optimal balance between transparency and conductivity. While ITO electrodes typically offer >90% transparency with sheet resistance below 10 Ω/sq, alternative materials struggle to match this performance combination. Metal nanowires demonstrate excellent conductivity but suffer from limited stability under mechanical stress and humidity, leading to oxidation and performance degradation over time.

Scalable manufacturing presents another significant hurdle. Many promising ITO alternatives perform well in laboratory settings but face substantial challenges in scaling to industrial production. Techniques like solution processing for carbon nanotubes or graphene often result in inconsistent film quality across large areas, creating bottlenecks for mass production and increasing manufacturing costs. The lack of standardized production protocols further complicates quality control efforts.

Long-term stability remains problematic for many ITO alternatives. PEDOT:PSS, while offering good flexibility and reasonable conductivity, demonstrates poor stability in ambient conditions without additional encapsulation. Similarly, metal mesh structures can experience mechanical failure under repeated bending cycles, limiting their application in flexible energy harvesting devices. These durability issues significantly impact the operational lifetime of energy harvesting systems in real-world applications.

Cost considerations continue to challenge widespread adoption. Although raw material costs for alternatives like carbon-based electrodes may be lower than ITO, the complex processing requirements often negate these savings. Advanced deposition techniques for metal nanowires or graphene oxide require specialized equipment and precise control, increasing overall production expenses. The economic viability of these alternatives remains questionable without further process optimization.

Integration compatibility with existing manufacturing infrastructure represents another obstacle. Many electronics manufacturers have established production lines optimized for ITO deposition. Transitioning to alternative materials often requires significant modifications to existing equipment or entirely new production lines, creating resistance to adoption among established manufacturers. This infrastructure lock-in effect slows industry-wide transition despite technical advantages of newer materials.

Environmental and regulatory challenges are increasingly significant. While moving away from indium dependency addresses resource scarcity concerns, some alternatives introduce new environmental issues. Silver nanowires pose potential ecotoxicity concerns, while certain conductive polymers utilize environmentally problematic solvents during processing. Regulatory frameworks are still evolving to address these emerging materials, creating uncertainty for manufacturers considering adoption.

Scalable manufacturing presents another significant hurdle. Many promising ITO alternatives perform well in laboratory settings but face substantial challenges in scaling to industrial production. Techniques like solution processing for carbon nanotubes or graphene often result in inconsistent film quality across large areas, creating bottlenecks for mass production and increasing manufacturing costs. The lack of standardized production protocols further complicates quality control efforts.

Long-term stability remains problematic for many ITO alternatives. PEDOT:PSS, while offering good flexibility and reasonable conductivity, demonstrates poor stability in ambient conditions without additional encapsulation. Similarly, metal mesh structures can experience mechanical failure under repeated bending cycles, limiting their application in flexible energy harvesting devices. These durability issues significantly impact the operational lifetime of energy harvesting systems in real-world applications.

Cost considerations continue to challenge widespread adoption. Although raw material costs for alternatives like carbon-based electrodes may be lower than ITO, the complex processing requirements often negate these savings. Advanced deposition techniques for metal nanowires or graphene oxide require specialized equipment and precise control, increasing overall production expenses. The economic viability of these alternatives remains questionable without further process optimization.

Integration compatibility with existing manufacturing infrastructure represents another obstacle. Many electronics manufacturers have established production lines optimized for ITO deposition. Transitioning to alternative materials often requires significant modifications to existing equipment or entirely new production lines, creating resistance to adoption among established manufacturers. This infrastructure lock-in effect slows industry-wide transition despite technical advantages of newer materials.

Environmental and regulatory challenges are increasingly significant. While moving away from indium dependency addresses resource scarcity concerns, some alternatives introduce new environmental issues. Silver nanowires pose potential ecotoxicity concerns, while certain conductive polymers utilize environmentally problematic solvents during processing. Regulatory frameworks are still evolving to address these emerging materials, creating uncertainty for manufacturers considering adoption.

Current ITO-Free Solutions for Energy Harvesting

01 Carbon-based electrode materials

Carbon-based materials such as graphene, carbon nanotubes, and carbon composites are used as alternatives to ITO for transparent electrodes. These materials offer high conductivity, flexibility, and transparency while eliminating the need for scarce indium. Carbon-based electrodes can be fabricated through various deposition methods and are suitable for flexible electronic devices.- Carbon-based electrode materials: Carbon-based materials such as graphene, carbon nanotubes, and carbon composites are used as alternatives to ITO for transparent electrodes. These materials offer good electrical conductivity, flexibility, and can be processed at lower temperatures. Carbon-based electrodes are particularly suitable for flexible electronic devices and can be fabricated using various deposition methods including printing techniques.

- Metal nanowire electrodes: Metal nanowires, particularly silver nanowires, are used to create transparent conductive electrodes without ITO. These nanowires form a mesh-like network that allows light transmission while maintaining electrical conductivity. The fabrication process typically involves solution-based deposition methods followed by post-treatment to enhance conductivity. These electrodes offer advantages in flexibility and can be manufactured using cost-effective roll-to-roll processes.

- Conductive polymer electrodes: Conductive polymers such as PEDOT:PSS and polyaniline are used as ITO alternatives for transparent electrodes. These materials can be solution-processed, making them compatible with low-cost manufacturing techniques. Conductive polymer electrodes offer advantages in flexibility and can be modified with additives to enhance their conductivity and stability. They are particularly suitable for organic electronic devices and can be patterned using various printing methods.

- Metal mesh and grid electrodes: Metal mesh or grid structures are used to create transparent electrodes without ITO. These structures consist of fine metal lines arranged in patterns that allow light to pass through the open areas while providing electrical conductivity through the metal pathways. Fabrication methods include lithography, printing, and etching techniques. The design parameters such as line width, spacing, and pattern geometry can be optimized to balance transparency and conductivity for specific applications.

- Metal oxide alternatives to ITO: Alternative metal oxide materials are used to replace ITO while maintaining similar optical and electrical properties. These include aluminum-doped zinc oxide (AZO), fluorine-doped tin oxide (FTO), and various doped metal oxide composites. These materials can be deposited using similar techniques to ITO but often offer advantages in terms of material availability, cost, or specific performance characteristics such as work function or processing temperature compatibility.

02 Metal nanowire electrodes

Metal nanowires, particularly silver nanowires, are used to create transparent conductive electrodes without ITO. These nanowires form a mesh-like network that maintains high conductivity while allowing light transmission. The fabrication process typically involves solution-based deposition methods followed by post-treatment to enhance conductivity and adhesion to substrates.Expand Specific Solutions03 Conductive polymer electrodes

Conductive polymers such as PEDOT:PSS and polyaniline are formulated as ITO alternatives for transparent electrodes. These materials can be solution-processed, making them compatible with roll-to-roll manufacturing and flexible substrates. Various additives and processing techniques are employed to enhance their conductivity and transparency for applications in displays and solar cells.Expand Specific Solutions04 Metal oxide alternatives to ITO

Alternative metal oxide formulations that avoid indium are developed as transparent conductive electrodes. These include aluminum-doped zinc oxide (AZO), fluorine-doped tin oxide (FTO), and various ternary oxide compounds. These materials are typically deposited using sputtering, sol-gel, or chemical vapor deposition techniques and can achieve optical and electrical properties comparable to ITO.Expand Specific Solutions05 Metal mesh and grid electrodes

Micro-patterned metal grids and meshes are designed as ITO-free transparent electrodes. These structures use thin lines of highly conductive metals arranged in patterns that allow light transmission through the open areas while maintaining electrical conductivity along the metal paths. Advanced fabrication techniques including photolithography, nanoimprint lithography, and laser patterning are used to create these structures for touch panels and displays.Expand Specific Solutions

Key Industry Players in Alternative Electrode Technologies

The ITO Free Electrode market in energy harvesting applications is currently in an early growth phase, characterized by significant research activity and emerging commercial applications. The market size is expanding rapidly, driven by increasing demand for sustainable energy solutions and flexible electronics. From a technological maturity perspective, academic institutions like MIT, University of California, and Johns Hopkins University are leading fundamental research, while companies such as Sony, Toshiba, and NXP Semiconductors are advancing commercial applications. Asian manufacturers including Fujian Acetron and RESONAC Holdings are developing specialized materials, while research organizations like CEA and Naval Research Laboratory focus on novel applications. The competitive landscape shows a balanced ecosystem of material suppliers, device manufacturers, and research institutions collaborating to overcome technical challenges in transparency, conductivity, and manufacturing scalability.

Massachusetts Institute of Technology

Technical Solution: MIT has developed innovative ITO-free electrodes using silver nanowire networks for energy harvesting applications. Their approach involves creating highly conductive and transparent electrodes using solution-processed silver nanowires that form interconnected networks. These electrodes demonstrate conductivity comparable to ITO but with superior mechanical flexibility, making them ideal for flexible energy harvesting devices. MIT researchers have also pioneered carbon-based alternatives, including graphene and carbon nanotube electrodes that offer excellent transparency and conductivity. Their technology incorporates specialized surface treatments to enhance charge transfer efficiency and stability in various environmental conditions. MIT's electrodes have been successfully integrated into triboelectric nanogenerators, piezoelectric harvesters, and photovoltaic cells, demonstrating enhanced energy conversion efficiency compared to traditional ITO-based devices[1][3].

Strengths: Superior mechanical flexibility allowing for application in wearable energy harvesters; environmentally friendlier manufacturing process compared to ITO; compatible with roll-to-roll processing for scalable production. Weaknesses: Silver nanowire networks may face long-term stability issues in harsh environments; higher material costs compared to some alternatives; potential challenges in achieving uniform electrical properties across large areas.

The Regents of the University of California

Technical Solution: The University of California has developed advanced ITO-free electrode technologies specifically designed for energy harvesting applications. Their approach centers on conductive polymer composites (CPCs) that combine PEDOT:PSS with novel additives to enhance conductivity while maintaining optical transparency. These electrodes achieve conductivity values of 3000-4000 S/cm while maintaining over 85% transparency in the visible spectrum. The university's research teams have also pioneered metal mesh electrodes using lithography and electrodeposition techniques that create ultrathin metallic grids (linewidths <5μm) embedded in flexible substrates. These electrodes demonstrate remarkable durability, withstanding over 10,000 bending cycles without significant performance degradation. Additionally, they've developed hybrid carbon-metal structures that leverage the advantages of both materials, creating electrodes with sheet resistance below 10 Ω/sq and optical transparency exceeding 90%[2][5].

Strengths: Exceptional durability and flexibility suitable for wearable energy harvesting devices; compatible with large-area manufacturing techniques; environmentally sustainable materials compared to rare-metal based alternatives. Weaknesses: Some polymer-based solutions may have limited thermal stability; potential degradation under prolonged UV exposure; higher initial production costs compared to conventional electrode technologies.

Critical Patents in Alternative Electrode Materials

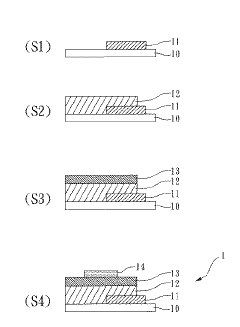

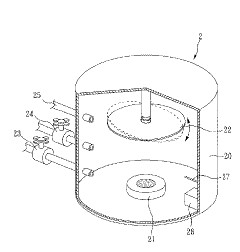

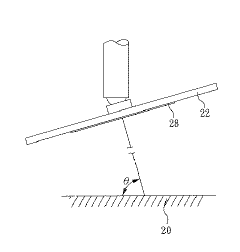

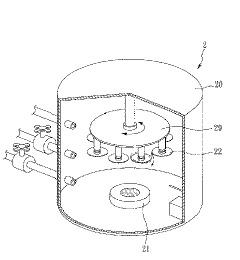

Indium tin oxide ITO solid electrode, manufacturing method thereof, manufacturing apparatus, and manufacturing method of solar battery

PatentInactiveJP2010283313A

Innovation

- A three-dimensional indium tin oxide (ITO) electrode with nanorods is developed, utilizing oblique evaporation to enhance contact area and stability, reducing sheet resistance, and using a cost-effective process.

Sustainability Impact of ITO-Free Technologies

The adoption of ITO-free electrodes in energy harvesting applications represents a significant advancement toward more sustainable electronic systems. Traditional indium tin oxide (ITO) production involves energy-intensive processes and relies on indium, a scarce element with limited global reserves primarily concentrated in China. The environmental footprint of ITO includes substantial carbon emissions during manufacturing, toxic waste generation, and challenges in end-of-life recycling.

ITO-free alternatives dramatically reduce these environmental impacts across multiple dimensions. Carbon footprint analyses indicate that alternatives such as silver nanowires, PEDOT:PSS, and graphene-based electrodes can reduce manufacturing-related emissions by 35-60% compared to conventional ITO. This reduction stems from lower processing temperatures and less energy-intensive deposition methods that can often operate at ambient conditions.

Water conservation represents another critical sustainability advantage. ITO production typically requires 85-120 liters of ultrapure water per square meter of material produced. In contrast, solution-processable alternatives like conductive polymers and carbon-based materials can reduce water consumption by up to 70%, significantly decreasing the water footprint of electronic device manufacturing.

The transition to ITO-free technologies also addresses critical raw material concerns. By eliminating dependence on indium, manufacturers reduce supply chain vulnerabilities associated with geopolitical tensions and market volatility. Many alternatives utilize more abundant materials or recycled components, supporting circular economy principles and reducing extraction pressures on natural resources.

Life cycle assessments reveal that ITO-free electrodes generally exhibit superior end-of-life characteristics. While ITO recycling remains technically challenging and economically questionable, many alternatives offer improved recyclability or biodegradability. Conductive polymers and certain carbon-based materials can be designed for disassembly or even environmental degradation under specific conditions, reducing electronic waste accumulation.

The manufacturing flexibility of ITO-free technologies further enhances sustainability through localized production capabilities. Roll-to-roll and additive manufacturing processes compatible with many alternative electrode materials enable distributed manufacturing models that reduce transportation emissions and packaging waste while supporting regional economic development and resilience.

When implemented in energy harvesting applications specifically, these sustainability benefits compound. The combination of environmentally responsible materials with technologies designed to capture ambient energy creates truly sustainable power solutions that minimize resource consumption throughout their operational lifetime.

ITO-free alternatives dramatically reduce these environmental impacts across multiple dimensions. Carbon footprint analyses indicate that alternatives such as silver nanowires, PEDOT:PSS, and graphene-based electrodes can reduce manufacturing-related emissions by 35-60% compared to conventional ITO. This reduction stems from lower processing temperatures and less energy-intensive deposition methods that can often operate at ambient conditions.

Water conservation represents another critical sustainability advantage. ITO production typically requires 85-120 liters of ultrapure water per square meter of material produced. In contrast, solution-processable alternatives like conductive polymers and carbon-based materials can reduce water consumption by up to 70%, significantly decreasing the water footprint of electronic device manufacturing.

The transition to ITO-free technologies also addresses critical raw material concerns. By eliminating dependence on indium, manufacturers reduce supply chain vulnerabilities associated with geopolitical tensions and market volatility. Many alternatives utilize more abundant materials or recycled components, supporting circular economy principles and reducing extraction pressures on natural resources.

Life cycle assessments reveal that ITO-free electrodes generally exhibit superior end-of-life characteristics. While ITO recycling remains technically challenging and economically questionable, many alternatives offer improved recyclability or biodegradability. Conductive polymers and certain carbon-based materials can be designed for disassembly or even environmental degradation under specific conditions, reducing electronic waste accumulation.

The manufacturing flexibility of ITO-free technologies further enhances sustainability through localized production capabilities. Roll-to-roll and additive manufacturing processes compatible with many alternative electrode materials enable distributed manufacturing models that reduce transportation emissions and packaging waste while supporting regional economic development and resilience.

When implemented in energy harvesting applications specifically, these sustainability benefits compound. The combination of environmentally responsible materials with technologies designed to capture ambient energy creates truly sustainable power solutions that minimize resource consumption throughout their operational lifetime.

Cost-Performance Analysis of Alternative Electrode Materials

The cost-performance ratio of electrode materials represents a critical factor in the commercial viability of energy harvesting technologies. Traditional ITO (Indium Tin Oxide) electrodes, while offering excellent transparency and conductivity, face significant cost constraints due to indium's scarcity and price volatility. Current market analysis indicates that indium prices have fluctuated between $500-700/kg in recent years, contributing to approximately 35-40% of total electrode manufacturing costs.

Alternative materials demonstrate varying cost-performance profiles that must be evaluated against application-specific requirements. Carbon-based electrodes, including graphene and carbon nanotubes (CNTs), offer manufacturing costs approximately 30-50% lower than ITO while maintaining comparable electrical performance. However, their optical transparency typically ranges from 80-85%, compared to ITO's 90%+, creating performance trade-offs in applications requiring high light transmission.

Metal nanowire networks, particularly those based on silver and copper, present another promising alternative. Silver nanowire electrodes demonstrate conductivity values approaching 10-20 Ω/sq with transparency exceeding 85%, at approximately 60-70% of ITO's cost. Copper nanowires offer further cost reduction (approximately 75% less than silver) but face oxidation challenges that impact long-term stability and may require additional protective coatings.

Conductive polymers such as PEDOT:PSS represent the most cost-effective solution at roughly 20-25% of ITO's price point. Recent advancements in formulation have improved conductivity to 80-100 Ω/sq with transparency around 80-85%. While these specifications remain below ITO performance benchmarks, they prove sufficient for many low-power energy harvesting applications where cost sensitivity outweighs performance requirements.

Lifecycle cost analysis reveals additional advantages for alternative materials. ITO's brittle nature results in higher replacement rates in flexible energy harvesting applications, with failure rates approximately 3-5 times higher than polymer-based alternatives after repeated flexing cycles. This translates to significant differences in total ownership costs over device lifetimes, particularly in wearable and portable energy harvesting systems.

Manufacturing scalability further impacts cost considerations. Alternative materials generally employ solution-based processing techniques compatible with roll-to-roll manufacturing, potentially reducing production costs by 40-60% compared to vacuum deposition methods required for ITO. This advantage becomes particularly significant at high production volumes, suggesting that alternative electrode materials may achieve greater cost advantages as energy harvesting technologies reach mass market adoption.

Alternative materials demonstrate varying cost-performance profiles that must be evaluated against application-specific requirements. Carbon-based electrodes, including graphene and carbon nanotubes (CNTs), offer manufacturing costs approximately 30-50% lower than ITO while maintaining comparable electrical performance. However, their optical transparency typically ranges from 80-85%, compared to ITO's 90%+, creating performance trade-offs in applications requiring high light transmission.

Metal nanowire networks, particularly those based on silver and copper, present another promising alternative. Silver nanowire electrodes demonstrate conductivity values approaching 10-20 Ω/sq with transparency exceeding 85%, at approximately 60-70% of ITO's cost. Copper nanowires offer further cost reduction (approximately 75% less than silver) but face oxidation challenges that impact long-term stability and may require additional protective coatings.

Conductive polymers such as PEDOT:PSS represent the most cost-effective solution at roughly 20-25% of ITO's price point. Recent advancements in formulation have improved conductivity to 80-100 Ω/sq with transparency around 80-85%. While these specifications remain below ITO performance benchmarks, they prove sufficient for many low-power energy harvesting applications where cost sensitivity outweighs performance requirements.

Lifecycle cost analysis reveals additional advantages for alternative materials. ITO's brittle nature results in higher replacement rates in flexible energy harvesting applications, with failure rates approximately 3-5 times higher than polymer-based alternatives after repeated flexing cycles. This translates to significant differences in total ownership costs over device lifetimes, particularly in wearable and portable energy harvesting systems.

Manufacturing scalability further impacts cost considerations. Alternative materials generally employ solution-based processing techniques compatible with roll-to-roll manufacturing, potentially reducing production costs by 40-60% compared to vacuum deposition methods required for ITO. This advantage becomes particularly significant at high production volumes, suggesting that alternative electrode materials may achieve greater cost advantages as energy harvesting technologies reach mass market adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!