QLED Technology: A Blueprint for Future Innovations

JUN 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QLED Evolution and Objectives

Quantum Dot Light-Emitting Diode (QLED) technology has emerged as a groundbreaking innovation in display technology, promising superior color performance and energy efficiency. The evolution of QLED technology can be traced back to the early 2000s when researchers first began exploring the potential of quantum dots in light-emitting applications.

The journey of QLED technology has been marked by significant milestones. Initially, the focus was on developing stable and efficient quantum dot materials. As the technology progressed, efforts shifted towards integrating these quantum dots into display structures. The first QLED displays were demonstrated in laboratory settings around 2010, showcasing the potential for vibrant colors and high brightness.

In recent years, QLED technology has made substantial strides in commercialization. Major display manufacturers have introduced QLED TVs and monitors to the consumer market, competing directly with OLED technology. The ongoing evolution of QLED is driven by the pursuit of enhanced color accuracy, improved energy efficiency, and increased longevity of displays.

The primary objectives of QLED technology development are multifaceted. Firstly, there is a strong focus on improving the quantum yield of quantum dots, aiming to maximize the efficiency of light emission. Secondly, researchers are working on expanding the color gamut to cover an even wider range of the visible spectrum, potentially surpassing the capabilities of current display technologies.

Another crucial objective is to enhance the stability of quantum dots, addressing issues related to degradation over time. This involves developing new encapsulation techniques and exploring alternative materials that can withstand high temperatures and intense light exposure without losing their optical properties.

Furthermore, the integration of QLED technology with flexible and transparent substrates is a key area of research. This could pave the way for innovative display applications, such as foldable screens and transparent displays for augmented reality devices.

As QLED technology continues to evolve, there is also a growing emphasis on sustainability. Researchers are exploring eco-friendly quantum dot materials and manufacturing processes to reduce the environmental impact of QLED production. Additionally, efforts are being made to improve the recyclability of QLED displays, aligning with global initiatives for sustainable electronics.

The future trajectory of QLED technology is expected to focus on miniaturization, enabling the development of micro-LED displays that combine the benefits of quantum dots with the precision of micro-LED technology. This convergence could lead to ultra-high-resolution displays with unprecedented color accuracy and energy efficiency, potentially revolutionizing both consumer electronics and professional display applications.

The journey of QLED technology has been marked by significant milestones. Initially, the focus was on developing stable and efficient quantum dot materials. As the technology progressed, efforts shifted towards integrating these quantum dots into display structures. The first QLED displays were demonstrated in laboratory settings around 2010, showcasing the potential for vibrant colors and high brightness.

In recent years, QLED technology has made substantial strides in commercialization. Major display manufacturers have introduced QLED TVs and monitors to the consumer market, competing directly with OLED technology. The ongoing evolution of QLED is driven by the pursuit of enhanced color accuracy, improved energy efficiency, and increased longevity of displays.

The primary objectives of QLED technology development are multifaceted. Firstly, there is a strong focus on improving the quantum yield of quantum dots, aiming to maximize the efficiency of light emission. Secondly, researchers are working on expanding the color gamut to cover an even wider range of the visible spectrum, potentially surpassing the capabilities of current display technologies.

Another crucial objective is to enhance the stability of quantum dots, addressing issues related to degradation over time. This involves developing new encapsulation techniques and exploring alternative materials that can withstand high temperatures and intense light exposure without losing their optical properties.

Furthermore, the integration of QLED technology with flexible and transparent substrates is a key area of research. This could pave the way for innovative display applications, such as foldable screens and transparent displays for augmented reality devices.

As QLED technology continues to evolve, there is also a growing emphasis on sustainability. Researchers are exploring eco-friendly quantum dot materials and manufacturing processes to reduce the environmental impact of QLED production. Additionally, efforts are being made to improve the recyclability of QLED displays, aligning with global initiatives for sustainable electronics.

The future trajectory of QLED technology is expected to focus on miniaturization, enabling the development of micro-LED displays that combine the benefits of quantum dots with the precision of micro-LED technology. This convergence could lead to ultra-high-resolution displays with unprecedented color accuracy and energy efficiency, potentially revolutionizing both consumer electronics and professional display applications.

QLED Market Dynamics

The QLED market has experienced significant growth in recent years, driven by increasing demand for high-quality displays in various applications. The global QLED market size was valued at approximately $8.5 billion in 2020 and is projected to reach $25.7 billion by 2026, growing at a CAGR of 20.1% during the forecast period. This robust growth is attributed to the superior picture quality, energy efficiency, and longer lifespan offered by QLED technology compared to traditional LED and OLED displays.

Consumer electronics, particularly televisions, remain the primary driver of QLED market growth. Major manufacturers such as Samsung, TCL, and Hisense have heavily invested in QLED technology, expanding their product lines and improving performance. The increasing adoption of 4K and 8K resolution displays has further boosted the demand for QLED panels, as they can deliver vibrant colors and high contrast ratios required for these ultra-high-definition formats.

Beyond consumer electronics, QLED technology is gaining traction in other sectors. The automotive industry is increasingly incorporating QLED displays in infotainment systems and digital dashboards, capitalizing on their brightness and durability. Additionally, the commercial display market, including digital signage and large-format displays, is embracing QLED technology for its superior visibility in bright environments and potential for seamless video walls.

Geographically, Asia-Pacific dominates the QLED market, with South Korea and China leading in production and consumption. North America and Europe follow closely, driven by high consumer spending on premium display technologies. Emerging markets in Latin America and the Middle East are showing promising growth potential as disposable incomes rise and awareness of advanced display technologies increases.

The competitive landscape of the QLED market is characterized by intense rivalry among key players. Samsung Electronics holds a significant market share, leveraging its vertically integrated supply chain and strong brand presence. Other major players include TCL, Hisense, and Vizio, who are rapidly expanding their QLED offerings. This competition is driving innovation and pushing down prices, making QLED technology more accessible to a broader consumer base.

Looking ahead, the QLED market is poised for continued growth, with several trends shaping its trajectory. The development of micro-LED and nano-LED technologies is expected to further enhance QLED performance, potentially leading to new product categories. Additionally, the integration of artificial intelligence and smart features in QLED displays is likely to open up new applications and use cases, further driving market expansion.

Consumer electronics, particularly televisions, remain the primary driver of QLED market growth. Major manufacturers such as Samsung, TCL, and Hisense have heavily invested in QLED technology, expanding their product lines and improving performance. The increasing adoption of 4K and 8K resolution displays has further boosted the demand for QLED panels, as they can deliver vibrant colors and high contrast ratios required for these ultra-high-definition formats.

Beyond consumer electronics, QLED technology is gaining traction in other sectors. The automotive industry is increasingly incorporating QLED displays in infotainment systems and digital dashboards, capitalizing on their brightness and durability. Additionally, the commercial display market, including digital signage and large-format displays, is embracing QLED technology for its superior visibility in bright environments and potential for seamless video walls.

Geographically, Asia-Pacific dominates the QLED market, with South Korea and China leading in production and consumption. North America and Europe follow closely, driven by high consumer spending on premium display technologies. Emerging markets in Latin America and the Middle East are showing promising growth potential as disposable incomes rise and awareness of advanced display technologies increases.

The competitive landscape of the QLED market is characterized by intense rivalry among key players. Samsung Electronics holds a significant market share, leveraging its vertically integrated supply chain and strong brand presence. Other major players include TCL, Hisense, and Vizio, who are rapidly expanding their QLED offerings. This competition is driving innovation and pushing down prices, making QLED technology more accessible to a broader consumer base.

Looking ahead, the QLED market is poised for continued growth, with several trends shaping its trajectory. The development of micro-LED and nano-LED technologies is expected to further enhance QLED performance, potentially leading to new product categories. Additionally, the integration of artificial intelligence and smart features in QLED displays is likely to open up new applications and use cases, further driving market expansion.

QLED Technical Hurdles

QLED technology, while promising, faces several significant technical hurdles that need to be addressed for its widespread adoption and continued advancement. One of the primary challenges lies in the quantum dot synthesis process. Achieving uniform size distribution and maintaining high quantum yield across different colors remains a complex task. The precision required in controlling the size of quantum dots, typically ranging from 2 to 10 nanometers, demands sophisticated manufacturing techniques and stringent quality control measures.

Another critical hurdle is the stability of quantum dots, particularly under high-temperature and high-luminance conditions. The performance of QLED displays can degrade over time due to oxidation and photo-bleaching of quantum dots, leading to color shift and reduced brightness. This issue is especially pronounced in blue quantum dots, which are crucial for achieving a full-color gamut. Developing more robust encapsulation methods and exploring alternative materials for blue quantum dots are active areas of research to overcome this limitation.

The efficiency of charge injection and transport in QLED devices presents another significant challenge. The interface between the quantum dot layer and the charge transport layers is critical for device performance. Improving the charge balance and reducing energy barriers at these interfaces is essential for enhancing the overall efficiency and longevity of QLED displays. This requires careful engineering of the device architecture and the development of novel materials for charge transport layers.

Mass production and scalability of QLED technology also pose considerable technical difficulties. The transition from laboratory-scale production to large-scale manufacturing while maintaining consistent quality and performance is a complex process. It involves optimizing the deposition methods for quantum dot layers, ensuring uniformity across large areas, and developing cost-effective production techniques that can compete with established display technologies.

Environmental concerns and regulatory compliance add another layer of complexity to QLED development. Many quantum dots contain heavy metals like cadmium, which are subject to strict regulations in many countries. Finding alternative, non-toxic materials that can match the performance of traditional quantum dots is a significant research focus. This challenge extends to developing eco-friendly manufacturing processes and addressing end-of-life recycling issues for QLED displays.

Lastly, the integration of QLED technology with flexible and transparent display applications presents unique technical challenges. Achieving the same level of performance and durability in flexible substrates as in rigid displays requires innovative approaches to materials science and device engineering. These hurdles encompass not only the quantum dots themselves but also the entire display stack, including electrodes, transport layers, and encapsulation materials.

Another critical hurdle is the stability of quantum dots, particularly under high-temperature and high-luminance conditions. The performance of QLED displays can degrade over time due to oxidation and photo-bleaching of quantum dots, leading to color shift and reduced brightness. This issue is especially pronounced in blue quantum dots, which are crucial for achieving a full-color gamut. Developing more robust encapsulation methods and exploring alternative materials for blue quantum dots are active areas of research to overcome this limitation.

The efficiency of charge injection and transport in QLED devices presents another significant challenge. The interface between the quantum dot layer and the charge transport layers is critical for device performance. Improving the charge balance and reducing energy barriers at these interfaces is essential for enhancing the overall efficiency and longevity of QLED displays. This requires careful engineering of the device architecture and the development of novel materials for charge transport layers.

Mass production and scalability of QLED technology also pose considerable technical difficulties. The transition from laboratory-scale production to large-scale manufacturing while maintaining consistent quality and performance is a complex process. It involves optimizing the deposition methods for quantum dot layers, ensuring uniformity across large areas, and developing cost-effective production techniques that can compete with established display technologies.

Environmental concerns and regulatory compliance add another layer of complexity to QLED development. Many quantum dots contain heavy metals like cadmium, which are subject to strict regulations in many countries. Finding alternative, non-toxic materials that can match the performance of traditional quantum dots is a significant research focus. This challenge extends to developing eco-friendly manufacturing processes and addressing end-of-life recycling issues for QLED displays.

Lastly, the integration of QLED technology with flexible and transparent display applications presents unique technical challenges. Achieving the same level of performance and durability in flexible substrates as in rigid displays requires innovative approaches to materials science and device engineering. These hurdles encompass not only the quantum dots themselves but also the entire display stack, including electrodes, transport layers, and encapsulation materials.

Current QLED Solutions

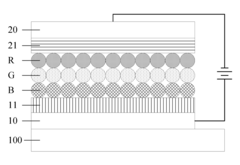

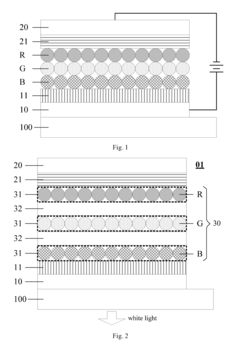

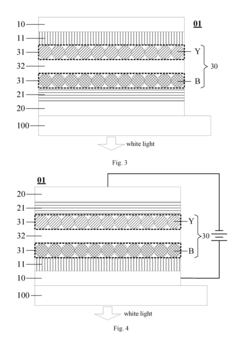

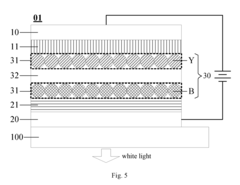

01 QLED structure and materials

QLED technology involves the use of quantum dots as light-emitting materials. The structure typically includes layers of quantum dots sandwiched between electron and hole transport layers. Various materials and compositions are used to optimize the performance of these layers, including the quantum dot emissive layer, which can be tuned to produce different colors.- QLED structure and composition: QLED technology involves the use of quantum dots as light-emitting materials in display devices. The structure typically includes layers of quantum dots sandwiched between electron and hole transport layers. The composition of quantum dots, often made of semiconductor materials like cadmium selenide or indium phosphide, plays a crucial role in determining the color and efficiency of the display.

- Quantum dot synthesis and optimization: The synthesis of quantum dots is a critical aspect of QLED technology. Various methods are employed to produce quantum dots with specific size distributions and surface properties. Optimization techniques focus on improving quantum yield, color purity, and stability of the quantum dots, which directly impact the performance of QLED displays.

- QLED device fabrication techniques: Fabrication of QLED devices involves several steps, including deposition of quantum dot layers, electrode formation, and encapsulation. Advanced techniques such as inkjet printing, photolithography, and roll-to-roll processing are being developed to improve manufacturing efficiency and device performance. These methods aim to achieve uniform quantum dot layers and precise patterning for high-resolution displays.

- Color conversion and enhancement in QLEDs: QLED technology utilizes quantum dots for color conversion and enhancement. By carefully selecting quantum dot materials and sizes, the color gamut of displays can be significantly expanded. This allows for more vibrant and accurate color reproduction compared to traditional LED displays. Techniques for optimizing color conversion efficiency and reducing energy loss are key areas of research in QLED development.

- Integration of QLEDs with other display technologies: Research is ongoing to integrate QLED technology with other display technologies such as OLED and micro-LED. This hybrid approach aims to combine the advantages of different technologies, potentially leading to displays with improved brightness, color accuracy, and energy efficiency. Challenges include developing compatible materials and processes for seamless integration.

02 Quantum dot synthesis and processing

The synthesis and processing of quantum dots are crucial for QLED performance. This includes methods for producing quantum dots with specific sizes and compositions, as well as techniques for incorporating them into devices. Surface treatments and ligand exchange processes are often employed to improve stability and efficiency.Expand Specific Solutions03 QLED device fabrication techniques

Various fabrication techniques are used in QLED production, including solution processing, inkjet printing, and vacuum deposition methods. These techniques aim to create uniform and defect-free layers, which are essential for high-performance devices. Innovations in manufacturing processes focus on improving yield, reducing costs, and enabling large-scale production.Expand Specific Solutions04 QLED efficiency and lifetime improvements

Enhancing the efficiency and lifetime of QLED devices is a key area of research. This includes developing new materials for charge transport layers, improving quantum dot stability, and optimizing device architectures. Strategies to reduce degradation mechanisms and enhance light outcoupling are also explored to improve overall device performance.Expand Specific Solutions05 QLED applications and integration

QLED technology is being applied in various fields, including displays, lighting, and sensors. Research focuses on integrating QLEDs with other technologies, such as flexible substrates for bendable displays or combining them with traditional LED backlights. Efforts are also made to develop QLED-based micro-displays for augmented and virtual reality applications.Expand Specific Solutions

QLED Industry Leaders

QLED technology is in a growth phase, with increasing market adoption and ongoing innovations. The global QLED market is expanding rapidly, driven by demand for high-quality displays in consumer electronics and commercial applications. Technologically, QLED is maturing but still evolving, with key players like Samsung Electronics, BOE Technology Group, and TCL China Star Optoelectronics leading advancements. These companies, along with others like Apple and Huawei Technologies, are investing heavily in R&D to improve QLED performance, efficiency, and manufacturing processes. Universities such as The Hong Kong University of Science & Technology and Penn State Research Foundation are contributing to fundamental research, while collaborations between industry leaders and research institutions are accelerating technological progress in this competitive field.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced QLED technology using quantum dot materials to enhance color performance and efficiency. Their approach involves applying a quantum dot film layer over traditional LCD panels, which significantly improves color gamut and brightness. BOE's QLED displays utilize specially designed blue LED backlights to excite the quantum dots, resulting in purer and more vibrant red and green colors. The company has also made strides in improving the stability and longevity of quantum dot materials, addressing one of the key challenges in QLED technology.

Strengths: Wide color gamut, high brightness, and improved energy efficiency. Weaknesses: Higher production costs compared to traditional LCD, potential for color shift over time.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has invested heavily in QLED technology, focusing on developing high-performance quantum dot films and advanced backlight systems. Their QLED displays use a proprietary quantum dot enhancement film (QDEF) that converts blue light from LEDs into pure red and green light. This results in a wider color gamut and improved color accuracy. TCL CSOT has also made advancements in quantum dot on-chip (QD-on-Chip) technology, where quantum dots are directly applied to the LED chip, potentially reducing costs and improving efficiency in future QLED displays.

Strengths: Excellent color performance, cost-effective production methods, and ongoing innovation in QD-on-Chip technology. Weaknesses: Competition from OLED technology in high-end markets.

QLED Core Innovations

Light emitting device and fabricating method thereof, display device

PatentActiveUS20180054872A1

Innovation

- Incorporating a transparent insulating layer between neighboring QD light-emitting layers of different colors in a light-emitting device, which blocks high-energy exciton transfer and acts as a buffer to maintain light balance and prevent electric leakage.

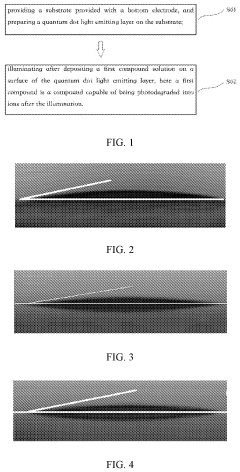

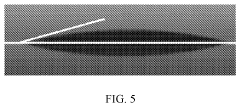

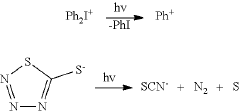

QLED and manufacturing method thereof

PatentActiveUS11965124B2

Innovation

- A QLED manufacturing method involving the use of a first compound solution that photodegrades into ions upon illumination, applied to the quantum dot light emitting layer, which reduces the contact angle and improves the compatibility between layers, enhancing the flatness and luminous efficiency of the QLED device.

QLED Manufacturing Process

The QLED manufacturing process is a complex and highly sophisticated procedure that involves several critical steps to produce high-quality quantum dot light-emitting diodes. The process begins with the synthesis of quantum dots, typically using colloidal chemistry methods. These nanocrystals are carefully engineered to emit specific colors of light when excited, forming the foundation of QLED technology.

Once the quantum dots are synthesized, they undergo a purification process to remove any impurities that could affect their performance. This is followed by a ligand exchange step, where the surface of the quantum dots is modified to enhance their stability and compatibility with other materials used in the QLED structure.

The next phase involves the deposition of multiple layers that make up the QLED device. This typically starts with the preparation of a substrate, often glass or plastic, which is coated with a transparent conductive layer, usually indium tin oxide (ITO). A hole transport layer is then deposited on top of the ITO, followed by the crucial quantum dot emissive layer.

The quantum dot layer is typically deposited using solution-based techniques such as spin-coating or inkjet printing. Precise control over the thickness and uniformity of this layer is essential for optimal device performance. Following the quantum dot layer, an electron transport layer is applied, and finally, a metal cathode is deposited to complete the device structure.

Throughout the manufacturing process, strict environmental controls are maintained to prevent contamination and ensure consistency. Many steps are performed in cleanroom environments, with careful monitoring of temperature, humidity, and particulate levels.

Quality control is an integral part of QLED manufacturing, with various testing and characterization techniques employed at different stages. These may include spectroscopic analysis, electrical testing, and visual inspection to ensure that each device meets the required specifications.

The final stages of QLED manufacturing involve encapsulation to protect the device from environmental factors and extend its lifespan. This may include the application of barrier films or the integration of the QLED into a larger display or lighting system.

Continuous improvements in manufacturing techniques are driving advancements in QLED technology. Researchers and engineers are constantly exploring new methods to enhance the efficiency of quantum dot synthesis, improve layer deposition techniques, and optimize device architectures. These efforts aim to increase production yields, reduce costs, and ultimately bring QLED technology to a wider range of applications in displays, lighting, and beyond.

Once the quantum dots are synthesized, they undergo a purification process to remove any impurities that could affect their performance. This is followed by a ligand exchange step, where the surface of the quantum dots is modified to enhance their stability and compatibility with other materials used in the QLED structure.

The next phase involves the deposition of multiple layers that make up the QLED device. This typically starts with the preparation of a substrate, often glass or plastic, which is coated with a transparent conductive layer, usually indium tin oxide (ITO). A hole transport layer is then deposited on top of the ITO, followed by the crucial quantum dot emissive layer.

The quantum dot layer is typically deposited using solution-based techniques such as spin-coating or inkjet printing. Precise control over the thickness and uniformity of this layer is essential for optimal device performance. Following the quantum dot layer, an electron transport layer is applied, and finally, a metal cathode is deposited to complete the device structure.

Throughout the manufacturing process, strict environmental controls are maintained to prevent contamination and ensure consistency. Many steps are performed in cleanroom environments, with careful monitoring of temperature, humidity, and particulate levels.

Quality control is an integral part of QLED manufacturing, with various testing and characterization techniques employed at different stages. These may include spectroscopic analysis, electrical testing, and visual inspection to ensure that each device meets the required specifications.

The final stages of QLED manufacturing involve encapsulation to protect the device from environmental factors and extend its lifespan. This may include the application of barrier films or the integration of the QLED into a larger display or lighting system.

Continuous improvements in manufacturing techniques are driving advancements in QLED technology. Researchers and engineers are constantly exploring new methods to enhance the efficiency of quantum dot synthesis, improve layer deposition techniques, and optimize device architectures. These efforts aim to increase production yields, reduce costs, and ultimately bring QLED technology to a wider range of applications in displays, lighting, and beyond.

QLED Environmental Impact

The environmental impact of QLED (Quantum Dot Light Emitting Diode) technology is a crucial consideration as this innovative display technology continues to evolve and gain market share. QLED displays offer several environmental advantages over traditional LED and OLED technologies, particularly in terms of energy efficiency and longevity.

One of the primary environmental benefits of QLED technology is its superior energy efficiency. QLED displays consume less power compared to conventional LED and OLED screens, resulting in reduced electricity consumption and lower carbon emissions over the lifetime of the device. This improved efficiency is attributed to the quantum dots' ability to produce more precise and vibrant colors with less energy input.

The longevity of QLED displays also contributes to their positive environmental impact. These screens typically have a longer lifespan than their OLED counterparts, which means fewer replacements and less electronic waste generated over time. The extended durability of QLED technology helps mitigate the environmental burden associated with the production and disposal of display devices.

However, the production of quantum dots used in QLED technology does raise some environmental concerns. The manufacturing process of quantum dots often involves the use of heavy metals and toxic materials, which can pose potential risks to the environment if not properly managed. Efforts are underway to develop more environmentally friendly quantum dot materials and production methods to address these concerns.

Recycling and end-of-life management of QLED displays present both challenges and opportunities. While the quantum dot layer adds complexity to the recycling process, advancements in recycling technologies are being made to effectively recover and reuse valuable materials from QLED screens. Proper recycling practices can significantly reduce the environmental footprint of these devices.

The reduced reliance on rare earth elements in QLED technology compared to some other display technologies is another positive environmental aspect. This can help alleviate the environmental impact associated with mining and processing these scarce resources, which often involve environmentally damaging extraction methods.

As QLED technology continues to advance, researchers and manufacturers are focusing on further improving its environmental performance. This includes developing quantum dots from more sustainable materials, enhancing energy efficiency, and designing products with easier disassembly and recycling in mind. These ongoing efforts aim to solidify QLED's position as an environmentally responsible choice in the display technology landscape.

One of the primary environmental benefits of QLED technology is its superior energy efficiency. QLED displays consume less power compared to conventional LED and OLED screens, resulting in reduced electricity consumption and lower carbon emissions over the lifetime of the device. This improved efficiency is attributed to the quantum dots' ability to produce more precise and vibrant colors with less energy input.

The longevity of QLED displays also contributes to their positive environmental impact. These screens typically have a longer lifespan than their OLED counterparts, which means fewer replacements and less electronic waste generated over time. The extended durability of QLED technology helps mitigate the environmental burden associated with the production and disposal of display devices.

However, the production of quantum dots used in QLED technology does raise some environmental concerns. The manufacturing process of quantum dots often involves the use of heavy metals and toxic materials, which can pose potential risks to the environment if not properly managed. Efforts are underway to develop more environmentally friendly quantum dot materials and production methods to address these concerns.

Recycling and end-of-life management of QLED displays present both challenges and opportunities. While the quantum dot layer adds complexity to the recycling process, advancements in recycling technologies are being made to effectively recover and reuse valuable materials from QLED screens. Proper recycling practices can significantly reduce the environmental footprint of these devices.

The reduced reliance on rare earth elements in QLED technology compared to some other display technologies is another positive environmental aspect. This can help alleviate the environmental impact associated with mining and processing these scarce resources, which often involve environmentally damaging extraction methods.

As QLED technology continues to advance, researchers and manufacturers are focusing on further improving its environmental performance. This includes developing quantum dots from more sustainable materials, enhancing energy efficiency, and designing products with easier disassembly and recycling in mind. These ongoing efforts aim to solidify QLED's position as an environmentally responsible choice in the display technology landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!