Quantum Dots: Key Drivers in QLED Display Technology

JUN 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dots Evolution

Quantum dots have undergone a remarkable evolution since their discovery in the 1980s, transforming from a scientific curiosity to a key driver in display technology. The journey began with the theoretical work of Alexey Ekimov and Louis Brus, who independently observed quantum confinement effects in semiconductor nanocrystals. This breakthrough laid the foundation for understanding the unique optical properties of quantum dots.

In the 1990s, researchers focused on refining synthesis methods to produce high-quality quantum dots with precise size control. The hot-injection method, developed by Moungi Bawendi and colleagues, marked a significant milestone, enabling the production of monodisperse quantum dots with narrow size distributions. This advancement was crucial for achieving the precise color control necessary for display applications.

The early 2000s saw the emergence of core-shell quantum dots, where a semiconductor core is encapsulated within a shell of a different material. This structure dramatically improved quantum yield and stability, addressing key challenges that had previously limited practical applications. Concurrently, efforts to integrate quantum dots into devices gained momentum, with early prototypes of quantum dot-based LEDs and displays emerging.

By the mid-2000s, the potential of quantum dots in display technology became increasingly apparent. Researchers and companies began exploring ways to incorporate quantum dots into existing display architectures. The introduction of quantum dot enhancement film (QDEF) in LCD displays marked a significant commercialization milestone, offering improved color gamut and energy efficiency.

The late 2000s and early 2010s witnessed rapid advancements in quantum dot synthesis and integration techniques. Cadmium-free quantum dots were developed to address environmental concerns, paving the way for wider adoption in consumer electronics. Simultaneously, efforts to create electroluminescent quantum dot displays intensified, laying the groundwork for QLED technology.

Recent years have seen a focus on improving the efficiency and stability of quantum dots for display applications. Innovations in materials science have led to the development of perovskite quantum dots, offering exceptional color purity and easier processability. Additionally, advancements in quantum dot printing techniques have opened new possibilities for large-scale, cost-effective manufacturing of QLED displays.

Looking ahead, the evolution of quantum dots in display technology continues to accelerate. Current research is exploring novel quantum dot architectures, such as quantum rods and quantum platelets, which promise even greater control over optical properties. The integration of quantum dots with other emerging technologies, such as flexible electronics and augmented reality displays, represents the next frontier in this exciting field.

In the 1990s, researchers focused on refining synthesis methods to produce high-quality quantum dots with precise size control. The hot-injection method, developed by Moungi Bawendi and colleagues, marked a significant milestone, enabling the production of monodisperse quantum dots with narrow size distributions. This advancement was crucial for achieving the precise color control necessary for display applications.

The early 2000s saw the emergence of core-shell quantum dots, where a semiconductor core is encapsulated within a shell of a different material. This structure dramatically improved quantum yield and stability, addressing key challenges that had previously limited practical applications. Concurrently, efforts to integrate quantum dots into devices gained momentum, with early prototypes of quantum dot-based LEDs and displays emerging.

By the mid-2000s, the potential of quantum dots in display technology became increasingly apparent. Researchers and companies began exploring ways to incorporate quantum dots into existing display architectures. The introduction of quantum dot enhancement film (QDEF) in LCD displays marked a significant commercialization milestone, offering improved color gamut and energy efficiency.

The late 2000s and early 2010s witnessed rapid advancements in quantum dot synthesis and integration techniques. Cadmium-free quantum dots were developed to address environmental concerns, paving the way for wider adoption in consumer electronics. Simultaneously, efforts to create electroluminescent quantum dot displays intensified, laying the groundwork for QLED technology.

Recent years have seen a focus on improving the efficiency and stability of quantum dots for display applications. Innovations in materials science have led to the development of perovskite quantum dots, offering exceptional color purity and easier processability. Additionally, advancements in quantum dot printing techniques have opened new possibilities for large-scale, cost-effective manufacturing of QLED displays.

Looking ahead, the evolution of quantum dots in display technology continues to accelerate. Current research is exploring novel quantum dot architectures, such as quantum rods and quantum platelets, which promise even greater control over optical properties. The integration of quantum dots with other emerging technologies, such as flexible electronics and augmented reality displays, represents the next frontier in this exciting field.

QLED Market Dynamics

The QLED display market has experienced significant growth in recent years, driven by the increasing demand for high-quality, energy-efficient displays across various sectors. Quantum Dot Light Emitting Diode (QLED) technology has emerged as a key player in the premium display market, offering superior color reproduction, brightness, and energy efficiency compared to traditional LED and OLED displays.

The global QLED market has been expanding rapidly, with major consumer electronics manufacturers incorporating this technology into their product lines. The market is primarily segmented into televisions, monitors, and smartphones, with QLED TVs dominating the revenue share. The adoption of QLED technology in these segments has been fueled by the growing consumer preference for enhanced visual experiences and the increasing affordability of QLED displays.

In the television sector, QLED has gained substantial market share, particularly in the high-end segment. Major manufacturers such as Samsung, TCL, and Hisense have been at the forefront of QLED TV production, continuously improving their offerings to meet consumer demands. The large-screen TV market has been a key driver for QLED adoption, as the technology's advantages become more pronounced in larger display sizes.

The monitor market has also seen a surge in QLED adoption, particularly in the gaming and professional segments. QLED monitors offer high refresh rates, wide color gamuts, and excellent brightness levels, making them attractive to both gamers and content creators. This has led to increased competition among monitor manufacturers to incorporate QLED technology into their product lines.

In the smartphone market, QLED technology is still in its early stages but shows promising growth potential. Some manufacturers have begun integrating QLED displays into their high-end smartphones, offering improved color accuracy and energy efficiency compared to traditional OLED displays.

The QLED market dynamics are also influenced by regional factors. North America and Europe have been early adopters of QLED technology, driven by high consumer purchasing power and a strong preference for premium display products. The Asia-Pacific region, particularly China, has emerged as a significant market for QLED displays, with local manufacturers rapidly expanding their production capabilities.

Looking ahead, the QLED market is expected to continue its growth trajectory. Factors such as increasing disposable income, growing demand for 4K and 8K resolution displays, and the expansion of the gaming industry are likely to fuel further adoption of QLED technology. Additionally, ongoing research and development efforts aimed at improving quantum dot efficiency and reducing production costs are expected to make QLED displays more competitive in the broader display market.

The global QLED market has been expanding rapidly, with major consumer electronics manufacturers incorporating this technology into their product lines. The market is primarily segmented into televisions, monitors, and smartphones, with QLED TVs dominating the revenue share. The adoption of QLED technology in these segments has been fueled by the growing consumer preference for enhanced visual experiences and the increasing affordability of QLED displays.

In the television sector, QLED has gained substantial market share, particularly in the high-end segment. Major manufacturers such as Samsung, TCL, and Hisense have been at the forefront of QLED TV production, continuously improving their offerings to meet consumer demands. The large-screen TV market has been a key driver for QLED adoption, as the technology's advantages become more pronounced in larger display sizes.

The monitor market has also seen a surge in QLED adoption, particularly in the gaming and professional segments. QLED monitors offer high refresh rates, wide color gamuts, and excellent brightness levels, making them attractive to both gamers and content creators. This has led to increased competition among monitor manufacturers to incorporate QLED technology into their product lines.

In the smartphone market, QLED technology is still in its early stages but shows promising growth potential. Some manufacturers have begun integrating QLED displays into their high-end smartphones, offering improved color accuracy and energy efficiency compared to traditional OLED displays.

The QLED market dynamics are also influenced by regional factors. North America and Europe have been early adopters of QLED technology, driven by high consumer purchasing power and a strong preference for premium display products. The Asia-Pacific region, particularly China, has emerged as a significant market for QLED displays, with local manufacturers rapidly expanding their production capabilities.

Looking ahead, the QLED market is expected to continue its growth trajectory. Factors such as increasing disposable income, growing demand for 4K and 8K resolution displays, and the expansion of the gaming industry are likely to fuel further adoption of QLED technology. Additionally, ongoing research and development efforts aimed at improving quantum dot efficiency and reducing production costs are expected to make QLED displays more competitive in the broader display market.

QLED Tech Challenges

Despite the significant advancements in QLED display technology, several technical challenges persist, hindering its widespread adoption and optimal performance. One of the primary obstacles is the stability of quantum dots, particularly their susceptibility to degradation when exposed to air, moisture, and high temperatures. This instability can lead to reduced color accuracy and shortened device lifespan, necessitating robust encapsulation techniques to protect the quantum dots from environmental factors.

Another critical challenge lies in achieving uniform quantum dot distribution within the display structure. Inconsistent distribution can result in color variations across the screen, compromising overall image quality. Developing precise deposition methods and ensuring even dispersion of quantum dots remains a key focus area for researchers and manufacturers.

The efficiency of energy transfer from the backlight to the quantum dots presents another hurdle. Current QLED displays still suffer from energy losses during the excitation process, reducing overall power efficiency. Improving the quantum yield of the dots and optimizing the interaction between the backlight and quantum dot layer are crucial for enhancing energy efficiency and display brightness.

Color purity and gamut expansion continue to be areas of intense research. While QLEDs offer superior color performance compared to traditional LED displays, achieving the perfect balance of narrow emission spectra for each primary color while maintaining high brightness remains challenging. Fine-tuning the composition and structure of quantum dots to achieve optimal spectral characteristics is an ongoing process.

Manufacturing scalability poses a significant challenge for QLED technology. The production of high-quality quantum dots with consistent properties in large quantities is complex and costly. Developing more efficient and cost-effective manufacturing processes is essential for making QLED displays more competitive in the consumer market.

Lastly, the environmental impact and toxicity of certain quantum dot materials, particularly those containing heavy metals like cadmium, raise concerns. Finding alternative, eco-friendly materials that can match or exceed the performance of traditional quantum dots is a critical challenge facing the industry. This involves exploring new compositions and synthesis methods that align with sustainability goals while maintaining the superior optical properties of quantum dots.

Another critical challenge lies in achieving uniform quantum dot distribution within the display structure. Inconsistent distribution can result in color variations across the screen, compromising overall image quality. Developing precise deposition methods and ensuring even dispersion of quantum dots remains a key focus area for researchers and manufacturers.

The efficiency of energy transfer from the backlight to the quantum dots presents another hurdle. Current QLED displays still suffer from energy losses during the excitation process, reducing overall power efficiency. Improving the quantum yield of the dots and optimizing the interaction between the backlight and quantum dot layer are crucial for enhancing energy efficiency and display brightness.

Color purity and gamut expansion continue to be areas of intense research. While QLEDs offer superior color performance compared to traditional LED displays, achieving the perfect balance of narrow emission spectra for each primary color while maintaining high brightness remains challenging. Fine-tuning the composition and structure of quantum dots to achieve optimal spectral characteristics is an ongoing process.

Manufacturing scalability poses a significant challenge for QLED technology. The production of high-quality quantum dots with consistent properties in large quantities is complex and costly. Developing more efficient and cost-effective manufacturing processes is essential for making QLED displays more competitive in the consumer market.

Lastly, the environmental impact and toxicity of certain quantum dot materials, particularly those containing heavy metals like cadmium, raise concerns. Finding alternative, eco-friendly materials that can match or exceed the performance of traditional quantum dots is a critical challenge facing the industry. This involves exploring new compositions and synthesis methods that align with sustainability goals while maintaining the superior optical properties of quantum dots.

Current QLED Solutions

01 Quantum dot composition and fabrication

This category focuses on the composition and fabrication methods of quantum dots used in display technology. It includes techniques for synthesizing quantum dots with specific properties, such as size, shape, and material composition, which directly affect their optical characteristics. Advanced fabrication methods aim to improve quantum yield, stability, and color purity of the quantum dots for enhanced display performance.- Quantum dot composition and fabrication: This category focuses on the composition and manufacturing processes of quantum dots used in display technology. It includes methods for synthesizing quantum dots with specific properties, such as size, shape, and material composition, to achieve desired optical characteristics. The fabrication techniques aim to improve the efficiency, stability, and color purity of quantum dots for display applications.

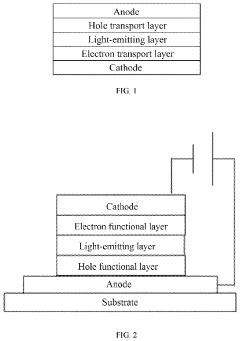

- Quantum dot integration in display devices: This area covers the integration of quantum dots into various display device structures. It includes methods for incorporating quantum dots into LED backlights, color conversion layers, and pixel structures. The integration techniques aim to enhance color gamut, brightness, and energy efficiency of displays while addressing challenges such as light leakage and degradation.

- Optical components for quantum dot displays: This category encompasses the development of optical components specifically designed for quantum dot displays. It includes innovations in light guide plates, diffusers, reflectors, and filters that work in conjunction with quantum dots to optimize light extraction, color purity, and viewing angles in display devices.

- Quantum dot color conversion films: This area focuses on the development of color conversion films using quantum dots. It includes methods for creating thin, uniform films with precise quantum dot distributions, as well as techniques for enhancing the stability and efficiency of these films. The goal is to achieve improved color reproduction and brightness in display applications.

- Driving and control systems for quantum dot displays: This category covers the electronic systems and algorithms used to drive and control quantum dot displays. It includes innovations in backlight control, color management, and image processing techniques tailored to the unique characteristics of quantum dot displays. These systems aim to optimize display performance, power efficiency, and image quality.

02 Quantum dot integration in display structures

This aspect covers the integration of quantum dots into various display structures, including LCD and OLED technologies. It involves methods for incorporating quantum dots into color conversion layers, light-emitting layers, or as separate components in the display stack. The integration aims to enhance color gamut, brightness, and energy efficiency of displays while maintaining manufacturability and cost-effectiveness.Expand Specific Solutions03 Optical management in quantum dot displays

Optical management techniques are crucial for optimizing the performance of quantum dot displays. This category includes methods for light extraction, color filtering, and backlight design. It also covers approaches to reduce light loss, improve color accuracy, and enhance overall display efficiency through the strategic placement and design of optical components in conjunction with quantum dot layers.Expand Specific Solutions04 Quantum dot color conversion films

This point focuses on the development and application of quantum dot color conversion films in displays. These films convert blue or UV light from LEDs into pure red and green light, enabling wider color gamut and improved color accuracy. The category includes innovations in film composition, structure, and manufacturing processes to enhance stability, efficiency, and integration with existing display technologies.Expand Specific Solutions05 Quantum dot display driving and control

This category encompasses the electronic driving and control systems specific to quantum dot displays. It includes innovations in pixel addressing, color management algorithms, and power efficiency optimization. Advanced driving schemes aim to leverage the unique properties of quantum dots to achieve superior image quality, reduce power consumption, and extend the lifespan of quantum dot-based displays.Expand Specific Solutions

QLED Industry Leaders

The quantum dot (QD) technology in QLED displays is currently in a growth phase, with the market expected to expand significantly in the coming years. The global QLED market size is projected to reach substantial figures, driven by increasing demand for high-quality displays in various applications. Technologically, QDs are advancing rapidly, with companies like Nanosys, BOE Technology Group, and TCL China Star Optoelectronics leading innovation. These firms, along with others like Sharp Corp. and LG Display, are pushing the boundaries of QD technology, improving color accuracy, brightness, and energy efficiency. The involvement of diverse players, from established display manufacturers to specialized nanotechnology firms, indicates a competitive and dynamic landscape, with ongoing research and development efforts aimed at enhancing QLED performance and reducing production costs.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced Quantum Dot (QD) technology for QLED displays. Their approach involves using high-purity, narrow-spectrum QDs to enhance color gamut and brightness. BOE's QD solution includes a unique QD film structure that improves light efficiency and color purity. They have also implemented a proprietary QD encapsulation technique to enhance the stability and longevity of QDs in display applications. BOE's QLED displays feature local dimming technology combined with QDs to achieve high contrast ratios and deep blacks.

Strengths: Wide color gamut, high brightness, and improved energy efficiency. Weaknesses: Potential for QD degradation over time, higher production costs compared to traditional LCD.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL CSOT has developed a proprietary Quantum Dot Display technology called "Q-dot". Their approach involves using a QD color conversion layer in combination with blue LED backlights. The Q-dot technology employs specially designed QD materials that offer high quantum yield and narrow emission spectra. TCL CSOT has also implemented advanced QD deposition techniques to ensure uniform distribution and optimal performance. Their QLED displays feature local dimming technology and AI-powered image processing to enhance contrast and color accuracy.

Strengths: Excellent color performance, high brightness, and compatibility with existing LCD production lines. Weaknesses: Potential for blue light leakage, challenges in achieving perfect black levels compared to OLED.

QD Innovations Review

Optoelectronic device

PatentPendingUS20240107791A1

Innovation

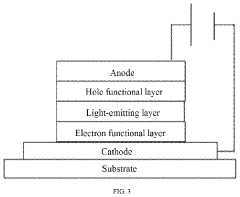

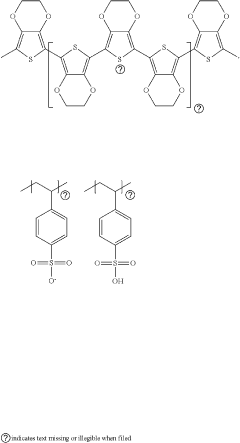

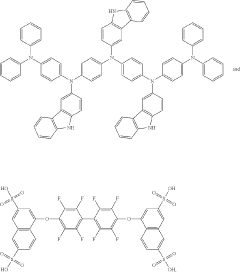

- An optoelectronic device with a quantum dot light-emitting layer in a core-shell structure, where the valence band top energy level difference between the shell layer material and the hole transport material is greater than or equal to 0.5 eV, and the electron transport layer comprises zinc oxide nanomaterials bound with amine/carboxyl ligands of 3-8 carbon atoms, optimizing hole and electron injection balance and reducing charge accumulation.

Semiconductor light emitting nanoparticle

PatentWO2019072884A1

Innovation

- The use of metal phosphonate ligands and their derivatives, which coordinate with both positive and negative atoms on the surface of quantum dots, effectively passivating traps and increasing quantum yields by up to 60% through surface coating and subsequent illumination.

QD Material Sourcing

Quantum dot (QD) material sourcing plays a crucial role in the development and production of QLED display technology. The quality and availability of QD materials directly impact the performance and cost-effectiveness of QLED displays. As the demand for high-quality displays continues to grow, securing a stable and reliable supply chain for QD materials has become a top priority for manufacturers.

The primary sources of QD materials are specialized chemical companies and nanotechnology firms. These suppliers have invested heavily in research and development to produce high-quality quantum dots with precise size control and uniform properties. Some of the leading suppliers in the market include Nanosys, Quantum Materials Corporation, and Nanoco Group.

The production of quantum dots involves complex synthesis processes, requiring advanced facilities and expertise. The most common methods for QD synthesis include colloidal synthesis and molecular beam epitaxy. Each method has its advantages and challenges, influencing the quality, scalability, and cost of the final product.

Quality control is a critical aspect of QD material sourcing. Manufacturers must ensure that the sourced materials meet strict specifications for size distribution, quantum yield, and stability. This often involves rigorous testing and characterization procedures, including spectroscopic analysis and electron microscopy.

Sustainability and environmental considerations are becoming increasingly important in QD material sourcing. Traditional quantum dots often contain heavy metals like cadmium, which pose environmental and health risks. As a result, there is a growing trend towards developing and sourcing cadmium-free quantum dots, such as indium phosphide-based QDs.

The global supply chain for QD materials faces several challenges, including potential disruptions due to geopolitical factors and raw material shortages. To mitigate these risks, many display manufacturers are diversifying their supplier base and exploring vertical integration strategies to gain more control over their supply chain.

Intellectual property considerations also play a significant role in QD material sourcing. Many key technologies and production methods are protected by patents, which can impact the availability and cost of certain materials. Companies must navigate this complex landscape to ensure they have access to the necessary materials without infringing on intellectual property rights.

As QLED technology continues to evolve, the demands on QD material suppliers are likely to increase. Future developments may include the need for new types of quantum dots with enhanced properties, such as improved color purity or longer lifetimes. This will require ongoing collaboration between material suppliers and display manufacturers to drive innovation and meet market demands.

The primary sources of QD materials are specialized chemical companies and nanotechnology firms. These suppliers have invested heavily in research and development to produce high-quality quantum dots with precise size control and uniform properties. Some of the leading suppliers in the market include Nanosys, Quantum Materials Corporation, and Nanoco Group.

The production of quantum dots involves complex synthesis processes, requiring advanced facilities and expertise. The most common methods for QD synthesis include colloidal synthesis and molecular beam epitaxy. Each method has its advantages and challenges, influencing the quality, scalability, and cost of the final product.

Quality control is a critical aspect of QD material sourcing. Manufacturers must ensure that the sourced materials meet strict specifications for size distribution, quantum yield, and stability. This often involves rigorous testing and characterization procedures, including spectroscopic analysis and electron microscopy.

Sustainability and environmental considerations are becoming increasingly important in QD material sourcing. Traditional quantum dots often contain heavy metals like cadmium, which pose environmental and health risks. As a result, there is a growing trend towards developing and sourcing cadmium-free quantum dots, such as indium phosphide-based QDs.

The global supply chain for QD materials faces several challenges, including potential disruptions due to geopolitical factors and raw material shortages. To mitigate these risks, many display manufacturers are diversifying their supplier base and exploring vertical integration strategies to gain more control over their supply chain.

Intellectual property considerations also play a significant role in QD material sourcing. Many key technologies and production methods are protected by patents, which can impact the availability and cost of certain materials. Companies must navigate this complex landscape to ensure they have access to the necessary materials without infringing on intellectual property rights.

As QLED technology continues to evolve, the demands on QD material suppliers are likely to increase. Future developments may include the need for new types of quantum dots with enhanced properties, such as improved color purity or longer lifetimes. This will require ongoing collaboration between material suppliers and display manufacturers to drive innovation and meet market demands.

QLED Energy Efficiency

QLED displays have gained significant attention in recent years due to their superior energy efficiency compared to traditional display technologies. This efficiency is primarily attributed to the unique properties of quantum dots, which are the key components in QLED technology.

Quantum dots exhibit exceptional light-emitting properties, allowing for precise control over the color and intensity of emitted light. This precision translates into reduced energy consumption, as less power is wasted in producing unwanted wavelengths. The ability to fine-tune the emission spectrum also enables QLEDs to achieve a wider color gamut with less energy input.

One of the primary factors contributing to QLED energy efficiency is the direct light emission process. Unlike traditional LCD displays that require a backlight and color filters, QLEDs emit light directly from the quantum dots when electrically stimulated. This direct emission eliminates the need for additional layers and filters, reducing energy loss and improving overall efficiency.

Furthermore, quantum dots have a high quantum yield, meaning they convert a large percentage of input energy into light output. This high conversion efficiency minimizes energy waste in the form of heat, leading to cooler operation and reduced power consumption. The improved thermal management also contributes to the longevity of QLED displays, as excessive heat can degrade display components over time.

QLED technology also benefits from advancements in quantum dot synthesis and manufacturing processes. Researchers have developed methods to create quantum dots with increasingly uniform size distributions and improved stability. These enhancements result in more consistent and efficient light emission, further reducing energy requirements.

The energy efficiency of QLED displays extends beyond the device level to impact overall environmental sustainability. Lower power consumption translates to reduced carbon emissions and energy costs for consumers. As energy efficiency becomes an increasingly important factor in consumer electronics, QLED technology positions itself as a competitive option in the display market.

Looking ahead, ongoing research in quantum dot materials and QLED architectures promises even greater energy efficiency gains. Scientists are exploring new quantum dot compositions and structures that could further improve light emission efficiency and color purity. Additionally, advancements in quantum dot integration techniques may lead to more streamlined manufacturing processes, potentially reducing the overall energy footprint of QLED production.

Quantum dots exhibit exceptional light-emitting properties, allowing for precise control over the color and intensity of emitted light. This precision translates into reduced energy consumption, as less power is wasted in producing unwanted wavelengths. The ability to fine-tune the emission spectrum also enables QLEDs to achieve a wider color gamut with less energy input.

One of the primary factors contributing to QLED energy efficiency is the direct light emission process. Unlike traditional LCD displays that require a backlight and color filters, QLEDs emit light directly from the quantum dots when electrically stimulated. This direct emission eliminates the need for additional layers and filters, reducing energy loss and improving overall efficiency.

Furthermore, quantum dots have a high quantum yield, meaning they convert a large percentage of input energy into light output. This high conversion efficiency minimizes energy waste in the form of heat, leading to cooler operation and reduced power consumption. The improved thermal management also contributes to the longevity of QLED displays, as excessive heat can degrade display components over time.

QLED technology also benefits from advancements in quantum dot synthesis and manufacturing processes. Researchers have developed methods to create quantum dots with increasingly uniform size distributions and improved stability. These enhancements result in more consistent and efficient light emission, further reducing energy requirements.

The energy efficiency of QLED displays extends beyond the device level to impact overall environmental sustainability. Lower power consumption translates to reduced carbon emissions and energy costs for consumers. As energy efficiency becomes an increasingly important factor in consumer electronics, QLED technology positions itself as a competitive option in the display market.

Looking ahead, ongoing research in quantum dot materials and QLED architectures promises even greater energy efficiency gains. Scientists are exploring new quantum dot compositions and structures that could further improve light emission efficiency and color purity. Additionally, advancements in quantum dot integration techniques may lead to more streamlined manufacturing processes, potentially reducing the overall energy footprint of QLED production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!