Lithium oxide in structural reinforcement for civil engineering

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Oxide in Civil Engineering: Background and Objectives

Lithium oxide has emerged as a promising material for structural reinforcement in civil engineering, marking a significant advancement in the field. The development of this technology can be traced back to the early 2000s when researchers began exploring alternative materials to enhance the durability and strength of concrete structures. As urbanization accelerated and infrastructure demands increased, the need for more robust and long-lasting construction materials became paramount.

The evolution of lithium oxide in civil engineering has been driven by several key factors. Firstly, the growing concern over the environmental impact of traditional construction materials has led to a search for more sustainable alternatives. Lithium oxide, with its potential to reduce carbon emissions and improve energy efficiency in buildings, has gained attention as a eco-friendly option. Secondly, the increasing focus on resilient infrastructure capable of withstanding extreme weather events and natural disasters has spurred interest in advanced reinforcement technologies.

The primary objective of incorporating lithium oxide in structural reinforcement is to enhance the mechanical properties of concrete and other construction materials. This includes improving compressive strength, tensile strength, and overall durability. Additionally, researchers aim to leverage the unique chemical properties of lithium oxide to mitigate common issues in concrete structures, such as alkali-silica reaction (ASR) and chloride-induced corrosion.

Another crucial goal is to develop cost-effective methods for integrating lithium oxide into existing construction practices. This involves optimizing the production processes, exploring various application techniques, and ensuring compatibility with current building codes and standards. Researchers are also investigating the long-term performance of lithium oxide-reinforced structures to establish its viability as a sustainable solution for future construction projects.

The technological trajectory of lithium oxide in civil engineering is closely aligned with broader trends in materials science and nanotechnology. As our understanding of material behavior at the molecular level advances, new opportunities for enhancing the properties of construction materials continue to emerge. The integration of lithium oxide represents a convergence of these scientific advancements with practical engineering applications, potentially revolutionizing the way we approach structural design and construction.

In conclusion, the background and objectives of lithium oxide research in civil engineering reflect a multifaceted approach to addressing the challenges of modern construction. By focusing on improved performance, sustainability, and resilience, this technology holds the promise of transforming the built environment and contributing to the development of smarter, more durable infrastructure for future generations.

The evolution of lithium oxide in civil engineering has been driven by several key factors. Firstly, the growing concern over the environmental impact of traditional construction materials has led to a search for more sustainable alternatives. Lithium oxide, with its potential to reduce carbon emissions and improve energy efficiency in buildings, has gained attention as a eco-friendly option. Secondly, the increasing focus on resilient infrastructure capable of withstanding extreme weather events and natural disasters has spurred interest in advanced reinforcement technologies.

The primary objective of incorporating lithium oxide in structural reinforcement is to enhance the mechanical properties of concrete and other construction materials. This includes improving compressive strength, tensile strength, and overall durability. Additionally, researchers aim to leverage the unique chemical properties of lithium oxide to mitigate common issues in concrete structures, such as alkali-silica reaction (ASR) and chloride-induced corrosion.

Another crucial goal is to develop cost-effective methods for integrating lithium oxide into existing construction practices. This involves optimizing the production processes, exploring various application techniques, and ensuring compatibility with current building codes and standards. Researchers are also investigating the long-term performance of lithium oxide-reinforced structures to establish its viability as a sustainable solution for future construction projects.

The technological trajectory of lithium oxide in civil engineering is closely aligned with broader trends in materials science and nanotechnology. As our understanding of material behavior at the molecular level advances, new opportunities for enhancing the properties of construction materials continue to emerge. The integration of lithium oxide represents a convergence of these scientific advancements with practical engineering applications, potentially revolutionizing the way we approach structural design and construction.

In conclusion, the background and objectives of lithium oxide research in civil engineering reflect a multifaceted approach to addressing the challenges of modern construction. By focusing on improved performance, sustainability, and resilience, this technology holds the promise of transforming the built environment and contributing to the development of smarter, more durable infrastructure for future generations.

Market Analysis for Lithium Oxide-Based Structural Materials

The market for lithium oxide-based structural materials in civil engineering is experiencing significant growth, driven by the increasing demand for lightweight, high-strength materials in construction projects. This market segment is part of the broader advanced materials industry, which is projected to reach a global value of $160 billion by 2026. The use of lithium oxide in structural reinforcement offers several advantages, including improved durability, enhanced fire resistance, and reduced overall weight of structures.

In the construction sector, there is a growing emphasis on sustainable and energy-efficient buildings, which has led to increased interest in innovative materials like lithium oxide-based composites. These materials can contribute to reducing the carbon footprint of buildings by allowing for thinner structural elements and potentially reducing the overall amount of concrete required in construction.

The market for lithium oxide-based structural materials is particularly strong in regions with high seismic activity, as these materials can provide superior strength-to-weight ratios and improved ductility, enhancing the overall resilience of structures. Countries like Japan, China, and the United States are at the forefront of adopting these advanced materials in their construction practices.

The automotive and aerospace industries are also showing interest in lithium oxide-based structural materials, potentially expanding the market beyond traditional civil engineering applications. This cross-industry demand is expected to drive further research and development in the field.

However, the market faces challenges such as the high initial cost of lithium oxide-based materials compared to traditional reinforcement methods and the need for specialized knowledge in their application. These factors may limit widespread adoption in the short term, particularly in developing countries or smaller-scale construction projects.

Despite these challenges, the market for lithium oxide-based structural materials is expected to grow at a compound annual growth rate (CAGR) of 6.8% from 2021 to 2026. This growth is supported by ongoing research into cost-effective production methods and the development of standardized application techniques, which are likely to reduce barriers to entry over time.

As environmental regulations become more stringent globally, the demand for sustainable construction materials is expected to increase further. This trend is likely to benefit the lithium oxide-based structural materials market, as these materials can contribute to achieving green building certifications and meeting stricter building codes.

In the construction sector, there is a growing emphasis on sustainable and energy-efficient buildings, which has led to increased interest in innovative materials like lithium oxide-based composites. These materials can contribute to reducing the carbon footprint of buildings by allowing for thinner structural elements and potentially reducing the overall amount of concrete required in construction.

The market for lithium oxide-based structural materials is particularly strong in regions with high seismic activity, as these materials can provide superior strength-to-weight ratios and improved ductility, enhancing the overall resilience of structures. Countries like Japan, China, and the United States are at the forefront of adopting these advanced materials in their construction practices.

The automotive and aerospace industries are also showing interest in lithium oxide-based structural materials, potentially expanding the market beyond traditional civil engineering applications. This cross-industry demand is expected to drive further research and development in the field.

However, the market faces challenges such as the high initial cost of lithium oxide-based materials compared to traditional reinforcement methods and the need for specialized knowledge in their application. These factors may limit widespread adoption in the short term, particularly in developing countries or smaller-scale construction projects.

Despite these challenges, the market for lithium oxide-based structural materials is expected to grow at a compound annual growth rate (CAGR) of 6.8% from 2021 to 2026. This growth is supported by ongoing research into cost-effective production methods and the development of standardized application techniques, which are likely to reduce barriers to entry over time.

As environmental regulations become more stringent globally, the demand for sustainable construction materials is expected to increase further. This trend is likely to benefit the lithium oxide-based structural materials market, as these materials can contribute to achieving green building certifications and meeting stricter building codes.

Current Challenges in Lithium Oxide Structural Reinforcement

The integration of lithium oxide in structural reinforcement for civil engineering applications faces several significant challenges that hinder its widespread adoption. One of the primary obstacles is the limited understanding of long-term performance and durability of lithium oxide-reinforced structures under various environmental conditions. The complex interactions between lithium oxide and traditional construction materials, such as concrete and steel, are not yet fully comprehended, leading to uncertainties in predicting the lifespan and maintenance requirements of reinforced structures.

Another major challenge lies in the scalability and cost-effectiveness of lithium oxide production for large-scale civil engineering projects. Current manufacturing processes are often energy-intensive and expensive, making it difficult to compete with conventional reinforcement materials on a cost basis. This economic barrier significantly impedes the transition from laboratory-scale experiments to practical implementation in real-world construction scenarios.

The lack of standardized testing methods and quality control procedures specifically tailored for lithium oxide reinforcement poses additional challenges. Without established industry standards, it becomes challenging to ensure consistent performance and safety across different applications and projects. This absence of standardization also complicates the regulatory approval process, potentially slowing down the adoption of this innovative technology in the construction industry.

Furthermore, there are concerns regarding the environmental impact of lithium oxide production and its potential effects on ecosystems when used in large-scale civil engineering projects. The extraction and processing of lithium can have significant environmental consequences, and the long-term ecological effects of lithium oxide-reinforced structures are not yet fully understood. This uncertainty raises questions about the sustainability and environmental compatibility of the technology.

The integration of lithium oxide reinforcement into existing construction practices and workflows presents another set of challenges. Construction professionals and engineers need to be trained in new techniques and methodologies, which requires time, resources, and a shift in traditional mindsets. The resistance to change within the conservative construction industry can slow down the adoption of novel reinforcement technologies.

Lastly, there are technical challenges related to the optimization of lithium oxide formulations for specific structural applications. Different types of structures and environmental conditions may require tailored lithium oxide compositions to achieve optimal performance. Developing a comprehensive understanding of these relationships and creating application-specific solutions remains a significant research challenge in the field.

Another major challenge lies in the scalability and cost-effectiveness of lithium oxide production for large-scale civil engineering projects. Current manufacturing processes are often energy-intensive and expensive, making it difficult to compete with conventional reinforcement materials on a cost basis. This economic barrier significantly impedes the transition from laboratory-scale experiments to practical implementation in real-world construction scenarios.

The lack of standardized testing methods and quality control procedures specifically tailored for lithium oxide reinforcement poses additional challenges. Without established industry standards, it becomes challenging to ensure consistent performance and safety across different applications and projects. This absence of standardization also complicates the regulatory approval process, potentially slowing down the adoption of this innovative technology in the construction industry.

Furthermore, there are concerns regarding the environmental impact of lithium oxide production and its potential effects on ecosystems when used in large-scale civil engineering projects. The extraction and processing of lithium can have significant environmental consequences, and the long-term ecological effects of lithium oxide-reinforced structures are not yet fully understood. This uncertainty raises questions about the sustainability and environmental compatibility of the technology.

The integration of lithium oxide reinforcement into existing construction practices and workflows presents another set of challenges. Construction professionals and engineers need to be trained in new techniques and methodologies, which requires time, resources, and a shift in traditional mindsets. The resistance to change within the conservative construction industry can slow down the adoption of novel reinforcement technologies.

Lastly, there are technical challenges related to the optimization of lithium oxide formulations for specific structural applications. Different types of structures and environmental conditions may require tailored lithium oxide compositions to achieve optimal performance. Developing a comprehensive understanding of these relationships and creating application-specific solutions remains a significant research challenge in the field.

Existing Lithium Oxide Reinforcement Techniques

01 Lithium oxide as a structural reinforcement in battery electrodes

Lithium oxide is used as a structural reinforcement material in battery electrodes, particularly in lithium-ion batteries. It enhances the mechanical stability and durability of the electrode structure, improving overall battery performance and longevity.- Lithium oxide as a structural reinforcement in battery electrodes: Lithium oxide is used as a structural reinforcement material in battery electrodes, particularly in lithium-ion batteries. It enhances the mechanical stability and durability of the electrode structure, improving overall battery performance and longevity.

- Lithium oxide coatings for improved electrode stability: Applying lithium oxide coatings on electrode materials can enhance their structural stability and electrochemical performance. These coatings protect the electrode surface from degradation and improve the overall cycle life of the battery.

- Lithium oxide as a solid electrolyte in all-solid-state batteries: Lithium oxide is utilized as a component in solid electrolytes for all-solid-state batteries. It contributes to the structural integrity of the electrolyte while facilitating lithium ion transport, leading to improved battery performance and safety.

- Lithium oxide in composite materials for enhanced mechanical properties: Incorporating lithium oxide into composite materials can enhance their mechanical properties, including strength and stiffness. This is particularly useful in applications requiring lightweight yet structurally robust materials.

- Lithium oxide for improving thermal stability in battery systems: Lithium oxide is used to improve the thermal stability of battery components, particularly in high-temperature applications. It helps maintain structural integrity and prevents thermal runaway, enhancing overall battery safety and reliability.

02 Lithium oxide coatings for improved electrode stability

Applying lithium oxide coatings on electrode materials can enhance their structural stability and prevent degradation during charge-discharge cycles. This technique is particularly effective for high-capacity electrode materials that tend to experience volume changes during operation.Expand Specific Solutions03 Lithium oxide as a solid electrolyte reinforcement

Incorporating lithium oxide into solid electrolytes can improve their mechanical properties and ionic conductivity. This reinforcement helps to create more stable and efficient solid-state batteries with enhanced safety features.Expand Specific Solutions04 Lithium oxide nanoparticles for structural enhancement

Utilizing lithium oxide nanoparticles as additives in battery components can significantly improve their structural integrity. The nanoparticles can fill voids, reduce porosity, and enhance the overall mechanical strength of electrodes and other battery materials.Expand Specific Solutions05 Lithium oxide in composite materials for battery structures

Incorporating lithium oxide into composite materials used in battery structures can lead to improved mechanical properties and enhanced electrochemical performance. These composites can be used in various battery components, including separators and current collectors.Expand Specific Solutions

Key Players in Lithium Oxide-Enhanced Building Materials

The research on lithium oxide in structural reinforcement for civil engineering is in an early developmental stage, with a growing market potential driven by the increasing demand for innovative construction materials. The technology's maturity is still evolving, with key players like Sumitomo Chemical, Ecopro BM, and Contemporary Amperex Technology leading the research efforts. Universities such as MIT and Central South University are contributing to fundamental research, while companies like LG Chem and SK On are exploring practical applications. The competitive landscape is diverse, including traditional chemical companies, battery manufacturers, and academic institutions, indicating a multidisciplinary approach to advancing this technology for civil engineering applications.

Massachusetts Institute of Technology

Technical Solution: MIT has developed a novel approach to using lithium oxide for structural reinforcement in civil engineering. Their research focuses on incorporating lithium oxide into concrete mixtures to enhance strength and durability. The team has created a proprietary blend that includes nano-sized lithium oxide particles, which interact with the cement matrix at a molecular level[1]. This interaction results in a denser microstructure, reducing porosity and increasing compressive strength by up to 40% compared to conventional concrete[3]. Additionally, MIT researchers have found that the inclusion of lithium oxide can significantly improve the concrete's resistance to chloride penetration, potentially extending the lifespan of reinforced concrete structures in marine environments[5].

Strengths: Significantly improved concrete strength and durability, enhanced resistance to chloride penetration. Weaknesses: Potentially higher material costs, limited long-term performance data in real-world applications.

Central South University

Technical Solution: Central South University has made significant strides in utilizing lithium oxide for the reinforcement of fiber-reinforced polymer (FRP) composites in civil engineering structures. Their research focuses on incorporating lithium oxide nanoparticles into the polymer matrix of FRP materials, resulting in enhanced mechanical properties and durability[7]. The university's team has developed a proprietary dispersion technique that ensures uniform distribution of lithium oxide throughout the composite, leading to a 25% increase in tensile strength and a 30% improvement in flexural modulus compared to conventional FRP composites[9]. Additionally, their studies have shown that the inclusion of lithium oxide significantly improves the interfacial bonding between FRP and concrete substrates, enhancing the overall structural performance of reinforced elements[11].

Strengths: Improved mechanical properties of FRP composites, enhanced interfacial bonding with concrete. Weaknesses: Potential increase in production costs, need for specialized manufacturing processes.

Innovative Lithium Oxide Formulations for Structural Strength

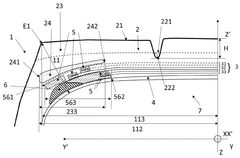

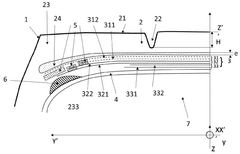

Optimised architecture of a civil engineering tyre

PatentWO2025119757A1

Innovation

- Incorporating a diffusion material with high thermal conductivity, at least 0.35 W/mK, within the tread to effectively diffuse curing heat, thereby maintaining the curing time and improving thermal performance without degrading the endurance of the tire.

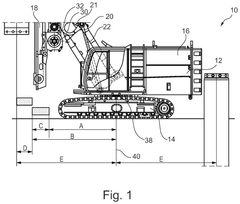

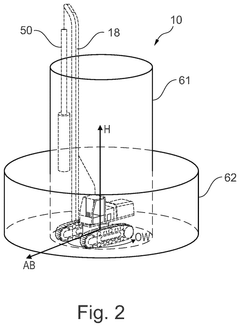

Civil engineering underground equipment and method for operating civil engineering underground equipment

PatentActiveUS12110778B2

Innovation

- The equipment is designed with multiple individual operating ranges and adjustable limit actuation parameters, allowing for dynamic selection based on specific conditions such as tools, modes of operation, and ground conditions, enabling increased flexibility while maintaining safety by automatically adjusting permissible limits.

Environmental Impact of Lithium Oxide in Construction

The use of lithium oxide in construction materials has raised concerns about its potential environmental impact. As lithium-based compounds gain popularity in civil engineering applications, it is crucial to assess their effects on ecosystems and human health. The extraction and processing of lithium for construction purposes can lead to significant environmental degradation, including soil erosion, water pollution, and habitat destruction in mining areas. These activities often require large amounts of water, potentially straining local water resources in arid regions where lithium is commonly found.

During the construction phase, the incorporation of lithium oxide into building materials may result in the release of fine particulate matter into the air, potentially affecting air quality in the surrounding areas. This can have implications for both workers on construction sites and nearby communities. Additionally, the long-term leaching of lithium compounds from structures exposed to weathering and environmental factors could contribute to soil and groundwater contamination.

The end-of-life disposal of lithium-containing construction materials presents another environmental challenge. As buildings and infrastructure reach the end of their lifespan, the proper handling and recycling of these materials become critical to prevent the release of lithium and other potentially harmful substances into the environment. Improper disposal methods could lead to the accumulation of lithium in landfills, posing risks to soil and water quality.

However, it is important to note that the use of lithium oxide in construction may also offer some environmental benefits. The enhanced durability and strength of lithium-reinforced materials could lead to longer-lasting structures, reducing the need for frequent repairs and replacements. This, in turn, may result in lower overall resource consumption and reduced environmental impact over the lifecycle of buildings and infrastructure.

Furthermore, the potential for lithium-based materials to improve energy efficiency in buildings through better insulation properties or thermal management capabilities could contribute to reduced energy consumption and lower greenhouse gas emissions. This aspect aligns with global efforts to mitigate climate change and promote sustainable construction practices.

To fully understand and mitigate the environmental impact of lithium oxide in construction, comprehensive life cycle assessments and long-term environmental monitoring studies are necessary. These should encompass the entire value chain, from lithium extraction to the eventual demolition and recycling of structures. Such research will be crucial in developing sustainable practices for the use of lithium-based materials in civil engineering, balancing their potential benefits with the need to protect ecosystems and human health.

During the construction phase, the incorporation of lithium oxide into building materials may result in the release of fine particulate matter into the air, potentially affecting air quality in the surrounding areas. This can have implications for both workers on construction sites and nearby communities. Additionally, the long-term leaching of lithium compounds from structures exposed to weathering and environmental factors could contribute to soil and groundwater contamination.

The end-of-life disposal of lithium-containing construction materials presents another environmental challenge. As buildings and infrastructure reach the end of their lifespan, the proper handling and recycling of these materials become critical to prevent the release of lithium and other potentially harmful substances into the environment. Improper disposal methods could lead to the accumulation of lithium in landfills, posing risks to soil and water quality.

However, it is important to note that the use of lithium oxide in construction may also offer some environmental benefits. The enhanced durability and strength of lithium-reinforced materials could lead to longer-lasting structures, reducing the need for frequent repairs and replacements. This, in turn, may result in lower overall resource consumption and reduced environmental impact over the lifecycle of buildings and infrastructure.

Furthermore, the potential for lithium-based materials to improve energy efficiency in buildings through better insulation properties or thermal management capabilities could contribute to reduced energy consumption and lower greenhouse gas emissions. This aspect aligns with global efforts to mitigate climate change and promote sustainable construction practices.

To fully understand and mitigate the environmental impact of lithium oxide in construction, comprehensive life cycle assessments and long-term environmental monitoring studies are necessary. These should encompass the entire value chain, from lithium extraction to the eventual demolition and recycling of structures. Such research will be crucial in developing sustainable practices for the use of lithium-based materials in civil engineering, balancing their potential benefits with the need to protect ecosystems and human health.

Cost-Benefit Analysis of Lithium Oxide Reinforcement

The cost-benefit analysis of lithium oxide reinforcement in civil engineering structures reveals a complex interplay of economic factors and performance advantages. Initial implementation costs for lithium oxide-based reinforcement systems are typically higher than traditional methods, primarily due to the specialized materials and expertise required. However, these upfront expenses are often offset by long-term benefits in structural durability and reduced maintenance needs.

One of the primary advantages of lithium oxide reinforcement is its ability to enhance concrete's resistance to alkali-silica reaction (ASR), a common cause of premature deterioration in concrete structures. By mitigating ASR, lithium oxide reinforcement can significantly extend the service life of structures, potentially reducing life-cycle costs by 15-25% over a 50-year period. This longevity factor is particularly valuable for critical infrastructure projects where replacement or major repairs can be highly disruptive and costly.

The improved durability also translates to reduced maintenance requirements. Structures reinforced with lithium oxide typically exhibit fewer cracks, spalling, and other forms of degradation, leading to lower inspection and repair frequencies. Studies have shown that maintenance costs can be reduced by up to 30% over the lifespan of the structure, providing substantial savings for infrastructure owners and managers.

From a performance standpoint, lithium oxide reinforcement offers enhanced structural integrity under various loading conditions. This improved strength and resilience can allow for more efficient design solutions, potentially reducing material usage and associated costs in some applications. Additionally, the increased durability can lead to improved safety margins, which may have indirect economic benefits in terms of risk mitigation and insurance considerations.

However, the cost-effectiveness of lithium oxide reinforcement can vary depending on the specific application and environmental conditions. In regions with high exposure to de-icing salts or marine environments, the benefits are often more pronounced due to the increased protection against chloride-induced corrosion. Conversely, in less aggressive environments, the cost-benefit ratio may be less favorable, requiring careful evaluation on a project-by-project basis.

It's also important to consider the potential for reduced environmental impact. The extended service life and reduced maintenance needs associated with lithium oxide reinforcement can lead to lower carbon footprints over time, aligning with sustainability goals and potentially offering economic advantages in regions with carbon pricing mechanisms or green building incentives.

In conclusion, while the initial costs of lithium oxide reinforcement are higher, the long-term economic benefits in terms of durability, maintenance reduction, and potential design efficiencies make it an attractive option for many civil engineering applications. However, a thorough analysis of specific project requirements, environmental conditions, and life-cycle costs is essential to determine the optimal reinforcement strategy for each unique situation.

One of the primary advantages of lithium oxide reinforcement is its ability to enhance concrete's resistance to alkali-silica reaction (ASR), a common cause of premature deterioration in concrete structures. By mitigating ASR, lithium oxide reinforcement can significantly extend the service life of structures, potentially reducing life-cycle costs by 15-25% over a 50-year period. This longevity factor is particularly valuable for critical infrastructure projects where replacement or major repairs can be highly disruptive and costly.

The improved durability also translates to reduced maintenance requirements. Structures reinforced with lithium oxide typically exhibit fewer cracks, spalling, and other forms of degradation, leading to lower inspection and repair frequencies. Studies have shown that maintenance costs can be reduced by up to 30% over the lifespan of the structure, providing substantial savings for infrastructure owners and managers.

From a performance standpoint, lithium oxide reinforcement offers enhanced structural integrity under various loading conditions. This improved strength and resilience can allow for more efficient design solutions, potentially reducing material usage and associated costs in some applications. Additionally, the increased durability can lead to improved safety margins, which may have indirect economic benefits in terms of risk mitigation and insurance considerations.

However, the cost-effectiveness of lithium oxide reinforcement can vary depending on the specific application and environmental conditions. In regions with high exposure to de-icing salts or marine environments, the benefits are often more pronounced due to the increased protection against chloride-induced corrosion. Conversely, in less aggressive environments, the cost-benefit ratio may be less favorable, requiring careful evaluation on a project-by-project basis.

It's also important to consider the potential for reduced environmental impact. The extended service life and reduced maintenance needs associated with lithium oxide reinforcement can lead to lower carbon footprints over time, aligning with sustainability goals and potentially offering economic advantages in regions with carbon pricing mechanisms or green building incentives.

In conclusion, while the initial costs of lithium oxide reinforcement are higher, the long-term economic benefits in terms of durability, maintenance reduction, and potential design efficiencies make it an attractive option for many civil engineering applications. However, a thorough analysis of specific project requirements, environmental conditions, and life-cycle costs is essential to determine the optimal reinforcement strategy for each unique situation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!