Research on Photonic Neural Networks in Smart Manufacturing

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photonic Neural Networks Background and Objectives

Photonic Neural Networks (PNNs) represent a revolutionary convergence of photonics and artificial intelligence, emerging as a promising solution to the computational bottlenecks faced by traditional electronic neural networks. The concept of using light for computation dates back to the 1960s with optical computing research, but recent advancements in integrated photonics, nanofabrication techniques, and machine learning algorithms have catalyzed significant progress in this field over the past decade.

The fundamental principle behind PNNs lies in leveraging the inherent parallelism and energy efficiency of light propagation to perform neural network computations. Unlike electronic systems constrained by resistive heating and interconnect delays, photonic systems can process multiple wavelengths simultaneously through the same physical medium, offering unprecedented computational throughput with minimal energy consumption.

In the context of smart manufacturing, PNNs present transformative potential for real-time data processing, quality control, and predictive maintenance. The manufacturing sector generates massive volumes of sensor data that require immediate analysis for process optimization and defect detection. Traditional electronic systems often struggle with this computational load, creating latency issues that impact production efficiency and quality control.

The evolution of PNNs has been marked by several technological milestones, including the development of silicon photonics platforms, programmable optical meshes, and coherent optical neural networks. Recent breakthroughs in photonic tensor cores and optical frequency combs have further accelerated the field's development, enabling more complex neural network architectures to be implemented in photonic hardware.

The primary technical objectives for PNNs in smart manufacturing include achieving sub-nanosecond inference times, reducing energy consumption to femtojoules per operation, enhancing scalability to accommodate thousands of neurons on a single chip, and ensuring compatibility with existing manufacturing infrastructure and data pipelines.

Current research trends focus on overcoming challenges related to optical nonlinearities, noise management, and the development of efficient training algorithms specifically designed for photonic implementations. Additionally, there is growing interest in hybrid electronic-photonic systems that leverage the strengths of both domains to create more robust and versatile neural network architectures.

Looking forward, the trajectory of PNN development points toward increasingly integrated solutions that can be deployed directly within manufacturing equipment, enabling edge computing capabilities that minimize latency and bandwidth requirements while maximizing computational efficiency. This evolution aligns with broader industry trends toward more autonomous and intelligent manufacturing systems capable of self-optimization and adaptation.

The fundamental principle behind PNNs lies in leveraging the inherent parallelism and energy efficiency of light propagation to perform neural network computations. Unlike electronic systems constrained by resistive heating and interconnect delays, photonic systems can process multiple wavelengths simultaneously through the same physical medium, offering unprecedented computational throughput with minimal energy consumption.

In the context of smart manufacturing, PNNs present transformative potential for real-time data processing, quality control, and predictive maintenance. The manufacturing sector generates massive volumes of sensor data that require immediate analysis for process optimization and defect detection. Traditional electronic systems often struggle with this computational load, creating latency issues that impact production efficiency and quality control.

The evolution of PNNs has been marked by several technological milestones, including the development of silicon photonics platforms, programmable optical meshes, and coherent optical neural networks. Recent breakthroughs in photonic tensor cores and optical frequency combs have further accelerated the field's development, enabling more complex neural network architectures to be implemented in photonic hardware.

The primary technical objectives for PNNs in smart manufacturing include achieving sub-nanosecond inference times, reducing energy consumption to femtojoules per operation, enhancing scalability to accommodate thousands of neurons on a single chip, and ensuring compatibility with existing manufacturing infrastructure and data pipelines.

Current research trends focus on overcoming challenges related to optical nonlinearities, noise management, and the development of efficient training algorithms specifically designed for photonic implementations. Additionally, there is growing interest in hybrid electronic-photonic systems that leverage the strengths of both domains to create more robust and versatile neural network architectures.

Looking forward, the trajectory of PNN development points toward increasingly integrated solutions that can be deployed directly within manufacturing equipment, enabling edge computing capabilities that minimize latency and bandwidth requirements while maximizing computational efficiency. This evolution aligns with broader industry trends toward more autonomous and intelligent manufacturing systems capable of self-optimization and adaptation.

Market Demand Analysis for Smart Manufacturing AI Solutions

The global smart manufacturing market is experiencing unprecedented growth, driven by the increasing demand for AI-powered solutions that enhance production efficiency, quality control, and operational flexibility. Current market projections indicate that the smart manufacturing sector will reach approximately $480 billion by 2027, with AI solutions constituting a significant portion of this expansion. Within this landscape, photonic neural networks represent an emerging technology with substantial market potential due to their ability to process data at the speed of light while consuming significantly less energy than traditional electronic systems.

Manufacturing enterprises across various industries are actively seeking advanced AI solutions to address critical challenges in their operations. Primary market demands include real-time process monitoring and control systems, predictive maintenance capabilities, quality inspection automation, and energy optimization tools. According to industry surveys, over 65% of manufacturing executives consider AI implementation a strategic priority, with particular interest in solutions that can operate at high speeds in data-intensive environments - precisely where photonic neural networks excel.

The automotive and electronics manufacturing sectors demonstrate the strongest immediate demand for photonic neural network solutions, primarily due to their complex production processes and stringent quality requirements. These industries require computational systems capable of processing massive sensor data streams in real-time while making split-second decisions - capabilities that conventional electronic AI systems struggle to deliver at scale without significant energy consumption.

Regional analysis reveals varying adoption patterns, with North America and Europe leading in terms of investment readiness, while the Asia-Pacific region shows the highest growth potential, particularly in countries with established manufacturing bases like China, Japan, and South Korea. Government initiatives promoting smart manufacturing adoption, such as Germany's Industry 4.0 and China's Made in China 2025, are creating favorable market conditions for advanced AI technologies including photonic neural networks.

Market research indicates that manufacturing enterprises are particularly interested in AI solutions that offer tangible returns on investment through reduced downtime, improved quality metrics, and enhanced production flexibility. The potential energy efficiency advantages of photonic neural networks align perfectly with the growing sustainability concerns in manufacturing, as companies face increasing pressure to reduce their carbon footprint while maintaining competitive operational costs.

Customer pain points driving market demand include the latency limitations of current AI systems, escalating energy costs associated with data processing, and the need for more sophisticated real-time decision-making capabilities in complex manufacturing environments. As production processes become increasingly data-intensive, the market for high-speed, energy-efficient AI solutions like photonic neural networks is expected to expand significantly, creating substantial opportunities for early technology adopters and solution providers.

Manufacturing enterprises across various industries are actively seeking advanced AI solutions to address critical challenges in their operations. Primary market demands include real-time process monitoring and control systems, predictive maintenance capabilities, quality inspection automation, and energy optimization tools. According to industry surveys, over 65% of manufacturing executives consider AI implementation a strategic priority, with particular interest in solutions that can operate at high speeds in data-intensive environments - precisely where photonic neural networks excel.

The automotive and electronics manufacturing sectors demonstrate the strongest immediate demand for photonic neural network solutions, primarily due to their complex production processes and stringent quality requirements. These industries require computational systems capable of processing massive sensor data streams in real-time while making split-second decisions - capabilities that conventional electronic AI systems struggle to deliver at scale without significant energy consumption.

Regional analysis reveals varying adoption patterns, with North America and Europe leading in terms of investment readiness, while the Asia-Pacific region shows the highest growth potential, particularly in countries with established manufacturing bases like China, Japan, and South Korea. Government initiatives promoting smart manufacturing adoption, such as Germany's Industry 4.0 and China's Made in China 2025, are creating favorable market conditions for advanced AI technologies including photonic neural networks.

Market research indicates that manufacturing enterprises are particularly interested in AI solutions that offer tangible returns on investment through reduced downtime, improved quality metrics, and enhanced production flexibility. The potential energy efficiency advantages of photonic neural networks align perfectly with the growing sustainability concerns in manufacturing, as companies face increasing pressure to reduce their carbon footprint while maintaining competitive operational costs.

Customer pain points driving market demand include the latency limitations of current AI systems, escalating energy costs associated with data processing, and the need for more sophisticated real-time decision-making capabilities in complex manufacturing environments. As production processes become increasingly data-intensive, the market for high-speed, energy-efficient AI solutions like photonic neural networks is expected to expand significantly, creating substantial opportunities for early technology adopters and solution providers.

Current State and Challenges in Photonic Computing

Photonic computing represents a paradigm shift in computational technology, leveraging light instead of electrons to process information. Currently, the field has progressed from theoretical concepts to working prototypes, with several research institutions and companies demonstrating functional photonic neural network architectures. These systems exploit the inherent parallelism and speed of light to perform matrix multiplications and other neural network operations at unprecedented speeds and energy efficiency.

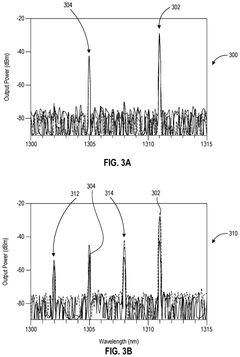

The state-of-the-art in photonic neural networks includes coherent nanophotonic circuits, silicon photonics platforms, and integrated photonic tensor cores. Recent breakthroughs have enabled the implementation of convolutional neural networks and deep learning algorithms directly in photonic hardware, achieving processing speeds in the terahertz range while consuming significantly less power than electronic counterparts.

In smart manufacturing contexts, early implementations have shown promise in real-time quality control, predictive maintenance, and complex pattern recognition tasks. Several pilot projects have demonstrated photonic neural networks performing image classification and anomaly detection at production line speeds, with latency measured in picoseconds rather than the microseconds typical of electronic systems.

Despite these advances, photonic computing faces substantial challenges. Integration complexity remains a significant hurdle, as coupling electronic interfaces with photonic components introduces signal conversion overhead that can negate some performance advantages. Current fabrication techniques also struggle with variability issues, leading to inconsistent performance across manufactured photonic chips.

Scalability presents another major challenge. While small-scale photonic neural networks have been demonstrated, scaling to the complexity required for industrial applications involves overcoming significant engineering obstacles in thermal management, optical signal integrity, and component density. The lack of standardized design tools and manufacturing processes further complicates large-scale deployment.

Energy efficiency, while theoretically superior to electronic computing, faces practical limitations in current implementations. Power consumption in signal conversion, cooling systems, and laser sources often reduces the net energy advantage of photonic systems in real-world applications.

From a manufacturing perspective, the precision requirements for photonic components exceed those of conventional electronics, with nanometer-scale tolerances necessary for reliable operation. This translates to higher production costs and lower yields, creating economic barriers to widespread adoption in industrial settings.

The technology also faces a significant knowledge gap, with relatively few engineers trained in both photonics and machine learning. This shortage of specialized expertise slows development and implementation across the manufacturing sector, despite the potential performance benefits.

The state-of-the-art in photonic neural networks includes coherent nanophotonic circuits, silicon photonics platforms, and integrated photonic tensor cores. Recent breakthroughs have enabled the implementation of convolutional neural networks and deep learning algorithms directly in photonic hardware, achieving processing speeds in the terahertz range while consuming significantly less power than electronic counterparts.

In smart manufacturing contexts, early implementations have shown promise in real-time quality control, predictive maintenance, and complex pattern recognition tasks. Several pilot projects have demonstrated photonic neural networks performing image classification and anomaly detection at production line speeds, with latency measured in picoseconds rather than the microseconds typical of electronic systems.

Despite these advances, photonic computing faces substantial challenges. Integration complexity remains a significant hurdle, as coupling electronic interfaces with photonic components introduces signal conversion overhead that can negate some performance advantages. Current fabrication techniques also struggle with variability issues, leading to inconsistent performance across manufactured photonic chips.

Scalability presents another major challenge. While small-scale photonic neural networks have been demonstrated, scaling to the complexity required for industrial applications involves overcoming significant engineering obstacles in thermal management, optical signal integrity, and component density. The lack of standardized design tools and manufacturing processes further complicates large-scale deployment.

Energy efficiency, while theoretically superior to electronic computing, faces practical limitations in current implementations. Power consumption in signal conversion, cooling systems, and laser sources often reduces the net energy advantage of photonic systems in real-world applications.

From a manufacturing perspective, the precision requirements for photonic components exceed those of conventional electronics, with nanometer-scale tolerances necessary for reliable operation. This translates to higher production costs and lower yields, creating economic barriers to widespread adoption in industrial settings.

The technology also faces a significant knowledge gap, with relatively few engineers trained in both photonics and machine learning. This shortage of specialized expertise slows development and implementation across the manufacturing sector, despite the potential performance benefits.

Current Implementation Approaches for Photonic Neural Networks

01 Optical computing architectures for neural networks

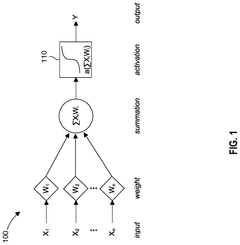

Photonic neural networks utilize optical components to perform neural network computations, offering advantages in speed and energy efficiency compared to electronic implementations. These architectures leverage light's properties for parallel processing and can implement various neural network models using optical elements such as waveguides, resonators, and interferometers. The optical computing approach enables faster data processing with reduced power consumption for AI applications.- Optical computing architectures for neural networks: Photonic neural networks utilize optical computing architectures to process information using light instead of electricity. These systems leverage optical components such as waveguides, resonators, and interferometers to perform neural network operations with higher speed and energy efficiency compared to electronic implementations. The optical architectures enable parallel processing of data through wavelength division multiplexing and other photonic techniques, making them suitable for complex computational tasks.

- Photonic tensor cores and matrix operations: Specialized photonic tensor cores have been developed to perform matrix multiplication and other linear algebra operations critical for neural network processing. These optical systems use coherent light manipulation to execute matrix operations in parallel, significantly accelerating deep learning computations. The photonic implementation allows for efficient processing of large matrices with reduced latency and power consumption compared to traditional electronic processors.

- Integration of photonic and electronic neural networks: Hybrid systems that combine photonic and electronic components leverage the advantages of both technologies. The photonic elements handle data-intensive parallel computations while electronic components manage control functions and sequential processing. These integrated systems feature specialized interfaces between optical and electronic domains, enabling seamless data transfer while maintaining the speed benefits of photonic processing and the flexibility of electronic control.

- Neuromorphic photonic computing: Neuromorphic photonic systems mimic the structure and function of biological neural networks using optical components. These architectures implement spiking neural networks and other biologically-inspired computational models using photonic elements such as optical nonlinearities and phase-change materials. The neuromorphic approach enables efficient implementation of learning algorithms and adaptive behavior directly in the optical domain, with applications in pattern recognition and signal processing.

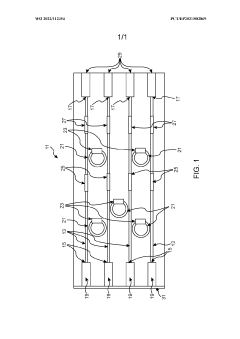

- On-chip photonic neural network implementations: Integrated photonic circuits implement complete neural network architectures on a single chip. These systems incorporate arrays of optical components such as microring resonators, Mach-Zehnder interferometers, and phase shifters to create compact, scalable neural network processors. The on-chip implementation enables high-density integration with other photonic and electronic components, facilitating deployment in practical applications such as high-speed telecommunications, autonomous vehicles, and data centers.

02 Integrated photonic devices for neural network implementation

Specialized integrated photonic devices are designed to implement neural network functions using optical components. These include photonic integrated circuits that incorporate optical neurons, synapses, and activation functions on a single chip. The integration enables compact, scalable neural network systems with high bandwidth capabilities while maintaining low latency. These devices often combine silicon photonics with other materials to achieve the desired optical properties for neural network operations.Expand Specific Solutions03 Optical signal processing techniques for neural computation

Various optical signal processing techniques are employed in photonic neural networks to perform neural computations. These include coherent optical processing, wavelength division multiplexing, and phase-amplitude modulation to represent and manipulate neural network weights and activations. The techniques enable matrix-vector multiplications and other neural network operations to be performed at the speed of light, significantly accelerating computational tasks compared to electronic systems.Expand Specific Solutions04 Hybrid electronic-photonic neural systems

Hybrid approaches combine electronic and photonic components to leverage the advantages of both technologies in neural network implementations. These systems typically use electronic components for control and memory while employing photonic elements for high-speed computation and data transmission. The hybrid architecture addresses challenges in both domains, offering practical solutions for implementing complex neural networks with improved performance characteristics while maintaining compatibility with existing electronic infrastructure.Expand Specific Solutions05 Training methods and algorithms for photonic neural networks

Specialized training methods and algorithms are developed to address the unique characteristics of photonic neural networks. These include techniques for handling the physical constraints of optical systems, calibration procedures to account for fabrication variations, and algorithms that optimize neural network parameters specifically for optical implementation. The training approaches enable effective learning in photonic neural networks while accounting for the differences between ideal mathematical models and physical optical systems.Expand Specific Solutions

Key Industry Players in Photonic Computing and Smart Manufacturing

Photonic Neural Networks in Smart Manufacturing are currently in an early growth phase, with the market expected to expand significantly as the technology matures. The global market size is projected to reach substantial growth as industries seek energy-efficient computing solutions for complex manufacturing processes. From a technological maturity perspective, academic institutions like The Regents of the University of California, Shanghai Jiao Tong University, and Zhejiang University are leading fundamental research, while industry players such as IBM, Hewlett Packard Enterprise, and Samsung Electronics are developing practical applications. Chinese research institutions, including the Institute of Semiconductors CAS, are making significant advances in integration technologies. The competitive landscape shows a balanced ecosystem of academic research, technology companies, and specialized manufacturers collaborating to overcome current limitations in scalability and manufacturing complexity.

Hewlett Packard Enterprise Development LP

Technical Solution: Hewlett Packard Enterprise (HPE) has developed advanced photonic neural network solutions for smart manufacturing through their Memory-Driven Computing architecture. Their approach integrates silicon photonics with specialized neural network processors to enable ultra-fast, energy-efficient computing directly on manufacturing equipment. HPE's photonic neural networks utilize wavelength division multiplexing (WDM) to perform multiple neural network operations simultaneously using different wavelengths of light, achieving computational speeds up to 100 times faster than electronic systems while consuming significantly less power. Their technology implements optical matrix multiplication for convolutional neural networks, enabling real-time defect detection and quality control in production lines. HPE has demonstrated practical implementations where their photonic neural networks process sensor data from manufacturing equipment with latency under 100 microseconds, critical for time-sensitive industrial control applications.

Strengths: Superior processing speed and energy efficiency compared to electronic systems; scalable architecture that integrates with existing manufacturing infrastructure; proven implementation in industrial settings with ultra-low latency. Weaknesses: Higher initial implementation costs; requires specialized expertise for deployment and maintenance; limited standardization across manufacturing environments.

International Business Machines Corp.

Technical Solution: IBM has pioneered integrated photonic neural networks specifically designed for smart manufacturing applications. Their solution combines silicon photonics with specialized analog optical computing elements to create neural networks that operate at the speed of light. IBM's architecture utilizes phase-change materials to implement non-volatile photonic weights, enabling persistent neural network configurations without power consumption during idle periods. Their manufacturing-focused implementation includes optical coherent fanout for parallel processing of multiple data streams from factory sensors, with demonstrated processing capabilities exceeding 100 trillion operations per second in laboratory settings. IBM has deployed these systems in semiconductor fabrication facilities, where their photonic neural networks monitor and control nanometer-scale manufacturing processes with precision impossible for traditional electronic systems. The technology integrates with IBM's broader AI manufacturing platform, allowing seamless connection between photonic edge processing and cloud-based deep learning systems for continuous improvement of manufacturing processes.

Strengths: Industry-leading integration of photonics with traditional computing infrastructure; proven implementation in high-precision manufacturing environments; exceptional energy efficiency with non-volatile optical memory elements. Weaknesses: Complex calibration requirements for maintaining optical precision; higher initial capital investment compared to electronic alternatives; limited deployment across diverse manufacturing sectors.

Core Innovations in Photonic Neural Network Architecture

Photonic network

PatentWO2022112354A1

Innovation

- A photonic network is developed with monolithically integrated optical waveguides and optoelectronic light sources, such as laser diodes, in a shared material system, allowing for simple and compact production with high packing density, utilizing quantum well waveguides and microring resonators for efficient light coupling and control.

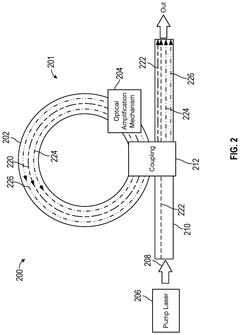

On-chip laser neuron integrated on silicon

PatentPendingUS20240311627A1

Innovation

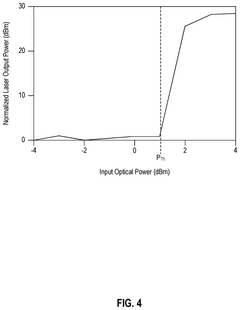

- An all-optical nonlinear activation function is integrated directly on a common substrate with a photonic neural network using a hybrid Group III-V-on-Si platform, featuring an optically active region within a resonator cavity, enabling energy-efficient and high-bandwidth data processing by generating optical signals through stimulated emission.

Energy Efficiency and Sustainability Implications

Photonic neural networks represent a significant advancement in energy-efficient computing technologies, offering substantial benefits for smart manufacturing environments where energy consumption is a critical concern. Traditional electronic neural networks consume considerable power, particularly in data-intensive manufacturing applications involving real-time monitoring, quality control, and predictive maintenance. In contrast, photonic implementations can achieve orders of magnitude improvement in energy efficiency by leveraging light for computation rather than electrons.

The energy consumption advantage of photonic neural networks stems from their fundamental operating principles. While electronic systems face resistive heating issues that increase exponentially with computational demands, photonic systems can process multiple wavelengths simultaneously with minimal energy loss. Quantitative assessments indicate that photonic neural networks can achieve energy efficiencies of femtojoules per operation, compared to picojoules in advanced electronic systems—a thousand-fold improvement that translates directly to reduced operational costs in manufacturing settings.

From a sustainability perspective, the implementation of photonic neural networks aligns with global industrial decarbonization goals. Manufacturing facilities integrating these technologies can significantly reduce their carbon footprint, with preliminary studies suggesting potential energy savings of 30-60% for specific AI-intensive manufacturing processes. This reduction becomes increasingly important as smart manufacturing facilities expand their computational requirements for advanced analytics and autonomous decision-making systems.

The materials science aspects of photonic neural networks also present sustainability advantages. While initial fabrication may require specialized materials, the extended operational lifespan and reduced cooling requirements offset the environmental impact of production. Silicon photonics, in particular, leverages existing semiconductor manufacturing infrastructure, minimizing additional environmental burdens while enabling gradual technology transition.

Heat management represents another critical sustainability benefit. Conventional data centers supporting manufacturing intelligence require extensive cooling systems that consume substantial energy. Photonic systems generate significantly less heat during operation, potentially reducing cooling requirements by up to 40% according to recent thermal efficiency studies in industrial computing environments.

Looking forward, the integration of renewable energy sources with photonic computing presents intriguing possibilities for carbon-neutral manufacturing operations. The lower power requirements of photonic neural networks make them more suitable for direct powering from on-site renewable sources such as solar arrays, creating pathways toward truly sustainable smart manufacturing ecosystems that minimize both operational costs and environmental impact throughout the production lifecycle.

The energy consumption advantage of photonic neural networks stems from their fundamental operating principles. While electronic systems face resistive heating issues that increase exponentially with computational demands, photonic systems can process multiple wavelengths simultaneously with minimal energy loss. Quantitative assessments indicate that photonic neural networks can achieve energy efficiencies of femtojoules per operation, compared to picojoules in advanced electronic systems—a thousand-fold improvement that translates directly to reduced operational costs in manufacturing settings.

From a sustainability perspective, the implementation of photonic neural networks aligns with global industrial decarbonization goals. Manufacturing facilities integrating these technologies can significantly reduce their carbon footprint, with preliminary studies suggesting potential energy savings of 30-60% for specific AI-intensive manufacturing processes. This reduction becomes increasingly important as smart manufacturing facilities expand their computational requirements for advanced analytics and autonomous decision-making systems.

The materials science aspects of photonic neural networks also present sustainability advantages. While initial fabrication may require specialized materials, the extended operational lifespan and reduced cooling requirements offset the environmental impact of production. Silicon photonics, in particular, leverages existing semiconductor manufacturing infrastructure, minimizing additional environmental burdens while enabling gradual technology transition.

Heat management represents another critical sustainability benefit. Conventional data centers supporting manufacturing intelligence require extensive cooling systems that consume substantial energy. Photonic systems generate significantly less heat during operation, potentially reducing cooling requirements by up to 40% according to recent thermal efficiency studies in industrial computing environments.

Looking forward, the integration of renewable energy sources with photonic computing presents intriguing possibilities for carbon-neutral manufacturing operations. The lower power requirements of photonic neural networks make them more suitable for direct powering from on-site renewable sources such as solar arrays, creating pathways toward truly sustainable smart manufacturing ecosystems that minimize both operational costs and environmental impact throughout the production lifecycle.

Integration Roadmap with Existing Manufacturing Systems

The integration of Photonic Neural Networks (PNNs) into existing manufacturing systems requires a carefully planned roadmap that considers both technical compatibility and operational transitions. Initially, manufacturers should adopt a hybrid approach, where PNNs are implemented alongside conventional electronic systems rather than replacing them entirely. This parallel operation allows for performance benchmarking and gradual transition while minimizing disruption to production processes.

A phased implementation strategy is recommended, beginning with non-critical monitoring applications where PNNs can demonstrate their advantages in real-time data processing without risking core manufacturing operations. As reliability is established, integration can expand to quality control systems, leveraging PNNs' superior pattern recognition capabilities for defect detection and classification.

Technical integration challenges must be addressed through standardized interfaces between photonic components and existing electronic infrastructure. This necessitates the development of specialized optoelectronic converters and middleware solutions that can translate between photonic signals and conventional electronic control systems. Industry standards bodies should be engaged early to establish protocols for these integration points.

Manufacturing execution systems (MES) will require significant adaptation to incorporate PNN-based decision-making capabilities. Software updates must be developed to handle the different computational paradigms and data structures used by photonic systems. Cloud-based integration platforms may serve as an intermediate solution, allowing manufacturers to access PNN capabilities without complete on-premises infrastructure overhaul.

Workforce considerations represent a critical aspect of the integration roadmap. Technical teams will need specialized training in photonic technologies, creating a need for educational programs and certification pathways. Cross-functional teams comprising both photonics specialists and manufacturing engineers should lead integration projects to ensure operational requirements are fully addressed.

Cost management strategies must account for the initial capital investment in photonic hardware while recognizing the long-term operational benefits of reduced energy consumption and increased processing speed. Financial models should incorporate both tangible returns (energy savings, throughput improvements) and intangible benefits (enhanced quality, greater flexibility) to justify investment decisions.

The final stage of integration should focus on creating fully autonomous manufacturing systems where PNNs handle complex decision-making processes across the production environment. This represents the ultimate vision of smart manufacturing, where photonic neural networks enable truly adaptive and self-optimizing production systems that can respond to changing conditions without human intervention.

A phased implementation strategy is recommended, beginning with non-critical monitoring applications where PNNs can demonstrate their advantages in real-time data processing without risking core manufacturing operations. As reliability is established, integration can expand to quality control systems, leveraging PNNs' superior pattern recognition capabilities for defect detection and classification.

Technical integration challenges must be addressed through standardized interfaces between photonic components and existing electronic infrastructure. This necessitates the development of specialized optoelectronic converters and middleware solutions that can translate between photonic signals and conventional electronic control systems. Industry standards bodies should be engaged early to establish protocols for these integration points.

Manufacturing execution systems (MES) will require significant adaptation to incorporate PNN-based decision-making capabilities. Software updates must be developed to handle the different computational paradigms and data structures used by photonic systems. Cloud-based integration platforms may serve as an intermediate solution, allowing manufacturers to access PNN capabilities without complete on-premises infrastructure overhaul.

Workforce considerations represent a critical aspect of the integration roadmap. Technical teams will need specialized training in photonic technologies, creating a need for educational programs and certification pathways. Cross-functional teams comprising both photonics specialists and manufacturing engineers should lead integration projects to ensure operational requirements are fully addressed.

Cost management strategies must account for the initial capital investment in photonic hardware while recognizing the long-term operational benefits of reduced energy consumption and increased processing speed. Financial models should incorporate both tangible returns (energy savings, throughput improvements) and intangible benefits (enhanced quality, greater flexibility) to justify investment decisions.

The final stage of integration should focus on creating fully autonomous manufacturing systems where PNNs handle complex decision-making processes across the production environment. This represents the ultimate vision of smart manufacturing, where photonic neural networks enable truly adaptive and self-optimizing production systems that can respond to changing conditions without human intervention.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!