Natural Dye Wastewater Management: Treatment And Reuse Strategies

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Natural Dye Wastewater Background and Objectives

Natural dyes have been utilized for centuries across various civilizations, with evidence dating back to 3000 BCE in ancient Egypt, China, and India. These dyes, derived from plants, animals, and minerals, were the primary coloring agents for textiles, food, and cosmetics until the mid-19th century when synthetic dyes emerged. The natural dye industry has experienced a renaissance in recent decades due to increasing environmental consciousness and consumer preference for sustainable products.

The global natural dye market has been growing at a compound annual growth rate of approximately 11.3% since 2018, with projections indicating continued expansion through 2030. This resurgence is driven by the textile industry's shift toward eco-friendly practices and the rising demand for naturally colored products in fashion, food, and cosmetics sectors. However, this growth has brought significant environmental challenges, particularly regarding wastewater management.

Natural dye production generates substantial volumes of wastewater containing various organic compounds, suspended solids, and in some cases, mordants like aluminum, iron, tin, and chromium salts. Despite their natural origin, these effluents can exhibit high chemical oxygen demand (COD), biological oxygen demand (BOD), and color intensity, potentially causing environmental degradation if discharged untreated. Traditional dyeing processes typically consume 80-100 liters of water per kilogram of textile material, highlighting the magnitude of the wastewater challenge.

The evolution of natural dye wastewater treatment has progressed from basic physical separation methods to sophisticated integrated systems. Early approaches focused primarily on dilution and rudimentary filtration, while contemporary strategies incorporate advanced oxidation processes, membrane filtration, biological treatments, and resource recovery technologies. This technological progression reflects the industry's growing commitment to circular economy principles.

The primary objectives of this technical research report are to comprehensively evaluate existing natural dye wastewater treatment technologies, identify innovative reuse strategies, and develop a roadmap for sustainable wastewater management in the natural dye industry. Specifically, we aim to assess the efficiency, cost-effectiveness, and scalability of various treatment methodologies while exploring opportunities for water reclamation and valuable by-product recovery.

Furthermore, this report seeks to identify technological gaps in current treatment approaches and propose research directions that could lead to breakthrough solutions. By analyzing global best practices and emerging technologies, we intend to provide actionable insights for industry stakeholders to implement environmentally responsible wastewater management systems that align with circular economy principles and increasingly stringent regulatory frameworks.

The global natural dye market has been growing at a compound annual growth rate of approximately 11.3% since 2018, with projections indicating continued expansion through 2030. This resurgence is driven by the textile industry's shift toward eco-friendly practices and the rising demand for naturally colored products in fashion, food, and cosmetics sectors. However, this growth has brought significant environmental challenges, particularly regarding wastewater management.

Natural dye production generates substantial volumes of wastewater containing various organic compounds, suspended solids, and in some cases, mordants like aluminum, iron, tin, and chromium salts. Despite their natural origin, these effluents can exhibit high chemical oxygen demand (COD), biological oxygen demand (BOD), and color intensity, potentially causing environmental degradation if discharged untreated. Traditional dyeing processes typically consume 80-100 liters of water per kilogram of textile material, highlighting the magnitude of the wastewater challenge.

The evolution of natural dye wastewater treatment has progressed from basic physical separation methods to sophisticated integrated systems. Early approaches focused primarily on dilution and rudimentary filtration, while contemporary strategies incorporate advanced oxidation processes, membrane filtration, biological treatments, and resource recovery technologies. This technological progression reflects the industry's growing commitment to circular economy principles.

The primary objectives of this technical research report are to comprehensively evaluate existing natural dye wastewater treatment technologies, identify innovative reuse strategies, and develop a roadmap for sustainable wastewater management in the natural dye industry. Specifically, we aim to assess the efficiency, cost-effectiveness, and scalability of various treatment methodologies while exploring opportunities for water reclamation and valuable by-product recovery.

Furthermore, this report seeks to identify technological gaps in current treatment approaches and propose research directions that could lead to breakthrough solutions. By analyzing global best practices and emerging technologies, we intend to provide actionable insights for industry stakeholders to implement environmentally responsible wastewater management systems that align with circular economy principles and increasingly stringent regulatory frameworks.

Market Analysis for Sustainable Textile Processing

The global market for sustainable textile processing has witnessed significant growth in recent years, driven by increasing environmental awareness and stringent regulations regarding textile wastewater management. The natural dye sector, valued at approximately $1.5 billion in 2022, is projected to grow at a CAGR of 11.3% through 2030, reflecting the rising demand for eco-friendly dyeing alternatives.

Consumer preferences have shifted dramatically toward environmentally responsible products, with surveys indicating that 73% of global consumers are willing to pay premium prices for sustainable textiles. This trend is particularly pronounced in European and North American markets, where regulatory frameworks increasingly penalize conventional dyeing processes with high environmental footprints.

The industrial adoption of natural dye technologies faces economic challenges despite growing consumer demand. Traditional chemical dyeing processes remain 30-40% less expensive than natural dye alternatives, creating a significant barrier to widespread industry transition. However, this gap is narrowing as water treatment costs for conventional processes continue to rise and economies of scale develop in the natural dye sector.

Water resource economics plays a crucial role in market development. Regions experiencing water scarcity, particularly in Asia where 80% of global textile production is concentrated, are seeing accelerated adoption of water-efficient dyeing technologies and closed-loop systems. The cost of freshwater in textile manufacturing hubs has increased by an average of 15% annually over the past five years, making water recycling and reuse economically attractive.

Investment patterns reveal growing confidence in sustainable textile technologies. Venture capital funding for innovative natural dye wastewater treatment solutions reached $450 million in 2022, a threefold increase from 2018 levels. Major textile manufacturers have committed to sustainability targets, with 65% of leading brands pledging to implement water-efficient dyeing processes by 2030.

Market segmentation shows varying adoption rates across different textile sectors. The fashion apparel segment leads with 42% of sustainable dyeing technology implementation, followed by home textiles (28%) and technical textiles (18%). Geographically, Europe represents the most mature market for sustainable textile processing, while Asia-Pacific demonstrates the highest growth potential due to its manufacturing dominance and increasing regulatory pressure.

The competitive landscape features both established players and innovative startups. Traditional chemical suppliers are diversifying their portfolios to include natural dye solutions, while specialized sustainability-focused companies are gaining market share through technological innovation in wastewater treatment and dye recovery systems.

Consumer preferences have shifted dramatically toward environmentally responsible products, with surveys indicating that 73% of global consumers are willing to pay premium prices for sustainable textiles. This trend is particularly pronounced in European and North American markets, where regulatory frameworks increasingly penalize conventional dyeing processes with high environmental footprints.

The industrial adoption of natural dye technologies faces economic challenges despite growing consumer demand. Traditional chemical dyeing processes remain 30-40% less expensive than natural dye alternatives, creating a significant barrier to widespread industry transition. However, this gap is narrowing as water treatment costs for conventional processes continue to rise and economies of scale develop in the natural dye sector.

Water resource economics plays a crucial role in market development. Regions experiencing water scarcity, particularly in Asia where 80% of global textile production is concentrated, are seeing accelerated adoption of water-efficient dyeing technologies and closed-loop systems. The cost of freshwater in textile manufacturing hubs has increased by an average of 15% annually over the past five years, making water recycling and reuse economically attractive.

Investment patterns reveal growing confidence in sustainable textile technologies. Venture capital funding for innovative natural dye wastewater treatment solutions reached $450 million in 2022, a threefold increase from 2018 levels. Major textile manufacturers have committed to sustainability targets, with 65% of leading brands pledging to implement water-efficient dyeing processes by 2030.

Market segmentation shows varying adoption rates across different textile sectors. The fashion apparel segment leads with 42% of sustainable dyeing technology implementation, followed by home textiles (28%) and technical textiles (18%). Geographically, Europe represents the most mature market for sustainable textile processing, while Asia-Pacific demonstrates the highest growth potential due to its manufacturing dominance and increasing regulatory pressure.

The competitive landscape features both established players and innovative startups. Traditional chemical suppliers are diversifying their portfolios to include natural dye solutions, while specialized sustainability-focused companies are gaining market share through technological innovation in wastewater treatment and dye recovery systems.

Current Challenges in Natural Dye Effluent Treatment

The treatment of natural dye wastewater presents significant challenges due to the complex composition and variable characteristics of these effluents. Unlike synthetic dyes, natural dyes derive from diverse plant, animal, and mineral sources, resulting in effluents with highly heterogeneous properties. This variability makes standardized treatment approaches difficult to implement effectively across different natural dyeing operations.

One of the primary challenges is the high color intensity of natural dye effluents, which can persist even after conventional treatment methods. These colored compounds often demonstrate resistance to biodegradation and can significantly impact aquatic ecosystems by reducing light penetration, affecting photosynthetic activity, and potentially harming aquatic organisms through toxicity or bioaccumulation effects.

The organic load in natural dye wastewater presents another substantial challenge. Many natural dyeing processes utilize mordants and auxiliaries that contribute to elevated levels of Chemical Oxygen Demand (COD) and Biological Oxygen Demand (BOD). These high organic loads can overwhelm conventional treatment systems and lead to oxygen depletion in receiving water bodies if not adequately addressed.

pH variability constitutes a significant technical obstacle in treatment processes. Different natural dyes require specific pH conditions during application, resulting in effluents with widely varying pH levels. This variability necessitates additional neutralization steps before biological treatment can be effectively implemented, adding complexity and cost to treatment systems.

The presence of metals from mordants compounds the treatment challenges. Traditional natural dyeing often employs metal salts as mordants to improve color fastness, introducing metals like aluminum, iron, copper, and chromium into the wastewater stream. These metals can inhibit biological treatment processes and may require specialized removal techniques to prevent environmental contamination.

Seasonal and batch-to-batch variations in natural dye composition create inconsistency in wastewater characteristics, making continuous treatment system optimization necessary. Treatment facilities must be designed with sufficient flexibility to accommodate these variations, which increases operational complexity and costs.

Scale-appropriate technologies represent another challenge, particularly for small-scale artisanal dyers who lack access to sophisticated treatment infrastructure. Many existing treatment technologies are designed for large industrial operations and are not economically viable or technically feasible for smaller producers, creating a significant gap in treatment capabilities across the sector.

Finally, the lack of comprehensive research and standardized protocols specifically for natural dye effluent treatment hampers effective management strategies. While considerable research exists for synthetic dye treatment, natural dye wastewater has received comparatively less attention, resulting in knowledge gaps regarding optimal treatment approaches and potential reuse opportunities.

One of the primary challenges is the high color intensity of natural dye effluents, which can persist even after conventional treatment methods. These colored compounds often demonstrate resistance to biodegradation and can significantly impact aquatic ecosystems by reducing light penetration, affecting photosynthetic activity, and potentially harming aquatic organisms through toxicity or bioaccumulation effects.

The organic load in natural dye wastewater presents another substantial challenge. Many natural dyeing processes utilize mordants and auxiliaries that contribute to elevated levels of Chemical Oxygen Demand (COD) and Biological Oxygen Demand (BOD). These high organic loads can overwhelm conventional treatment systems and lead to oxygen depletion in receiving water bodies if not adequately addressed.

pH variability constitutes a significant technical obstacle in treatment processes. Different natural dyes require specific pH conditions during application, resulting in effluents with widely varying pH levels. This variability necessitates additional neutralization steps before biological treatment can be effectively implemented, adding complexity and cost to treatment systems.

The presence of metals from mordants compounds the treatment challenges. Traditional natural dyeing often employs metal salts as mordants to improve color fastness, introducing metals like aluminum, iron, copper, and chromium into the wastewater stream. These metals can inhibit biological treatment processes and may require specialized removal techniques to prevent environmental contamination.

Seasonal and batch-to-batch variations in natural dye composition create inconsistency in wastewater characteristics, making continuous treatment system optimization necessary. Treatment facilities must be designed with sufficient flexibility to accommodate these variations, which increases operational complexity and costs.

Scale-appropriate technologies represent another challenge, particularly for small-scale artisanal dyers who lack access to sophisticated treatment infrastructure. Many existing treatment technologies are designed for large industrial operations and are not economically viable or technically feasible for smaller producers, creating a significant gap in treatment capabilities across the sector.

Finally, the lack of comprehensive research and standardized protocols specifically for natural dye effluent treatment hampers effective management strategies. While considerable research exists for synthetic dye treatment, natural dye wastewater has received comparatively less attention, resulting in knowledge gaps regarding optimal treatment approaches and potential reuse opportunities.

Existing Treatment and Reuse Methodologies

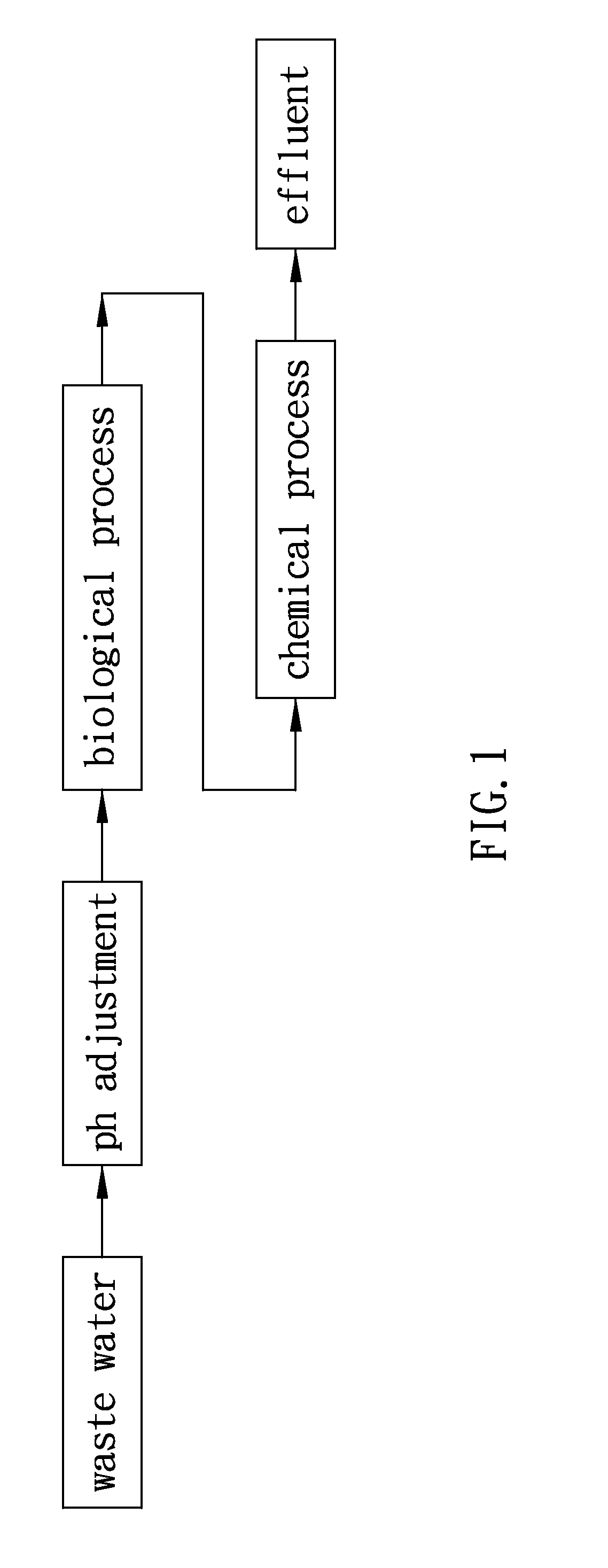

01 Biological treatment methods for natural dye wastewater

Biological treatment methods utilize microorganisms to degrade and remove natural dyes from wastewater. These methods include aerobic and anaerobic processes, as well as the use of specific bacteria, fungi, or enzymes that can break down complex dye molecules. Biological treatments are environmentally friendly and can achieve high removal efficiencies for certain types of natural dyes, making the treated water suitable for reuse in various applications.- Biological treatment methods for natural dye wastewater: Biological treatment methods utilize microorganisms to degrade and remove natural dyes from wastewater. These methods include aerobic and anaerobic processes, activated sludge systems, and the use of specific bacteria or fungi that can metabolize dye compounds. Biological treatments are environmentally friendly and can achieve high removal efficiencies for certain types of natural dyes, making the treated water suitable for reuse in various applications.

- Physical-chemical treatment processes: Physical-chemical processes involve the use of coagulation, flocculation, adsorption, and advanced oxidation for treating natural dye wastewater. These methods can effectively remove color, reduce chemical oxygen demand (COD), and eliminate toxicity from the wastewater. Adsorbents like activated carbon, clay minerals, and agricultural waste derivatives are commonly used to capture dye molecules, while oxidation processes break down complex dye structures into simpler, less harmful compounds.

- Membrane filtration and separation technologies: Membrane-based technologies such as ultrafiltration, nanofiltration, and reverse osmosis are effective for separating dye molecules from wastewater. These processes can achieve high-quality treated water suitable for reuse in textile processing or other industrial applications. Membrane systems can be combined with other treatment methods to create integrated systems that maximize dye removal efficiency while minimizing operational costs and environmental impact.

- Wastewater reuse systems for textile industry: Closed-loop systems for treating and reusing natural dye wastewater within textile manufacturing processes help conserve water resources and reduce environmental pollution. These systems typically involve multiple treatment stages tailored to specific dye types and production requirements. The treated water can be reused for dyeing processes, washing, or other manufacturing operations, significantly reducing freshwater consumption and wastewater discharge volumes.

- Novel materials and composite technologies for dye removal: Innovative materials and composite technologies have been developed specifically for natural dye wastewater treatment. These include nanocomposites, modified natural materials, and hybrid systems that combine multiple treatment mechanisms. Such advanced materials offer enhanced adsorption capacity, selectivity for specific dyes, antimicrobial properties, and improved regeneration capabilities. These technologies can significantly improve treatment efficiency while reducing operational costs and environmental footprint.

02 Physical-chemical treatment processes

Physical-chemical treatment processes involve the use of coagulation, flocculation, adsorption, and advanced oxidation to remove natural dyes from wastewater. These methods can effectively remove color and reduce the chemical oxygen demand of the wastewater. Adsorbents such as activated carbon, clay minerals, and agricultural waste products can be used to bind dye molecules, while oxidation processes break down the dye structures. These treatments enable the reuse of treated water in textile processing or other industrial applications.Expand Specific Solutions03 Membrane filtration technologies

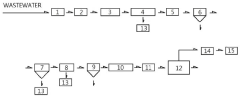

Membrane filtration technologies, including ultrafiltration, nanofiltration, and reverse osmosis, are effective for separating natural dyes from wastewater. These processes use semi-permeable membranes with different pore sizes to remove dye molecules, suspended solids, and other contaminants. Membrane filtration can produce high-quality treated water suitable for reuse in dyeing processes or other applications, reducing water consumption and environmental impact in textile industries.Expand Specific Solutions04 Combined treatment systems for enhanced efficiency

Combined treatment systems integrate multiple treatment methods to enhance the efficiency of natural dye wastewater treatment. These systems typically combine biological processes with physical-chemical treatments or membrane filtration to achieve better removal of dyes and other pollutants. The synergistic effects of combined treatments can overcome the limitations of individual methods, resulting in higher quality treated water that meets reuse standards for various applications in textile and other industries.Expand Specific Solutions05 Dye recovery and reuse technologies

Dye recovery and reuse technologies focus on extracting natural dyes from wastewater for reuse in dyeing processes. These methods include adsorption, precipitation, and advanced separation techniques that can isolate dye molecules from wastewater. The recovered dyes can be reused in textile dyeing, reducing the need for fresh dye materials and minimizing waste. Additionally, the treated water can be recycled back into the production process, creating a closed-loop system that conserves water resources and reduces environmental pollution.Expand Specific Solutions

Key Industry Players in Eco-friendly Wastewater Management

Natural dye wastewater management is currently in a transitional phase, moving from traditional treatment methods to more sustainable approaches. The global market for natural dye wastewater treatment is expanding rapidly, driven by stricter environmental regulations and growing consumer demand for eco-friendly products. Key players in this field include academic institutions like Zhejiang University and South China Normal University, which are pioneering research in advanced treatment technologies, alongside specialized companies such as Zhejiang Qicai Environmental Technology and Boying Technology, which are developing commercial applications. Established chemical companies like Zhejiang Longsheng Group and Clariant are also investing in sustainable dyeing processes. The technology is maturing with innovations in membrane filtration, advanced oxidation, and biological treatment methods, though cost-effectiveness and scalability remain challenges for widespread implementation.

Zhejiang Qicai Environmental Technology Co Ltd.

Technical Solution: Zhejiang Qicai has developed the "NaturaDye Recovery" system, a comprehensive natural dye wastewater treatment technology focusing on both pollution control and resource recovery. Their approach features a multi-stage separation process beginning with electroflocculation using proprietary electrode materials that selectively bind to different dye components. The system incorporates advanced oxidation using their patented catalytic peroxide activation technology that achieves over 95% color removal while minimizing chemical consumption. Their biological treatment stage utilizes specialized fungal strains capable of producing enzymes that specifically target natural dye molecules. The technology includes an innovative adsorption recovery system using modified agricultural waste materials as low-cost, sustainable adsorbents for valuable compound recovery. Their integrated control system continuously monitors multiple water quality parameters and adjusts treatment conditions accordingly, optimizing both treatment efficiency and operating costs while achieving water reuse rates of approximately 85%.

Strengths: High resource recovery capabilities from wastewater; sustainable use of agricultural waste as adsorbent materials; excellent color removal efficiency (>95%). Weaknesses: Complex multi-stage process requires careful monitoring and control; biological treatment using fungal strains requires specialized expertise; higher maintenance requirements than conventional systems.

Zhejiang Longsheng Group Co., Ltd.

Technical Solution: Zhejiang Longsheng Group has developed an integrated natural dye wastewater treatment system combining physical, chemical, and biological processes. Their approach features a multi-stage treatment process beginning with screening and sedimentation to remove suspended solids, followed by advanced oxidation using their proprietary catalytic oxidation technology that breaks down complex dye molecules. The system incorporates membrane bioreactor (MBR) technology with specialized microbial communities adapted to degrade recalcitrant dye compounds. Their closed-loop water recycling system achieves over 85% water reuse rates while recovering valuable chemicals from the wastewater stream. The technology employs real-time monitoring systems with AI-driven process control to optimize treatment parameters based on influent characteristics, significantly reducing energy consumption compared to conventional systems.

Strengths: Proprietary catalytic oxidation technology effectively breaks down complex dye molecules; integrated resource recovery system captures valuable chemicals; high water reuse rate (>85%). Weaknesses: Higher initial capital investment compared to conventional systems; requires specialized technical expertise for operation and maintenance.

Advanced Techniques for Natural Dye Effluent Remediation

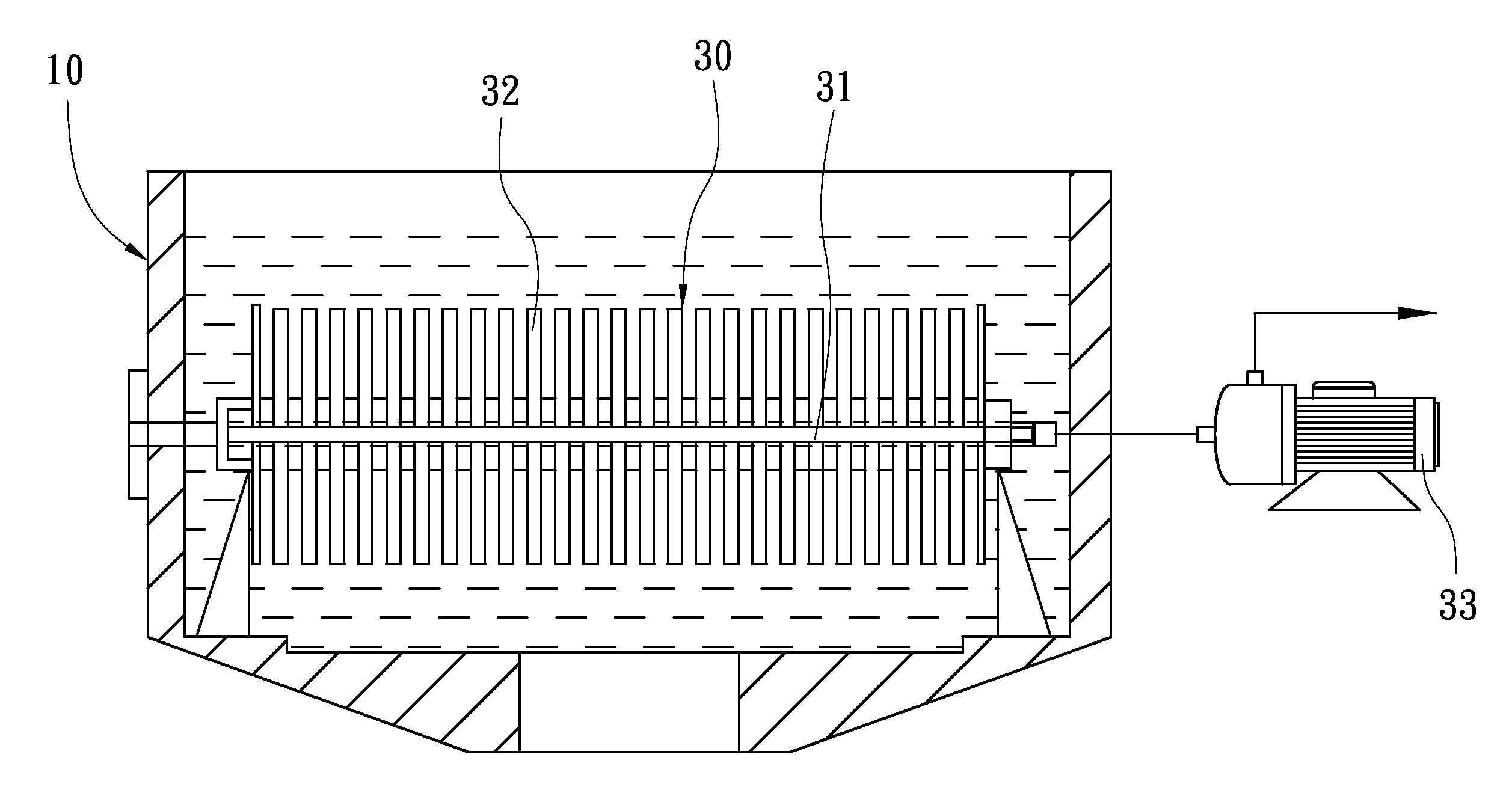

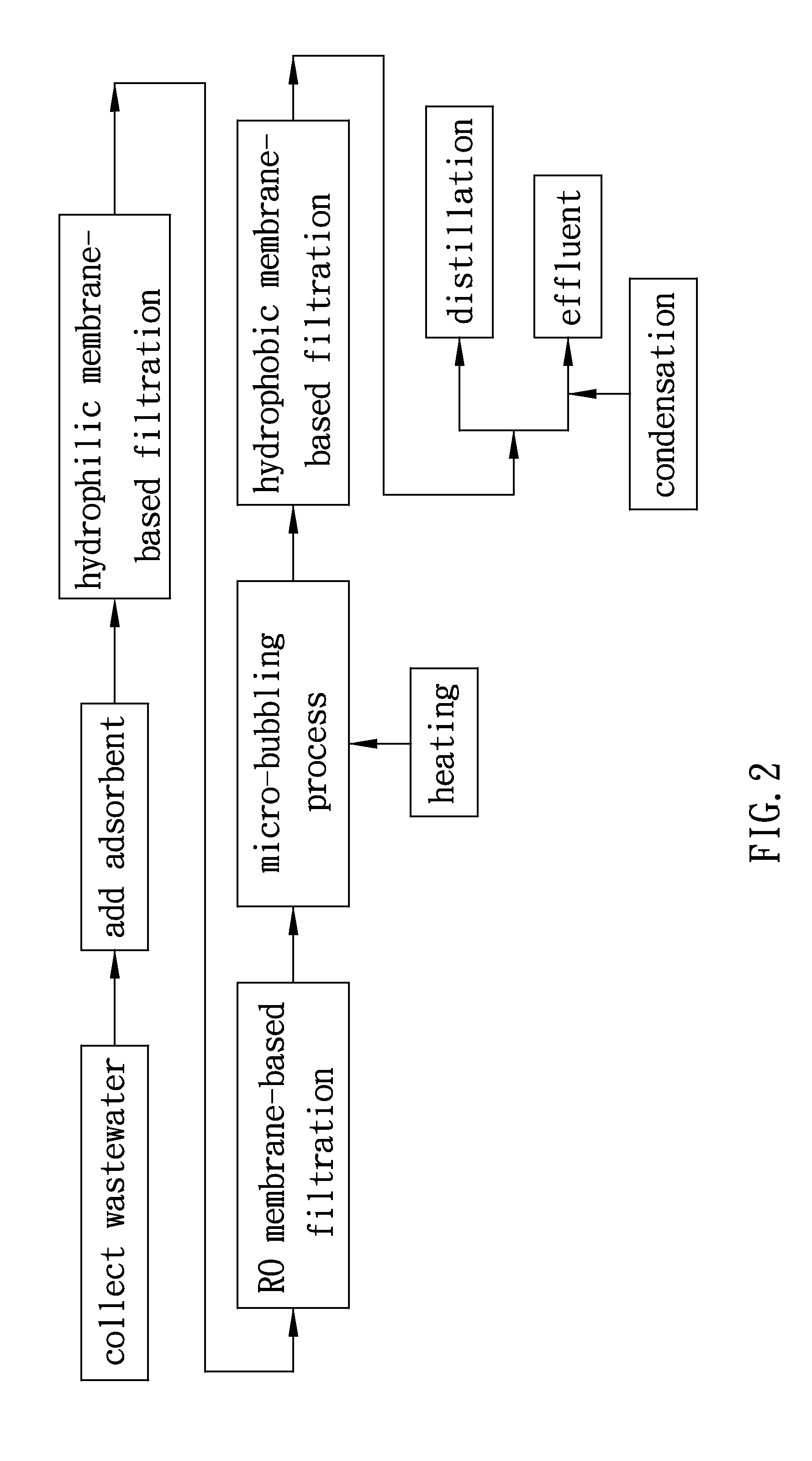

Method and system for recycling and treating dyeing wastewater

PatentInactiveUS20120223018A1

Innovation

- A method and system using a pre-treatment with hydrophilic porous membranes and a micro-bubbling process with hydrophobic membranes to reduce chromaticity and suspended solids, followed by reverse osmosis filtration and secondary treatment to produce an effluent meeting environmental standards, minimizing membrane fouling and energy consumption.

Printing and dyeing wastewater treatment and reuse apparatus and method therefor

PatentInactiveIN1222MUMNP2013A

Innovation

- A printing and dyeing wastewater treatment and reuse apparatus utilizing nanocatalytic electrolysis and membrane electrolysis technology, incorporating a series of processing steps including desulfurization, nanocatalytic electrolysis, flocculation, biochemical treatment, and membrane separation, to enhance CODCr removal efficiency and reduce chemical consumption and sludge generation.

Regulatory Framework for Textile Wastewater Discharge

The regulatory landscape governing textile wastewater discharge has evolved significantly in response to growing environmental concerns about natural dye effluents. At the international level, organizations such as the United Nations Environment Programme (UNEP) and the World Health Organization (WHO) have established guidelines that serve as benchmarks for national regulatory frameworks. These guidelines typically address parameters including Chemical Oxygen Demand (COD), Biological Oxygen Demand (BOD), Total Suspended Solids (TSS), pH levels, and specific concentrations of heavy metals and other toxins commonly found in natural dye wastewaters.

In developed economies, stringent regulatory frameworks have been implemented with comprehensive monitoring and enforcement mechanisms. The European Union's Water Framework Directive (WFD) and the Industrial Emissions Directive (IED) establish strict discharge limits for textile operations, with specific provisions for natural dye processing. Similarly, the United States Environmental Protection Agency (EPA) enforces the Clean Water Act with industry-specific effluent guidelines for textile manufacturing that include natural dye processing facilities.

Emerging economies with significant textile manufacturing sectors have been strengthening their regulatory approaches. India's Central Pollution Control Board (CPCB) has developed specialized standards for textile industry effluents, with particular attention to traditional natural dyeing clusters. China has implemented its Water Pollution Prevention and Control Law with increasingly stringent discharge standards for industrial wastewater, including specific provisions for natural dye processing facilities.

Compliance mechanisms vary across jurisdictions but typically include permitting systems, regular monitoring requirements, reporting obligations, and escalating penalty structures for non-compliance. Many regulatory frameworks now incorporate incentive structures that reward facilities implementing advanced treatment technologies or achieving zero liquid discharge (ZLD) status through tax benefits, subsidized technology upgrades, or expedited permitting processes.

Recent regulatory trends indicate a shift toward more holistic approaches that consider the entire water cycle within textile operations. This includes requirements for water consumption reduction, wastewater reuse, and resource recovery from treatment processes. Several jurisdictions have begun implementing regulations that mandate minimum percentages of treated wastewater to be recycled within facilities, particularly in water-stressed regions where natural dye processing is prevalent.

The regulatory landscape continues to evolve with increasing scientific understanding of the environmental impacts of natural dye components. Emerging regulations are beginning to address previously unregulated compounds found in natural dye wastewaters, including tannins, flavonoids, and other plant-derived bioactive substances that may have ecological impacts even at low concentrations.

In developed economies, stringent regulatory frameworks have been implemented with comprehensive monitoring and enforcement mechanisms. The European Union's Water Framework Directive (WFD) and the Industrial Emissions Directive (IED) establish strict discharge limits for textile operations, with specific provisions for natural dye processing. Similarly, the United States Environmental Protection Agency (EPA) enforces the Clean Water Act with industry-specific effluent guidelines for textile manufacturing that include natural dye processing facilities.

Emerging economies with significant textile manufacturing sectors have been strengthening their regulatory approaches. India's Central Pollution Control Board (CPCB) has developed specialized standards for textile industry effluents, with particular attention to traditional natural dyeing clusters. China has implemented its Water Pollution Prevention and Control Law with increasingly stringent discharge standards for industrial wastewater, including specific provisions for natural dye processing facilities.

Compliance mechanisms vary across jurisdictions but typically include permitting systems, regular monitoring requirements, reporting obligations, and escalating penalty structures for non-compliance. Many regulatory frameworks now incorporate incentive structures that reward facilities implementing advanced treatment technologies or achieving zero liquid discharge (ZLD) status through tax benefits, subsidized technology upgrades, or expedited permitting processes.

Recent regulatory trends indicate a shift toward more holistic approaches that consider the entire water cycle within textile operations. This includes requirements for water consumption reduction, wastewater reuse, and resource recovery from treatment processes. Several jurisdictions have begun implementing regulations that mandate minimum percentages of treated wastewater to be recycled within facilities, particularly in water-stressed regions where natural dye processing is prevalent.

The regulatory landscape continues to evolve with increasing scientific understanding of the environmental impacts of natural dye components. Emerging regulations are beginning to address previously unregulated compounds found in natural dye wastewaters, including tannins, flavonoids, and other plant-derived bioactive substances that may have ecological impacts even at low concentrations.

Life Cycle Assessment of Treatment Technologies

Life Cycle Assessment (LCA) provides a comprehensive framework for evaluating the environmental impacts of natural dye wastewater treatment technologies across their entire lifecycle. When comparing conventional and innovative treatment methods, LCA reveals significant differences in environmental footprints. Physical-chemical treatments like coagulation and adsorption typically show high energy consumption during operation but lower material requirements during installation. Conversely, biological treatments such as constructed wetlands demonstrate lower operational energy needs but higher land use impacts and initial construction material requirements.

Energy consumption represents a critical impact category in wastewater treatment LCAs. Advanced oxidation processes and membrane filtrations generally exhibit the highest energy demands, contributing substantially to their carbon footprints. However, these technologies often achieve superior contaminant removal efficiencies, creating a complex sustainability trade-off. Biological systems like activated sludge and membrane bioreactors present intermediate energy profiles but generate significant biomass waste requiring further management.

Chemical usage in treatment processes constitutes another significant environmental burden. Conventional treatments frequently rely on chemical coagulants and flocculants that contribute to resource depletion and potential ecotoxicity. Emerging technologies like electrocoagulation may reduce chemical inputs but increase electricity consumption, shifting rather than eliminating environmental impacts.

Water reuse potential significantly influences LCA outcomes. Closed-loop systems that enable high-quality water reclamation for dyeing processes demonstrate superior environmental performance despite potentially higher initial energy investments. The avoided impacts from reduced freshwater extraction and wastewater discharge often outweigh the additional treatment burdens over multiple cycles of water reuse.

Geographic and contextual factors substantially affect LCA results. Treatment technologies powered by renewable energy sources show dramatically improved environmental profiles compared to those dependent on fossil fuel electricity. Similarly, regional water scarcity conditions can amplify the benefits of water recovery technologies, while abundant water regions might prioritize energy efficiency instead.

Economic considerations integrated with environmental LCA (life cycle costing) reveal that technologies with higher capital costs but lower operational requirements often demonstrate better long-term sustainability. Membrane-based systems typically show higher lifetime costs but superior environmental performance compared to conventional physical-chemical treatments, highlighting the importance of considering both economic and environmental factors in technology selection for natural dye wastewater management.

Energy consumption represents a critical impact category in wastewater treatment LCAs. Advanced oxidation processes and membrane filtrations generally exhibit the highest energy demands, contributing substantially to their carbon footprints. However, these technologies often achieve superior contaminant removal efficiencies, creating a complex sustainability trade-off. Biological systems like activated sludge and membrane bioreactors present intermediate energy profiles but generate significant biomass waste requiring further management.

Chemical usage in treatment processes constitutes another significant environmental burden. Conventional treatments frequently rely on chemical coagulants and flocculants that contribute to resource depletion and potential ecotoxicity. Emerging technologies like electrocoagulation may reduce chemical inputs but increase electricity consumption, shifting rather than eliminating environmental impacts.

Water reuse potential significantly influences LCA outcomes. Closed-loop systems that enable high-quality water reclamation for dyeing processes demonstrate superior environmental performance despite potentially higher initial energy investments. The avoided impacts from reduced freshwater extraction and wastewater discharge often outweigh the additional treatment burdens over multiple cycles of water reuse.

Geographic and contextual factors substantially affect LCA results. Treatment technologies powered by renewable energy sources show dramatically improved environmental profiles compared to those dependent on fossil fuel electricity. Similarly, regional water scarcity conditions can amplify the benefits of water recovery technologies, while abundant water regions might prioritize energy efficiency instead.

Economic considerations integrated with environmental LCA (life cycle costing) reveal that technologies with higher capital costs but lower operational requirements often demonstrate better long-term sustainability. Membrane-based systems typically show higher lifetime costs but superior environmental performance compared to conventional physical-chemical treatments, highlighting the importance of considering both economic and environmental factors in technology selection for natural dye wastewater management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!