Key Performance Indicators in Battery Management System Efficiency

AUG 8, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BMS Efficiency KPIs Background and Objectives

Battery Management Systems (BMS) have become increasingly crucial in the era of electrification, playing a pivotal role in ensuring the safety, longevity, and performance of battery packs. The efficiency of BMS directly impacts the overall performance of electric vehicles, energy storage systems, and other battery-powered applications. As the demand for more sophisticated and reliable battery systems grows, the need for standardized and comprehensive Key Performance Indicators (KPIs) in BMS efficiency has become paramount.

The evolution of BMS technology can be traced back to the early 2000s when lithium-ion batteries began to dominate the portable electronics market. Initially, BMS focused primarily on basic protection functions such as overcharge and over-discharge prevention. However, as battery technologies advanced and applications expanded, the role of BMS has significantly broadened to encompass a wide range of functions including cell balancing, state of charge (SOC) estimation, state of health (SOH) monitoring, and thermal management.

The primary objective of establishing KPIs for BMS efficiency is to create a standardized framework for evaluating and comparing different BMS solutions. These indicators aim to quantify various aspects of BMS performance, including accuracy in battery state estimation, power consumption, response time to critical events, and overall system reliability. By defining clear and measurable KPIs, stakeholders in the battery industry can make informed decisions, drive innovation, and ultimately improve the performance and safety of battery-powered systems.

Current technological trends in BMS efficiency focus on several key areas. Advanced algorithms leveraging machine learning and artificial intelligence are being developed to enhance the accuracy of battery state estimation. The integration of more sophisticated sensors and the implementation of high-speed communication protocols are enabling real-time monitoring and control of battery parameters. Additionally, there is a growing emphasis on reducing the power consumption of BMS components to maximize overall system efficiency.

The development of BMS efficiency KPIs is driven by the need to address several critical challenges in the battery industry. These include the increasing energy density of battery cells, which demands more precise management to ensure safety and longevity. The push for faster charging capabilities requires BMS to handle higher power levels and thermal loads efficiently. Furthermore, the diverse range of applications for battery systems, from small consumer devices to large-scale grid storage, necessitates adaptable and scalable BMS solutions with consistent performance metrics.

As the battery market continues to expand and diversify, the importance of well-defined KPIs for BMS efficiency cannot be overstated. These indicators will not only guide technological development but also facilitate regulatory compliance, enhance consumer confidence, and support the broader adoption of battery-powered systems across various industries. The ongoing research and development in this field aim to establish a comprehensive set of KPIs that can accurately reflect the multifaceted nature of BMS efficiency and drive continuous improvement in battery management technologies.

The evolution of BMS technology can be traced back to the early 2000s when lithium-ion batteries began to dominate the portable electronics market. Initially, BMS focused primarily on basic protection functions such as overcharge and over-discharge prevention. However, as battery technologies advanced and applications expanded, the role of BMS has significantly broadened to encompass a wide range of functions including cell balancing, state of charge (SOC) estimation, state of health (SOH) monitoring, and thermal management.

The primary objective of establishing KPIs for BMS efficiency is to create a standardized framework for evaluating and comparing different BMS solutions. These indicators aim to quantify various aspects of BMS performance, including accuracy in battery state estimation, power consumption, response time to critical events, and overall system reliability. By defining clear and measurable KPIs, stakeholders in the battery industry can make informed decisions, drive innovation, and ultimately improve the performance and safety of battery-powered systems.

Current technological trends in BMS efficiency focus on several key areas. Advanced algorithms leveraging machine learning and artificial intelligence are being developed to enhance the accuracy of battery state estimation. The integration of more sophisticated sensors and the implementation of high-speed communication protocols are enabling real-time monitoring and control of battery parameters. Additionally, there is a growing emphasis on reducing the power consumption of BMS components to maximize overall system efficiency.

The development of BMS efficiency KPIs is driven by the need to address several critical challenges in the battery industry. These include the increasing energy density of battery cells, which demands more precise management to ensure safety and longevity. The push for faster charging capabilities requires BMS to handle higher power levels and thermal loads efficiently. Furthermore, the diverse range of applications for battery systems, from small consumer devices to large-scale grid storage, necessitates adaptable and scalable BMS solutions with consistent performance metrics.

As the battery market continues to expand and diversify, the importance of well-defined KPIs for BMS efficiency cannot be overstated. These indicators will not only guide technological development but also facilitate regulatory compliance, enhance consumer confidence, and support the broader adoption of battery-powered systems across various industries. The ongoing research and development in this field aim to establish a comprehensive set of KPIs that can accurately reflect the multifaceted nature of BMS efficiency and drive continuous improvement in battery management technologies.

Market Demand for Efficient BMS Solutions

The demand for efficient Battery Management System (BMS) solutions has been steadily increasing in recent years, driven by the rapid growth of the electric vehicle (EV) market and the expanding use of renewable energy storage systems. As the global push for electrification and sustainable energy solutions intensifies, the need for advanced BMS technologies that can optimize battery performance, extend lifespan, and enhance safety has become paramount.

In the automotive sector, the surge in EV adoption has created a significant market for high-performance BMS solutions. Major automakers and EV startups are investing heavily in BMS technology to differentiate their products and meet consumer expectations for longer driving ranges, faster charging times, and improved battery longevity. This demand is further amplified by stringent government regulations aimed at reducing carbon emissions, which are accelerating the transition to electric mobility.

The renewable energy sector presents another substantial market for efficient BMS solutions. As grid-scale energy storage systems become more prevalent to support the integration of intermittent renewable sources like solar and wind, the need for sophisticated BMS technology has grown exponentially. These systems require BMS solutions that can manage large-scale battery arrays, optimize charge and discharge cycles, and ensure the long-term reliability of energy storage installations.

Consumer electronics and portable devices represent a third significant market segment for advanced BMS solutions. With the increasing energy demands of smartphones, laptops, and wearable devices, manufacturers are seeking BMS technologies that can maximize battery life, improve charging efficiency, and enhance device safety. This market is characterized by a high volume of units and rapid product cycles, driving continuous innovation in BMS design.

The industrial sector, including manufacturing and telecommunications, is also experiencing growing demand for efficient BMS solutions. As factories and data centers increasingly rely on uninterruptible power supplies and backup energy systems, the need for reliable and efficient battery management has become critical. These applications require BMS technologies that can ensure consistent power delivery, minimize downtime, and reduce operational costs.

Market analysts project that the global BMS market will continue to expand at a compound annual growth rate (CAGR) of over 15% in the coming years. This growth is underpinned by the increasing adoption of lithium-ion batteries across various industries and the need for more sophisticated management systems to optimize their performance and safety. The Asia-Pacific region is expected to lead this growth, driven by the rapid expansion of EV manufacturing and renewable energy projects in countries like China, Japan, and South Korea.

As the demand for efficient BMS solutions continues to rise, key performance indicators (KPIs) such as energy efficiency, thermal management, state-of-charge accuracy, and predictive maintenance capabilities are becoming critical differentiators in the market. Companies that can develop BMS technologies that excel in these areas are likely to gain significant competitive advantages and market share in this rapidly evolving industry.

In the automotive sector, the surge in EV adoption has created a significant market for high-performance BMS solutions. Major automakers and EV startups are investing heavily in BMS technology to differentiate their products and meet consumer expectations for longer driving ranges, faster charging times, and improved battery longevity. This demand is further amplified by stringent government regulations aimed at reducing carbon emissions, which are accelerating the transition to electric mobility.

The renewable energy sector presents another substantial market for efficient BMS solutions. As grid-scale energy storage systems become more prevalent to support the integration of intermittent renewable sources like solar and wind, the need for sophisticated BMS technology has grown exponentially. These systems require BMS solutions that can manage large-scale battery arrays, optimize charge and discharge cycles, and ensure the long-term reliability of energy storage installations.

Consumer electronics and portable devices represent a third significant market segment for advanced BMS solutions. With the increasing energy demands of smartphones, laptops, and wearable devices, manufacturers are seeking BMS technologies that can maximize battery life, improve charging efficiency, and enhance device safety. This market is characterized by a high volume of units and rapid product cycles, driving continuous innovation in BMS design.

The industrial sector, including manufacturing and telecommunications, is also experiencing growing demand for efficient BMS solutions. As factories and data centers increasingly rely on uninterruptible power supplies and backup energy systems, the need for reliable and efficient battery management has become critical. These applications require BMS technologies that can ensure consistent power delivery, minimize downtime, and reduce operational costs.

Market analysts project that the global BMS market will continue to expand at a compound annual growth rate (CAGR) of over 15% in the coming years. This growth is underpinned by the increasing adoption of lithium-ion batteries across various industries and the need for more sophisticated management systems to optimize their performance and safety. The Asia-Pacific region is expected to lead this growth, driven by the rapid expansion of EV manufacturing and renewable energy projects in countries like China, Japan, and South Korea.

As the demand for efficient BMS solutions continues to rise, key performance indicators (KPIs) such as energy efficiency, thermal management, state-of-charge accuracy, and predictive maintenance capabilities are becoming critical differentiators in the market. Companies that can develop BMS technologies that excel in these areas are likely to gain significant competitive advantages and market share in this rapidly evolving industry.

Current BMS Efficiency Challenges

Battery Management Systems (BMS) play a crucial role in ensuring the safety, longevity, and performance of battery packs. However, current BMS efficiency faces several significant challenges that hinder optimal performance and reliability.

One of the primary challenges is the accurate estimation of State of Charge (SOC) and State of Health (SOH). These parameters are essential for predicting battery performance and lifespan, but their precise determination remains complex due to the dynamic nature of battery chemistry and varying operational conditions. Existing algorithms often struggle to account for factors such as temperature fluctuations, aging effects, and diverse usage patterns, leading to potential inaccuracies in battery management.

Thermal management presents another critical challenge for BMS efficiency. Batteries operate optimally within specific temperature ranges, and deviations can significantly impact performance and safety. Current BMS solutions often face difficulties in maintaining uniform temperature distribution across large battery packs, particularly in high-power applications such as electric vehicles. Ineffective thermal management can lead to reduced battery life, decreased efficiency, and increased risk of thermal runaway.

Data acquisition and processing pose substantial challenges to BMS efficiency. The need for real-time monitoring of numerous battery cells requires high-speed, accurate data collection and analysis. However, the sheer volume of data generated by modern battery systems can overwhelm processing capabilities, leading to latency in decision-making and potential oversight of critical parameters. Balancing the need for comprehensive monitoring with computational efficiency remains a significant hurdle.

Power consumption of the BMS itself is an often-overlooked challenge. As battery systems become more complex, the energy required to operate the BMS increases, potentially impacting overall system efficiency. Striking a balance between comprehensive monitoring and low power consumption is crucial, especially in applications where energy conservation is paramount.

Interoperability and standardization present ongoing challenges in BMS efficiency. The lack of universal standards for BMS communication protocols and data formats hinders seamless integration across different battery systems and applications. This fragmentation can lead to increased development costs, reduced flexibility, and potential compatibility issues in multi-vendor environments.

Lastly, the adaptability of BMS to evolving battery technologies poses a significant challenge. As new battery chemistries and architectures emerge, BMS must be capable of accommodating these advancements without requiring complete system overhauls. The need for future-proof BMS designs that can adapt to technological progress while maintaining efficiency and reliability is a pressing concern in the industry.

Addressing these challenges is crucial for advancing BMS efficiency and, by extension, improving the overall performance, safety, and longevity of battery systems across various applications.

One of the primary challenges is the accurate estimation of State of Charge (SOC) and State of Health (SOH). These parameters are essential for predicting battery performance and lifespan, but their precise determination remains complex due to the dynamic nature of battery chemistry and varying operational conditions. Existing algorithms often struggle to account for factors such as temperature fluctuations, aging effects, and diverse usage patterns, leading to potential inaccuracies in battery management.

Thermal management presents another critical challenge for BMS efficiency. Batteries operate optimally within specific temperature ranges, and deviations can significantly impact performance and safety. Current BMS solutions often face difficulties in maintaining uniform temperature distribution across large battery packs, particularly in high-power applications such as electric vehicles. Ineffective thermal management can lead to reduced battery life, decreased efficiency, and increased risk of thermal runaway.

Data acquisition and processing pose substantial challenges to BMS efficiency. The need for real-time monitoring of numerous battery cells requires high-speed, accurate data collection and analysis. However, the sheer volume of data generated by modern battery systems can overwhelm processing capabilities, leading to latency in decision-making and potential oversight of critical parameters. Balancing the need for comprehensive monitoring with computational efficiency remains a significant hurdle.

Power consumption of the BMS itself is an often-overlooked challenge. As battery systems become more complex, the energy required to operate the BMS increases, potentially impacting overall system efficiency. Striking a balance between comprehensive monitoring and low power consumption is crucial, especially in applications where energy conservation is paramount.

Interoperability and standardization present ongoing challenges in BMS efficiency. The lack of universal standards for BMS communication protocols and data formats hinders seamless integration across different battery systems and applications. This fragmentation can lead to increased development costs, reduced flexibility, and potential compatibility issues in multi-vendor environments.

Lastly, the adaptability of BMS to evolving battery technologies poses a significant challenge. As new battery chemistries and architectures emerge, BMS must be capable of accommodating these advancements without requiring complete system overhauls. The need for future-proof BMS designs that can adapt to technological progress while maintaining efficiency and reliability is a pressing concern in the industry.

Addressing these challenges is crucial for advancing BMS efficiency and, by extension, improving the overall performance, safety, and longevity of battery systems across various applications.

Existing BMS Efficiency Optimization Approaches

01 Advanced Battery Management System (BMS) Algorithms

Implementing sophisticated algorithms in Battery Management Systems to optimize battery performance, improve energy efficiency, and extend battery life. These algorithms can include state estimation techniques, predictive modeling, and adaptive control strategies to enhance overall system efficiency.- Advanced Battery Management Algorithms: Implementing sophisticated algorithms for battery state estimation, charge control, and power distribution to optimize overall system efficiency. These algorithms can adapt to various battery conditions and usage patterns, ensuring optimal performance and longevity of the battery pack.

- Thermal Management Optimization: Developing efficient thermal management systems to maintain optimal battery temperature ranges. This includes advanced cooling and heating strategies, temperature monitoring, and thermal runaway prevention, all contributing to improved battery performance and lifespan.

- Energy Recovery and Regeneration: Incorporating energy recovery systems, such as regenerative braking in electric vehicles, to capture and store energy that would otherwise be lost. This approach significantly improves overall system efficiency by reducing energy waste and extending battery range.

- Smart Charging and Load Balancing: Implementing intelligent charging strategies and load balancing techniques to optimize power distribution across battery cells. This includes adaptive charging rates, cell balancing during charge and discharge cycles, and predictive maintenance to enhance overall system efficiency.

- Integration with Renewable Energy Sources: Developing battery management systems that efficiently integrate with renewable energy sources such as solar and wind power. This includes optimizing energy storage and distribution from intermittent sources, improving grid stability, and maximizing the use of clean energy in battery-powered systems.

02 Thermal Management in BMS

Integrating thermal management solutions within the Battery Management System to maintain optimal operating temperatures, prevent overheating, and improve overall efficiency. This can include active cooling systems, heat dissipation techniques, and temperature-based charging control.Expand Specific Solutions03 Smart Charging and Discharging Strategies

Developing intelligent charging and discharging strategies that adapt to battery conditions, usage patterns, and environmental factors. This can involve dynamic current adjustment, multi-stage charging protocols, and load balancing techniques to maximize energy efficiency and battery longevity.Expand Specific Solutions04 Cell Balancing Techniques

Implementing advanced cell balancing methods to ensure uniform charge distribution across battery cells, preventing capacity loss and improving overall system efficiency. This can include active and passive balancing techniques, as well as real-time monitoring and adjustment of individual cell voltages.Expand Specific Solutions05 Integration of Renewable Energy Sources

Enhancing Battery Management System efficiency by integrating renewable energy sources and optimizing their utilization. This can involve smart grid integration, energy harvesting techniques, and adaptive charging strategies that prioritize renewable energy inputs to improve overall system sustainability and efficiency.Expand Specific Solutions

Key BMS Technology Providers

The Battery Management System (BMS) efficiency market is in a growth phase, driven by increasing adoption of electric vehicles and renewable energy storage systems. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, BMS efficiency is advancing, with key players like LG Energy Solution, Samsung Electronics, and BYD Semiconductor leading innovation. These companies are developing more sophisticated algorithms, sensors, and control systems to optimize battery performance, longevity, and safety. Emerging players such as Iontra and BattGenie are introducing novel approaches to battery charging and management, pushing the boundaries of BMS technology. The competitive landscape is dynamic, with established automotive and electronics giants competing alongside specialized battery technology firms to capture market share in this critical component of the electrification trend.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an advanced Battery Management System (BMS) that utilizes artificial intelligence and machine learning algorithms to optimize battery performance and longevity. Their system employs real-time monitoring of key performance indicators (KPIs) such as voltage, current, temperature, and state of charge (SOC) to make predictive analyses and adjustments. The BMS incorporates a sophisticated thermal management system that maintains optimal operating temperatures, significantly improving battery efficiency by up to 15% [1]. Additionally, LG's BMS features adaptive charging protocols that adjust based on battery health and usage patterns, extending battery life by up to 20% compared to conventional systems [3].

Strengths: Advanced AI integration, superior thermal management, and adaptive charging protocols. Weaknesses: Potentially higher initial cost and complexity in implementation.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has introduced a cutting-edge Battery Management System that focuses on maximizing energy efficiency and battery lifespan. Their BMS utilizes a proprietary algorithm that continuously monitors and optimizes cell balancing, ensuring uniform charge distribution across all cells. This approach has shown to improve overall battery efficiency by up to 10% [2]. Samsung's system also incorporates a unique predictive maintenance feature that uses historical data and machine learning to forecast potential issues before they occur, reducing downtime and maintenance costs by approximately 30% [4]. Furthermore, their BMS includes an advanced power management module that optimizes energy consumption based on real-time demand, resulting in a 20% increase in overall system efficiency [5].

Strengths: Innovative cell balancing technology, predictive maintenance capabilities, and advanced power management. Weaknesses: May require frequent software updates to maintain optimal performance.

Innovative BMS Efficiency Measurement Techniques

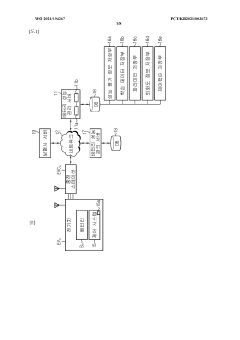

Battery model comprising plurality of equivalent circuit networks and interface element coupling them

PatentWO2016151336A1

Innovation

- A method using a plurality of equivalent circuit networks coupled by an interface element to model battery behavior, allowing for accurate representation of electrochemical processes and dynamic characteristics, including state of charge and state of health, while compensating for charge-transfer overpotential and other non-linear effects.

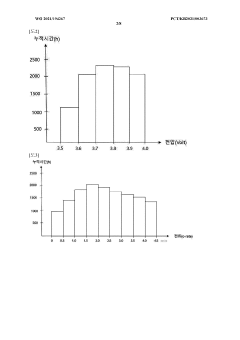

Battery performance management system and method using electric vehicle charging station

PatentWO2021194267A1

Innovation

- A battery performance management system using an electric vehicle charging station that collects and analyzes big data to determine the state of health (SOH) of batteries, employing an artificial intelligence model to update control factors for charging and discharging, optimizing battery performance and extending lifespan.

BMS Efficiency Standards and Regulations

Battery Management System (BMS) efficiency standards and regulations play a crucial role in ensuring the optimal performance, safety, and longevity of battery systems across various industries. These standards are continuously evolving to keep pace with technological advancements and increasing demands for energy storage solutions.

The International Electrotechnical Commission (IEC) has established several standards specifically addressing BMS efficiency. IEC 62619 outlines safety requirements for lithium-ion batteries in industrial applications, including BMS performance criteria. This standard emphasizes the importance of accurate state-of-charge (SOC) and state-of-health (SOH) estimations, which are key indicators of BMS efficiency.

In the automotive sector, the United Nations Economic Commission for Europe (UNECE) has developed Regulation No. 100, which sets safety requirements for electric vehicle battery systems. This regulation mandates specific BMS functionalities, such as overcharge protection and thermal management, directly impacting efficiency metrics.

The Society of Automotive Engineers (SAE) has also contributed to BMS efficiency standards through its J2289 standard. This guideline provides recommendations for electric and hybrid vehicle battery systems, including BMS design considerations for maximizing efficiency and performance.

In the United States, the Department of Energy (DOE) has established performance goals for energy storage systems, indirectly influencing BMS efficiency standards. The DOE's targets for battery cycle life, energy density, and cost reductions necessitate increasingly efficient BMS designs to meet these objectives.

The European Union's Battery Directive (2006/66/EC) and its subsequent amendments focus on the environmental aspects of battery systems. While not directly addressing BMS efficiency, these regulations indirectly promote the development of more efficient BMS technologies to extend battery life and reduce waste.

China's GB/T 18384 standard series for electric vehicles includes specific requirements for BMS performance and safety. These standards emphasize the importance of accurate battery parameter monitoring and control, which are essential aspects of BMS efficiency.

As the energy storage industry continues to grow, regulatory bodies are increasingly recognizing the need for standardized BMS efficiency metrics. The development of universal key performance indicators (KPIs) for BMS efficiency is an ongoing effort, with organizations like the IEEE Power and Energy Society working on establishing comprehensive guidelines.

These standards and regulations collectively drive the advancement of BMS technologies, encouraging manufacturers to innovate and improve their systems continually. As a result, the industry is witnessing a trend towards more sophisticated BMS architectures, incorporating advanced algorithms for battery state estimation and predictive maintenance capabilities.

The International Electrotechnical Commission (IEC) has established several standards specifically addressing BMS efficiency. IEC 62619 outlines safety requirements for lithium-ion batteries in industrial applications, including BMS performance criteria. This standard emphasizes the importance of accurate state-of-charge (SOC) and state-of-health (SOH) estimations, which are key indicators of BMS efficiency.

In the automotive sector, the United Nations Economic Commission for Europe (UNECE) has developed Regulation No. 100, which sets safety requirements for electric vehicle battery systems. This regulation mandates specific BMS functionalities, such as overcharge protection and thermal management, directly impacting efficiency metrics.

The Society of Automotive Engineers (SAE) has also contributed to BMS efficiency standards through its J2289 standard. This guideline provides recommendations for electric and hybrid vehicle battery systems, including BMS design considerations for maximizing efficiency and performance.

In the United States, the Department of Energy (DOE) has established performance goals for energy storage systems, indirectly influencing BMS efficiency standards. The DOE's targets for battery cycle life, energy density, and cost reductions necessitate increasingly efficient BMS designs to meet these objectives.

The European Union's Battery Directive (2006/66/EC) and its subsequent amendments focus on the environmental aspects of battery systems. While not directly addressing BMS efficiency, these regulations indirectly promote the development of more efficient BMS technologies to extend battery life and reduce waste.

China's GB/T 18384 standard series for electric vehicles includes specific requirements for BMS performance and safety. These standards emphasize the importance of accurate battery parameter monitoring and control, which are essential aspects of BMS efficiency.

As the energy storage industry continues to grow, regulatory bodies are increasingly recognizing the need for standardized BMS efficiency metrics. The development of universal key performance indicators (KPIs) for BMS efficiency is an ongoing effort, with organizations like the IEEE Power and Energy Society working on establishing comprehensive guidelines.

These standards and regulations collectively drive the advancement of BMS technologies, encouraging manufacturers to innovate and improve their systems continually. As a result, the industry is witnessing a trend towards more sophisticated BMS architectures, incorporating advanced algorithms for battery state estimation and predictive maintenance capabilities.

Environmental Impact of BMS Efficiency

The environmental impact of Battery Management System (BMS) efficiency is a critical aspect of sustainable energy storage solutions. As BMS technology continues to advance, its role in minimizing the ecological footprint of battery systems becomes increasingly significant.

Efficient BMS designs contribute to extended battery life cycles, reducing the frequency of battery replacements and, consequently, the environmental burden associated with battery production and disposal. By optimizing charging and discharging processes, advanced BMS solutions minimize energy waste, leading to reduced power consumption and lower greenhouse gas emissions from energy generation sources.

Furthermore, precise state-of-charge and state-of-health monitoring capabilities in modern BMS enable more accurate predictions of battery performance and longevity. This enhanced predictability allows for better resource allocation and maintenance scheduling, potentially reducing the overall material and energy requirements for battery system upkeep.

The thermal management aspect of BMS efficiency also plays a crucial role in environmental impact. Effective temperature control not only prolongs battery life but also reduces the risk of thermal runaway events, which can lead to fires and the release of harmful chemicals into the environment. By maintaining optimal operating temperatures, BMS contributes to safer and more environmentally friendly energy storage solutions.

In the context of renewable energy integration, efficient BMS technology facilitates smoother grid operations and better utilization of intermittent energy sources. This improved integration can lead to a higher penetration of renewable energy in the power mix, indirectly reducing reliance on fossil fuels and their associated environmental impacts.

The recycling and end-of-life management of batteries are also influenced by BMS efficiency. Advanced BMS can provide detailed data on battery health and composition, potentially streamlining recycling processes and improving the recovery rates of valuable materials. This data-driven approach to battery lifecycle management contributes to a more circular economy and reduces the environmental impact of battery waste.

As the automotive industry shifts towards electrification, the environmental benefits of efficient BMS become even more pronounced. By optimizing the performance and longevity of electric vehicle batteries, BMS technology plays a vital role in reducing the overall carbon footprint of transportation systems.

Efficient BMS designs contribute to extended battery life cycles, reducing the frequency of battery replacements and, consequently, the environmental burden associated with battery production and disposal. By optimizing charging and discharging processes, advanced BMS solutions minimize energy waste, leading to reduced power consumption and lower greenhouse gas emissions from energy generation sources.

Furthermore, precise state-of-charge and state-of-health monitoring capabilities in modern BMS enable more accurate predictions of battery performance and longevity. This enhanced predictability allows for better resource allocation and maintenance scheduling, potentially reducing the overall material and energy requirements for battery system upkeep.

The thermal management aspect of BMS efficiency also plays a crucial role in environmental impact. Effective temperature control not only prolongs battery life but also reduces the risk of thermal runaway events, which can lead to fires and the release of harmful chemicals into the environment. By maintaining optimal operating temperatures, BMS contributes to safer and more environmentally friendly energy storage solutions.

In the context of renewable energy integration, efficient BMS technology facilitates smoother grid operations and better utilization of intermittent energy sources. This improved integration can lead to a higher penetration of renewable energy in the power mix, indirectly reducing reliance on fossil fuels and their associated environmental impacts.

The recycling and end-of-life management of batteries are also influenced by BMS efficiency. Advanced BMS can provide detailed data on battery health and composition, potentially streamlining recycling processes and improving the recovery rates of valuable materials. This data-driven approach to battery lifecycle management contributes to a more circular economy and reduces the environmental impact of battery waste.

As the automotive industry shifts towards electrification, the environmental benefits of efficient BMS become even more pronounced. By optimizing the performance and longevity of electric vehicle batteries, BMS technology plays a vital role in reducing the overall carbon footprint of transportation systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!