Polypropylene Recycling Methods for Enhanced Circular Economy

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PP Recycling Background and Objectives

Polypropylene (PP) recycling has emerged as a critical focus in the pursuit of a circular economy, driven by the increasing global demand for sustainable plastic management. The evolution of PP recycling technologies has been marked by significant advancements over the past few decades, transitioning from basic mechanical recycling to more sophisticated chemical and thermal processes.

The primary objective of PP recycling is to reduce the environmental impact of plastic waste while simultaneously recovering valuable resources. This aligns with the broader goals of circular economy principles, which aim to minimize waste and maximize resource efficiency. As PP is one of the most widely used plastics in various industries, including packaging, automotive, and consumer goods, developing effective recycling methods for this material is paramount.

The technical evolution of PP recycling has been characterized by several key milestones. Initially, mechanical recycling dominated the field, involving sorting, grinding, washing, and re-pelletizing of PP waste. However, this method faced limitations in terms of maintaining material quality over multiple recycling cycles. This led to the exploration of more advanced techniques, such as chemical recycling and thermal depolymerization, which aim to break down PP into its constituent monomers or other valuable chemical feedstocks.

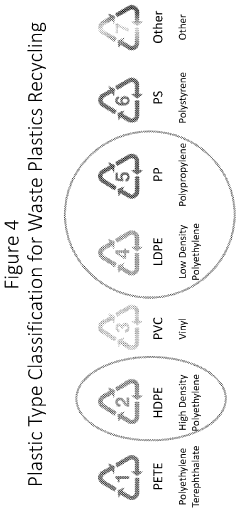

Recent technological trends in PP recycling include the development of improved sorting and separation technologies, such as near-infrared (NIR) spectroscopy and artificial intelligence-driven robotic sorting systems. These advancements have significantly enhanced the purity of recycled PP streams, addressing one of the major challenges in plastic recycling.

Another notable trend is the increasing focus on upcycling PP waste into higher-value products, rather than merely recycling it into similar or lower-grade applications. This approach not only adds economic value but also expands the potential applications of recycled PP, contributing to a more robust circular economy.

The global push towards sustainability and stricter environmental regulations has been a key driver in accelerating PP recycling innovations. Many countries have implemented policies to increase plastic recycling rates, creating a favorable environment for technological advancements in this field. Additionally, consumer demand for eco-friendly products has incentivized businesses to invest in and adopt more efficient PP recycling methods.

Looking ahead, the objectives for PP recycling technology development are multifaceted. These include improving the energy efficiency of recycling processes, developing methods to handle mixed plastic waste streams more effectively, and creating closed-loop systems where PP products can be recycled indefinitely without loss of quality. Achieving these objectives will require continued research and development, cross-industry collaboration, and supportive policy frameworks to drive innovation and implementation of advanced PP recycling technologies.

The primary objective of PP recycling is to reduce the environmental impact of plastic waste while simultaneously recovering valuable resources. This aligns with the broader goals of circular economy principles, which aim to minimize waste and maximize resource efficiency. As PP is one of the most widely used plastics in various industries, including packaging, automotive, and consumer goods, developing effective recycling methods for this material is paramount.

The technical evolution of PP recycling has been characterized by several key milestones. Initially, mechanical recycling dominated the field, involving sorting, grinding, washing, and re-pelletizing of PP waste. However, this method faced limitations in terms of maintaining material quality over multiple recycling cycles. This led to the exploration of more advanced techniques, such as chemical recycling and thermal depolymerization, which aim to break down PP into its constituent monomers or other valuable chemical feedstocks.

Recent technological trends in PP recycling include the development of improved sorting and separation technologies, such as near-infrared (NIR) spectroscopy and artificial intelligence-driven robotic sorting systems. These advancements have significantly enhanced the purity of recycled PP streams, addressing one of the major challenges in plastic recycling.

Another notable trend is the increasing focus on upcycling PP waste into higher-value products, rather than merely recycling it into similar or lower-grade applications. This approach not only adds economic value but also expands the potential applications of recycled PP, contributing to a more robust circular economy.

The global push towards sustainability and stricter environmental regulations has been a key driver in accelerating PP recycling innovations. Many countries have implemented policies to increase plastic recycling rates, creating a favorable environment for technological advancements in this field. Additionally, consumer demand for eco-friendly products has incentivized businesses to invest in and adopt more efficient PP recycling methods.

Looking ahead, the objectives for PP recycling technology development are multifaceted. These include improving the energy efficiency of recycling processes, developing methods to handle mixed plastic waste streams more effectively, and creating closed-loop systems where PP products can be recycled indefinitely without loss of quality. Achieving these objectives will require continued research and development, cross-industry collaboration, and supportive policy frameworks to drive innovation and implementation of advanced PP recycling technologies.

Market Analysis for Recycled PP

The global market for recycled polypropylene (PP) has been experiencing significant growth in recent years, driven by increasing environmental awareness, regulatory pressures, and the shift towards a circular economy. The demand for recycled PP is expected to continue its upward trajectory, with projections indicating a compound annual growth rate (CAGR) of over 6% from 2021 to 2026.

Key factors contributing to this market expansion include the growing emphasis on sustainable packaging solutions, particularly in the food and beverage industry, as well as the automotive sector's increasing use of recycled plastics in vehicle components. The packaging industry remains the largest consumer of recycled PP, accounting for approximately 40% of the total market share.

Geographically, Europe leads the recycled PP market, owing to stringent regulations promoting plastic recycling and circular economy initiatives. The European Union's Circular Economy Action Plan and the Single-Use Plastics Directive have been instrumental in driving demand for recycled PP in the region. North America follows closely, with the United States showing substantial growth potential due to increasing corporate sustainability commitments and consumer preferences for eco-friendly products.

Asia-Pacific is emerging as a rapidly growing market for recycled PP, particularly in countries like China and India. The region's expanding manufacturing sector, coupled with rising environmental concerns, is expected to fuel demand for recycled PP in various applications, including textiles, automotive parts, and consumer goods.

Despite the positive market outlook, several challenges persist in the recycled PP industry. These include the need for improved collection and sorting infrastructure, technological limitations in processing contaminated PP waste, and price volatility of virgin PP affecting the competitiveness of recycled materials. Additionally, ensuring consistent quality and performance of recycled PP remains a concern for many end-users, particularly in high-performance applications.

To address these challenges, industry players are investing in advanced recycling technologies, such as chemical recycling and artificial intelligence-powered sorting systems. These innovations aim to improve the quality and yield of recycled PP, making it more competitive with virgin materials across a broader range of applications.

The market landscape is characterized by a mix of established plastic recycling companies and new entrants, including chemical companies and startups focusing on innovative recycling technologies. Collaborations between recyclers, brand owners, and packaging manufacturers are becoming increasingly common, driving the development of closed-loop recycling systems and improving the overall circularity of PP materials.

Key factors contributing to this market expansion include the growing emphasis on sustainable packaging solutions, particularly in the food and beverage industry, as well as the automotive sector's increasing use of recycled plastics in vehicle components. The packaging industry remains the largest consumer of recycled PP, accounting for approximately 40% of the total market share.

Geographically, Europe leads the recycled PP market, owing to stringent regulations promoting plastic recycling and circular economy initiatives. The European Union's Circular Economy Action Plan and the Single-Use Plastics Directive have been instrumental in driving demand for recycled PP in the region. North America follows closely, with the United States showing substantial growth potential due to increasing corporate sustainability commitments and consumer preferences for eco-friendly products.

Asia-Pacific is emerging as a rapidly growing market for recycled PP, particularly in countries like China and India. The region's expanding manufacturing sector, coupled with rising environmental concerns, is expected to fuel demand for recycled PP in various applications, including textiles, automotive parts, and consumer goods.

Despite the positive market outlook, several challenges persist in the recycled PP industry. These include the need for improved collection and sorting infrastructure, technological limitations in processing contaminated PP waste, and price volatility of virgin PP affecting the competitiveness of recycled materials. Additionally, ensuring consistent quality and performance of recycled PP remains a concern for many end-users, particularly in high-performance applications.

To address these challenges, industry players are investing in advanced recycling technologies, such as chemical recycling and artificial intelligence-powered sorting systems. These innovations aim to improve the quality and yield of recycled PP, making it more competitive with virgin materials across a broader range of applications.

The market landscape is characterized by a mix of established plastic recycling companies and new entrants, including chemical companies and startups focusing on innovative recycling technologies. Collaborations between recyclers, brand owners, and packaging manufacturers are becoming increasingly common, driving the development of closed-loop recycling systems and improving the overall circularity of PP materials.

Current PP Recycling Challenges

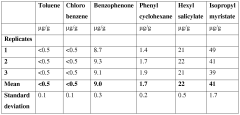

Polypropylene (PP) recycling faces several significant challenges in the current circular economy landscape. One of the primary obstacles is the contamination of PP waste streams. PP products often contain additives, fillers, and other materials that complicate the recycling process. These contaminants can degrade the quality of recycled PP, limiting its potential applications and market value.

The heterogeneity of PP waste is another major challenge. PP is used in a wide range of products with varying compositions, making it difficult to establish standardized recycling processes. This diversity in PP waste sources leads to inconsistencies in the recycled material's properties, which can deter potential end-users from incorporating recycled PP into their products.

Sorting and separation of PP from other plastics and materials present a significant technical hurdle. While advances have been made in automated sorting technologies, the process remains imperfect, leading to the presence of other polymers in PP waste streams. This contamination can compromise the mechanical and chemical properties of recycled PP, further limiting its usability in high-value applications.

The degradation of PP during its lifecycle and subsequent recycling processes poses another challenge. Exposure to heat, light, and mechanical stress during use and recycling can lead to chain scission and oxidation, resulting in a decrease in molecular weight and deterioration of mechanical properties. This degradation often necessitates the use of virgin PP or additives to maintain desired material characteristics, which can increase costs and reduce the environmental benefits of recycling.

Economic factors also play a crucial role in PP recycling challenges. The cost of collecting, sorting, and processing PP waste can be high, especially when compared to the relatively low cost of virgin PP production. Fluctuations in oil prices, which affect virgin PP prices, can make recycled PP less competitive in the market. Additionally, the lack of consistent demand for recycled PP products creates uncertainty in the recycling industry, discouraging investment in advanced recycling technologies.

Regulatory and policy-related challenges further complicate PP recycling efforts. Inconsistent regulations across regions and countries can hinder the development of efficient recycling systems and markets for recycled PP. The absence of standardized quality metrics for recycled PP also creates barriers to its widespread adoption in various industries.

Addressing these challenges requires a multifaceted approach involving technological innovation, policy support, and market development. Advances in chemical recycling methods, improved sorting technologies, and the development of compatibilizers for mixed plastic streams offer promising solutions. However, significant research and development efforts are still needed to overcome these obstacles and enhance the circular economy for polypropylene.

The heterogeneity of PP waste is another major challenge. PP is used in a wide range of products with varying compositions, making it difficult to establish standardized recycling processes. This diversity in PP waste sources leads to inconsistencies in the recycled material's properties, which can deter potential end-users from incorporating recycled PP into their products.

Sorting and separation of PP from other plastics and materials present a significant technical hurdle. While advances have been made in automated sorting technologies, the process remains imperfect, leading to the presence of other polymers in PP waste streams. This contamination can compromise the mechanical and chemical properties of recycled PP, further limiting its usability in high-value applications.

The degradation of PP during its lifecycle and subsequent recycling processes poses another challenge. Exposure to heat, light, and mechanical stress during use and recycling can lead to chain scission and oxidation, resulting in a decrease in molecular weight and deterioration of mechanical properties. This degradation often necessitates the use of virgin PP or additives to maintain desired material characteristics, which can increase costs and reduce the environmental benefits of recycling.

Economic factors also play a crucial role in PP recycling challenges. The cost of collecting, sorting, and processing PP waste can be high, especially when compared to the relatively low cost of virgin PP production. Fluctuations in oil prices, which affect virgin PP prices, can make recycled PP less competitive in the market. Additionally, the lack of consistent demand for recycled PP products creates uncertainty in the recycling industry, discouraging investment in advanced recycling technologies.

Regulatory and policy-related challenges further complicate PP recycling efforts. Inconsistent regulations across regions and countries can hinder the development of efficient recycling systems and markets for recycled PP. The absence of standardized quality metrics for recycled PP also creates barriers to its widespread adoption in various industries.

Addressing these challenges requires a multifaceted approach involving technological innovation, policy support, and market development. Advances in chemical recycling methods, improved sorting technologies, and the development of compatibilizers for mixed plastic streams offer promising solutions. However, significant research and development efforts are still needed to overcome these obstacles and enhance the circular economy for polypropylene.

Existing PP Recycling Solutions

01 Mechanical recycling of polypropylene

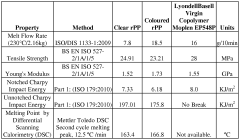

This method involves sorting, cleaning, shredding, and melting polypropylene waste to produce recycled pellets. The process may include additional steps such as washing, drying, and extrusion to improve the quality of the recycled material. Mechanical recycling is widely used due to its simplicity and cost-effectiveness.- Mechanical recycling methods: Mechanical recycling involves sorting, washing, grinding, and melting polypropylene waste to produce recycled pellets. This process preserves the polymer structure and is suitable for relatively clean and homogeneous waste streams. It often includes steps like contaminant removal, size reduction, and extrusion to create new products.

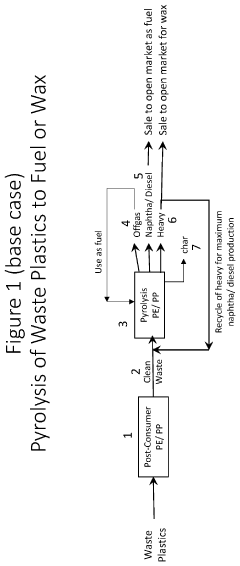

- Chemical recycling techniques: Chemical recycling breaks down polypropylene into its chemical components through processes like pyrolysis, gasification, or depolymerization. These methods can handle mixed plastic waste and produce feedstock for new plastics or other chemical products. They often involve high temperatures and catalysts to facilitate the breakdown of polymer chains.

- Solvent-based recycling: Solvent-based recycling uses specific solvents to dissolve polypropylene, separating it from contaminants and other materials. The polymer is then precipitated out and recovered. This method can produce high-quality recycled polypropylene and is effective for separating different types of plastics in mixed waste streams.

- Advanced sorting and separation technologies: Advanced technologies like near-infrared spectroscopy, X-ray fluorescence, and electrostatic separation are used to improve the sorting and separation of polypropylene from mixed plastic waste. These methods enhance the purity of the recycled material and increase the efficiency of subsequent recycling processes.

- Upcycling and value-added recycling: Upcycling processes aim to convert recycled polypropylene into higher-value products. This may involve adding reinforcing materials, blending with virgin polymers, or using compatibilizers to improve properties. These methods focus on enhancing the quality and performance of recycled polypropylene for use in more demanding applications.

02 Chemical recycling of polypropylene

Chemical recycling breaks down polypropylene into its chemical components through processes such as pyrolysis, gasification, or depolymerization. This method allows for the production of high-quality recycled materials and can handle mixed plastic waste streams. The resulting monomers or chemical feedstocks can be used to produce new plastics or other chemical products.Expand Specific Solutions03 Solvent-based recycling of polypropylene

This method uses solvents to dissolve polypropylene, separating it from contaminants and other materials. The dissolved polypropylene is then precipitated and recovered. Solvent-based recycling can produce high-purity recycled polypropylene and is particularly useful for handling mixed plastic waste or contaminated materials.Expand Specific Solutions04 Compatibilization techniques for polypropylene recycling

Compatibilization involves the use of additives or processing techniques to improve the compatibility and properties of recycled polypropylene blends. This method is particularly useful when dealing with mixed plastic waste or when aiming to enhance the mechanical properties of recycled polypropylene. Techniques may include the use of coupling agents, reactive extrusion, or the addition of virgin polypropylene.Expand Specific Solutions05 Advanced sorting and separation technologies

These technologies improve the efficiency and effectiveness of polypropylene recycling by enhancing the sorting and separation of plastic waste. Methods may include near-infrared spectroscopy, X-ray fluorescence, electrostatic separation, or flotation techniques. Advanced sorting ensures higher purity of recycled polypropylene and enables more efficient recycling processes.Expand Specific Solutions

Key Players in PP Recycling Industry

The polypropylene recycling market is in a growth phase, driven by increasing focus on circular economy principles and sustainability. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is evolving rapidly, with various methods being developed and refined. Key players like Chevron U.S.A., China Petroleum & Chemical Corp., and SABIC Global Technologies BV are investing in advanced recycling technologies. Companies such as Procter & Gamble Co. and Esenttia SA are also contributing to innovations in this space. Academic institutions like Jilin University and the Indian Institute of Science are conducting research to improve recycling efficiency and quality, indicating a collaborative effort between industry and academia to advance polypropylene recycling methods.

SABIC Global Technologies BV

Technical Solution: SABIC has developed a certified circular polypropylene using advanced recycling technologies. Their TRUCIRCLE™ portfolio includes mechanically recycled, certified circular, and certified renewable polypropylene solutions. The certified circular PP is produced using pyrolysis oil from mixed plastic waste as a feedstock. This process can handle difficult-to-recycle plastics and produces virgin-quality PP. SABIC has also invested in a semi-commercial plant in the Netherlands to upscale its advanced recycling technology, with plans to process up to 200,000 tonnes of mixed plastic waste annually[5]. Additionally, SABIC has developed design for recyclability guidelines to improve the recyclability of PP-based products[6].

Strengths: Produces virgin-quality PP from mixed plastic waste. Offers a comprehensive portfolio of recycled PP solutions. Weaknesses: Advanced recycling process is energy-intensive. Relies on the availability of suitable plastic waste feedstock.

Procter & Gamble Co.

Technical Solution: Procter & Gamble has developed a proprietary recycling technology called PureCycle, which has since been spun off into a separate company. The PureCycle process uses a solvent-based extraction method to remove contaminants from PP waste, including color, odor, and other impurities. This results in ultra-pure recycled PP that can be used in a wide range of applications, including food-grade packaging. The process can handle various PP waste streams, including those traditionally difficult to recycle. PureCycle aims to scale up its technology, with plans to produce over 1 billion pounds of ultra-pure recycled PP annually[9]. P&G continues to collaborate with PureCycle and other partners to increase the use of recycled PP in its products and packaging[10].

Strengths: Produces ultra-pure recycled PP suitable for food-grade applications. Can handle a wide range of PP waste streams. Weaknesses: Process may be more expensive than traditional mechanical recycling. Requires significant energy input for solvent-based extraction and purification.

Innovative PP Recycling Technologies

Recycling of polypropylene

PatentWO2012117250A1

Innovation

- A process involving sorting to ensure at least 99% food-grade PP, followed by extrusion with controlled residence time and temperature, and vacuum devolatilization to remove contaminants, resulting in food-grade recycled PP.

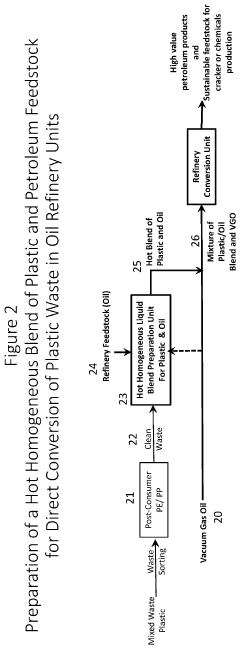

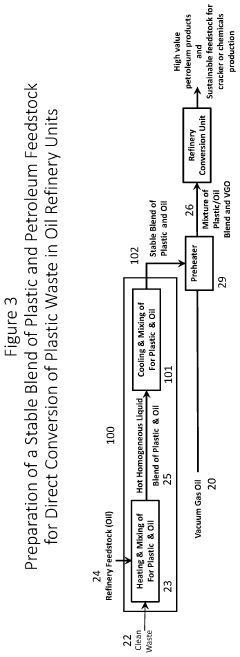

Circular economy for plastic waste to polypropylene via refinery FCC unit

PatentPendingUS20230312437A1

Innovation

- A continuous process that blends waste plastics with petroleum feedstock, creating a stable mixture which is then processed in a refinery FCC unit to produce high-quality hydrocarbons, including propylene, for subsequent polymerization into polypropylene, thereby establishing a circular economy.

Environmental Impact Assessment

The environmental impact assessment of polypropylene recycling methods for enhanced circular economy reveals both positive and negative effects on the ecosystem. On the positive side, recycling polypropylene significantly reduces the demand for virgin plastic production, thereby decreasing the consumption of fossil fuels and associated greenhouse gas emissions. Studies indicate that recycling polypropylene can result in up to 80% reduction in carbon dioxide emissions compared to producing new polypropylene from raw materials.

Furthermore, effective recycling methods contribute to the reduction of plastic waste in landfills and oceans, mitigating the harmful effects on marine life and ecosystems. The circular economy approach to polypropylene recycling also helps conserve natural resources and reduces the overall environmental footprint of plastic production and disposal.

However, the recycling process itself is not without environmental concerns. Energy consumption during the collection, sorting, and processing of polypropylene waste can contribute to carbon emissions. Additionally, the use of chemical additives and solvents in some recycling methods may lead to water pollution if not properly managed. The transportation of plastic waste to recycling facilities also adds to the carbon footprint of the recycling process.

Another environmental consideration is the potential release of microplastics during the mechanical recycling of polypropylene. These tiny plastic particles can enter waterways and pose risks to aquatic ecosystems. Advanced filtration systems and closed-loop recycling processes are being developed to address this issue.

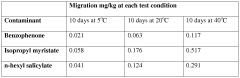

The quality of recycled polypropylene can sometimes be lower than virgin material, potentially leading to increased consumption of additives or the need for blending with virgin plastic. This may partially offset the environmental benefits of recycling. However, ongoing research and technological advancements are improving the quality and purity of recycled polypropylene, enhancing its environmental performance.

In terms of land use, recycling facilities require space and infrastructure, which can impact local ecosystems. However, this is generally considered a lesser impact compared to the land requirements for landfills or the environmental damage caused by improper disposal of plastic waste.

Overall, while polypropylene recycling methods present some environmental challenges, the net impact is largely positive when compared to linear production and disposal models. Continued improvements in recycling technologies and processes are expected to further enhance the environmental benefits of polypropylene recycling in the circular economy.

Furthermore, effective recycling methods contribute to the reduction of plastic waste in landfills and oceans, mitigating the harmful effects on marine life and ecosystems. The circular economy approach to polypropylene recycling also helps conserve natural resources and reduces the overall environmental footprint of plastic production and disposal.

However, the recycling process itself is not without environmental concerns. Energy consumption during the collection, sorting, and processing of polypropylene waste can contribute to carbon emissions. Additionally, the use of chemical additives and solvents in some recycling methods may lead to water pollution if not properly managed. The transportation of plastic waste to recycling facilities also adds to the carbon footprint of the recycling process.

Another environmental consideration is the potential release of microplastics during the mechanical recycling of polypropylene. These tiny plastic particles can enter waterways and pose risks to aquatic ecosystems. Advanced filtration systems and closed-loop recycling processes are being developed to address this issue.

The quality of recycled polypropylene can sometimes be lower than virgin material, potentially leading to increased consumption of additives or the need for blending with virgin plastic. This may partially offset the environmental benefits of recycling. However, ongoing research and technological advancements are improving the quality and purity of recycled polypropylene, enhancing its environmental performance.

In terms of land use, recycling facilities require space and infrastructure, which can impact local ecosystems. However, this is generally considered a lesser impact compared to the land requirements for landfills or the environmental damage caused by improper disposal of plastic waste.

Overall, while polypropylene recycling methods present some environmental challenges, the net impact is largely positive when compared to linear production and disposal models. Continued improvements in recycling technologies and processes are expected to further enhance the environmental benefits of polypropylene recycling in the circular economy.

Regulatory Framework for PP Recycling

The regulatory framework for polypropylene (PP) recycling plays a crucial role in shaping the circular economy landscape for this widely used plastic material. Governments and international organizations have been increasingly implementing policies and regulations to promote PP recycling and reduce plastic waste.

In the European Union, the Circular Economy Action Plan sets ambitious targets for plastic recycling, including a goal of recycling 55% of plastic packaging by 2030. This plan has led to the development of specific regulations for PP recycling, such as the Single-Use Plastics Directive, which aims to reduce the environmental impact of certain plastic products, including those made from PP.

The United States has a more fragmented approach to PP recycling regulations, with policies varying at the state and local levels. However, federal initiatives like the Save Our Seas 2.0 Act aim to improve plastic waste management and promote recycling technologies. Some states, such as California, have implemented more stringent regulations, including mandatory recycling programs and extended producer responsibility schemes for plastic packaging.

In Asia, countries like Japan and South Korea have established comprehensive recycling systems that include PP. Japan's Container and Packaging Recycling Law mandates the recycling of plastic containers and packaging, including PP products. South Korea's Extended Producer Responsibility system requires manufacturers to take responsibility for the entire lifecycle of their products, including recycling.

China's National Sword Policy, implemented in 2018, has had a significant impact on the global PP recycling landscape. This policy banned the import of most plastic waste, forcing many countries to develop domestic recycling capabilities and improve their waste management systems.

International agreements, such as the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal, have been amended to include plastic waste. This has led to stricter regulations on the global trade of plastic waste, including PP, and has encouraged countries to improve their domestic recycling infrastructure.

The regulatory framework for PP recycling also includes standards and certifications for recycled materials. Organizations like the Association of Plastic Recyclers (APR) and the European PET Bottle Platform (EPBP) have developed guidelines and protocols for recycling processes and the use of recycled PP in various applications.

As the circular economy concept gains traction, many countries are exploring the implementation of plastic taxes or levies to incentivize the use of recycled PP and discourage the production of virgin plastic. These economic instruments are expected to play an increasingly important role in shaping the regulatory landscape for PP recycling in the coming years.

In the European Union, the Circular Economy Action Plan sets ambitious targets for plastic recycling, including a goal of recycling 55% of plastic packaging by 2030. This plan has led to the development of specific regulations for PP recycling, such as the Single-Use Plastics Directive, which aims to reduce the environmental impact of certain plastic products, including those made from PP.

The United States has a more fragmented approach to PP recycling regulations, with policies varying at the state and local levels. However, federal initiatives like the Save Our Seas 2.0 Act aim to improve plastic waste management and promote recycling technologies. Some states, such as California, have implemented more stringent regulations, including mandatory recycling programs and extended producer responsibility schemes for plastic packaging.

In Asia, countries like Japan and South Korea have established comprehensive recycling systems that include PP. Japan's Container and Packaging Recycling Law mandates the recycling of plastic containers and packaging, including PP products. South Korea's Extended Producer Responsibility system requires manufacturers to take responsibility for the entire lifecycle of their products, including recycling.

China's National Sword Policy, implemented in 2018, has had a significant impact on the global PP recycling landscape. This policy banned the import of most plastic waste, forcing many countries to develop domestic recycling capabilities and improve their waste management systems.

International agreements, such as the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal, have been amended to include plastic waste. This has led to stricter regulations on the global trade of plastic waste, including PP, and has encouraged countries to improve their domestic recycling infrastructure.

The regulatory framework for PP recycling also includes standards and certifications for recycled materials. Organizations like the Association of Plastic Recyclers (APR) and the European PET Bottle Platform (EPBP) have developed guidelines and protocols for recycling processes and the use of recycled PP in various applications.

As the circular economy concept gains traction, many countries are exploring the implementation of plastic taxes or levies to incentivize the use of recycled PP and discourage the production of virgin plastic. These economic instruments are expected to play an increasingly important role in shaping the regulatory landscape for PP recycling in the coming years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!