Graphene Oxide: Critical in Creating Transparent Electronics

Graphene Oxide Evolution

Graphene oxide has undergone a remarkable evolution since its initial discovery, marking significant milestones in the field of materials science. The journey began with the isolation of graphene in 2004 by Andre Geim and Konstantin Novoselov, which laid the foundation for graphene oxide research. This breakthrough sparked intense interest in graphene-based materials, leading to the development of various synthesis methods for graphene oxide.

The early stages of graphene oxide evolution focused on understanding its structure and properties. Researchers discovered that graphene oxide possessed a unique layered structure with oxygen-containing functional groups, which significantly altered its electronic, mechanical, and chemical properties compared to pristine graphene. This realization opened up new avenues for potential applications, particularly in the realm of transparent electronics.

As research progressed, scientists developed more refined methods for synthesizing graphene oxide. The Hummers method, initially proposed in 1958, became the most widely adopted approach. However, researchers continually modified and improved this method to enhance the quality and yield of graphene oxide production. These advancements led to better control over the oxidation degree and the size of graphene oxide sheets, crucial factors for its application in transparent electronics.

The evolution of graphene oxide also saw significant improvements in reduction techniques. Researchers explored various chemical, thermal, and electrochemical methods to convert graphene oxide back to graphene-like materials with enhanced electrical conductivity. This step was critical in tailoring the properties of graphene oxide for specific applications in transparent electronics, such as flexible displays and touch screens.

In recent years, the focus has shifted towards large-scale production and functionalization of graphene oxide. Researchers have developed continuous flow methods and industrial-scale processes to produce high-quality graphene oxide in larger quantities. Additionally, the functionalization of graphene oxide with various organic and inorganic materials has expanded its potential applications, enabling the creation of hybrid materials with enhanced properties for transparent electronics.

The evolution of graphene oxide has also been marked by advancements in characterization techniques. Improved microscopy and spectroscopy methods have allowed researchers to gain deeper insights into the structure and properties of graphene oxide at the atomic level. This enhanced understanding has been crucial in optimizing the material for specific applications in transparent electronics.

As research continues, the evolution of graphene oxide is expected to focus on addressing remaining challenges, such as improving its stability, enhancing its electrical properties, and developing more environmentally friendly production methods. These ongoing efforts are likely to further solidify graphene oxide's position as a critical material in the creation of next-generation transparent electronics.

Market for Transparent Electronics

The market for transparent electronics has been experiencing significant growth and transformation in recent years, driven by advancements in materials science and increasing demand for innovative display technologies. Transparent electronics, which combine optical transparency with electronic functionality, have found applications across various sectors, including consumer electronics, automotive, aerospace, and healthcare.

The global transparent electronics market is projected to expand rapidly, with estimates suggesting a compound annual growth rate (CAGR) of over 20% in the coming years. This growth is primarily fueled by the rising adoption of transparent displays in smartphones, smartwatches, and other wearable devices. The automotive industry has also emerged as a key driver, with heads-up displays (HUDs) and smart windshields gaining traction in high-end vehicles.

Consumer electronics remain the largest segment within the transparent electronics market. Manufacturers are increasingly incorporating transparent displays into products such as televisions, laptops, and tablets to enhance user experience and differentiate their offerings. The demand for augmented reality (AR) and virtual reality (VR) devices is further propelling market growth, as these technologies rely heavily on transparent display components.

In the automotive sector, the integration of transparent electronics is revolutionizing in-vehicle infotainment systems and safety features. Advanced driver-assistance systems (ADAS) are leveraging transparent displays to provide crucial information to drivers without obstructing their view. This trend is expected to accelerate with the development of autonomous vehicles, where transparent displays will play a vital role in human-machine interfaces.

The healthcare industry is another promising market for transparent electronics. Applications include smart contact lenses for monitoring glucose levels, transparent biosensors for real-time health monitoring, and augmented reality surgical displays. These innovations have the potential to transform patient care and medical procedures, driving further investment in transparent electronics research and development.

Geographically, North America and Asia-Pacific are the leading markets for transparent electronics. The presence of major technology companies and research institutions in these regions has fostered innovation and commercialization efforts. However, Europe is also witnessing significant growth, particularly in the automotive sector, where luxury car manufacturers are incorporating transparent display technologies.

As the market for transparent electronics continues to evolve, challenges such as high production costs and technical limitations in large-scale manufacturing persist. However, ongoing research in materials like graphene oxide and advancements in fabrication techniques are expected to address these issues, paving the way for wider adoption and market expansion in the coming years.

Graphene Oxide Challenges

Despite the promising potential of graphene oxide in transparent electronics, several significant challenges hinder its widespread adoption and application. One of the primary obstacles is the difficulty in achieving consistent and uniform production of high-quality graphene oxide sheets. The synthesis process often results in variations in thickness, size, and oxidation levels, which can significantly impact the material's electrical and optical properties.

Another major challenge lies in the scalability of graphene oxide production. While laboratory-scale synthesis has shown promising results, scaling up to industrial levels while maintaining quality and consistency remains a formidable task. This scalability issue directly affects the cost-effectiveness and commercial viability of graphene oxide-based transparent electronics.

The stability of graphene oxide under various environmental conditions poses another significant challenge. Graphene oxide is sensitive to temperature, humidity, and chemical exposure, which can lead to degradation of its properties over time. This instability can result in reduced performance and shortened lifespan of transparent electronic devices, limiting their practical applications.

Integration of graphene oxide with existing electronic manufacturing processes presents additional hurdles. The material's unique properties often require the development of new fabrication techniques and equipment, which can be costly and time-consuming. Furthermore, ensuring compatibility with other materials used in electronic devices without compromising performance is a complex task.

The reduction process of graphene oxide to restore its conductive properties is another critical challenge. While various reduction methods exist, achieving a balance between conductivity and transparency remains difficult. Over-reduction can lead to loss of transparency, while under-reduction results in poor electrical performance.

Controlling the surface chemistry of graphene oxide is crucial for its application in transparent electronics, yet it remains a significant challenge. The presence of oxygen-containing functional groups on the surface of graphene oxide affects its electronic properties and interactions with other materials. Fine-tuning these surface properties to optimize device performance is a complex and ongoing area of research.

Lastly, the environmental impact and potential health risks associated with graphene oxide production and use are areas of concern. As with any new material, comprehensive studies on long-term environmental effects and potential health hazards are necessary but currently lacking, which could potentially hinder regulatory approval and public acceptance of graphene oxide-based transparent electronics.

Current GO-based Solutions

01 Synthesis methods for transparent graphene oxide

Various methods are developed to synthesize transparent graphene oxide films. These include chemical vapor deposition, modified Hummers' method, and solution-based processes. The synthesis techniques focus on producing high-quality, uniform graphene oxide sheets with controlled thickness and transparency.- Synthesis methods for transparent graphene oxide: Various methods are developed to synthesize transparent graphene oxide films or sheets. These techniques focus on controlling the oxidation process, exfoliation, and deposition to achieve high transparency while maintaining other desirable properties of graphene oxide.

- Doping and functionalization for improved transparency: Doping graphene oxide with various elements or functionalizing it with specific chemical groups can enhance its transparency. These modifications alter the electronic structure and optical properties of graphene oxide, leading to increased light transmission.

- Transparent graphene oxide-based electrodes: Graphene oxide is used to create transparent electrodes for various applications, including solar cells, displays, and touch screens. The high transparency and conductivity of graphene oxide make it an attractive material for these applications.

- Reduction techniques for controlling transparency: Various reduction methods are employed to control the transparency of graphene oxide. These techniques allow for fine-tuning of the optical properties by adjusting the degree of reduction, which affects the electronic structure and light absorption of the material.

- Transparent graphene oxide composites: Graphene oxide is incorporated into composite materials to create transparent films or coatings with enhanced properties. These composites combine the transparency of graphene oxide with additional functionalities provided by the matrix material or other additives.

02 Doping and functionalization for enhanced transparency

Doping graphene oxide with various elements or functionalizing it with specific groups can improve its transparency. This approach allows for fine-tuning of the optical properties while maintaining or enhancing other desirable characteristics such as conductivity and mechanical strength.Expand Specific Solutions03 Graphene oxide-based transparent electrodes

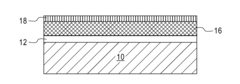

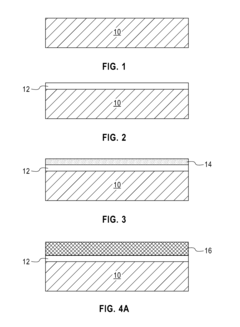

Transparent graphene oxide films are utilized as electrodes in various electronic devices. These electrodes offer a combination of high transparency and good electrical conductivity, making them suitable for applications in solar cells, displays, and touch screens.Expand Specific Solutions04 Multilayer structures for improved transparency

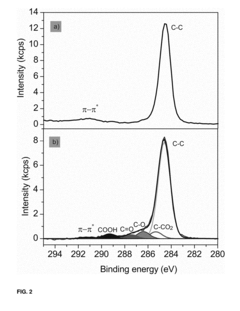

Multilayer structures incorporating graphene oxide are designed to enhance overall transparency. These structures may include alternating layers of graphene oxide with other materials or specific arrangements of graphene oxide sheets to optimize light transmission while maintaining desired functional properties.Expand Specific Solutions05 Characterization and measurement of graphene oxide transparency

Various techniques and methods are developed to accurately characterize and measure the transparency of graphene oxide films. These include spectroscopic methods, optical measurements, and advanced imaging techniques to quantify and analyze the transparency properties of graphene oxide materials.Expand Specific Solutions

Key Graphene Oxide Players

The research on graphene oxide for transparent electronics is in a rapidly evolving phase, with significant market potential and technological advancements. The global market for transparent electronics is expanding, driven by increasing demand for flexible displays and touch screens. While the technology is still maturing, several key players are making substantial progress. Companies like Samsung Electronics Co., Ltd. and BOE Technology Group Co., Ltd. are at the forefront, leveraging their expertise in display technologies. Academic institutions such as Massachusetts Institute of Technology and The University of Manchester are contributing groundbreaking research. Emerging players like Paragraf Ltd. and Archer Materials Ltd. are focusing on commercializing graphene-based technologies, indicating a competitive and diverse landscape in this field.

Paragraf Ltd.

BOE Technology Group Co., Ltd.

GO Innovations Analysis

- A doped graphene transparent conductive electrode is used, with a chemically doped graphene layer having a higher work function to enhance hole injection, and an optional interfacial layer of conductive polymer or metal oxide to reduce injection barriers, replacing indium tin oxide.

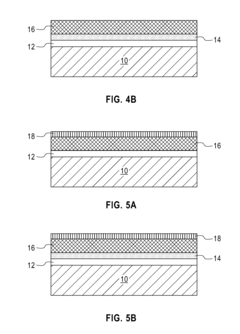

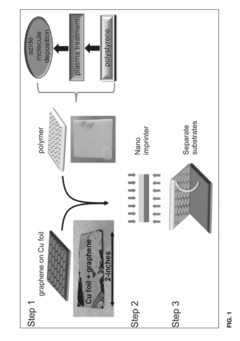

- A dry graphene transfer method using plasma-treated polymer substrates with N-ethylamino-4-azidotetrafluorobenzoate (TFPA) linker molecules to enhance adhesion, allowing for pressure and heat-assisted transfer printing without chemical etching, preserving the metal foil and maintaining graphene quality.

Environmental Impact of GO

The environmental impact of graphene oxide (GO) is a critical consideration in the development of transparent electronics. As GO production and application increase, its potential effects on ecosystems and human health require thorough examination. The synthesis of GO often involves strong oxidizing agents and acids, which can lead to the generation of hazardous waste if not properly managed. These processes may contribute to water pollution and soil contamination if appropriate safeguards are not implemented.

GO nanoparticles, due to their small size and unique properties, have the potential to interact with living organisms in complex ways. Studies have shown that GO can accumulate in various organs of aquatic organisms, potentially disrupting their physiological functions. The long-term effects of GO exposure on terrestrial ecosystems are still under investigation, with concerns about its persistence in the environment and potential bioaccumulation in food chains.

In terms of human health, the inhalation of GO particles during manufacturing or handling poses potential risks. Respiratory exposure to GO has been associated with lung inflammation and oxidative stress in laboratory studies. However, the extent of these effects in real-world scenarios and the long-term consequences of chronic exposure are not yet fully understood.

On the positive side, GO has shown promise in environmental remediation applications. Its high adsorption capacity makes it effective in removing pollutants from water and air. GO-based materials have been developed for water purification, demonstrating the ability to remove heavy metals, organic contaminants, and even some pathogens. This dual nature of GO – as both a potential environmental concern and a solution – highlights the complexity of its environmental impact.

The lifecycle assessment of GO-based transparent electronics is an emerging area of research. While these devices may offer energy efficiency benefits during use, the environmental costs of production and end-of-life disposal must be carefully evaluated. Recycling and safe disposal methods for GO-containing products are still in development, presenting challenges for sustainable management of electronic waste.

As research progresses, efforts are being made to develop greener synthesis methods for GO, aiming to reduce the environmental footprint of its production. Additionally, the development of guidelines for safe handling and disposal of GO materials is crucial for mitigating potential environmental risks. Balancing the technological benefits of GO in transparent electronics with its environmental implications remains a key challenge for researchers and policymakers alike.

GO Scalability and Production

The scalability and production of graphene oxide (GO) are critical factors in its potential application for transparent electronics. Current production methods have made significant strides in recent years, but challenges remain in achieving large-scale, cost-effective manufacturing of high-quality GO.

The most common method for GO production is the modified Hummers' method, which involves the oxidation of graphite using strong oxidizing agents. This process has been optimized to increase yield and reduce environmental impact. However, it still faces limitations in terms of scalability and consistency of product quality.

Several companies and research institutions are working on developing more efficient and scalable production techniques. One promising approach is the electrochemical exfoliation of graphite, which offers better control over the oxidation process and can be more easily scaled up. This method also has the advantage of using less harsh chemicals, making it more environmentally friendly.

Another area of focus is the development of continuous flow reactors for GO production. These systems allow for a more controlled and consistent oxidation process, potentially leading to higher quality GO at larger scales. Some researchers have reported success in producing GO sheets with lateral dimensions of several micrometers using this approach.

Despite these advancements, challenges persist in maintaining the quality and uniformity of GO when scaling up production. The size and thickness of GO sheets can vary significantly, which can affect their performance in transparent electronic applications. Efforts are ongoing to develop better characterization techniques and quality control measures to ensure consistency in large-scale production.

Cost remains a significant factor in GO scalability. While production costs have decreased over the years, further reductions are necessary to make GO-based transparent electronics commercially viable. This includes not only the cost of raw materials and production processes but also the expenses associated with purification and post-processing steps.

Environmental considerations are also driving research into more sustainable production methods. Water-based exfoliation techniques and the use of bio-derived precursors are being explored as alternatives to traditional chemical oxidation methods. These approaches aim to reduce the environmental footprint of GO production while maintaining or improving product quality.

As research progresses, it is likely that a combination of improved chemical processes, advanced reactor designs, and innovative characterization techniques will lead to more scalable and efficient GO production methods. This will be crucial in realizing the full potential of GO in transparent electronics and other applications.