Polypropylene’s Role in Modular Construction Innovations

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PP in Modular Building

Polypropylene (PP) has emerged as a key material in the evolution of modular construction, offering innovative solutions to traditional building challenges. The construction industry has long sought ways to improve efficiency, reduce costs, and enhance sustainability. Modular construction, with its off-site fabrication and on-site assembly approach, addresses these needs, and PP plays a crucial role in this paradigm shift.

PP's unique properties make it an ideal candidate for modular building components. Its high strength-to-weight ratio allows for the creation of lightweight yet durable structural elements. This characteristic is particularly advantageous in modular construction, where transportation and assembly of pre-fabricated units are critical factors. The material's resistance to moisture, chemicals, and temperature fluctuations ensures longevity and stability in various environmental conditions, addressing common concerns in traditional construction methods.

In the realm of modular construction, PP is utilized in diverse applications. It serves as a primary material in the production of wall panels, roofing systems, and flooring components. These PP-based elements offer excellent thermal insulation properties, contributing to energy efficiency in buildings. Additionally, PP's moldability allows for the creation of complex shapes and designs, enabling architects and engineers to push the boundaries of modular construction aesthetics.

The integration of PP in modular construction has led to significant advancements in building technology. Innovative joining techniques have been developed to connect PP components securely, ensuring structural integrity while maintaining the flexibility inherent to modular designs. These techniques include heat welding, mechanical fastening, and adhesive bonding, each tailored to specific modular construction requirements.

Furthermore, PP's recyclability aligns with the growing emphasis on sustainable construction practices. The ability to recycle and repurpose PP components at the end of a building's lifecycle contributes to the circular economy model, reducing waste and environmental impact. This aspect of PP usage in modular construction resonates with the increasing demand for eco-friendly building solutions.

As the modular construction industry continues to evolve, PP is at the forefront of material innovation. Research and development efforts are focused on enhancing PP's properties for specific modular applications, such as improving fire resistance and acoustic performance. These advancements are expanding the potential applications of PP in modular construction, from residential buildings to commercial and industrial structures.

PP's unique properties make it an ideal candidate for modular building components. Its high strength-to-weight ratio allows for the creation of lightweight yet durable structural elements. This characteristic is particularly advantageous in modular construction, where transportation and assembly of pre-fabricated units are critical factors. The material's resistance to moisture, chemicals, and temperature fluctuations ensures longevity and stability in various environmental conditions, addressing common concerns in traditional construction methods.

In the realm of modular construction, PP is utilized in diverse applications. It serves as a primary material in the production of wall panels, roofing systems, and flooring components. These PP-based elements offer excellent thermal insulation properties, contributing to energy efficiency in buildings. Additionally, PP's moldability allows for the creation of complex shapes and designs, enabling architects and engineers to push the boundaries of modular construction aesthetics.

The integration of PP in modular construction has led to significant advancements in building technology. Innovative joining techniques have been developed to connect PP components securely, ensuring structural integrity while maintaining the flexibility inherent to modular designs. These techniques include heat welding, mechanical fastening, and adhesive bonding, each tailored to specific modular construction requirements.

Furthermore, PP's recyclability aligns with the growing emphasis on sustainable construction practices. The ability to recycle and repurpose PP components at the end of a building's lifecycle contributes to the circular economy model, reducing waste and environmental impact. This aspect of PP usage in modular construction resonates with the increasing demand for eco-friendly building solutions.

As the modular construction industry continues to evolve, PP is at the forefront of material innovation. Research and development efforts are focused on enhancing PP's properties for specific modular applications, such as improving fire resistance and acoustic performance. These advancements are expanding the potential applications of PP in modular construction, from residential buildings to commercial and industrial structures.

Market Demand Analysis

The market demand for polypropylene in modular construction innovations has been steadily increasing in recent years, driven by the growing need for sustainable, cost-effective, and efficient building solutions. The global modular construction market is projected to reach significant growth, with polypropylene playing a crucial role in this expansion.

One of the primary factors fueling the demand for polypropylene in modular construction is its versatility and durability. As a lightweight yet strong material, polypropylene offers excellent resistance to moisture, chemicals, and temperature fluctuations, making it ideal for various components in prefabricated building modules. This has led to increased adoption in wall panels, flooring systems, and insulation materials.

The construction industry's shift towards more sustainable practices has also contributed to the rising demand for polypropylene in modular construction. Polypropylene's recyclability and energy-efficient production process align well with the growing emphasis on environmentally friendly building materials. This trend is particularly evident in developed markets where stringent regulations on carbon emissions and waste reduction are driving the adoption of eco-friendly construction methods.

In the residential sector, the demand for affordable housing solutions has created a significant market opportunity for polypropylene-based modular construction. The material's ability to reduce construction time and labor costs while maintaining high-quality standards has made it an attractive option for large-scale housing projects, especially in rapidly urbanizing regions.

The commercial and industrial sectors are also showing increased interest in polypropylene-based modular construction. The material's adaptability to various designs and its ability to create flexible, reconfigurable spaces have made it popular for office buildings, retail spaces, and temporary structures. This trend is expected to continue as businesses seek more agile and cost-effective building solutions.

Geographically, the Asia-Pacific region is emerging as a key market for polypropylene in modular construction, driven by rapid urbanization, population growth, and government initiatives to promote sustainable building practices. North America and Europe are also witnessing steady growth, particularly in the renovation and retrofit segments, where polypropylene-based modular solutions offer efficient and minimally disruptive alternatives to traditional construction methods.

The healthcare sector represents another significant growth area for polypropylene in modular construction. The material's hygienic properties and ease of maintenance make it suitable for creating sterile environments in hospitals and clinics. The recent global health crisis has further accelerated this trend, with an increased focus on rapidly deployable healthcare facilities.

As the modular construction industry continues to evolve, the demand for innovative polypropylene-based solutions is expected to grow. This includes advancements in fire-resistant formulations, enhanced structural capabilities, and improved integration with smart building technologies. These developments are likely to expand the application scope of polypropylene in modular construction, further driving market growth in the coming years.

One of the primary factors fueling the demand for polypropylene in modular construction is its versatility and durability. As a lightweight yet strong material, polypropylene offers excellent resistance to moisture, chemicals, and temperature fluctuations, making it ideal for various components in prefabricated building modules. This has led to increased adoption in wall panels, flooring systems, and insulation materials.

The construction industry's shift towards more sustainable practices has also contributed to the rising demand for polypropylene in modular construction. Polypropylene's recyclability and energy-efficient production process align well with the growing emphasis on environmentally friendly building materials. This trend is particularly evident in developed markets where stringent regulations on carbon emissions and waste reduction are driving the adoption of eco-friendly construction methods.

In the residential sector, the demand for affordable housing solutions has created a significant market opportunity for polypropylene-based modular construction. The material's ability to reduce construction time and labor costs while maintaining high-quality standards has made it an attractive option for large-scale housing projects, especially in rapidly urbanizing regions.

The commercial and industrial sectors are also showing increased interest in polypropylene-based modular construction. The material's adaptability to various designs and its ability to create flexible, reconfigurable spaces have made it popular for office buildings, retail spaces, and temporary structures. This trend is expected to continue as businesses seek more agile and cost-effective building solutions.

Geographically, the Asia-Pacific region is emerging as a key market for polypropylene in modular construction, driven by rapid urbanization, population growth, and government initiatives to promote sustainable building practices. North America and Europe are also witnessing steady growth, particularly in the renovation and retrofit segments, where polypropylene-based modular solutions offer efficient and minimally disruptive alternatives to traditional construction methods.

The healthcare sector represents another significant growth area for polypropylene in modular construction. The material's hygienic properties and ease of maintenance make it suitable for creating sterile environments in hospitals and clinics. The recent global health crisis has further accelerated this trend, with an increased focus on rapidly deployable healthcare facilities.

As the modular construction industry continues to evolve, the demand for innovative polypropylene-based solutions is expected to grow. This includes advancements in fire-resistant formulations, enhanced structural capabilities, and improved integration with smart building technologies. These developments are likely to expand the application scope of polypropylene in modular construction, further driving market growth in the coming years.

Current Tech Challenges

Polypropylene's integration into modular construction faces several significant challenges that hinder its widespread adoption and optimal utilization. One of the primary obstacles is the material's susceptibility to UV degradation, which can lead to reduced durability and structural integrity over time when exposed to sunlight. This limitation necessitates the development of effective UV stabilizers or protective coatings to enhance the longevity of polypropylene-based modular components.

Another challenge lies in the thermal expansion properties of polypropylene. The material's relatively high coefficient of thermal expansion can cause dimensional instability in modular units, potentially leading to gaps, misalignments, or structural issues in assembled buildings. This characteristic requires careful consideration in design and engineering to accommodate temperature-induced changes without compromising the overall structure.

Fire resistance remains a critical concern for polypropylene in construction applications. While the material has inherent flame-retardant properties, it may not meet stringent fire safety regulations for certain building types or locations. Enhancing the fire performance of polypropylene-based modules without significantly increasing costs or compromising other desirable properties presents a substantial technical challenge.

The joining and bonding of polypropylene components in modular construction also pose difficulties. Traditional welding techniques may not be suitable for all applications, and adhesive bonding can be challenging due to the material's low surface energy. Developing reliable, cost-effective, and efficient joining methods that ensure structural integrity and weather resistance is crucial for the advancement of polypropylene in modular construction.

Environmental concerns and sustainability requirements present another set of challenges. While polypropylene is recyclable, the incorporation of additives, coatings, and other materials in modular construction can complicate the recycling process. Designing for end-of-life disassembly and recycling, while maintaining the performance and cost-effectiveness of the modules, requires innovative approaches and potentially new material formulations.

Lastly, the perception and acceptance of polypropylene as a primary construction material among architects, engineers, and end-users remain hurdles to overcome. Concerns about the long-term performance, aesthetics, and overall quality of polypropylene-based modular buildings need to be addressed through extensive testing, demonstration projects, and education initiatives to build confidence in the material's capabilities and benefits in the construction industry.

Another challenge lies in the thermal expansion properties of polypropylene. The material's relatively high coefficient of thermal expansion can cause dimensional instability in modular units, potentially leading to gaps, misalignments, or structural issues in assembled buildings. This characteristic requires careful consideration in design and engineering to accommodate temperature-induced changes without compromising the overall structure.

Fire resistance remains a critical concern for polypropylene in construction applications. While the material has inherent flame-retardant properties, it may not meet stringent fire safety regulations for certain building types or locations. Enhancing the fire performance of polypropylene-based modules without significantly increasing costs or compromising other desirable properties presents a substantial technical challenge.

The joining and bonding of polypropylene components in modular construction also pose difficulties. Traditional welding techniques may not be suitable for all applications, and adhesive bonding can be challenging due to the material's low surface energy. Developing reliable, cost-effective, and efficient joining methods that ensure structural integrity and weather resistance is crucial for the advancement of polypropylene in modular construction.

Environmental concerns and sustainability requirements present another set of challenges. While polypropylene is recyclable, the incorporation of additives, coatings, and other materials in modular construction can complicate the recycling process. Designing for end-of-life disassembly and recycling, while maintaining the performance and cost-effectiveness of the modules, requires innovative approaches and potentially new material formulations.

Lastly, the perception and acceptance of polypropylene as a primary construction material among architects, engineers, and end-users remain hurdles to overcome. Concerns about the long-term performance, aesthetics, and overall quality of polypropylene-based modular buildings need to be addressed through extensive testing, demonstration projects, and education initiatives to build confidence in the material's capabilities and benefits in the construction industry.

Existing PP Solutions

01 Polypropylene synthesis and production methods

Various methods for synthesizing and producing polypropylene, including polymerization techniques, catalyst systems, and process improvements to enhance yield and quality of the resulting polymer.- Polypropylene synthesis and production methods: Various methods for synthesizing and producing polypropylene, including polymerization techniques, catalyst systems, and process improvements to enhance yield and quality of the resulting polymer.

- Polypropylene compositions and blends: Development of polypropylene compositions and blends with other materials to enhance specific properties such as strength, flexibility, or heat resistance for various applications.

- Polypropylene modification techniques: Methods for modifying polypropylene through chemical or physical processes to improve its characteristics, such as impact resistance, weatherability, or compatibility with other materials.

- Polypropylene applications in packaging and films: Utilization of polypropylene in packaging materials and film production, including techniques for improving barrier properties, printability, and sealability of polypropylene-based products.

- Recycling and sustainability of polypropylene: Advancements in recycling technologies for polypropylene, as well as the development of more sustainable production methods and biodegradable polypropylene alternatives to address environmental concerns.

02 Polypropylene compositions and blends

Development of polypropylene compositions and blends with other materials to enhance specific properties such as strength, flexibility, or heat resistance for various applications.Expand Specific Solutions03 Polypropylene modification techniques

Methods for modifying polypropylene through chemical or physical processes to improve its characteristics, such as impact resistance, weatherability, or compatibility with other materials.Expand Specific Solutions04 Polypropylene applications in packaging and films

Utilization of polypropylene in packaging materials and films, including development of specialized grades for food packaging, barrier films, and other industrial applications.Expand Specific Solutions05 Polypropylene recycling and sustainability

Advancements in polypropylene recycling technologies and development of more sustainable production methods to reduce environmental impact and improve circular economy practices in the plastics industry.Expand Specific Solutions

Key Industry Players

The polypropylene market in modular construction is experiencing rapid growth, driven by increasing demand for sustainable and efficient building solutions. The industry is in an early expansion phase, with a projected market size reaching billions of dollars globally in the coming years. Technologically, polypropylene applications are advancing, with companies like Borealis AG, SABIC, and Sumitomo Chemical leading innovations in high-performance materials. Emerging players such as Kingfa Sci. & Tech. and Japan Polypropylene Corp. are also contributing to material advancements. The competitive landscape is characterized by a mix of established petrochemical giants and specialized polymer manufacturers, all vying to develop stronger, lighter, and more versatile polypropylene solutions for modular construction applications.

Borealis AG

Technical Solution: Borealis AG has developed innovative polypropylene (PP) solutions specifically tailored for modular construction. Their Bormed™ PP portfolio offers high-performance materials with enhanced mechanical properties and processing characteristics. These materials are designed to meet the stringent requirements of modular construction, including improved impact resistance, dimensional stability, and weatherability. Borealis has also introduced lightweight PP foam solutions that provide excellent thermal insulation and acoustic properties, crucial for modular building components[1]. Their PP compounds incorporate advanced additives to enhance fire retardancy and UV stability, addressing key safety and durability concerns in modular construction[2].

Strengths: Tailored PP solutions for modular construction, advanced material properties, and focus on sustainability. Weaknesses: Potential higher costs compared to traditional materials, and reliance on petrochemical feedstocks.

SABIC Global Technologies BV

Technical Solution: SABIC has developed a range of polypropylene solutions specifically for modular construction applications. Their SABIC® PP compounds offer high stiffness-to-weight ratios, making them ideal for lightweight yet strong modular components. SABIC has introduced long glass fiber-reinforced PP grades that provide exceptional mechanical properties and dimensional stability, crucial for load-bearing elements in modular structures[3]. They have also developed flame-retardant PP grades that meet stringent fire safety standards for building materials. SABIC's focus on circular economy has led to the development of recycled content PP grades for sustainable modular construction solutions, aligning with the growing demand for eco-friendly building materials[4].

Strengths: Wide range of specialized PP grades, strong focus on sustainability and circular economy. Weaknesses: Potential higher costs for advanced grades, and challenges in recycling complex PP compounds.

Core PP Innovations

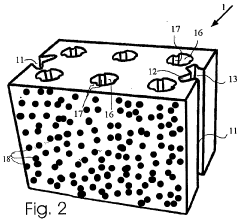

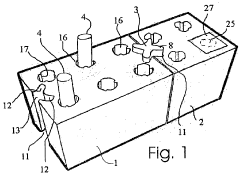

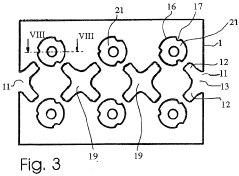

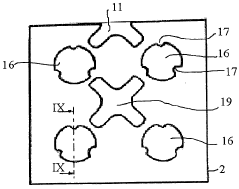

Set of building elements with elements of polypropylene

PatentWO2008138377A1

Innovation

- The use of expanded polypropylene (EPP) with a molding density of 40-70 kg/m³ for building components, combined with a ribbed surface design for enhanced sound absorption, and the integration of connecting elements with dovetail-like engagement structures for easy assembly and disassembly, along with the option to include electrical and water ducts for installation of lines.

Sustainability Aspects

Polypropylene's integration into modular construction innovations brings significant sustainability benefits to the building industry. This versatile material contributes to reduced environmental impact throughout the lifecycle of modular structures, from manufacturing to end-of-life considerations.

During the production phase, polypropylene's lightweight nature allows for more efficient transportation of modular components, resulting in lower fuel consumption and reduced carbon emissions. The material's durability and resistance to moisture, chemicals, and UV radiation extend the lifespan of modular buildings, minimizing the need for frequent replacements and repairs. This longevity translates to reduced resource consumption and waste generation over time.

Polypropylene's thermal insulation properties contribute to improved energy efficiency in modular structures. By enhancing the building envelope's performance, it helps reduce heating and cooling demands, leading to lower energy consumption and associated greenhouse gas emissions during the operational phase of the building.

The recyclability of polypropylene aligns with circular economy principles, allowing for the recovery and reuse of materials at the end of a modular building's life. This characteristic significantly reduces the amount of construction waste sent to landfills and conserves raw materials for future applications.

In terms of indoor environmental quality, polypropylene's low VOC emissions contribute to healthier living and working spaces. This aspect is particularly crucial in modular construction, where off-site manufacturing can better control material emissions and ensure a safer indoor environment upon installation.

Polypropylene's role in water conservation is noteworthy, particularly in plumbing systems for modular units. Its corrosion resistance and durability reduce the likelihood of leaks and the need for water-intensive repairs, contributing to overall water efficiency in buildings.

The material's adaptability to various designs and its ability to be molded into complex shapes facilitate the creation of more efficient and sustainable modular components. This flexibility allows for optimized designs that maximize space utilization and minimize material waste during the manufacturing process.

As the construction industry moves towards more sustainable practices, polypropylene's role in modular construction innovations represents a significant step towards reducing the sector's environmental footprint. Its contributions to energy efficiency, waste reduction, and resource conservation align with global sustainability goals and regulations, positioning modular construction as a key player in the transition to more environmentally responsible building practices.

During the production phase, polypropylene's lightweight nature allows for more efficient transportation of modular components, resulting in lower fuel consumption and reduced carbon emissions. The material's durability and resistance to moisture, chemicals, and UV radiation extend the lifespan of modular buildings, minimizing the need for frequent replacements and repairs. This longevity translates to reduced resource consumption and waste generation over time.

Polypropylene's thermal insulation properties contribute to improved energy efficiency in modular structures. By enhancing the building envelope's performance, it helps reduce heating and cooling demands, leading to lower energy consumption and associated greenhouse gas emissions during the operational phase of the building.

The recyclability of polypropylene aligns with circular economy principles, allowing for the recovery and reuse of materials at the end of a modular building's life. This characteristic significantly reduces the amount of construction waste sent to landfills and conserves raw materials for future applications.

In terms of indoor environmental quality, polypropylene's low VOC emissions contribute to healthier living and working spaces. This aspect is particularly crucial in modular construction, where off-site manufacturing can better control material emissions and ensure a safer indoor environment upon installation.

Polypropylene's role in water conservation is noteworthy, particularly in plumbing systems for modular units. Its corrosion resistance and durability reduce the likelihood of leaks and the need for water-intensive repairs, contributing to overall water efficiency in buildings.

The material's adaptability to various designs and its ability to be molded into complex shapes facilitate the creation of more efficient and sustainable modular components. This flexibility allows for optimized designs that maximize space utilization and minimize material waste during the manufacturing process.

As the construction industry moves towards more sustainable practices, polypropylene's role in modular construction innovations represents a significant step towards reducing the sector's environmental footprint. Its contributions to energy efficiency, waste reduction, and resource conservation align with global sustainability goals and regulations, positioning modular construction as a key player in the transition to more environmentally responsible building practices.

Regulatory Framework

The regulatory framework surrounding polypropylene's use in modular construction innovations is a critical aspect that shapes the industry's development and adoption of this material. As modular construction techniques gain traction, governments and regulatory bodies are adapting their policies to ensure safety, sustainability, and compliance with building codes.

In many jurisdictions, building codes are being updated to specifically address modular construction methods, including the use of materials like polypropylene. These updates often focus on structural integrity, fire safety, and durability requirements. For instance, some regulations now include provisions for the testing and certification of polypropylene-based modular components to ensure they meet or exceed traditional construction standards.

Environmental regulations also play a significant role in shaping the use of polypropylene in modular construction. Many countries have implemented stricter guidelines on the recyclability and environmental impact of construction materials. This has led to increased emphasis on the development of recyclable polypropylene formulations and the establishment of recycling programs for modular construction components.

Occupational health and safety regulations have been adapted to address the unique challenges posed by modular construction techniques. These include guidelines for the safe handling and installation of polypropylene-based modules, as well as requirements for personal protective equipment during manufacturing and assembly processes.

International standards organizations, such as ISO and ASTM, have developed specific standards for the use of plastics in construction, including polypropylene. These standards provide a framework for quality control, testing methodologies, and performance criteria, facilitating the global adoption of polypropylene in modular construction innovations.

Some regulatory bodies have introduced incentives to promote the use of sustainable and innovative construction methods, including those utilizing polypropylene. These may include expedited permitting processes, tax incentives, or grants for projects that demonstrate improved energy efficiency or reduced environmental impact through the use of advanced materials and modular techniques.

As the industry evolves, regulatory frameworks are likely to continue adapting to address emerging challenges and opportunities. This may include the development of new testing protocols for long-term durability of polypropylene in various climatic conditions, as well as regulations governing the integration of smart technologies within modular polypropylene structures.

In many jurisdictions, building codes are being updated to specifically address modular construction methods, including the use of materials like polypropylene. These updates often focus on structural integrity, fire safety, and durability requirements. For instance, some regulations now include provisions for the testing and certification of polypropylene-based modular components to ensure they meet or exceed traditional construction standards.

Environmental regulations also play a significant role in shaping the use of polypropylene in modular construction. Many countries have implemented stricter guidelines on the recyclability and environmental impact of construction materials. This has led to increased emphasis on the development of recyclable polypropylene formulations and the establishment of recycling programs for modular construction components.

Occupational health and safety regulations have been adapted to address the unique challenges posed by modular construction techniques. These include guidelines for the safe handling and installation of polypropylene-based modules, as well as requirements for personal protective equipment during manufacturing and assembly processes.

International standards organizations, such as ISO and ASTM, have developed specific standards for the use of plastics in construction, including polypropylene. These standards provide a framework for quality control, testing methodologies, and performance criteria, facilitating the global adoption of polypropylene in modular construction innovations.

Some regulatory bodies have introduced incentives to promote the use of sustainable and innovative construction methods, including those utilizing polypropylene. These may include expedited permitting processes, tax incentives, or grants for projects that demonstrate improved energy efficiency or reduced environmental impact through the use of advanced materials and modular techniques.

As the industry evolves, regulatory frameworks are likely to continue adapting to address emerging challenges and opportunities. This may include the development of new testing protocols for long-term durability of polypropylene in various climatic conditions, as well as regulations governing the integration of smart technologies within modular polypropylene structures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!