Compressed Natural Gas Adaptations in 454 Big Block Engines

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CNG Adaptation Background and Objectives

The adaptation of Compressed Natural Gas (CNG) in 454 Big Block Engines represents a significant technological evolution in the automotive industry, driven by the growing need for cleaner and more sustainable fuel alternatives. This research aims to explore the feasibility, challenges, and potential benefits of integrating CNG systems into these large displacement engines, which have traditionally been associated with high fuel consumption and emissions.

The 454 Big Block Engine, renowned for its power and torque, has been a staple in heavy-duty vehicles and high-performance applications. However, increasing environmental concerns and stricter emission regulations have necessitated the exploration of alternative fuel sources. CNG, with its lower carbon footprint and potential for reduced operating costs, emerges as a promising solution.

The primary objective of this research is to comprehensively analyze the technical aspects of adapting CNG to 454 Big Block Engines. This includes investigating the necessary modifications to the engine's fuel delivery system, ignition timing, and overall performance characteristics. The study aims to determine whether CNG adaptation can maintain or enhance the engine's power output while significantly reducing emissions.

Another crucial goal is to assess the economic viability of this adaptation. This involves evaluating the initial conversion costs, long-term fuel savings, and potential government incentives for adopting cleaner fuel technologies. The research will also consider the infrastructure requirements for CNG refueling and maintenance, which are critical factors in the widespread adoption of this technology.

Furthermore, this study seeks to understand the broader implications of CNG adaptation in the context of evolving environmental policies and market trends. It will examine how this technology aligns with global efforts to reduce greenhouse gas emissions and dependence on fossil fuels.

The technological evolution of CNG systems has seen significant advancements in recent years, including improved storage solutions, more efficient fuel injection systems, and enhanced engine management software. This research will explore how these developments can be specifically applied to the 454 Big Block Engine platform, potentially opening new avenues for its continued use in an increasingly eco-conscious market.

By thoroughly investigating these aspects, this research aims to provide a comprehensive understanding of the potential for CNG adaptation in 454 Big Block Engines. The findings will serve as a valuable resource for engine manufacturers, vehicle designers, and policymakers in shaping the future of large displacement engines in an environmentally sustainable automotive landscape.

The 454 Big Block Engine, renowned for its power and torque, has been a staple in heavy-duty vehicles and high-performance applications. However, increasing environmental concerns and stricter emission regulations have necessitated the exploration of alternative fuel sources. CNG, with its lower carbon footprint and potential for reduced operating costs, emerges as a promising solution.

The primary objective of this research is to comprehensively analyze the technical aspects of adapting CNG to 454 Big Block Engines. This includes investigating the necessary modifications to the engine's fuel delivery system, ignition timing, and overall performance characteristics. The study aims to determine whether CNG adaptation can maintain or enhance the engine's power output while significantly reducing emissions.

Another crucial goal is to assess the economic viability of this adaptation. This involves evaluating the initial conversion costs, long-term fuel savings, and potential government incentives for adopting cleaner fuel technologies. The research will also consider the infrastructure requirements for CNG refueling and maintenance, which are critical factors in the widespread adoption of this technology.

Furthermore, this study seeks to understand the broader implications of CNG adaptation in the context of evolving environmental policies and market trends. It will examine how this technology aligns with global efforts to reduce greenhouse gas emissions and dependence on fossil fuels.

The technological evolution of CNG systems has seen significant advancements in recent years, including improved storage solutions, more efficient fuel injection systems, and enhanced engine management software. This research will explore how these developments can be specifically applied to the 454 Big Block Engine platform, potentially opening new avenues for its continued use in an increasingly eco-conscious market.

By thoroughly investigating these aspects, this research aims to provide a comprehensive understanding of the potential for CNG adaptation in 454 Big Block Engines. The findings will serve as a valuable resource for engine manufacturers, vehicle designers, and policymakers in shaping the future of large displacement engines in an environmentally sustainable automotive landscape.

Market Analysis for CNG-Powered Vehicles

The market for Compressed Natural Gas (CNG) powered vehicles has been experiencing significant growth in recent years, driven by increasing environmental concerns and the need for more sustainable transportation solutions. The adaptation of 454 Big Block Engines to run on CNG represents a crucial development in this market, particularly for heavy-duty vehicles and industrial applications.

The global CNG vehicle market is projected to expand at a compound annual growth rate (CAGR) of 3.2% from 2021 to 2028. This growth is primarily attributed to the lower operating costs of CNG vehicles compared to their gasoline and diesel counterparts, as well as the reduced emissions of greenhouse gases and particulate matter. Government initiatives and regulations promoting cleaner fuel alternatives have also played a significant role in driving market demand.

In the context of 454 Big Block Engines, the market potential is particularly promising in sectors such as public transportation, long-haul trucking, and construction equipment. These industries are increasingly seeking ways to reduce their carbon footprint while maintaining the power and performance required for their operations. The adaptation of these large displacement engines to CNG offers a viable solution that balances environmental concerns with operational requirements.

The North American market shows strong potential for CNG-powered vehicles using adapted 454 Big Block Engines. The United States, in particular, has seen a growing interest in CNG as an alternative fuel source, with the number of CNG fueling stations increasing by 15% over the past five years. This infrastructure development is crucial for the widespread adoption of CNG vehicles, especially those equipped with high-performance engines like the 454 Big Block.

However, challenges remain in the market adoption of CNG-powered 454 Big Block Engines. The initial cost of conversion or purchasing CNG-equipped vehicles is higher than traditional gasoline or diesel options. Additionally, the limited range of CNG vehicles compared to their conventional counterparts poses a concern for long-distance applications. These factors have somewhat tempered the growth rate in certain market segments.

Despite these challenges, the long-term outlook for CNG-powered vehicles, particularly those utilizing adapted 454 Big Block Engines, remains positive. As technology advances and economies of scale are realized, the cost of CNG conversions is expected to decrease, making them more accessible to a broader range of consumers and businesses. Furthermore, the ongoing development of more efficient CNG storage solutions is likely to address range concerns, further expanding the market potential for these vehicles.

The global CNG vehicle market is projected to expand at a compound annual growth rate (CAGR) of 3.2% from 2021 to 2028. This growth is primarily attributed to the lower operating costs of CNG vehicles compared to their gasoline and diesel counterparts, as well as the reduced emissions of greenhouse gases and particulate matter. Government initiatives and regulations promoting cleaner fuel alternatives have also played a significant role in driving market demand.

In the context of 454 Big Block Engines, the market potential is particularly promising in sectors such as public transportation, long-haul trucking, and construction equipment. These industries are increasingly seeking ways to reduce their carbon footprint while maintaining the power and performance required for their operations. The adaptation of these large displacement engines to CNG offers a viable solution that balances environmental concerns with operational requirements.

The North American market shows strong potential for CNG-powered vehicles using adapted 454 Big Block Engines. The United States, in particular, has seen a growing interest in CNG as an alternative fuel source, with the number of CNG fueling stations increasing by 15% over the past five years. This infrastructure development is crucial for the widespread adoption of CNG vehicles, especially those equipped with high-performance engines like the 454 Big Block.

However, challenges remain in the market adoption of CNG-powered 454 Big Block Engines. The initial cost of conversion or purchasing CNG-equipped vehicles is higher than traditional gasoline or diesel options. Additionally, the limited range of CNG vehicles compared to their conventional counterparts poses a concern for long-distance applications. These factors have somewhat tempered the growth rate in certain market segments.

Despite these challenges, the long-term outlook for CNG-powered vehicles, particularly those utilizing adapted 454 Big Block Engines, remains positive. As technology advances and economies of scale are realized, the cost of CNG conversions is expected to decrease, making them more accessible to a broader range of consumers and businesses. Furthermore, the ongoing development of more efficient CNG storage solutions is likely to address range concerns, further expanding the market potential for these vehicles.

Technical Challenges in 454 Big Block CNG Conversion

The conversion of 454 big block engines to run on compressed natural gas (CNG) presents several significant technical challenges. One of the primary obstacles is the need to modify the fuel delivery system to accommodate the gaseous nature of CNG. Unlike liquid gasoline, CNG requires specialized injectors and fuel rails capable of handling high-pressure gas. These components must be precisely engineered to ensure proper fuel metering and distribution across all cylinders.

Another major challenge lies in the ignition system adaptation. CNG has a higher octane rating and different combustion characteristics compared to gasoline. This necessitates adjustments to the ignition timing and spark intensity to optimize engine performance and efficiency. Engineers must carefully calibrate the ignition system to prevent pre-ignition or knocking, which can cause severe engine damage.

The compression ratio of the engine also requires modification when converting to CNG. Big block engines typically have lower compression ratios, which are not ideal for CNG combustion. Increasing the compression ratio is often necessary to achieve optimal efficiency and power output with CNG. This may involve redesigning pistons, cylinder heads, or even the entire combustion chamber geometry.

Valve train components present another area of concern. CNG burns hotter than gasoline, which can lead to increased valve and seat wear. Upgrading to hardened valve seats and sodium-filled valves may be necessary to ensure longevity and reliability under CNG operation. Additionally, valve timing and lift may need adjustment to accommodate the different burning characteristics of natural gas.

The engine management system requires extensive reprogramming to handle CNG operation. This includes developing new fuel maps, adjusting air-fuel ratios, and implementing specific control strategies for cold starts and varying load conditions. The complexity of this task is compounded by the need to maintain compliance with emissions regulations while optimizing performance.

Thermal management is another critical challenge in CNG conversions. The cooler-burning nature of CNG can lead to reduced exhaust gas temperatures, potentially affecting catalytic converter performance and overall emissions control. Engineers must devise strategies to ensure proper catalyst light-off and maintain effective emissions reduction across all operating conditions.

Lastly, the integration of CNG storage tanks and associated high-pressure fuel lines presents both packaging and safety challenges. The large size of 454 big block engines often leaves limited space for CNG tanks, requiring creative solutions for tank placement without compromising vehicle balance or safety. Furthermore, the entire fuel system must be engineered to withstand the high pressures associated with CNG storage and delivery, necessitating robust materials and fail-safe mechanisms.

Another major challenge lies in the ignition system adaptation. CNG has a higher octane rating and different combustion characteristics compared to gasoline. This necessitates adjustments to the ignition timing and spark intensity to optimize engine performance and efficiency. Engineers must carefully calibrate the ignition system to prevent pre-ignition or knocking, which can cause severe engine damage.

The compression ratio of the engine also requires modification when converting to CNG. Big block engines typically have lower compression ratios, which are not ideal for CNG combustion. Increasing the compression ratio is often necessary to achieve optimal efficiency and power output with CNG. This may involve redesigning pistons, cylinder heads, or even the entire combustion chamber geometry.

Valve train components present another area of concern. CNG burns hotter than gasoline, which can lead to increased valve and seat wear. Upgrading to hardened valve seats and sodium-filled valves may be necessary to ensure longevity and reliability under CNG operation. Additionally, valve timing and lift may need adjustment to accommodate the different burning characteristics of natural gas.

The engine management system requires extensive reprogramming to handle CNG operation. This includes developing new fuel maps, adjusting air-fuel ratios, and implementing specific control strategies for cold starts and varying load conditions. The complexity of this task is compounded by the need to maintain compliance with emissions regulations while optimizing performance.

Thermal management is another critical challenge in CNG conversions. The cooler-burning nature of CNG can lead to reduced exhaust gas temperatures, potentially affecting catalytic converter performance and overall emissions control. Engineers must devise strategies to ensure proper catalyst light-off and maintain effective emissions reduction across all operating conditions.

Lastly, the integration of CNG storage tanks and associated high-pressure fuel lines presents both packaging and safety challenges. The large size of 454 big block engines often leaves limited space for CNG tanks, requiring creative solutions for tank placement without compromising vehicle balance or safety. Furthermore, the entire fuel system must be engineered to withstand the high pressures associated with CNG storage and delivery, necessitating robust materials and fail-safe mechanisms.

Current CNG Conversion Solutions for Big Block Engines

01 Engine block design and construction

The 454 Big Block Engine features a robust engine block design, typically made of cast iron. This design provides a strong foundation for high-performance applications, allowing for increased displacement and power output. The block construction includes reinforced cylinder walls and main bearing caps to withstand the increased stresses associated with high-performance use.- Engine block design and construction: The 454 Big Block Engine features a robust engine block design, typically made of cast iron. This design provides a strong foundation for high-performance applications, allowing for increased displacement and power output. The block construction includes reinforced cylinder walls and main bearing caps to withstand high compression ratios and torque loads.

- Cylinder head and valve train improvements: Advancements in cylinder head design and valve train components enhance the performance of 454 Big Block Engines. These improvements may include larger intake and exhaust valves, optimized port designs, and high-flow cylinder heads. Such modifications contribute to increased airflow, improved combustion efficiency, and overall engine performance.

- Fuel system and intake manifold optimization: The fuel system and intake manifold of 454 Big Block Engines are often optimized for improved performance. This may involve the use of high-flow fuel injectors, performance carburetors, or electronic fuel injection systems. Intake manifold designs are engineered to enhance air distribution and velocity, contributing to better fuel atomization and combustion efficiency.

- Cooling system enhancements: To manage the increased heat generated by high-performance 454 Big Block Engines, cooling system enhancements are often implemented. These may include larger capacity radiators, high-flow water pumps, and improved coolant passages within the engine block and cylinder heads. Such modifications help maintain optimal operating temperatures and prevent overheating during demanding conditions.

- Performance tuning and aftermarket modifications: 454 Big Block Engines are popular platforms for performance tuning and aftermarket modifications. This can include the installation of high-performance camshafts, forged pistons, stronger connecting rods, and balanced crankshafts. Additionally, aftermarket superchargers or turbochargers may be added to significantly increase power output. These modifications often require careful tuning and calibration to optimize performance and reliability.

02 Cylinder head and valve train improvements

Advancements in cylinder head design and valve train components have been made to enhance the performance of 454 Big Block Engines. These improvements may include larger valves, optimized port designs, and stronger valve springs to support higher RPM operation. Such modifications contribute to improved airflow and combustion efficiency, resulting in increased power output.Expand Specific Solutions03 Fuel system and intake manifold optimization

The fuel system and intake manifold of 454 Big Block Engines have been optimized to support increased power demands. This may involve the use of high-flow fuel injectors, performance carburetors, or electronic fuel injection systems. Intake manifold designs have been refined to improve air distribution and velocity, enhancing overall engine performance and efficiency.Expand Specific Solutions04 Cooling system enhancements

To manage the increased heat generated by high-performance 454 Big Block Engines, cooling system enhancements have been developed. These may include improved water pump designs, larger capacity radiators, and optimized coolant flow paths within the engine block and cylinder heads. Such improvements help maintain optimal operating temperatures and prevent overheating during high-load conditions.Expand Specific Solutions05 Performance tuning and aftermarket modifications

A wide range of aftermarket modifications and performance tuning options are available for 454 Big Block Engines. These may include high-performance camshafts, forged pistons, stroker kits for increased displacement, and forced induction systems such as superchargers or turbochargers. These modifications allow enthusiasts to further increase the power output and customize the engine's performance characteristics to suit specific applications.Expand Specific Solutions

Key Players in CNG Engine Adaptation Industry

The research on Compressed Natural Gas (CNG) adaptations in 454 Big Block Engines is in a developing stage, with the market showing potential for growth due to increasing environmental concerns and the push for cleaner fuel alternatives. The technology's maturity varies among key players, with companies like ExxonMobil, Caterpillar, and Cummins leading in research and development. Westport Fuel Systems and Prometheus Applied Technologies are specializing in CNG-specific solutions, while automotive giants such as GM and Toyota are exploring CNG adaptations for their existing engine lines. Universities like Tianjin University and the University of British Columbia are contributing to academic research in this field, indicating a collaborative effort between industry and academia to advance CNG technology for large engines.

Cummins, Inc.

Technical Solution: Cummins has developed advanced CNG adaptation technologies for large displacement engines, including the 454 Big Block. Their system incorporates high-pressure direct injection (HPDI) technology, which allows for the use of CNG as the primary fuel while retaining a small amount of diesel for ignition[1]. This dual-fuel approach enables the engine to maintain high thermal efficiency and power output comparable to traditional diesel engines. Cummins has also implemented advanced engine control modules (ECM) that optimize fuel mixture and ignition timing for CNG operation, resulting in reduced emissions and improved fuel economy[2]. Their CNG systems include specially designed fuel storage tanks, fuel lines, and injectors capable of handling high-pressure natural gas[3].

Strengths: High thermal efficiency, maintains power output, reduced emissions. Weaknesses: Complexity of dual-fuel system, higher initial cost compared to standard diesel engines.

Westport Fuel Systems Canada, Inc.

Technical Solution: Westport has pioneered HPDI 2.0 technology specifically for heavy-duty engines, which is applicable to 454 Big Block engines. This system allows for up to 95% natural gas substitution rate, maintaining diesel-like performance and efficiency[4]. Westport's technology includes proprietary fuel injectors that can handle both diesel and natural gas at high pressures, along with advanced ECU programming for precise fuel control. They have also developed cryogenic fuel storage solutions that increase the energy density of CNG, extending vehicle range[5]. Westport's CNG adaptations incorporate advanced thermal management systems to optimize engine performance and durability when running on natural gas[6].

Strengths: High natural gas substitution rate, maintains diesel-like performance. Weaknesses: Requires significant engine modifications, potential for increased maintenance complexity.

Innovative CNG Fuel System Designs for 454 Engines

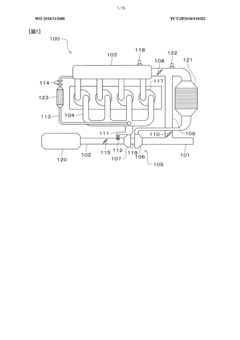

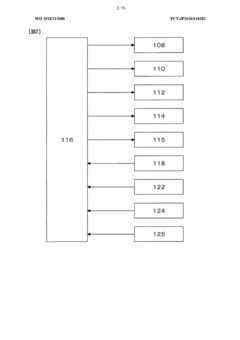

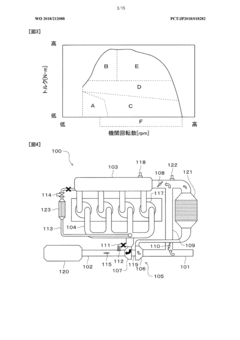

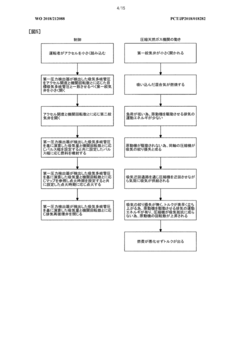

Air intake/exhaust structure for compressed natural gas engine

PatentWO2018212088A1

Innovation

- An intake and exhaust structure for compressed natural gas engines incorporating a supercharger with a compressor and prime mover, throttle valves, detour passages, and an exhaust recirculation system, controlled by a device to manage pressure and flow to minimize losses and temperature rise, while optimizing air and fuel supply.

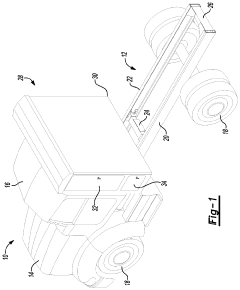

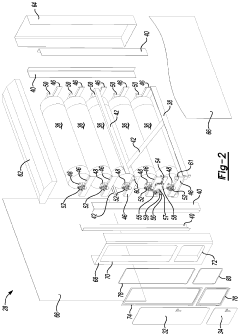

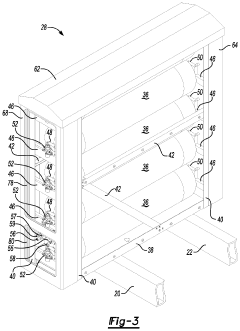

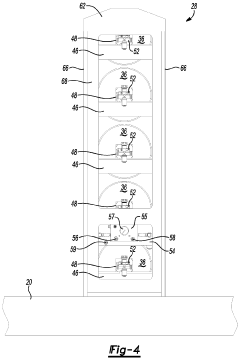

Compressed natural gas fueling system with integrated fill receptacle

PatentActiveUS20200238822A1

Innovation

- A CNG fuel system design that integrates a housing with tanks and a fill receptacle positioned above the frame rails of a truck, eliminating the need for a separate fuel management module by supporting the system with frame rails and using a manifold assembly to manage fuel distribution directly from the fill receptacle to the tanks.

Environmental Impact of CNG Adaptations

The adaptation of 454 big block engines to run on Compressed Natural Gas (CNG) has significant environmental implications. CNG is widely recognized as a cleaner-burning alternative to traditional gasoline and diesel fuels, offering reduced emissions of harmful pollutants. When compared to gasoline-powered engines, CNG adaptations in 454 big block engines can result in substantial reductions in carbon monoxide (CO) emissions, typically ranging from 60% to 90%. Additionally, these adaptations can lead to a 25% to 50% decrease in nitrogen oxide (NOx) emissions, which are major contributors to smog formation and acid rain.

Particulate matter emissions, which pose serious health risks, are also significantly reduced with CNG adaptations. Studies have shown that CNG-powered engines can produce up to 95% fewer particulate emissions compared to their diesel counterparts. This reduction is particularly important in urban areas where air quality is a major concern. Furthermore, the lower carbon content of natural gas results in reduced carbon dioxide (CO2) emissions, potentially lowering greenhouse gas emissions by 20% to 30% compared to gasoline engines.

The environmental benefits of CNG adaptations extend beyond tailpipe emissions. Natural gas production and distribution generally have a lower environmental impact compared to the extraction and refining processes of conventional petroleum fuels. This results in a reduced overall carbon footprint throughout the fuel lifecycle. Additionally, CNG is less likely to contaminate soil and water resources in the event of a spill, as it dissipates into the air rather than pooling on the ground or water surface.

However, it is important to consider the potential environmental drawbacks of CNG adaptations. The primary concern is methane leakage during natural gas extraction, transportation, and vehicle refueling. Methane is a potent greenhouse gas with a global warming potential significantly higher than CO2 in the short term. Therefore, minimizing methane leakage throughout the CNG supply chain is crucial to maximize the environmental benefits of these adaptations.

The conversion process itself also has environmental implications. While adapting existing 454 big block engines to run on CNG can extend their useful life and prevent premature disposal, the manufacturing of new components and modification of existing systems does have an environmental cost. However, this is generally outweighed by the long-term emissions reductions achieved through CNG use.

In conclusion, CNG adaptations in 454 big block engines offer significant environmental benefits, particularly in terms of reduced emissions of criteria pollutants and greenhouse gases. While challenges such as methane leakage must be addressed, the overall environmental impact of these adaptations is generally positive, contributing to improved air quality and reduced carbon footprint in the transportation sector.

Particulate matter emissions, which pose serious health risks, are also significantly reduced with CNG adaptations. Studies have shown that CNG-powered engines can produce up to 95% fewer particulate emissions compared to their diesel counterparts. This reduction is particularly important in urban areas where air quality is a major concern. Furthermore, the lower carbon content of natural gas results in reduced carbon dioxide (CO2) emissions, potentially lowering greenhouse gas emissions by 20% to 30% compared to gasoline engines.

The environmental benefits of CNG adaptations extend beyond tailpipe emissions. Natural gas production and distribution generally have a lower environmental impact compared to the extraction and refining processes of conventional petroleum fuels. This results in a reduced overall carbon footprint throughout the fuel lifecycle. Additionally, CNG is less likely to contaminate soil and water resources in the event of a spill, as it dissipates into the air rather than pooling on the ground or water surface.

However, it is important to consider the potential environmental drawbacks of CNG adaptations. The primary concern is methane leakage during natural gas extraction, transportation, and vehicle refueling. Methane is a potent greenhouse gas with a global warming potential significantly higher than CO2 in the short term. Therefore, minimizing methane leakage throughout the CNG supply chain is crucial to maximize the environmental benefits of these adaptations.

The conversion process itself also has environmental implications. While adapting existing 454 big block engines to run on CNG can extend their useful life and prevent premature disposal, the manufacturing of new components and modification of existing systems does have an environmental cost. However, this is generally outweighed by the long-term emissions reductions achieved through CNG use.

In conclusion, CNG adaptations in 454 big block engines offer significant environmental benefits, particularly in terms of reduced emissions of criteria pollutants and greenhouse gases. While challenges such as methane leakage must be addressed, the overall environmental impact of these adaptations is generally positive, contributing to improved air quality and reduced carbon footprint in the transportation sector.

Regulatory Framework for CNG Vehicle Conversions

The regulatory framework for Compressed Natural Gas (CNG) vehicle conversions plays a crucial role in ensuring safety, environmental compliance, and standardization in the adaptation of 454 Big Block Engines to run on CNG. This framework encompasses a complex web of federal, state, and local regulations that govern the conversion process, equipment standards, and operational requirements.

At the federal level, the U.S. Environmental Protection Agency (EPA) sets the primary standards for CNG vehicle conversions. The EPA's regulations focus on emissions control and require that converted vehicles meet or exceed the original emissions standards. Conversion systems must be certified under the EPA's Clean Alternative Fuel Vehicle and Engine Conversions program, which involves rigorous testing and documentation to demonstrate compliance with emissions regulations.

The National Highway Traffic Safety Administration (NHTSA) also plays a significant role in the regulatory landscape. NHTSA oversees vehicle safety standards, including those related to fuel system integrity and crashworthiness. Converted vehicles must maintain compliance with Federal Motor Vehicle Safety Standards (FMVSS), ensuring that the CNG adaptation does not compromise the vehicle's safety features.

State-level regulations add another layer of complexity to the conversion process. Many states have their own requirements for CNG vehicle conversions, which may include additional safety inspections, specific equipment certifications, or registration procedures. For instance, California's Air Resources Board (CARB) imposes stricter emissions standards than the federal EPA, requiring separate certification for vehicles operating within the state.

Local jurisdictions may also implement regulations affecting CNG vehicle conversions, particularly in areas with air quality concerns. These local rules can impact the permitting process for conversion facilities or impose additional operational requirements on CNG vehicles.

The regulatory framework also extends to the components and systems used in CNG conversions. Standards organizations such as the National Fire Protection Association (NFPA) and the American National Standards Institute (ANSI) provide guidelines for the design, installation, and maintenance of CNG fuel systems. These standards are often incorporated into regulatory requirements, ensuring a consistent approach to safety and performance across the industry.

For 454 Big Block Engines specifically, the conversion process must address the unique characteristics of these high-displacement engines. Regulators may require additional testing or modifications to ensure that the CNG adaptation maintains the engine's performance while meeting emissions and safety standards. This may involve specialized fuel injection systems, engine control unit reprogramming, and reinforced fuel storage solutions to accommodate the engine's power output and fuel consumption.

Compliance with this regulatory framework is essential for manufacturers, conversion specialists, and vehicle owners. Failure to adhere to these regulations can result in significant penalties, including fines, vehicle impoundment, and legal liabilities. As such, thorough understanding and careful navigation of the regulatory landscape are critical for successful CNG adaptations of 454 Big Block Engines.

At the federal level, the U.S. Environmental Protection Agency (EPA) sets the primary standards for CNG vehicle conversions. The EPA's regulations focus on emissions control and require that converted vehicles meet or exceed the original emissions standards. Conversion systems must be certified under the EPA's Clean Alternative Fuel Vehicle and Engine Conversions program, which involves rigorous testing and documentation to demonstrate compliance with emissions regulations.

The National Highway Traffic Safety Administration (NHTSA) also plays a significant role in the regulatory landscape. NHTSA oversees vehicle safety standards, including those related to fuel system integrity and crashworthiness. Converted vehicles must maintain compliance with Federal Motor Vehicle Safety Standards (FMVSS), ensuring that the CNG adaptation does not compromise the vehicle's safety features.

State-level regulations add another layer of complexity to the conversion process. Many states have their own requirements for CNG vehicle conversions, which may include additional safety inspections, specific equipment certifications, or registration procedures. For instance, California's Air Resources Board (CARB) imposes stricter emissions standards than the federal EPA, requiring separate certification for vehicles operating within the state.

Local jurisdictions may also implement regulations affecting CNG vehicle conversions, particularly in areas with air quality concerns. These local rules can impact the permitting process for conversion facilities or impose additional operational requirements on CNG vehicles.

The regulatory framework also extends to the components and systems used in CNG conversions. Standards organizations such as the National Fire Protection Association (NFPA) and the American National Standards Institute (ANSI) provide guidelines for the design, installation, and maintenance of CNG fuel systems. These standards are often incorporated into regulatory requirements, ensuring a consistent approach to safety and performance across the industry.

For 454 Big Block Engines specifically, the conversion process must address the unique characteristics of these high-displacement engines. Regulators may require additional testing or modifications to ensure that the CNG adaptation maintains the engine's performance while meeting emissions and safety standards. This may involve specialized fuel injection systems, engine control unit reprogramming, and reinforced fuel storage solutions to accommodate the engine's power output and fuel consumption.

Compliance with this regulatory framework is essential for manufacturers, conversion specialists, and vehicle owners. Failure to adhere to these regulations can result in significant penalties, including fines, vehicle impoundment, and legal liabilities. As such, thorough understanding and careful navigation of the regulatory landscape are critical for successful CNG adaptations of 454 Big Block Engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!