Next‑Gen QLED Technology: Trends and Predictions

JUN 19, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QLED Evolution and Objectives

Quantum Dot Light-Emitting Diode (QLED) technology has emerged as a revolutionary advancement in display technology, offering superior color performance and energy efficiency compared to traditional LED displays. The evolution of QLED technology can be traced back to the early 2000s when researchers first began exploring the potential of quantum dots in display applications. Since then, QLED has undergone significant improvements, leading to its current status as a formidable competitor in the high-end display market.

The primary objective of next-generation QLED technology is to further enhance display performance while addressing existing limitations. Key goals include improving color accuracy, expanding the color gamut, increasing brightness levels, and enhancing energy efficiency. Additionally, researchers aim to develop more stable and environmentally friendly quantum dot materials, reducing reliance on heavy metals such as cadmium.

One of the most significant trends in QLED evolution is the shift towards blue light-emitting quantum dots. Current QLED displays typically use a blue LED backlight in combination with red and green quantum dots. However, the development of efficient blue quantum dots could lead to all-QD displays, potentially offering even better color performance and energy efficiency.

Another important objective is to improve the stability and longevity of quantum dot materials. This involves developing new encapsulation techniques and exploring alternative materials that are less susceptible to degradation from heat and light exposure. Such advancements would not only enhance the lifespan of QLED displays but also expand their potential applications in various industries.

The integration of QLED technology with other emerging display technologies is also a key focus area. For instance, researchers are exploring the combination of QLED with micro-LED technology, which could result in displays with exceptional brightness, contrast, and color performance. Additionally, the development of flexible and transparent QLED displays is gaining traction, opening up new possibilities for innovative product designs and applications.

As QLED technology continues to evolve, there is a growing emphasis on sustainability and eco-friendliness. This includes efforts to reduce the environmental impact of quantum dot production, as well as developing recycling methods for QLED displays at the end of their lifecycle. These initiatives align with broader industry trends towards more sustainable and responsible technology development.

In conclusion, the evolution of QLED technology is driven by the objectives of enhancing display performance, improving material stability, expanding application possibilities, and addressing environmental concerns. As research and development in this field progress, we can expect to see QLED displays that offer unprecedented visual experiences while becoming more sustainable and versatile.

The primary objective of next-generation QLED technology is to further enhance display performance while addressing existing limitations. Key goals include improving color accuracy, expanding the color gamut, increasing brightness levels, and enhancing energy efficiency. Additionally, researchers aim to develop more stable and environmentally friendly quantum dot materials, reducing reliance on heavy metals such as cadmium.

One of the most significant trends in QLED evolution is the shift towards blue light-emitting quantum dots. Current QLED displays typically use a blue LED backlight in combination with red and green quantum dots. However, the development of efficient blue quantum dots could lead to all-QD displays, potentially offering even better color performance and energy efficiency.

Another important objective is to improve the stability and longevity of quantum dot materials. This involves developing new encapsulation techniques and exploring alternative materials that are less susceptible to degradation from heat and light exposure. Such advancements would not only enhance the lifespan of QLED displays but also expand their potential applications in various industries.

The integration of QLED technology with other emerging display technologies is also a key focus area. For instance, researchers are exploring the combination of QLED with micro-LED technology, which could result in displays with exceptional brightness, contrast, and color performance. Additionally, the development of flexible and transparent QLED displays is gaining traction, opening up new possibilities for innovative product designs and applications.

As QLED technology continues to evolve, there is a growing emphasis on sustainability and eco-friendliness. This includes efforts to reduce the environmental impact of quantum dot production, as well as developing recycling methods for QLED displays at the end of their lifecycle. These initiatives align with broader industry trends towards more sustainable and responsible technology development.

In conclusion, the evolution of QLED technology is driven by the objectives of enhancing display performance, improving material stability, expanding application possibilities, and addressing environmental concerns. As research and development in this field progress, we can expect to see QLED displays that offer unprecedented visual experiences while becoming more sustainable and versatile.

QLED Market Demand Analysis

The QLED (Quantum Dot Light Emitting Diode) technology has been gaining significant traction in the display market, with a growing demand for high-quality, energy-efficient displays across various sectors. The global QLED market is experiencing robust growth, driven by increasing consumer preference for superior picture quality and the technology's ability to deliver vibrant colors and high contrast ratios.

In the consumer electronics segment, QLED TVs have seen a surge in popularity, particularly in the premium and ultra-premium categories. This trend is expected to continue as consumers seek immersive viewing experiences and larger screen sizes for home entertainment. The gaming industry has also emerged as a key driver for QLED demand, with gamers valuing the technology's low input lag and high refresh rates.

The commercial display sector presents another significant growth opportunity for QLED technology. Digital signage, control rooms, and large-format displays in corporate and educational settings are increasingly adopting QLED solutions due to their superior brightness and color accuracy. This adoption is particularly notable in environments that require 24/7 operation and consistent image quality.

Automotive applications represent an emerging market for QLED technology. As vehicles become more technologically advanced, there is a growing demand for high-quality displays in infotainment systems, digital dashboards, and heads-up displays. QLED's ability to maintain visibility in bright sunlight and its wide color gamut make it an attractive option for automotive manufacturers.

The healthcare industry is another sector showing interest in QLED technology. Medical imaging displays require high color accuracy and contrast ratios, making QLED an ideal choice for diagnostic monitors and surgical displays. This niche market is expected to grow as healthcare facilities upgrade their imaging equipment.

Despite the positive market outlook, QLED technology faces competition from other display technologies such as OLED and MicroLED. However, QLED's advantages in terms of cost-effectiveness, longer lifespan, and resistance to burn-in are expected to maintain its strong market position.

Looking ahead, the QLED market is projected to expand further as manufacturers continue to innovate and improve the technology. Advancements in quantum dot materials, enhanced color conversion efficiency, and reduced production costs are likely to drive adoption across various industries. Additionally, the integration of QLED with other emerging technologies, such as flexible displays and transparent screens, could open up new application areas and market opportunities.

In the consumer electronics segment, QLED TVs have seen a surge in popularity, particularly in the premium and ultra-premium categories. This trend is expected to continue as consumers seek immersive viewing experiences and larger screen sizes for home entertainment. The gaming industry has also emerged as a key driver for QLED demand, with gamers valuing the technology's low input lag and high refresh rates.

The commercial display sector presents another significant growth opportunity for QLED technology. Digital signage, control rooms, and large-format displays in corporate and educational settings are increasingly adopting QLED solutions due to their superior brightness and color accuracy. This adoption is particularly notable in environments that require 24/7 operation and consistent image quality.

Automotive applications represent an emerging market for QLED technology. As vehicles become more technologically advanced, there is a growing demand for high-quality displays in infotainment systems, digital dashboards, and heads-up displays. QLED's ability to maintain visibility in bright sunlight and its wide color gamut make it an attractive option for automotive manufacturers.

The healthcare industry is another sector showing interest in QLED technology. Medical imaging displays require high color accuracy and contrast ratios, making QLED an ideal choice for diagnostic monitors and surgical displays. This niche market is expected to grow as healthcare facilities upgrade their imaging equipment.

Despite the positive market outlook, QLED technology faces competition from other display technologies such as OLED and MicroLED. However, QLED's advantages in terms of cost-effectiveness, longer lifespan, and resistance to burn-in are expected to maintain its strong market position.

Looking ahead, the QLED market is projected to expand further as manufacturers continue to innovate and improve the technology. Advancements in quantum dot materials, enhanced color conversion efficiency, and reduced production costs are likely to drive adoption across various industries. Additionally, the integration of QLED with other emerging technologies, such as flexible displays and transparent screens, could open up new application areas and market opportunities.

QLED Tech Challenges

QLED technology, while promising, faces several significant challenges that need to be addressed for its widespread adoption and continued advancement. One of the primary hurdles is the improvement of quantum dot efficiency and stability. Current QLED displays suffer from degradation over time, particularly in blue quantum dots, which can lead to color shifts and reduced lifespan of the displays.

Another major challenge lies in the manufacturing process. The precise deposition of quantum dots and the creation of uniform, defect-free layers at scale remain complex and costly. This impacts the overall production yield and, consequently, the market competitiveness of QLED displays.

Color accuracy and gamut present ongoing challenges. While QLEDs offer impressive color reproduction, achieving perfect color consistency across different viewing angles and maintaining color accuracy over the device's lifetime are areas that require further development.

Energy efficiency is another critical area for improvement. Although QLEDs are more energy-efficient than traditional LED-LCD displays, there is still room for enhancement, particularly in reducing power consumption without compromising brightness and color performance.

The environmental impact of quantum dot materials is a growing concern. Many current quantum dots contain heavy metals like cadmium, which pose potential health and environmental risks. Developing eco-friendly alternatives that maintain or exceed current performance standards is a significant challenge facing the industry.

Addressing motion blur and response time issues is crucial for QLED technology to compete effectively in markets such as gaming and fast-action content viewing. While improvements have been made, further enhancements are necessary to match or surpass OLED performance in these areas.

Lastly, cost reduction remains a persistent challenge. As QLED technology evolves, finding ways to decrease production costs while maintaining or improving quality is essential for broader market penetration, especially in competing with established technologies like OLED and emerging alternatives.

Another major challenge lies in the manufacturing process. The precise deposition of quantum dots and the creation of uniform, defect-free layers at scale remain complex and costly. This impacts the overall production yield and, consequently, the market competitiveness of QLED displays.

Color accuracy and gamut present ongoing challenges. While QLEDs offer impressive color reproduction, achieving perfect color consistency across different viewing angles and maintaining color accuracy over the device's lifetime are areas that require further development.

Energy efficiency is another critical area for improvement. Although QLEDs are more energy-efficient than traditional LED-LCD displays, there is still room for enhancement, particularly in reducing power consumption without compromising brightness and color performance.

The environmental impact of quantum dot materials is a growing concern. Many current quantum dots contain heavy metals like cadmium, which pose potential health and environmental risks. Developing eco-friendly alternatives that maintain or exceed current performance standards is a significant challenge facing the industry.

Addressing motion blur and response time issues is crucial for QLED technology to compete effectively in markets such as gaming and fast-action content viewing. While improvements have been made, further enhancements are necessary to match or surpass OLED performance in these areas.

Lastly, cost reduction remains a persistent challenge. As QLED technology evolves, finding ways to decrease production costs while maintaining or improving quality is essential for broader market penetration, especially in competing with established technologies like OLED and emerging alternatives.

Current QLED Solutions

01 QLED structure and materials

QLED technology involves the use of quantum dots as light-emitting materials. The structure typically includes layers of quantum dots sandwiched between electron and hole transport layers. Various materials and compositions are used to optimize the performance of QLEDs, including different types of quantum dots and charge transport materials.- QLED structure and materials: QLED technology involves the use of quantum dots as light-emitting materials. The structure typically includes layers of quantum dots sandwiched between electron and hole transport layers. Various materials and compositions are used to optimize the performance of QLEDs, including different types of quantum dots and charge transport materials.

- Quantum dot synthesis and processing: The synthesis and processing of quantum dots are crucial for QLED performance. This includes methods for producing quantum dots with specific sizes and compositions, as well as techniques for incorporating them into device structures. Surface treatments and ligand exchange processes are often employed to enhance the properties of quantum dots for QLED applications.

- QLED device fabrication techniques: Various fabrication techniques are used in QLED production, including solution processing, inkjet printing, and vacuum deposition methods. These techniques aim to create uniform and defect-free layers of quantum dots and other materials. Innovations in manufacturing processes focus on improving efficiency, reducing costs, and enabling large-scale production of QLED displays.

- Color tuning and light management in QLEDs: QLED technology allows for precise color tuning through the control of quantum dot size and composition. Advanced light management techniques, such as the use of optical microcavities and photonic crystals, are employed to enhance color purity and efficiency. Methods for achieving wide color gamut and high color accuracy in QLED displays are continually being developed.

- QLED efficiency and lifetime improvement: Ongoing research focuses on improving the efficiency and lifetime of QLED devices. This includes developing new materials for charge injection and transport, optimizing device architectures to reduce energy loss, and implementing strategies to mitigate degradation mechanisms. Encapsulation techniques and the use of barrier layers are also explored to enhance device stability and longevity.

02 Quantum dot synthesis and processing

The synthesis and processing of quantum dots are crucial for QLED performance. This includes methods for producing quantum dots with specific sizes, compositions, and surface properties. Techniques for incorporating quantum dots into device structures, such as solution processing or transfer printing, are also important aspects of QLED technology.Expand Specific Solutions03 Color conversion and light management

QLED technology often employs quantum dots for color conversion, where blue light is converted to other colors. This involves optimizing the quantum dot layers and incorporating light management structures to enhance color purity and efficiency. Techniques such as photonic crystals or micro-lens arrays may be used to improve light extraction.Expand Specific Solutions04 QLED display integration

Integrating QLED technology into display devices involves addressing challenges such as pixel patterning, driving schemes, and device stability. This includes developing methods for precise deposition of quantum dot materials, designing appropriate backplane technologies, and implementing strategies to prevent degradation during operation.Expand Specific Solutions05 QLED efficiency and lifetime improvement

Enhancing the efficiency and lifetime of QLED devices is a key focus of research and development. This involves optimizing the energy transfer between charge carriers and quantum dots, reducing non-radiative recombination, and developing encapsulation techniques to protect the sensitive materials from environmental factors.Expand Specific Solutions

QLED Industry Leaders

The next-generation QLED technology market is in a growth phase, with increasing competition among key players. The market size is expanding rapidly, driven by demand for high-quality displays in various sectors. Technologically, QLED is maturing, with companies like BOE Technology Group, LG Display, and Sharp Corp. leading innovation. These firms are investing heavily in R&D to enhance color accuracy, brightness, and energy efficiency. Emerging players such as Guangdong Juhua Printing Display Technology and Hefei Visionox Technology are also making significant strides. The industry is seeing collaborations between corporations and academic institutions like Zhejiang University and MIT, indicating a focus on cutting-edge research to push QLED technology boundaries.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced QLED technology using quantum dot materials to enhance color performance and efficiency. Their next-generation QLED displays utilize a hybrid quantum dot-OLED structure, combining the benefits of both technologies. This approach involves depositing a layer of quantum dots over a blue OLED backplane, resulting in improved color gamut, brightness, and energy efficiency. BOE's research focuses on optimizing quantum dot materials and deposition techniques to achieve better light conversion efficiency and color purity.

Strengths: Wide color gamut, high brightness, and energy efficiency. Weaknesses: Potential challenges in mass production and cost-effectiveness compared to traditional LCD and OLED technologies.

Shenzhen China Star Optoelectronics Semicon Display Tech Co.

Technical Solution: CSOT is developing next-generation QLED technology that focuses on improving quantum dot stability and light conversion efficiency. Their approach involves using a new encapsulation method for quantum dots, which protects them from environmental factors and extends their lifespan. CSOT is also exploring the use of quantum rods instead of traditional quantum dots, which offer improved light emission directionality and potentially higher efficiency. Additionally, they are researching the integration of quantum dots with advanced backplane technologies, such as oxide TFTs, to enhance overall display performance and reduce power consumption.

Strengths: Improved quantum dot stability, potential for higher efficiency, and compatibility with advanced backplane technologies. Weaknesses: Challenges in scaling up new quantum dot materials and potential increased production costs.

QLED Core Innovations

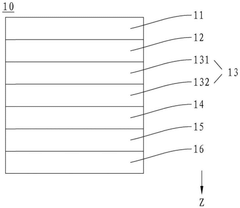

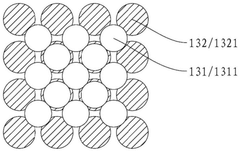

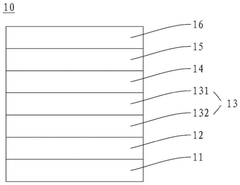

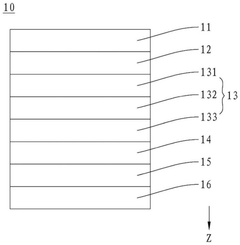

Quantum dot light-emitting device and display device

PatentPendingCN119730567A

Innovation

- By providing adjacent first quantum dot layers and second quantum dot layers in the luminous layer of the quantum dot light emitting device, the quantum dot diameters are different, and a self-filled dense light emitting layer is formed, thereby reducing leakage current and improving luminous efficiency.

Quantum dot composition and quantum dot light-emitting device

PatentWO2024139483A1

Innovation

- Using a core-shell quantum dot composition, by adjusting the core and shell energy level structures of the quantum dots, ensure that the conduction band and valence band energy level ratio of the core is within the range of 1:0.9-1.1, and the conduction band and valence band of the shell are The energy level is lower than the corresponding energy level of the nucleus, forming an appropriate energy level barrier to control carrier balance and exciton binding, and avoid exciton recombination region deviation.

QLED Supply Chain Analysis

The QLED supply chain is a complex network of manufacturers, suppliers, and distributors that work together to produce and deliver Quantum Dot Light Emitting Diode (QLED) displays to the market. This chain encompasses various stages, from raw material extraction to the final assembly of QLED panels and their integration into consumer electronics.

At the foundation of the QLED supply chain are the producers of quantum dots, the key component that gives QLED its superior color performance. Companies like Nanosys, Nanoco, and QD Vision are at the forefront of quantum dot production, continuously innovating to improve efficiency and reduce costs. These quantum dots are then supplied to panel manufacturers who integrate them into their display technologies.

The next crucial link in the chain is the production of thin-film transistors (TFTs) and color filters, which are essential components of QLED displays. Major players in this segment include LG Display, BOE Technology, and AUO. These companies have invested heavily in research and development to enhance the performance of these components, directly impacting the overall quality of QLED displays.

Panel manufacturers form the core of the QLED supply chain. Samsung Electronics, as the pioneer and leader in QLED technology, has a significant advantage in this area. Other manufacturers like TCL and Hisense have also entered the QLED market, diversifying the supply chain and increasing competition. These companies source components from various suppliers and assemble the final QLED panels.

The supply chain also includes providers of backlighting systems, which are crucial for QLED displays. Companies specializing in LED production, such as Nichia, Osram, and Seoul Semiconductor, play a vital role in supplying high-quality LEDs for QLED backlighting.

Logistics and distribution form the final link in the QLED supply chain. Global shipping companies and regional distributors ensure that QLED displays reach manufacturers of TVs, monitors, and other consumer electronics. The efficiency of this distribution network significantly impacts the availability and pricing of QLED products in different markets.

As QLED technology continues to evolve, the supply chain is expected to become more streamlined and efficient. Vertical integration strategies, where companies control multiple stages of the supply chain, are becoming increasingly common. This approach allows for better quality control, cost management, and faster innovation cycles.

The QLED supply chain is also influenced by global economic factors and geopolitical tensions. Trade disputes and tariffs can disrupt the flow of components and finished products, leading to price fluctuations and potential shortages. As a result, many companies are exploring ways to diversify their supply chains and reduce dependence on single sources for critical components.

At the foundation of the QLED supply chain are the producers of quantum dots, the key component that gives QLED its superior color performance. Companies like Nanosys, Nanoco, and QD Vision are at the forefront of quantum dot production, continuously innovating to improve efficiency and reduce costs. These quantum dots are then supplied to panel manufacturers who integrate them into their display technologies.

The next crucial link in the chain is the production of thin-film transistors (TFTs) and color filters, which are essential components of QLED displays. Major players in this segment include LG Display, BOE Technology, and AUO. These companies have invested heavily in research and development to enhance the performance of these components, directly impacting the overall quality of QLED displays.

Panel manufacturers form the core of the QLED supply chain. Samsung Electronics, as the pioneer and leader in QLED technology, has a significant advantage in this area. Other manufacturers like TCL and Hisense have also entered the QLED market, diversifying the supply chain and increasing competition. These companies source components from various suppliers and assemble the final QLED panels.

The supply chain also includes providers of backlighting systems, which are crucial for QLED displays. Companies specializing in LED production, such as Nichia, Osram, and Seoul Semiconductor, play a vital role in supplying high-quality LEDs for QLED backlighting.

Logistics and distribution form the final link in the QLED supply chain. Global shipping companies and regional distributors ensure that QLED displays reach manufacturers of TVs, monitors, and other consumer electronics. The efficiency of this distribution network significantly impacts the availability and pricing of QLED products in different markets.

As QLED technology continues to evolve, the supply chain is expected to become more streamlined and efficient. Vertical integration strategies, where companies control multiple stages of the supply chain, are becoming increasingly common. This approach allows for better quality control, cost management, and faster innovation cycles.

The QLED supply chain is also influenced by global economic factors and geopolitical tensions. Trade disputes and tariffs can disrupt the flow of components and finished products, leading to price fluctuations and potential shortages. As a result, many companies are exploring ways to diversify their supply chains and reduce dependence on single sources for critical components.

QLED Environmental Impact

The environmental impact of QLED (Quantum Dot Light Emitting Diode) technology is a crucial consideration as this next-generation display technology continues to evolve. QLED displays offer significant advantages in terms of energy efficiency and longevity compared to traditional LED and OLED technologies, potentially reducing overall energy consumption and electronic waste.

One of the primary environmental benefits of QLED technology is its improved energy efficiency. QLED displays can produce brighter and more vibrant colors while consuming less power than conventional LED displays. This reduced energy consumption translates to lower carbon emissions over the lifetime of the device, contributing to a smaller carbon footprint for consumer electronics.

The manufacturing process of QLED displays also presents some environmental challenges. The production of quantum dots, the key component in QLED technology, often involves the use of heavy metals such as cadmium. While the amount of cadmium used is minimal, concerns about its potential environmental impact have led to research into cadmium-free quantum dot alternatives. Several manufacturers have already developed cadmium-free QLED displays, addressing this environmental concern.

QLED technology also offers potential benefits in terms of product lifespan. The increased durability and resistance to burn-in compared to OLED displays mean that QLED screens may last longer, reducing the frequency of replacements and thereby decreasing electronic waste. This longevity is particularly important in the context of the growing global e-waste problem.

The recyclability of QLED displays is another important environmental consideration. While the quantum dot layer adds complexity to the recycling process, ongoing research is focused on developing efficient recycling methods for these displays. Improved recycling techniques could significantly reduce the environmental impact of QLED technology over its entire lifecycle.

As QLED technology continues to advance, manufacturers are increasingly focusing on sustainable production methods and materials. This includes efforts to reduce energy consumption in the manufacturing process, minimize the use of harmful chemicals, and improve the overall recyclability of QLED displays. These initiatives are crucial for ensuring that the environmental benefits of QLED technology in use are not offset by the environmental costs of production.

In conclusion, while QLED technology offers several environmental advantages, particularly in terms of energy efficiency and longevity, there are still challenges to address. Ongoing research and development efforts are focused on mitigating these challenges, with the goal of making QLED displays an environmentally sustainable option for next-generation display technology.

One of the primary environmental benefits of QLED technology is its improved energy efficiency. QLED displays can produce brighter and more vibrant colors while consuming less power than conventional LED displays. This reduced energy consumption translates to lower carbon emissions over the lifetime of the device, contributing to a smaller carbon footprint for consumer electronics.

The manufacturing process of QLED displays also presents some environmental challenges. The production of quantum dots, the key component in QLED technology, often involves the use of heavy metals such as cadmium. While the amount of cadmium used is minimal, concerns about its potential environmental impact have led to research into cadmium-free quantum dot alternatives. Several manufacturers have already developed cadmium-free QLED displays, addressing this environmental concern.

QLED technology also offers potential benefits in terms of product lifespan. The increased durability and resistance to burn-in compared to OLED displays mean that QLED screens may last longer, reducing the frequency of replacements and thereby decreasing electronic waste. This longevity is particularly important in the context of the growing global e-waste problem.

The recyclability of QLED displays is another important environmental consideration. While the quantum dot layer adds complexity to the recycling process, ongoing research is focused on developing efficient recycling methods for these displays. Improved recycling techniques could significantly reduce the environmental impact of QLED technology over its entire lifecycle.

As QLED technology continues to advance, manufacturers are increasingly focusing on sustainable production methods and materials. This includes efforts to reduce energy consumption in the manufacturing process, minimize the use of harmful chemicals, and improve the overall recyclability of QLED displays. These initiatives are crucial for ensuring that the environmental benefits of QLED technology in use are not offset by the environmental costs of production.

In conclusion, while QLED technology offers several environmental advantages, particularly in terms of energy efficiency and longevity, there are still challenges to address. Ongoing research and development efforts are focused on mitigating these challenges, with the goal of making QLED displays an environmentally sustainable option for next-generation display technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!