Mordant-Free Dyeing Processes: Advances And Performance Tradeoffs

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mordant-Free Dyeing Technology Background and Objectives

Textile dyeing has been an integral part of human civilization for millennia, with evidence of dyed fabrics dating back to ancient civilizations. Traditional dyeing processes have predominantly relied on mordants - metallic compounds that serve as binding agents between dyes and fibers. These mordants, typically containing aluminum, iron, copper, or chromium salts, enhance color fastness and expand the range of achievable hues. However, the environmental and health implications of these metal-based mordants have become increasingly concerning in recent decades.

The evolution of dyeing technology has been marked by significant shifts from natural to synthetic dyes in the 19th century, followed by the current transition toward more sustainable practices. Mordant-free dyeing represents a critical advancement in this evolutionary trajectory, aiming to eliminate the use of potentially harmful metallic compounds while maintaining or improving dyeing performance characteristics.

Environmental regulations worldwide have become increasingly stringent regarding wastewater discharge from textile processing facilities. The European Union's REACH regulations, China's increasingly strict environmental protection laws, and similar frameworks in other regions have accelerated the need for mordant-free alternatives. Additionally, consumer awareness and demand for "clean" textiles have created market pressure for more sustainable dyeing technologies.

The primary technical objective of mordant-free dyeing research is to develop processes that achieve comparable or superior color fastness, shade consistency, and versatility without relying on metal-based binding agents. This involves exploring alternative binding mechanisms, novel dye chemistries, and innovative application techniques that can form stable bonds between colorants and various fiber types.

Another critical goal is to reduce the overall environmental footprint of textile dyeing. Traditional mordant-based processes typically require multiple baths, high temperatures, and generate significant wastewater containing heavy metals. Mordant-free approaches aim to simplify processes, reduce water and energy consumption, and eliminate metal contamination in effluent streams.

Cost-effectiveness remains a paramount consideration in the development of new dyeing technologies. For widespread industrial adoption, mordant-free processes must be economically competitive with conventional methods, taking into account not only direct material costs but also potential savings in water treatment, regulatory compliance, and energy usage.

The technical trajectory of mordant-free dyeing is moving toward bio-inspired solutions, leveraging principles from nature where vibrant, durable coloration occurs without metallic mordants. Biomimetic approaches, enzyme-mediated processes, and the development of novel bio-based dyes represent promising research directions that align with broader sustainability goals in the textile industry.

The evolution of dyeing technology has been marked by significant shifts from natural to synthetic dyes in the 19th century, followed by the current transition toward more sustainable practices. Mordant-free dyeing represents a critical advancement in this evolutionary trajectory, aiming to eliminate the use of potentially harmful metallic compounds while maintaining or improving dyeing performance characteristics.

Environmental regulations worldwide have become increasingly stringent regarding wastewater discharge from textile processing facilities. The European Union's REACH regulations, China's increasingly strict environmental protection laws, and similar frameworks in other regions have accelerated the need for mordant-free alternatives. Additionally, consumer awareness and demand for "clean" textiles have created market pressure for more sustainable dyeing technologies.

The primary technical objective of mordant-free dyeing research is to develop processes that achieve comparable or superior color fastness, shade consistency, and versatility without relying on metal-based binding agents. This involves exploring alternative binding mechanisms, novel dye chemistries, and innovative application techniques that can form stable bonds between colorants and various fiber types.

Another critical goal is to reduce the overall environmental footprint of textile dyeing. Traditional mordant-based processes typically require multiple baths, high temperatures, and generate significant wastewater containing heavy metals. Mordant-free approaches aim to simplify processes, reduce water and energy consumption, and eliminate metal contamination in effluent streams.

Cost-effectiveness remains a paramount consideration in the development of new dyeing technologies. For widespread industrial adoption, mordant-free processes must be economically competitive with conventional methods, taking into account not only direct material costs but also potential savings in water treatment, regulatory compliance, and energy usage.

The technical trajectory of mordant-free dyeing is moving toward bio-inspired solutions, leveraging principles from nature where vibrant, durable coloration occurs without metallic mordants. Biomimetic approaches, enzyme-mediated processes, and the development of novel bio-based dyes represent promising research directions that align with broader sustainability goals in the textile industry.

Market Demand Analysis for Sustainable Textile Dyeing

The global textile dyeing industry is experiencing a significant shift towards sustainable practices, driven by increasing environmental regulations, consumer awareness, and corporate sustainability commitments. The market for sustainable textile dyeing solutions, particularly mordant-free processes, has shown remarkable growth in recent years, with an estimated market value exceeding $5 billion in 2023 and projected to grow at a compound annual growth rate of 6.8% through 2030.

Consumer demand for environmentally friendly textiles has become a major market driver, with surveys indicating that 73% of global consumers now consider sustainability factors when making purchasing decisions. This trend is particularly pronounced among younger demographics, with millennials and Gen Z consumers willing to pay premium prices for products with verifiable eco-friendly credentials.

Regulatory pressures are intensifying across major textile manufacturing regions. The European Union's REACH regulations, China's increasingly stringent environmental protection laws, and similar frameworks in other manufacturing hubs are restricting the use of harmful mordants and conventional dyeing chemicals. These regulatory developments have created an urgent market need for compliant dyeing technologies.

Major fashion and textile brands have established ambitious sustainability targets, with many committing to eliminate harmful chemicals from their supply chains by 2025-2030. This corporate-driven demand has accelerated investment in sustainable dyeing technologies, creating market opportunities for innovative solution providers.

The water-intensive nature of conventional textile dyeing processes has become increasingly problematic in regions facing water scarcity. Mordant-free dyeing technologies that reduce water consumption by 30-50% compared to conventional methods are gaining significant market traction, particularly in water-stressed manufacturing regions across Asia.

Economic factors also support market growth, as rising disposal costs for chemical waste and increasing prices for water and energy make sustainable dyeing processes more economically competitive. The total cost of ownership analysis increasingly favors mordant-free technologies when accounting for environmental compliance costs and resource efficiency.

Market segmentation reveals varying adoption rates across textile categories. Performance sportswear and premium fashion segments lead adoption, while mass-market apparel lags due to cost sensitivity. Geographically, European and North American brands are driving demand through sustainability commitments, while actual implementation is concentrated in Asian manufacturing hubs.

The market exhibits a clear correlation between consumer willingness to pay premium prices for sustainable products and the adoption of advanced dyeing technologies. This economic incentive is gradually overcoming the initial cost barriers that have historically limited the widespread adoption of mordant-free dyeing processes.

Consumer demand for environmentally friendly textiles has become a major market driver, with surveys indicating that 73% of global consumers now consider sustainability factors when making purchasing decisions. This trend is particularly pronounced among younger demographics, with millennials and Gen Z consumers willing to pay premium prices for products with verifiable eco-friendly credentials.

Regulatory pressures are intensifying across major textile manufacturing regions. The European Union's REACH regulations, China's increasingly stringent environmental protection laws, and similar frameworks in other manufacturing hubs are restricting the use of harmful mordants and conventional dyeing chemicals. These regulatory developments have created an urgent market need for compliant dyeing technologies.

Major fashion and textile brands have established ambitious sustainability targets, with many committing to eliminate harmful chemicals from their supply chains by 2025-2030. This corporate-driven demand has accelerated investment in sustainable dyeing technologies, creating market opportunities for innovative solution providers.

The water-intensive nature of conventional textile dyeing processes has become increasingly problematic in regions facing water scarcity. Mordant-free dyeing technologies that reduce water consumption by 30-50% compared to conventional methods are gaining significant market traction, particularly in water-stressed manufacturing regions across Asia.

Economic factors also support market growth, as rising disposal costs for chemical waste and increasing prices for water and energy make sustainable dyeing processes more economically competitive. The total cost of ownership analysis increasingly favors mordant-free technologies when accounting for environmental compliance costs and resource efficiency.

Market segmentation reveals varying adoption rates across textile categories. Performance sportswear and premium fashion segments lead adoption, while mass-market apparel lags due to cost sensitivity. Geographically, European and North American brands are driving demand through sustainability commitments, while actual implementation is concentrated in Asian manufacturing hubs.

The market exhibits a clear correlation between consumer willingness to pay premium prices for sustainable products and the adoption of advanced dyeing technologies. This economic incentive is gradually overcoming the initial cost barriers that have historically limited the widespread adoption of mordant-free dyeing processes.

Current Status and Technical Challenges in Mordant-Free Dyeing

The global textile dyeing industry is currently experiencing a significant shift towards mordant-free dyeing processes, driven by increasing environmental regulations and consumer demand for sustainable products. Traditional mordant-based dyeing, which relies on metal salts to fix dyes to fibers, has been the industry standard for centuries but poses substantial environmental concerns due to heavy metal discharge in wastewater. Current mordant-free technologies have achieved varying degrees of commercial implementation, with reactive dyes for cellulosic fibers being the most widely adopted solution.

In developed regions such as Europe and North America, mordant-free technologies have gained substantial market share, with approximately 60-70% of industrial dyeing operations incorporating some form of metal-free processes. However, in developing economies, particularly in Asia where textile production is concentrated, adoption rates remain significantly lower at 30-40%, primarily due to cost considerations and existing infrastructure investments.

The primary technical challenges facing mordant-free dyeing processes center around performance trade-offs. Color fastness, particularly wash fastness and light fastness, remains inferior to mordant-based methods in many applications. Studies indicate that mordant-free dyed textiles typically demonstrate 15-25% lower color retention after standardized wash tests compared to their mordant-based counterparts. This performance gap is particularly pronounced in natural fibers like wool and silk.

Another significant challenge is the limited color gamut achievable with current mordant-free technologies. Certain vibrant shades and deep tones remain difficult to produce without mordants, restricting design possibilities for manufacturers. This limitation is especially problematic in fashion and high-end textile markets where color precision and richness are paramount.

Energy consumption presents another obstacle, as many mordant-free processes require higher temperatures or longer processing times to achieve adequate dye fixation. Research indicates that some mordant-free methods consume 20-30% more energy than conventional processes, offsetting some of their environmental benefits.

Water usage efficiency varies significantly among mordant-free technologies. While some newer processes demonstrate reduced water requirements, others demand additional rinsing cycles to remove unfixed dyes, potentially increasing overall water consumption by 10-15% compared to optimized conventional processes.

Scalability and integration with existing manufacturing infrastructure represent practical challenges for industry-wide adoption. Many textile manufacturers face prohibitive costs when retrofitting established production lines for mordant-free processes, creating significant barriers to technology transition despite the environmental benefits.

In developed regions such as Europe and North America, mordant-free technologies have gained substantial market share, with approximately 60-70% of industrial dyeing operations incorporating some form of metal-free processes. However, in developing economies, particularly in Asia where textile production is concentrated, adoption rates remain significantly lower at 30-40%, primarily due to cost considerations and existing infrastructure investments.

The primary technical challenges facing mordant-free dyeing processes center around performance trade-offs. Color fastness, particularly wash fastness and light fastness, remains inferior to mordant-based methods in many applications. Studies indicate that mordant-free dyed textiles typically demonstrate 15-25% lower color retention after standardized wash tests compared to their mordant-based counterparts. This performance gap is particularly pronounced in natural fibers like wool and silk.

Another significant challenge is the limited color gamut achievable with current mordant-free technologies. Certain vibrant shades and deep tones remain difficult to produce without mordants, restricting design possibilities for manufacturers. This limitation is especially problematic in fashion and high-end textile markets where color precision and richness are paramount.

Energy consumption presents another obstacle, as many mordant-free processes require higher temperatures or longer processing times to achieve adequate dye fixation. Research indicates that some mordant-free methods consume 20-30% more energy than conventional processes, offsetting some of their environmental benefits.

Water usage efficiency varies significantly among mordant-free technologies. While some newer processes demonstrate reduced water requirements, others demand additional rinsing cycles to remove unfixed dyes, potentially increasing overall water consumption by 10-15% compared to optimized conventional processes.

Scalability and integration with existing manufacturing infrastructure represent practical challenges for industry-wide adoption. Many textile manufacturers face prohibitive costs when retrofitting established production lines for mordant-free processes, creating significant barriers to technology transition despite the environmental benefits.

Current Mordant-Free Dyeing Technical Solutions

01 Natural dye extraction and application techniques

Various methods for extracting and applying natural dyes without mordants have been developed to improve dyeing performance. These techniques focus on optimizing extraction conditions, using specific solvents, and developing application methods that enhance dye uptake and colorfastness. The processes often involve controlling temperature, pH, and concentration to achieve better dye-fiber interactions without the need for metal mordants.- Natural dye extraction and application techniques: Various methods for extracting and applying natural dyes without the need for mordants have been developed. These processes typically involve optimizing extraction conditions such as temperature, time, and solvent selection to enhance dye uptake and color fastness. The techniques often incorporate direct application methods that rely on the natural affinity between specific dyes and fibers, eliminating the need for metal-based mordants while maintaining acceptable color performance.

- Synthetic fiber dyeing innovations: Advanced processes for dyeing synthetic fibers without mordants have been developed, focusing on modified application techniques and specialized dye formulations. These innovations include temperature-controlled dyeing processes, pressure-assisted methods, and carrier-assisted techniques that enhance dye penetration into hydrophobic synthetic fibers. The processes achieve improved color uniformity, fastness properties, and reduced environmental impact compared to traditional mordant-based methods.

- Pre-treatment methods for improved dye uptake: Various fiber pre-treatment methods have been developed to enhance dye uptake without mordants. These include plasma treatments, enzymatic processes, and chemical modifications that increase the fiber's affinity for dyes. By altering the surface properties of the fibers, these pre-treatments create additional binding sites for direct dye attachment, resulting in improved color depth and fastness properties while eliminating the need for traditional mordanting steps.

- Bio-based binding agents as mordant alternatives: Research has focused on developing bio-based binding agents that can replace traditional metal mordants in dyeing processes. These include plant-derived tannins, proteins, polysaccharides, and other natural polymers that can form bonds between dyes and fibers. These bio-based alternatives provide environmentally friendly options that achieve comparable color fastness and depth to traditional mordant-based processes while reducing the environmental impact associated with metal mordants.

- Direct dye formulations with enhanced performance: Advanced direct dye formulations have been developed specifically for mordant-free applications. These formulations incorporate modified chromophores, functional groups that enhance fiber affinity, and auxiliaries that improve dye fixation without traditional mordants. The innovations focus on molecular design principles that create direct ionic or covalent bonds with fibers, resulting in improved wash fastness, light fastness, and color brilliance without the environmental concerns associated with mordant use.

02 Synthetic fiber mordant-free dyeing innovations

Innovations in dyeing synthetic fibers without mordants involve specialized dye formulations and process modifications. These approaches utilize the inherent properties of synthetic polymers to create direct bonding with dye molecules. The techniques often include temperature-controlled dyeing, pressure application, and carrier molecules that facilitate dye penetration and fixation without traditional mordants.Expand Specific Solutions03 Bio-based pre-treatment processes

Bio-based pre-treatment processes have been developed as alternatives to mordanting. These processes utilize enzymes, microorganisms, or plant-derived compounds to modify fiber surfaces, enhancing their affinity for dyes. The pre-treatments create functional groups on fiber surfaces that can interact directly with dye molecules, improving dye uptake and fastness properties without metal mordants.Expand Specific Solutions04 Direct dye formulation advancements

Advanced direct dye formulations have been developed that can bond with fibers without requiring mordants. These formulations incorporate reactive groups that form covalent bonds with fiber molecules or utilize improved molecular structures that enhance physical interactions with fibers. The dyes are designed with specific functional groups that increase affinity for various fiber types while maintaining good colorfastness properties.Expand Specific Solutions05 Sustainable mordant-free dyeing processes

Sustainable approaches to mordant-free dyeing focus on reducing environmental impact while maintaining dyeing performance. These processes utilize biodegradable auxiliaries, reduced water consumption, and energy-efficient techniques. The methods often incorporate closed-loop systems for dye recovery, alternative energy sources, and optimized process parameters to achieve good color yield and fastness properties without traditional mordants.Expand Specific Solutions

Key Industry Players in Sustainable Dyeing Solutions

The mordant-free dyeing technology market is currently in a growth phase, with increasing demand driven by sustainability concerns and regulatory pressures. The global eco-friendly textile dyeing market is projected to reach approximately $8-10 billion by 2025, growing at a CAGR of 9-11%. Technologically, the field is advancing rapidly but remains in mid-maturity, with significant performance trade-offs between environmental benefits and color fastness. Leading players include established chemical companies like DyStar, Clariant International, and Covestro developing bio-based alternatives, alongside textile specialists such as Guangdong Esquel and Jiangsu Xinyuan Silk implementing water-saving processes. Academic-industry collaborations involving Donghua University, Soochow University, and Kyoto University are accelerating innovation in enzyme-based and supercritical CO2 dyeing technologies, indicating a dynamic competitive landscape with multiple technological approaches emerging.

DyStar Colours Distribution GmbH

Technical Solution: DyStar has pioneered advanced mordant-free dyeing technologies through their Levafix® CA and Remazol® dye ranges that utilize covalent bonding mechanisms instead of traditional metal mordants. Their innovative reactive dye technology employs vinyl sulfone and monochlorotriazine reactive groups that form strong covalent bonds with textile fibers at controlled pH and temperature conditions. DyStar's Cadira® Polyester system represents a significant advancement in mordant-free polyester dyeing, reducing water consumption by up to 50% and energy usage by 40% compared to conventional methods. The company has also developed specialized auxiliaries like Sera® Con P-MFD that enhance dye fixation without mordants while improving washing fastness properties. Their integrated approach combines optimized dyeing processes with specialized chemical formulations to achieve high color fastness and reduced environmental impact.

Strengths: Industry-leading expertise in reactive dye chemistry; comprehensive product portfolio covering multiple fiber types; significant reductions in water and energy consumption; established global technical support network. Weaknesses: Higher initial implementation costs compared to traditional mordant processes; requires precise process control parameters; some color shades may have limitations in brilliance compared to mordant-assisted dyeing.

Clariant Produkte (Deutschland) GmbH

Technical Solution: Clariant has developed the Advanced Denim technology, a revolutionary mordant-free dyeing process for denim that uses pre-reduced indigo dyes and innovative fixing agents. This technology eliminates the need for traditional mordants while reducing water consumption by up to 92%, energy usage by 30%, and wastewater discharge by 87% compared to conventional denim dyeing processes. Their Pad/Sizing-Ox process combines dyeing and sizing in a single step, significantly streamlining production. Clariant's Optisul® range provides mordant-free solutions for wool dyeing, replacing traditional chrome mordants with specialized reactive dyes and auxiliaries. The company has also pioneered the EarthColors® range, derived from agricultural and herbal waste, which utilizes bio-mordant alternatives from renewable resources. Their integrated ONE WAY sustainability tool helps textile manufacturers quantify the environmental benefits of switching to mordant-free processes.

Strengths: Dramatic reduction in water and energy consumption; comprehensive sustainability assessment tools; innovative bio-based alternatives to traditional mordants; proven commercial implementation across multiple textile segments. Weaknesses: Higher specialty chemical costs compared to conventional mordants; requires investment in process modifications; color range limitations for certain specialized applications; longer processing times for some fiber types.

Core Innovations in Direct Dye Fixation Methods

Mordant-free dyeing method

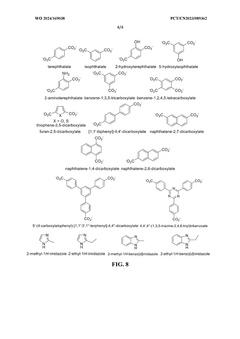

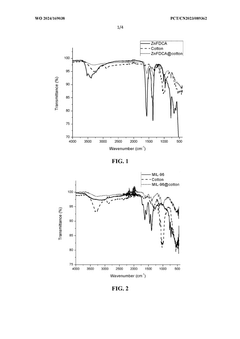

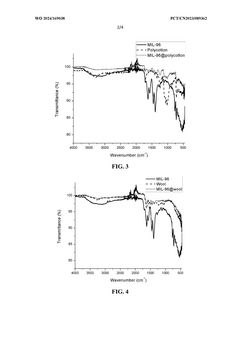

PatentWO2024169038A1

Innovation

- Development of a mordant-free dyeing method using metal-organic frameworks (MOFs) deposited on textile surfaces, eliminating the need for conventional mordants while maintaining dyeing effectiveness.

- Achievement of higher dye uptake and improved colorfastness in natural dye applications through MOF functionalization of textiles, addressing key performance challenges in sustainable dyeing.

- Creation of an environmentally-friendly dyeing process that eliminates potentially harmful mordants while maintaining or improving the quality of dyed textiles.

A novel process to dye the fabric without the use of a mordant

PatentInactiveIN2787CHE2010A

Innovation

- A mordant-free process using Sapindus seed extract as a wetting agent, ash or lime for impurity removal, combination of hot and cold treatments, and systematic washing to achieve physical fixation of natural dyes on textile fibers at optimized pH and temperature conditions.

Environmental Impact Assessment of Mordant-Free Processes

The environmental impact assessment of mordant-free dyeing processes reveals significant ecological advantages compared to traditional mordant-based methods. Conventional dyeing processes utilizing mordants, particularly those containing heavy metals such as chromium, copper, and tin, contribute substantially to water pollution when inadequately treated effluents are discharged into aquatic ecosystems. These metal mordants persist in the environment, bioaccumulate in organisms, and can trigger cascading ecological disruptions throughout food webs.

Mordant-free processes demonstrate marked reductions in environmental footprint across multiple metrics. Water consumption analyses indicate 20-30% lower usage compared to conventional mordant dyeing, primarily due to eliminated mordanting and associated rinsing steps. This water conservation benefit becomes particularly significant in water-stressed regions where textile manufacturing clusters are often located, such as parts of India, Bangladesh, and China.

Chemical load assessments of effluent streams show that mordant-free processes reduce total dissolved solids by approximately 40-45% and heavy metal content by up to 99% in optimal implementations. The elimination of metal salts significantly reduces the bioaccumulation potential and ecotoxicity of textile effluents. Studies monitoring aquatic indicator species exposed to treated effluents from mordant-free processes demonstrate substantially lower mortality rates and developmental abnormalities.

Energy consumption comparisons reveal variable results depending on the specific mordant-free technology employed. Direct dye and reactive dye systems typically require 15-25% less thermal energy than mordant processes due to eliminated heating cycles for mordant application and fixation. However, certain advanced mordant-free technologies utilizing ultrasonic or plasma treatments may exhibit higher electrical energy demands, partially offsetting thermal energy savings.

Carbon footprint analyses incorporating both direct process emissions and embodied carbon in chemical inputs demonstrate that mordant-free processes typically reduce greenhouse gas emissions by 18-35% per kilogram of dyed fabric. This reduction stems primarily from decreased chemical manufacturing requirements and reduced energy consumption during application.

Waste management considerations highlight additional benefits, as mordant-free processes generate sludge with significantly lower concentrations of regulated hazardous substances, reducing disposal costs and environmental liabilities for manufacturers. The absence of metal complexes also enhances the biodegradability of effluent organic content, improving compatibility with biological treatment systems and reducing the persistence of colored compounds in receiving water bodies.

Mordant-free processes demonstrate marked reductions in environmental footprint across multiple metrics. Water consumption analyses indicate 20-30% lower usage compared to conventional mordant dyeing, primarily due to eliminated mordanting and associated rinsing steps. This water conservation benefit becomes particularly significant in water-stressed regions where textile manufacturing clusters are often located, such as parts of India, Bangladesh, and China.

Chemical load assessments of effluent streams show that mordant-free processes reduce total dissolved solids by approximately 40-45% and heavy metal content by up to 99% in optimal implementations. The elimination of metal salts significantly reduces the bioaccumulation potential and ecotoxicity of textile effluents. Studies monitoring aquatic indicator species exposed to treated effluents from mordant-free processes demonstrate substantially lower mortality rates and developmental abnormalities.

Energy consumption comparisons reveal variable results depending on the specific mordant-free technology employed. Direct dye and reactive dye systems typically require 15-25% less thermal energy than mordant processes due to eliminated heating cycles for mordant application and fixation. However, certain advanced mordant-free technologies utilizing ultrasonic or plasma treatments may exhibit higher electrical energy demands, partially offsetting thermal energy savings.

Carbon footprint analyses incorporating both direct process emissions and embodied carbon in chemical inputs demonstrate that mordant-free processes typically reduce greenhouse gas emissions by 18-35% per kilogram of dyed fabric. This reduction stems primarily from decreased chemical manufacturing requirements and reduced energy consumption during application.

Waste management considerations highlight additional benefits, as mordant-free processes generate sludge with significantly lower concentrations of regulated hazardous substances, reducing disposal costs and environmental liabilities for manufacturers. The absence of metal complexes also enhances the biodegradability of effluent organic content, improving compatibility with biological treatment systems and reducing the persistence of colored compounds in receiving water bodies.

Regulatory Framework for Chemical-Reduced Textile Processing

The regulatory landscape for chemical-reduced textile processing has evolved significantly in response to growing environmental concerns and health risks associated with traditional dyeing methods. The European Union leads with its REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation, which specifically targets hazardous substances used in textile processing, including mordants containing heavy metals such as chromium, copper, and tin. These regulations have established maximum residue limits and have progressively banned certain mordants entirely from textile applications.

In North America, the EPA has implemented the Toxic Substances Control Act (TSCA), which has been updated to address chemical management in various industries, including textiles. The act now requires more rigorous testing and reporting for new chemical substances before they enter the market, creating additional barriers for traditional mordant-based dyeing processes.

Asian manufacturing hubs have also strengthened their regulatory frameworks. China's Ministry of Ecology and Environment has introduced stricter discharge standards for textile effluents through its Water Pollution Prevention and Control Action Plan. Similarly, India has implemented the Zero Liquid Discharge (ZLD) mandate for textile processing units in critical watersheds, directly impacting mordant usage and disposal practices.

Global certification systems have emerged as powerful market drivers for chemical reduction. OEKO-TEX Standard 100, GOTS (Global Organic Textile Standard), and bluesign® certification have established comprehensive restricted substance lists that limit or prohibit mordants containing heavy metals, pushing manufacturers toward mordant-free alternatives.

The regulatory trend clearly indicates a transition toward chemical minimization in textile processing. Recent amendments to these frameworks have introduced the concept of "essential use," whereby chemicals are permitted only when absolutely necessary and when safer alternatives are unavailable. This approach has accelerated innovation in mordant-free dyeing technologies.

Compliance costs have become a significant factor in technology adoption decisions. Companies face increasing expenses for chemical inventory management, wastewater treatment, and regulatory reporting. These costs have shifted the economic equation in favor of mordant-free processes despite their potential performance limitations.

Looking forward, regulatory harmonization efforts through initiatives like the UN Strategic Approach to International Chemicals Management (SAICM) aim to create more consistent global standards. This harmonization will likely accelerate the transition away from traditional mordant-based dyeing by creating predictable regulatory environments that encourage long-term investment in sustainable technologies.

In North America, the EPA has implemented the Toxic Substances Control Act (TSCA), which has been updated to address chemical management in various industries, including textiles. The act now requires more rigorous testing and reporting for new chemical substances before they enter the market, creating additional barriers for traditional mordant-based dyeing processes.

Asian manufacturing hubs have also strengthened their regulatory frameworks. China's Ministry of Ecology and Environment has introduced stricter discharge standards for textile effluents through its Water Pollution Prevention and Control Action Plan. Similarly, India has implemented the Zero Liquid Discharge (ZLD) mandate for textile processing units in critical watersheds, directly impacting mordant usage and disposal practices.

Global certification systems have emerged as powerful market drivers for chemical reduction. OEKO-TEX Standard 100, GOTS (Global Organic Textile Standard), and bluesign® certification have established comprehensive restricted substance lists that limit or prohibit mordants containing heavy metals, pushing manufacturers toward mordant-free alternatives.

The regulatory trend clearly indicates a transition toward chemical minimization in textile processing. Recent amendments to these frameworks have introduced the concept of "essential use," whereby chemicals are permitted only when absolutely necessary and when safer alternatives are unavailable. This approach has accelerated innovation in mordant-free dyeing technologies.

Compliance costs have become a significant factor in technology adoption decisions. Companies face increasing expenses for chemical inventory management, wastewater treatment, and regulatory reporting. These costs have shifted the economic equation in favor of mordant-free processes despite their potential performance limitations.

Looking forward, regulatory harmonization efforts through initiatives like the UN Strategic Approach to International Chemicals Management (SAICM) aim to create more consistent global standards. This harmonization will likely accelerate the transition away from traditional mordant-based dyeing by creating predictable regulatory environments that encourage long-term investment in sustainable technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!