MXene as Conductive Agent in Anti-Static Materials

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MXene Background and Goals

MXene, a class of two-dimensional transition metal carbides and nitrides, has emerged as a promising material in various applications, including anti-static materials. Discovered in 2011 by researchers at Drexel University, MXenes have garnered significant attention due to their unique combination of properties, including high electrical conductivity, mechanical strength, and surface functionality.

The development of MXene as a conductive agent in anti-static materials represents a convergence of nanotechnology and materials science. This research aims to address the growing demand for advanced anti-static solutions in industries such as electronics, aerospace, and automotive, where static electricity can cause significant damage to sensitive components and pose safety risks.

The primary goal of this research is to explore and optimize the integration of MXene into anti-static materials, leveraging its exceptional electrical conductivity and two-dimensional structure. By incorporating MXene as a conductive agent, researchers aim to enhance the overall performance of anti-static materials, potentially offering superior static dissipation capabilities compared to traditional conductive fillers such as carbon black or metal particles.

A key objective is to understand the fundamental mechanisms by which MXene interacts with polymer matrices in anti-static composites. This includes investigating the dispersion behavior of MXene sheets, their impact on the mechanical properties of the host material, and the resulting electrical conductivity network formed within the composite.

Another critical aspect of this research is to explore the scalability and cost-effectiveness of MXene-based anti-static materials. As a relatively new material, the production and integration of MXene into commercial products present challenges that need to be addressed to ensure its viability in real-world applications.

Furthermore, this research aims to investigate the long-term stability and environmental impact of MXene-enhanced anti-static materials. Understanding the degradation mechanisms and potential release of nanoparticles is crucial for ensuring the safety and sustainability of these advanced materials.

By focusing on these objectives, the research on MXene as a conductive agent in anti-static materials seeks to push the boundaries of material science and offer innovative solutions to industries grappling with static electricity challenges. The successful development of MXene-based anti-static materials could lead to significant advancements in electronics protection, workplace safety, and the overall performance of products in static-sensitive environments.

The development of MXene as a conductive agent in anti-static materials represents a convergence of nanotechnology and materials science. This research aims to address the growing demand for advanced anti-static solutions in industries such as electronics, aerospace, and automotive, where static electricity can cause significant damage to sensitive components and pose safety risks.

The primary goal of this research is to explore and optimize the integration of MXene into anti-static materials, leveraging its exceptional electrical conductivity and two-dimensional structure. By incorporating MXene as a conductive agent, researchers aim to enhance the overall performance of anti-static materials, potentially offering superior static dissipation capabilities compared to traditional conductive fillers such as carbon black or metal particles.

A key objective is to understand the fundamental mechanisms by which MXene interacts with polymer matrices in anti-static composites. This includes investigating the dispersion behavior of MXene sheets, their impact on the mechanical properties of the host material, and the resulting electrical conductivity network formed within the composite.

Another critical aspect of this research is to explore the scalability and cost-effectiveness of MXene-based anti-static materials. As a relatively new material, the production and integration of MXene into commercial products present challenges that need to be addressed to ensure its viability in real-world applications.

Furthermore, this research aims to investigate the long-term stability and environmental impact of MXene-enhanced anti-static materials. Understanding the degradation mechanisms and potential release of nanoparticles is crucial for ensuring the safety and sustainability of these advanced materials.

By focusing on these objectives, the research on MXene as a conductive agent in anti-static materials seeks to push the boundaries of material science and offer innovative solutions to industries grappling with static electricity challenges. The successful development of MXene-based anti-static materials could lead to significant advancements in electronics protection, workplace safety, and the overall performance of products in static-sensitive environments.

Anti-Static Market Analysis

The anti-static materials market has experienced significant growth in recent years, driven by the increasing demand for static control solutions across various industries. This market segment is closely tied to the electronics, automotive, healthcare, and packaging sectors, where static electricity can cause damage to sensitive components or create safety hazards.

In the electronics industry, the proliferation of miniaturized devices and the growing complexity of electronic components have heightened the need for effective anti-static materials. The semiconductor manufacturing process, in particular, requires stringent static control measures to prevent damage to sensitive integrated circuits and microchips.

The automotive sector has also emerged as a key driver for anti-static materials, especially with the rise of electric and hybrid vehicles. These vehicles contain numerous electronic systems that are susceptible to static discharge, necessitating the use of anti-static materials in various parts of the vehicle, including interior components and fuel systems.

In healthcare, the use of anti-static materials is crucial in environments where static electricity can interfere with sensitive medical equipment or pose risks in areas with flammable gases. Operating rooms, laboratories, and pharmaceutical manufacturing facilities are prime examples of where anti-static solutions are in high demand.

The packaging industry, particularly for electronic components and sensitive devices, relies heavily on anti-static materials to protect products during storage and transportation. This includes anti-static bags, foams, and packaging materials that prevent static buildup and discharge.

Market analysts project a compound annual growth rate (CAGR) for the anti-static materials market in the range of 6-8% over the next five years. This growth is attributed to the expanding electronics and semiconductor industries, particularly in emerging economies, as well as the increasing adoption of anti-static measures in various manufacturing processes.

The Asia-Pacific region dominates the anti-static materials market, owing to its strong presence in electronics manufacturing. Countries like China, Japan, South Korea, and Taiwan are major consumers and producers of anti-static materials. North America and Europe follow, with significant demand from high-tech industries and stringent safety regulations driving market growth.

As industries continue to evolve and adopt more sophisticated technologies, the demand for advanced anti-static solutions is expected to rise. This presents opportunities for innovative materials like MXene, which could potentially offer superior conductive properties and enhanced performance compared to traditional anti-static agents. The integration of such novel materials could reshape the anti-static market landscape, providing more effective and versatile solutions for static control across various applications.

In the electronics industry, the proliferation of miniaturized devices and the growing complexity of electronic components have heightened the need for effective anti-static materials. The semiconductor manufacturing process, in particular, requires stringent static control measures to prevent damage to sensitive integrated circuits and microchips.

The automotive sector has also emerged as a key driver for anti-static materials, especially with the rise of electric and hybrid vehicles. These vehicles contain numerous electronic systems that are susceptible to static discharge, necessitating the use of anti-static materials in various parts of the vehicle, including interior components and fuel systems.

In healthcare, the use of anti-static materials is crucial in environments where static electricity can interfere with sensitive medical equipment or pose risks in areas with flammable gases. Operating rooms, laboratories, and pharmaceutical manufacturing facilities are prime examples of where anti-static solutions are in high demand.

The packaging industry, particularly for electronic components and sensitive devices, relies heavily on anti-static materials to protect products during storage and transportation. This includes anti-static bags, foams, and packaging materials that prevent static buildup and discharge.

Market analysts project a compound annual growth rate (CAGR) for the anti-static materials market in the range of 6-8% over the next five years. This growth is attributed to the expanding electronics and semiconductor industries, particularly in emerging economies, as well as the increasing adoption of anti-static measures in various manufacturing processes.

The Asia-Pacific region dominates the anti-static materials market, owing to its strong presence in electronics manufacturing. Countries like China, Japan, South Korea, and Taiwan are major consumers and producers of anti-static materials. North America and Europe follow, with significant demand from high-tech industries and stringent safety regulations driving market growth.

As industries continue to evolve and adopt more sophisticated technologies, the demand for advanced anti-static solutions is expected to rise. This presents opportunities for innovative materials like MXene, which could potentially offer superior conductive properties and enhanced performance compared to traditional anti-static agents. The integration of such novel materials could reshape the anti-static market landscape, providing more effective and versatile solutions for static control across various applications.

MXene Challenges in Anti-Static Applications

Despite the promising potential of MXene as a conductive agent in anti-static materials, several challenges hinder its widespread adoption and optimal performance. One of the primary obstacles is the stability of MXene in various environments. MXene tends to oxidize when exposed to air and moisture, which can significantly degrade its electrical conductivity and overall performance as an anti-static agent. This oxidation process can lead to reduced effectiveness over time, limiting the long-term reliability of MXene-based anti-static materials.

Another challenge lies in the production and processing of MXene for large-scale applications. Current synthesis methods, such as selective etching of MAX phases, are often complex and time-consuming. Scaling up these processes while maintaining consistent quality and properties of MXene sheets remains a significant hurdle. Additionally, the high cost associated with MXene production poses a barrier to its widespread industrial adoption in anti-static applications.

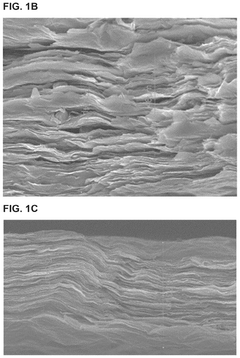

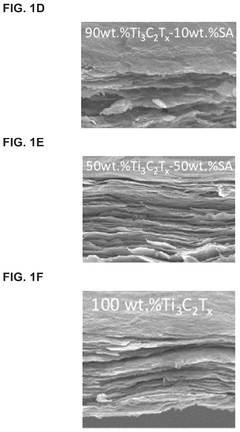

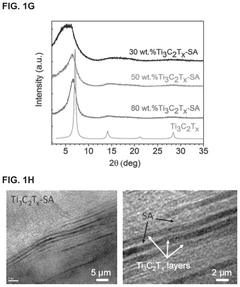

The dispersion and integration of MXene into various polymer matrices present another set of challenges. Achieving uniform dispersion of MXene sheets within the host material is crucial for optimal anti-static performance. However, the strong van der Waals interactions between MXene sheets can lead to agglomeration, resulting in non-uniform distribution and reduced effectiveness. Developing suitable dispersion techniques and compatible surface modifications for MXene to enhance its compatibility with different polymer matrices is an ongoing area of research.

Furthermore, the mechanical properties of MXene-based anti-static materials need improvement. While MXene itself possesses excellent mechanical strength, its incorporation into polymers can sometimes lead to a decrease in the overall mechanical properties of the composite. Balancing the trade-off between electrical conductivity and mechanical strength remains a challenge in developing high-performance anti-static materials.

The environmental impact and potential toxicity of MXene are also areas of concern. As a relatively new material, the long-term effects of MXene on human health and the environment are not yet fully understood. Comprehensive studies on the toxicology and environmental fate of MXene are necessary to ensure its safe and sustainable use in anti-static applications.

Lastly, the optimization of MXene's anti-static performance across a wide range of environmental conditions poses a challenge. Factors such as temperature, humidity, and pH can significantly affect the conductivity and anti-static properties of MXene-based materials. Developing robust formulations that maintain consistent performance under varying conditions is crucial for the practical implementation of MXene in diverse anti-static applications.

Another challenge lies in the production and processing of MXene for large-scale applications. Current synthesis methods, such as selective etching of MAX phases, are often complex and time-consuming. Scaling up these processes while maintaining consistent quality and properties of MXene sheets remains a significant hurdle. Additionally, the high cost associated with MXene production poses a barrier to its widespread industrial adoption in anti-static applications.

The dispersion and integration of MXene into various polymer matrices present another set of challenges. Achieving uniform dispersion of MXene sheets within the host material is crucial for optimal anti-static performance. However, the strong van der Waals interactions between MXene sheets can lead to agglomeration, resulting in non-uniform distribution and reduced effectiveness. Developing suitable dispersion techniques and compatible surface modifications for MXene to enhance its compatibility with different polymer matrices is an ongoing area of research.

Furthermore, the mechanical properties of MXene-based anti-static materials need improvement. While MXene itself possesses excellent mechanical strength, its incorporation into polymers can sometimes lead to a decrease in the overall mechanical properties of the composite. Balancing the trade-off between electrical conductivity and mechanical strength remains a challenge in developing high-performance anti-static materials.

The environmental impact and potential toxicity of MXene are also areas of concern. As a relatively new material, the long-term effects of MXene on human health and the environment are not yet fully understood. Comprehensive studies on the toxicology and environmental fate of MXene are necessary to ensure its safe and sustainable use in anti-static applications.

Lastly, the optimization of MXene's anti-static performance across a wide range of environmental conditions poses a challenge. Factors such as temperature, humidity, and pH can significantly affect the conductivity and anti-static properties of MXene-based materials. Developing robust formulations that maintain consistent performance under varying conditions is crucial for the practical implementation of MXene in diverse anti-static applications.

Current MXene Anti-Static Solutions

01 MXene composition and structure for enhanced conductivity

The conductivity of MXenes can be improved by optimizing their composition and structure. This includes controlling the type and ratio of transition metals, adjusting the number of atomic layers, and modifying the surface terminations. These factors influence the electronic properties and charge carrier mobility of MXenes, resulting in enhanced electrical conductivity.- MXene composition and structure for enhanced conductivity: The conductivity of MXenes can be improved by optimizing their composition and structure. This includes controlling the thickness of MXene layers, adjusting the interlayer spacing, and incorporating specific functional groups or dopants. These modifications can enhance electron mobility and increase the overall conductivity of MXene-based materials.

- Surface modification of MXenes for conductivity enhancement: Surface modification techniques can be applied to MXenes to improve their electrical conductivity. This may involve the attachment of conductive polymers, metal nanoparticles, or other functional groups to the MXene surface. These modifications can create additional conductive pathways and improve charge transfer, resulting in enhanced overall conductivity.

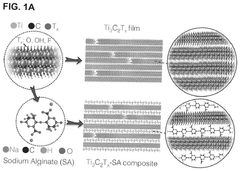

- MXene-based composite materials for improved conductivity: Combining MXenes with other conductive materials to form composites can lead to improved electrical conductivity. This approach may involve incorporating MXenes into polymer matrices, creating hybrid structures with carbon nanotubes or graphene, or developing MXene-metal composites. These composite materials can exhibit synergistic effects, resulting in enhanced conductivity compared to individual components.

- Defect engineering in MXenes for conductivity optimization: Introducing controlled defects or vacancies in MXene structures can be used to tailor their electronic properties and improve conductivity. This may involve creating atomic-scale defects, manipulating the edge structure of MXene flakes, or inducing specific crystal phase transitions. These defect engineering approaches can modify the band structure and charge carrier dynamics of MXenes, leading to enhanced conductivity.

- MXene processing techniques for conductivity enhancement: Various processing techniques can be employed to improve the conductivity of MXene-based materials. These may include optimized exfoliation methods, controlled drying processes, and post-synthesis treatments such as annealing or chemical reduction. By refining these processing techniques, the quality and conductivity of MXene materials can be significantly enhanced for various applications.

02 Doping and functionalization of MXenes

Doping MXenes with various elements or functionalizing their surfaces can significantly alter their electronic properties. This approach can introduce additional charge carriers or modify the band structure, leading to improved conductivity. Careful selection of dopants or functional groups can tailor the conductivity for specific applications.Expand Specific Solutions03 MXene-based composite materials for conductivity enhancement

Incorporating MXenes into composite materials with other conductive components can synergistically enhance overall conductivity. This includes creating hybrid structures with carbon nanotubes, graphene, or conductive polymers. The resulting composites often exhibit improved electrical properties compared to individual components.Expand Specific Solutions04 Processing techniques for optimizing MXene conductivity

Various processing techniques can be employed to optimize the conductivity of MXenes. These include methods for exfoliation, delamination, and assembly of MXene flakes, as well as post-processing treatments such as annealing or chemical reduction. These techniques can help minimize defects and improve the connectivity between MXene sheets.Expand Specific Solutions05 MXene-based electrodes and conductive films

MXenes can be used to create highly conductive electrodes and films for various applications. This involves developing methods for uniform deposition, controlling film thickness, and ensuring good adhesion to substrates. The resulting conductive films can be used in electronic devices, sensors, or energy storage systems.Expand Specific Solutions

Key MXene Industry Players

The research on MXene as a conductive agent in anti-static materials is in an emerging stage, with growing market potential due to increasing demand for advanced materials in electronics and energy storage. The technology is still evolving, with moderate maturity levels as researchers explore its unique properties and applications. Key players like Murata Manufacturing, Drexel University, and Peking University are driving innovation in this field. The competitive landscape is characterized by collaborations between academic institutions and industry partners, focusing on improving MXene's synthesis, scalability, and integration into anti-static materials. As the technology advances, we can expect increased commercialization efforts and market expansion in the coming years.

Trustees of the University of Pennsylvania

Technical Solution: The University of Pennsylvania has contributed to the research on MXene as a conductive agent in anti-static materials through their work on MXene-based aerogels and foams. Their approach involves creating ultralight, highly porous structures that maintain the excellent conductivity of MXene while providing enhanced surface area and flexibility. These MXene aerogels have shown promising results as anti-static materials in applications such as electromagnetic interference (EMI) shielding and electrostatic discharge (ESD) protection[11]. The university has also explored the use of MXene in combination with other materials, such as cellulose nanofibers, to create environmentally friendly and biodegradable anti-static composites[12].

Strengths: Development of novel MXene-based structures (aerogels and foams), focus on environmentally friendly materials, and applications in EMI shielding and ESD protection. Weaknesses: Potential challenges in scaling up production of complex MXene structures and maintaining structural integrity in harsh environments.

Peking University

Technical Solution: Peking University has developed a novel approach to using MXene as a conductive agent in anti-static materials, focusing on enhancing the dispersion and stability of MXene in polymer matrices. Their method involves surface modification of Ti3C2Tx MXene nanosheets with silane coupling agents, which improves compatibility with various polymers[4]. This technique allows for the creation of anti-static composites with a percolation threshold as low as 0.1 vol% MXene[5]. The university has also explored the use of MXene in combination with other conductive fillers, such as carbon nanotubes, to create synergistic effects that further enhance anti-static properties[6].

Strengths: Improved MXene dispersion and stability in polymers, low percolation threshold, and synergistic effects with other conductive fillers. Weaknesses: Complexity of surface modification processes and potential impact on MXene's intrinsic properties.

MXene Conductive Mechanisms

Two-dimensional metal carbide, nitride, and carbonitride films and composites for EMI shielding

PatentWO2017184957A1

Innovation

- The use of two-dimensional (2D) transition metal carbides, nitrides, and carbonitrides, specifically MXene films and MXene-polymer composites, which provide high EMI shielding effectiveness due to their exceptional electrical conductivity and mechanical properties, outperforming traditional materials by offering lightweight, flexible, and easily fabricated solutions.

Two-dimensional metal carbide, nitride, and carbonitride films and composites for EMI shielding

PatentPendingUS20240365522A1

Innovation

- The use of two-dimensional transition metal carbides, nitrides, and carbonitrides, specifically MXene films and MXene-polymer composites, which are applied as coatings to objects to provide high EMI shielding due to their exceptional electrical conductivity and mechanical properties.

MXene Environmental Impact

The environmental impact of MXene as a conductive agent in anti-static materials is a crucial aspect to consider in the development and application of this technology. MXene, a two-dimensional transition metal carbide or nitride, has shown promising potential in various applications, including anti-static materials. However, its environmental implications must be thoroughly examined to ensure sustainable and responsible use.

One of the primary environmental concerns associated with MXene is its production process. The synthesis of MXene typically involves the use of hydrofluoric acid (HF) or other strong acids, which can pose significant environmental risks if not properly managed. These acids are highly corrosive and toxic, requiring stringent safety measures and waste management protocols. Research is ongoing to develop alternative, more environmentally friendly synthesis methods that reduce or eliminate the use of hazardous chemicals.

The potential release of MXene nanoparticles into the environment during the production, use, or disposal of anti-static materials is another area of concern. Nanoparticles can have unique interactions with biological systems and ecosystems, and their long-term effects are not yet fully understood. Studies are needed to assess the potential bioaccumulation and toxicity of MXene in various environmental compartments, including soil, water, and air.

On the positive side, the use of MXene as a conductive agent in anti-static materials may lead to improved product performance and longevity. This could potentially reduce the overall environmental impact by decreasing the need for frequent replacements or the use of less efficient alternatives. Additionally, the high conductivity of MXene may allow for the use of smaller quantities of the material to achieve the desired anti-static properties, potentially reducing resource consumption and waste generation.

The recyclability and end-of-life management of MXene-containing anti-static materials are also important considerations. Research is needed to develop effective recycling processes that can recover and reuse MXene from discarded products, minimizing waste and promoting a circular economy approach. Furthermore, the potential for MXene to leach from products during use or disposal must be evaluated to prevent unintended environmental contamination.

As with any emerging technology, a comprehensive life cycle assessment (LCA) of MXene-based anti-static materials is essential to fully understand their environmental impact. This assessment should consider all stages of the material's life cycle, from raw material extraction and processing to product manufacturing, use, and disposal. Such studies will help identify areas for improvement and guide the development of more sustainable practices in the production and application of MXene-based anti-static materials.

One of the primary environmental concerns associated with MXene is its production process. The synthesis of MXene typically involves the use of hydrofluoric acid (HF) or other strong acids, which can pose significant environmental risks if not properly managed. These acids are highly corrosive and toxic, requiring stringent safety measures and waste management protocols. Research is ongoing to develop alternative, more environmentally friendly synthesis methods that reduce or eliminate the use of hazardous chemicals.

The potential release of MXene nanoparticles into the environment during the production, use, or disposal of anti-static materials is another area of concern. Nanoparticles can have unique interactions with biological systems and ecosystems, and their long-term effects are not yet fully understood. Studies are needed to assess the potential bioaccumulation and toxicity of MXene in various environmental compartments, including soil, water, and air.

On the positive side, the use of MXene as a conductive agent in anti-static materials may lead to improved product performance and longevity. This could potentially reduce the overall environmental impact by decreasing the need for frequent replacements or the use of less efficient alternatives. Additionally, the high conductivity of MXene may allow for the use of smaller quantities of the material to achieve the desired anti-static properties, potentially reducing resource consumption and waste generation.

The recyclability and end-of-life management of MXene-containing anti-static materials are also important considerations. Research is needed to develop effective recycling processes that can recover and reuse MXene from discarded products, minimizing waste and promoting a circular economy approach. Furthermore, the potential for MXene to leach from products during use or disposal must be evaluated to prevent unintended environmental contamination.

As with any emerging technology, a comprehensive life cycle assessment (LCA) of MXene-based anti-static materials is essential to fully understand their environmental impact. This assessment should consider all stages of the material's life cycle, from raw material extraction and processing to product manufacturing, use, and disposal. Such studies will help identify areas for improvement and guide the development of more sustainable practices in the production and application of MXene-based anti-static materials.

MXene Scalability and Cost Analysis

The scalability and cost analysis of MXene as a conductive agent in anti-static materials is crucial for its potential widespread adoption in industrial applications. MXene production currently faces challenges in scaling up from laboratory to industrial levels. The primary bottleneck lies in the etching process, which requires careful control of reaction conditions and is time-consuming. However, recent advancements in continuous flow synthesis methods show promise for increasing production rates and maintaining consistent quality.

Cost analysis of MXene production reveals that raw material expenses, particularly for the MAX phase precursors and etching agents, constitute a significant portion of the overall cost. The price of titanium-based MAX phases, commonly used for Ti3C2Tx MXene synthesis, remains relatively high due to limited commercial availability. Efforts to develop alternative, more cost-effective precursors are ongoing, with potential candidates including abundant clay minerals.

Energy consumption during the synthesis process also contributes substantially to the production cost. The high-temperature sintering required for MAX phase preparation and the subsequent etching process are energy-intensive steps. Researchers are exploring more energy-efficient synthesis routes, such as electrochemical etching and microwave-assisted methods, to reduce energy consumption and associated costs.

Post-processing steps, including delamination and purification, present additional challenges for large-scale production. Current methods often involve time-consuming centrifugation or filtration processes, which are difficult to scale up efficiently. Development of continuous separation techniques and optimization of delamination protocols are active areas of research aimed at improving scalability and reducing costs.

The environmental impact and sustainability of MXene production are also important considerations in scalability and cost analysis. The use of strong acids in the etching process raises concerns about waste management and potential environmental hazards. Efforts to develop greener synthesis routes, such as using milder etching agents or implementing closed-loop recycling systems, are underway to address these issues and potentially reduce long-term costs associated with environmental compliance.

As research progresses and production techniques improve, the cost of MXene is expected to decrease, making it more competitive with existing conductive agents used in anti-static materials. However, the current production scale and associated costs still limit its widespread adoption in commercial applications. Continued investment in research and development, as well as collaboration between academic institutions and industry partners, will be crucial for overcoming these challenges and realizing the full potential of MXene as a conductive agent in anti-static materials.

Cost analysis of MXene production reveals that raw material expenses, particularly for the MAX phase precursors and etching agents, constitute a significant portion of the overall cost. The price of titanium-based MAX phases, commonly used for Ti3C2Tx MXene synthesis, remains relatively high due to limited commercial availability. Efforts to develop alternative, more cost-effective precursors are ongoing, with potential candidates including abundant clay minerals.

Energy consumption during the synthesis process also contributes substantially to the production cost. The high-temperature sintering required for MAX phase preparation and the subsequent etching process are energy-intensive steps. Researchers are exploring more energy-efficient synthesis routes, such as electrochemical etching and microwave-assisted methods, to reduce energy consumption and associated costs.

Post-processing steps, including delamination and purification, present additional challenges for large-scale production. Current methods often involve time-consuming centrifugation or filtration processes, which are difficult to scale up efficiently. Development of continuous separation techniques and optimization of delamination protocols are active areas of research aimed at improving scalability and reducing costs.

The environmental impact and sustainability of MXene production are also important considerations in scalability and cost analysis. The use of strong acids in the etching process raises concerns about waste management and potential environmental hazards. Efforts to develop greener synthesis routes, such as using milder etching agents or implementing closed-loop recycling systems, are underway to address these issues and potentially reduce long-term costs associated with environmental compliance.

As research progresses and production techniques improve, the cost of MXene is expected to decrease, making it more competitive with existing conductive agents used in anti-static materials. However, the current production scale and associated costs still limit its widespread adoption in commercial applications. Continued investment in research and development, as well as collaboration between academic institutions and industry partners, will be crucial for overcoming these challenges and realizing the full potential of MXene as a conductive agent in anti-static materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!