QLED Technology for Brighter and More Vibrant Colors

JUN 19, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QLED Evolution and Objectives

Quantum Dot Light-Emitting Diode (QLED) technology has emerged as a revolutionary advancement in display technology, offering the potential for brighter and more vibrant colors. The evolution of QLED technology can be traced back to the early 2000s when researchers first began exploring the unique properties of quantum dots for display applications.

Initially, quantum dots were primarily used to enhance the color performance of LCD displays. However, as the technology progressed, researchers and engineers recognized the potential for quantum dots to serve as the primary light-emitting component in displays. This realization marked the beginning of QLED development as we know it today.

The primary objective of QLED technology is to achieve superior color reproduction, brightness, and energy efficiency compared to traditional display technologies such as LCD and OLED. By leveraging the unique properties of quantum dots, QLED displays aim to produce a wider color gamut, higher peak brightness, and improved power efficiency.

One of the key milestones in QLED evolution was the development of cadmium-free quantum dots, addressing environmental concerns and regulatory requirements. This breakthrough opened up new possibilities for widespread adoption of QLED technology in consumer electronics.

As QLED technology continues to evolve, researchers and manufacturers are focusing on several key objectives. These include improving the stability and longevity of quantum dots, enhancing the color purity and efficiency of blue quantum dots, and developing more cost-effective manufacturing processes for large-scale production.

Another important goal is to achieve direct-emissive QLED displays, where quantum dots serve as both the color converter and the light emitter. This approach promises to deliver even better color performance and energy efficiency compared to current QLED implementations that still rely on LED backlighting.

The pursuit of brighter and more vibrant colors through QLED technology is driven by the increasing demand for high-quality displays in various applications, including televisions, monitors, smartphones, and automotive displays. As consumers seek more immersive visual experiences, QLED technology is positioned to play a crucial role in meeting these expectations.

Looking ahead, the objectives for QLED technology include achieving 100% Rec. 2020 color gamut coverage, improving the viewing angle performance, and reducing power consumption while maintaining high brightness levels. Additionally, researchers are exploring the integration of QLED technology with flexible and transparent display substrates, opening up new possibilities for innovative display form factors.

Initially, quantum dots were primarily used to enhance the color performance of LCD displays. However, as the technology progressed, researchers and engineers recognized the potential for quantum dots to serve as the primary light-emitting component in displays. This realization marked the beginning of QLED development as we know it today.

The primary objective of QLED technology is to achieve superior color reproduction, brightness, and energy efficiency compared to traditional display technologies such as LCD and OLED. By leveraging the unique properties of quantum dots, QLED displays aim to produce a wider color gamut, higher peak brightness, and improved power efficiency.

One of the key milestones in QLED evolution was the development of cadmium-free quantum dots, addressing environmental concerns and regulatory requirements. This breakthrough opened up new possibilities for widespread adoption of QLED technology in consumer electronics.

As QLED technology continues to evolve, researchers and manufacturers are focusing on several key objectives. These include improving the stability and longevity of quantum dots, enhancing the color purity and efficiency of blue quantum dots, and developing more cost-effective manufacturing processes for large-scale production.

Another important goal is to achieve direct-emissive QLED displays, where quantum dots serve as both the color converter and the light emitter. This approach promises to deliver even better color performance and energy efficiency compared to current QLED implementations that still rely on LED backlighting.

The pursuit of brighter and more vibrant colors through QLED technology is driven by the increasing demand for high-quality displays in various applications, including televisions, monitors, smartphones, and automotive displays. As consumers seek more immersive visual experiences, QLED technology is positioned to play a crucial role in meeting these expectations.

Looking ahead, the objectives for QLED technology include achieving 100% Rec. 2020 color gamut coverage, improving the viewing angle performance, and reducing power consumption while maintaining high brightness levels. Additionally, researchers are exploring the integration of QLED technology with flexible and transparent display substrates, opening up new possibilities for innovative display form factors.

Display Market Dynamics

The display market has witnessed significant growth and transformation in recent years, driven by technological advancements and changing consumer preferences. QLED (Quantum Dot Light Emitting Diode) technology has emerged as a key player in this dynamic landscape, offering the potential for brighter and more vibrant colors in display devices.

The global display market is experiencing robust growth, with a particular emphasis on high-quality, energy-efficient displays. QLED technology aligns well with these market demands, as it offers superior color reproduction and brightness compared to traditional LED displays. This has led to increased adoption of QLED technology in various sectors, including consumer electronics, automotive, and commercial applications.

Consumer demand for larger screens with higher resolutions has been a significant driver in the display market. QLED technology's ability to deliver enhanced picture quality on larger screens has positioned it favorably in this trend. The technology's capacity to produce a wider color gamut and higher peak brightness levels has made it particularly attractive for premium television and monitor segments.

In the smartphone and tablet market, QLED technology is gaining traction due to its potential to offer vivid colors and improved energy efficiency. As mobile devices continue to be a primary source of content consumption, the demand for displays that can deliver superior visual experiences while maintaining battery life is increasing.

The automotive industry represents another growing market for QLED displays. With the rise of electric vehicles and advanced driver assistance systems, there is a growing need for high-quality, durable displays that can perform well in various lighting conditions. QLED technology's brightness and color accuracy make it well-suited for automotive applications, from infotainment systems to heads-up displays.

Commercial and professional markets are also showing interest in QLED technology. Industries such as digital signage, medical imaging, and professional video production are exploring QLED displays for their color accuracy and brightness capabilities. This diversification of applications is expected to contribute to the overall growth of the QLED market.

However, the display market is highly competitive, with various technologies vying for market share. OLED (Organic Light Emitting Diode) technology, in particular, presents strong competition to QLED, especially in certain market segments. The ongoing research and development in QLED technology, focused on improving brightness and color vibrancy, is crucial for maintaining and expanding its market position.

The global display market is experiencing robust growth, with a particular emphasis on high-quality, energy-efficient displays. QLED technology aligns well with these market demands, as it offers superior color reproduction and brightness compared to traditional LED displays. This has led to increased adoption of QLED technology in various sectors, including consumer electronics, automotive, and commercial applications.

Consumer demand for larger screens with higher resolutions has been a significant driver in the display market. QLED technology's ability to deliver enhanced picture quality on larger screens has positioned it favorably in this trend. The technology's capacity to produce a wider color gamut and higher peak brightness levels has made it particularly attractive for premium television and monitor segments.

In the smartphone and tablet market, QLED technology is gaining traction due to its potential to offer vivid colors and improved energy efficiency. As mobile devices continue to be a primary source of content consumption, the demand for displays that can deliver superior visual experiences while maintaining battery life is increasing.

The automotive industry represents another growing market for QLED displays. With the rise of electric vehicles and advanced driver assistance systems, there is a growing need for high-quality, durable displays that can perform well in various lighting conditions. QLED technology's brightness and color accuracy make it well-suited for automotive applications, from infotainment systems to heads-up displays.

Commercial and professional markets are also showing interest in QLED technology. Industries such as digital signage, medical imaging, and professional video production are exploring QLED displays for their color accuracy and brightness capabilities. This diversification of applications is expected to contribute to the overall growth of the QLED market.

However, the display market is highly competitive, with various technologies vying for market share. OLED (Organic Light Emitting Diode) technology, in particular, presents strong competition to QLED, especially in certain market segments. The ongoing research and development in QLED technology, focused on improving brightness and color vibrancy, is crucial for maintaining and expanding its market position.

QLED Tech Challenges

QLED technology, while promising, faces several significant challenges that hinder its widespread adoption and performance optimization. One of the primary obstacles is the stability of quantum dots, particularly blue quantum dots. These nanoparticles tend to degrade faster than their red and green counterparts, leading to color shift and reduced lifespan of QLED displays. This instability is exacerbated by high current densities and elevated temperatures, which are often necessary for achieving high brightness levels.

Another critical challenge lies in the efficiency of charge injection and transport within QLED devices. The interface between the quantum dot layer and the charge transport layers often suffers from energy level misalignment, resulting in inefficient charge transfer and increased non-radiative recombination. This not only reduces the overall efficiency of the device but also contributes to faster degradation of the quantum dots.

The manufacturing process for QLEDs presents its own set of challenges. Achieving uniform deposition of quantum dots across large areas while maintaining precise control over thickness and density is technically demanding. Additionally, the integration of QLED technology with existing display manufacturing infrastructure requires significant investment and process optimization, which can slow down the technology's adoption in the market.

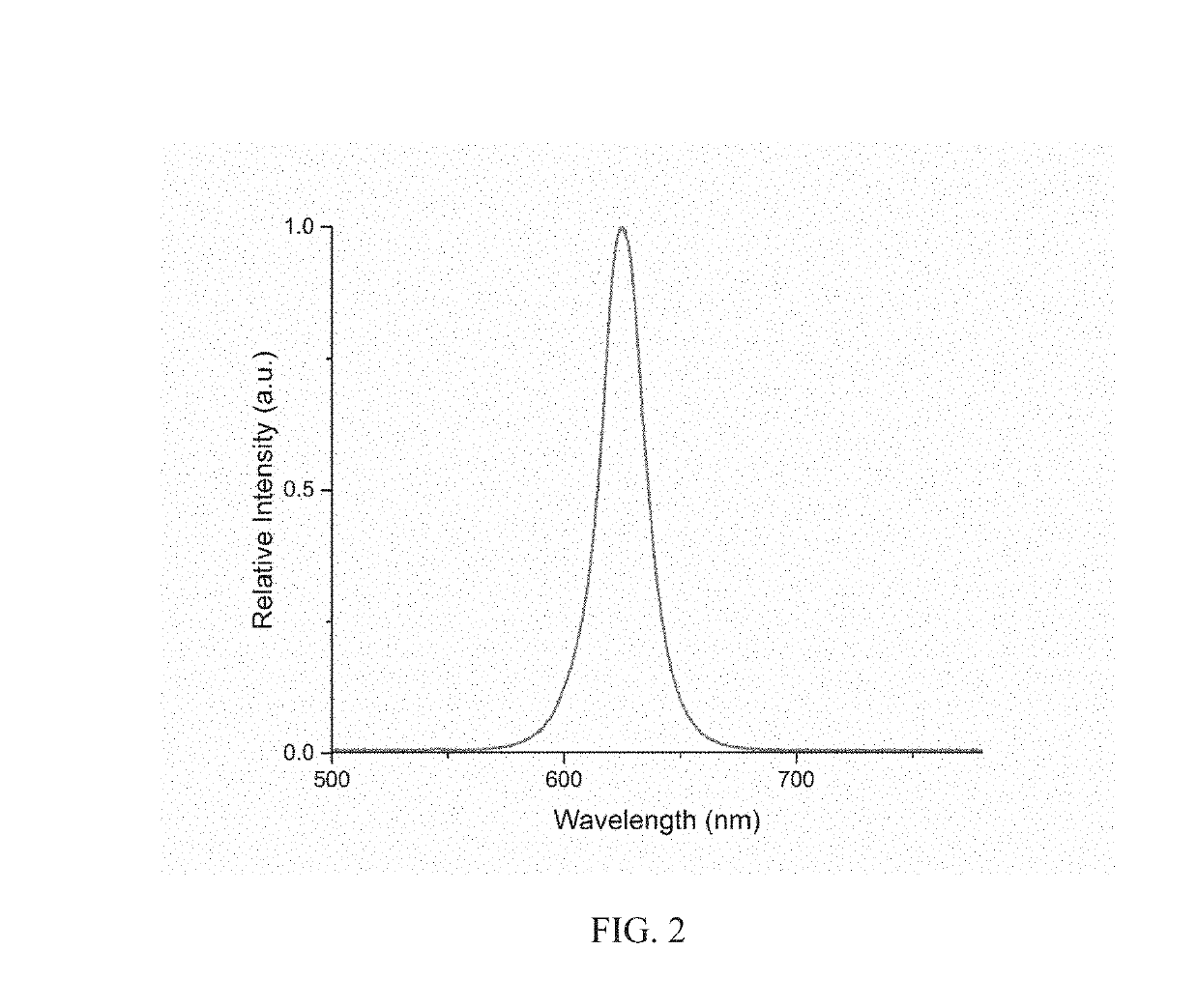

Color purity and gamut expansion remain ongoing challenges for QLED technology. While quantum dots offer the potential for extremely pure colors, achieving the ideal narrow emission spectrum for each primary color (red, green, and blue) simultaneously is difficult. This is particularly true for blue quantum dots, which often exhibit broader emission spectra compared to their red and green counterparts.

Lastly, environmental and health concerns associated with the materials used in quantum dots pose regulatory and consumer acceptance challenges. Many high-performance quantum dots contain heavy metals such as cadmium, which are subject to strict regulations in many countries. Developing cadmium-free alternatives that match the performance of cadmium-based quantum dots is an ongoing research focus, but current solutions often fall short in terms of efficiency and color purity.

Addressing these challenges requires interdisciplinary research efforts, combining advances in materials science, device physics, and manufacturing processes. Overcoming these hurdles is crucial for realizing the full potential of QLED technology in delivering brighter and more vibrant displays across various applications, from consumer electronics to professional imaging systems.

Another critical challenge lies in the efficiency of charge injection and transport within QLED devices. The interface between the quantum dot layer and the charge transport layers often suffers from energy level misalignment, resulting in inefficient charge transfer and increased non-radiative recombination. This not only reduces the overall efficiency of the device but also contributes to faster degradation of the quantum dots.

The manufacturing process for QLEDs presents its own set of challenges. Achieving uniform deposition of quantum dots across large areas while maintaining precise control over thickness and density is technically demanding. Additionally, the integration of QLED technology with existing display manufacturing infrastructure requires significant investment and process optimization, which can slow down the technology's adoption in the market.

Color purity and gamut expansion remain ongoing challenges for QLED technology. While quantum dots offer the potential for extremely pure colors, achieving the ideal narrow emission spectrum for each primary color (red, green, and blue) simultaneously is difficult. This is particularly true for blue quantum dots, which often exhibit broader emission spectra compared to their red and green counterparts.

Lastly, environmental and health concerns associated with the materials used in quantum dots pose regulatory and consumer acceptance challenges. Many high-performance quantum dots contain heavy metals such as cadmium, which are subject to strict regulations in many countries. Developing cadmium-free alternatives that match the performance of cadmium-based quantum dots is an ongoing research focus, but current solutions often fall short in terms of efficiency and color purity.

Addressing these challenges requires interdisciplinary research efforts, combining advances in materials science, device physics, and manufacturing processes. Overcoming these hurdles is crucial for realizing the full potential of QLED technology in delivering brighter and more vibrant displays across various applications, from consumer electronics to professional imaging systems.

Current QLED Solutions

01 Quantum dot enhancement for improved brightness and color

QLED technology utilizes quantum dots to enhance brightness and color vibrancy. These nanocrystals emit light when excited, producing more saturated colors and higher luminance compared to traditional LED displays. The size and composition of quantum dots can be tuned to achieve specific color outputs, resulting in a wider color gamut and improved overall picture quality.- Quantum dot enhancement for improved brightness and color: QLED technology utilizes quantum dots to enhance brightness and color vibrancy. These nanocrystals emit light when excited, producing more vivid and accurate colors across a wider color gamut. The size and composition of quantum dots can be tuned to emit specific wavelengths, resulting in improved color purity and brightness compared to traditional LED displays.

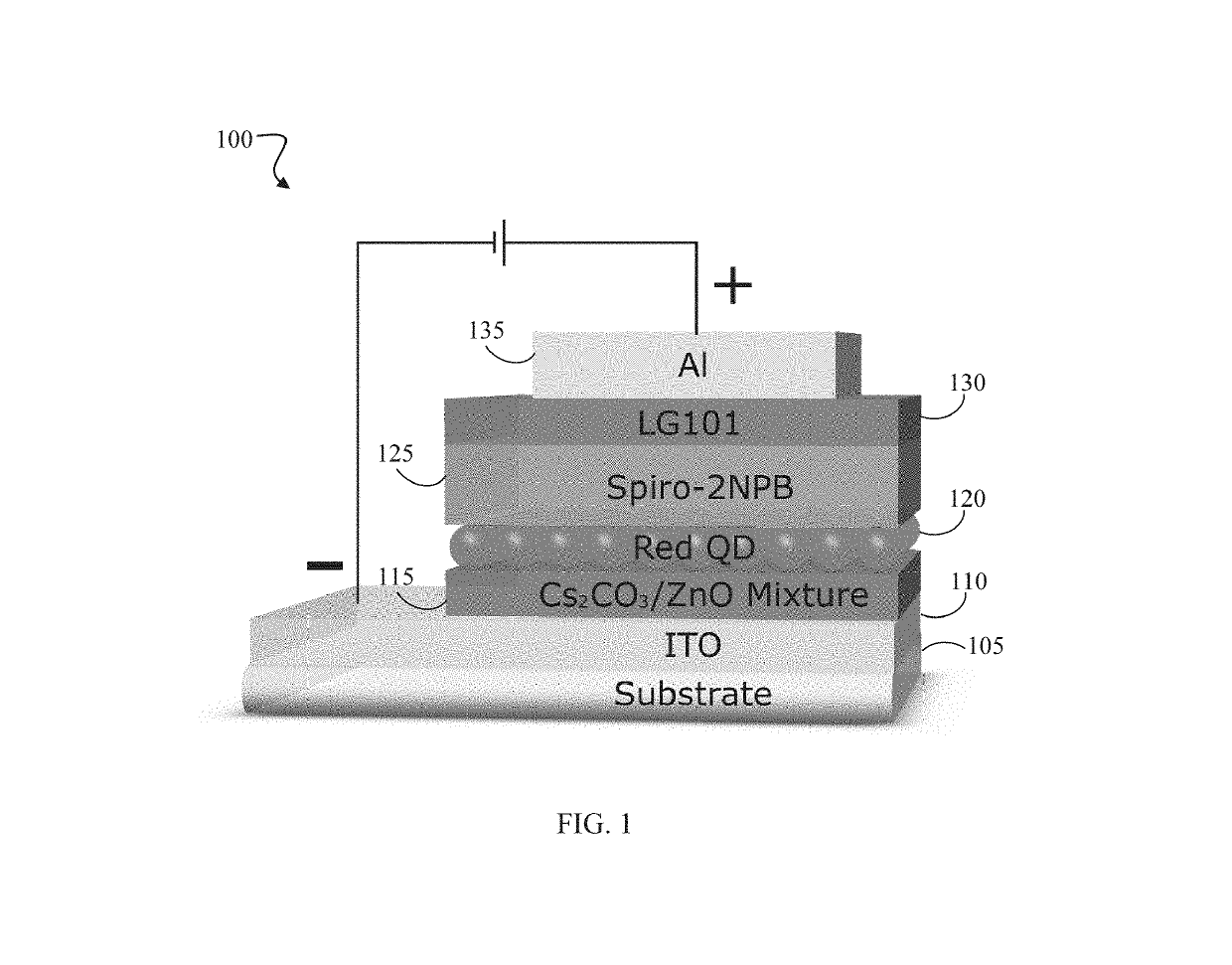

- Advanced light-emitting layer structures: QLED displays incorporate sophisticated light-emitting layer structures to optimize brightness and color performance. These structures may include multiple quantum dot layers, color conversion layers, and light management films. The arrangement and composition of these layers are designed to maximize light output and color accuracy while minimizing energy loss and color crosstalk.

- Quantum dot synthesis and encapsulation techniques: Advancements in quantum dot synthesis and encapsulation methods contribute to improved brightness and color vibrancy in QLED technology. These techniques focus on creating highly efficient and stable quantum dots, protecting them from environmental factors, and enhancing their light-emitting properties. Improved encapsulation also helps maintain long-term performance and reliability of QLED displays.

- Backlight and optical film optimization: QLED displays employ optimized backlight systems and optical films to enhance brightness and color vibrancy. These components work together to improve light distribution, reduce light loss, and enhance color purity. Advanced optical designs may include specialized diffusers, reflectors, and color filters to maximize the efficiency of light output and color reproduction.

- Color management and image processing algorithms: Sophisticated color management systems and image processing algorithms are employed in QLED technology to optimize brightness and color vibrancy. These software-based solutions fine-tune color reproduction, adjust brightness levels, and enhance contrast ratios. Advanced algorithms may also compensate for variations in quantum dot performance and adapt to different viewing conditions to maintain consistent image quality.

02 Advanced light-emitting layer structures

QLED displays incorporate sophisticated light-emitting layer structures to optimize brightness and color performance. These structures may include multiple quantum dot layers, electron transport layers, and hole transport layers. The arrangement and composition of these layers are designed to maximize light output efficiency and color purity, contributing to the overall vibrancy of the display.Expand Specific Solutions03 Color conversion and filtering techniques

QLED technology employs advanced color conversion and filtering techniques to enhance color vibrancy. This may involve the use of color filters in combination with quantum dots, or the implementation of color conversion layers that transform blue light into other colors. These methods help to achieve a wider color gamut and more accurate color reproduction, resulting in more vivid and lifelike images.Expand Specific Solutions04 Backlight and optical film optimization

To improve brightness and color performance, QLED displays utilize optimized backlight systems and optical films. This may include the use of advanced LED backlights, light guide plates, and reflective or diffractive optical elements. These components work together to enhance light distribution, increase efficiency, and improve overall luminance while maintaining color accuracy.Expand Specific Solutions05 Quantum dot synthesis and encapsulation

The brightness and color vibrancy of QLED displays are significantly influenced by the quality and stability of the quantum dots used. Advanced synthesis methods and encapsulation techniques are employed to produce high-performance quantum dots with improved efficiency and longevity. This includes the development of core-shell structures and protective coatings to enhance quantum yield and prevent degradation, ensuring sustained brightness and color performance over time.Expand Specific Solutions

QLED Industry Leaders

The QLED technology market for brighter and more vibrant colors is in a growth phase, with increasing market size and technological advancements. Major players like Samsung Electronics, BOE Technology Group, and TCL China Star Optoelectronics are driving innovation in this field. The technology's maturity is progressing rapidly, with companies such as Nanosys and Nanoco Technologies focusing on quantum dot materials. Research institutions like MIT and the University of Washington are contributing to fundamental advancements. The competitive landscape is characterized by a mix of established display manufacturers, specialized quantum dot developers, and academic institutions, indicating a dynamic and evolving market with significant potential for further growth and technological breakthroughs.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has made significant strides in QLED technology, focusing on improving color gamut and brightness. Their approach involves using a new type of quantum dot material that offers enhanced stability and longevity. BOE has also developed a proprietary quantum dot deposition technique that allows for more precise control over the quantum dot layer, resulting in improved color uniformity across the display. Furthermore, the company has integrated advanced local dimming technology to enhance contrast ratios in their QLED displays.

Strengths: Excellent color uniformity and stability. Weaknesses: Slightly behind some competitors in terms of peak brightness levels.

TCL China Star Optoelectronics Technology Co., Ltd.

Technical Solution: TCL has invested heavily in QLED research, developing a unique quantum dot on-glass (QDOG) technology. This approach involves directly depositing quantum dots onto the glass substrate, eliminating the need for a separate quantum dot film. TCL has also created a new quantum dot synthesis method that produces more uniform nanoparticles, resulting in better color consistency. Additionally, the company has implemented advanced thermal management systems to maintain optimal quantum dot performance over extended periods.

Strengths: Innovative QDOG technology, good thermal management. Weaknesses: Limited experience compared to some larger competitors.

Key QLED Innovations

QUANTUM DOT LIGHT EMITTING DEVICES (QLEDs) AND METHOD OF MANUFACTURE

PatentActiveUS20190103571A1

Innovation

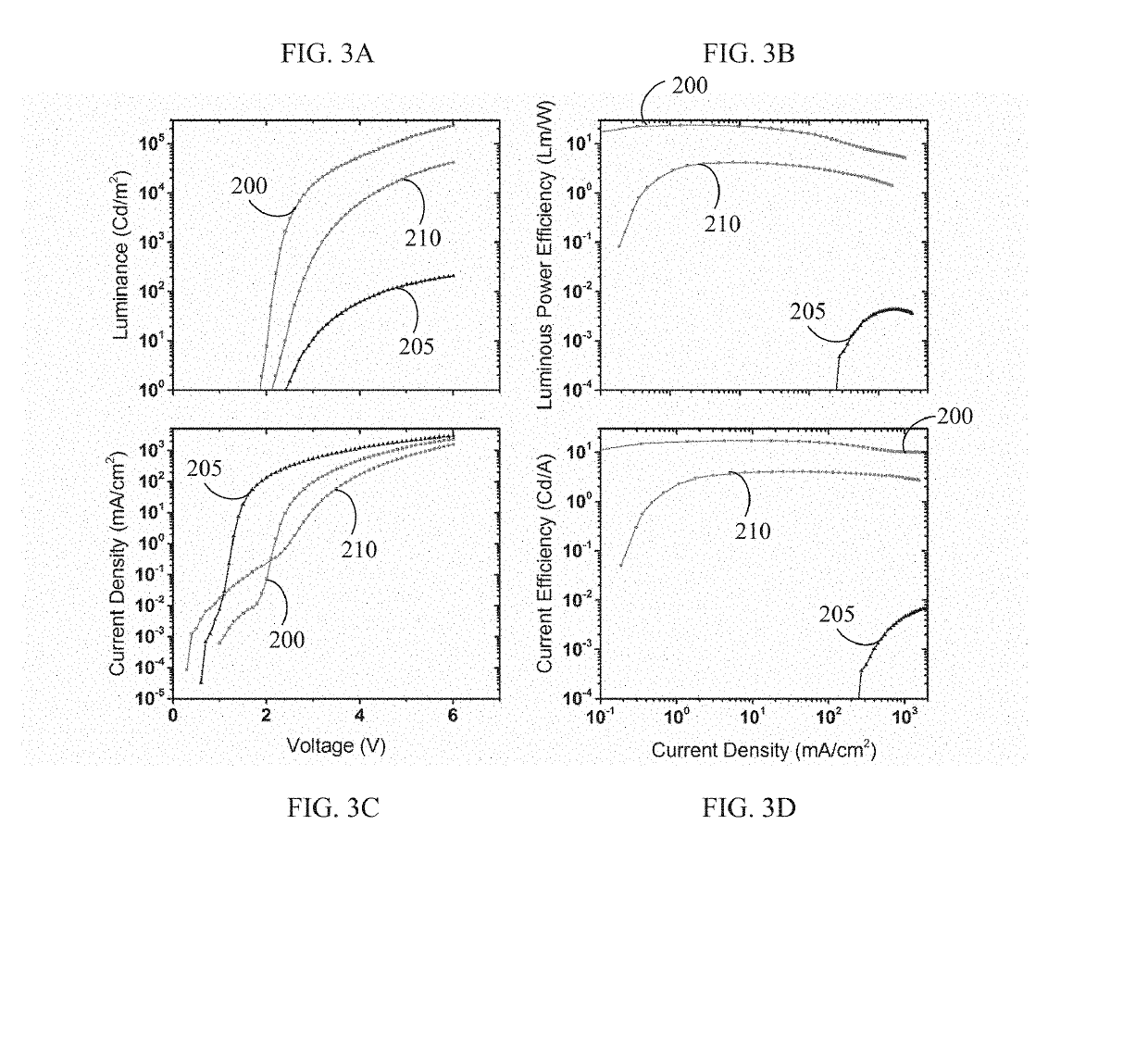

- The development of ultrabright QLEDs using a layer of quantum dots combined with a mixture of metal oxide nanoparticles and alkali metal compounds for simultaneous electron injection and hole blocking, achieving charge balance at high driving current densities, resulting in significantly higher brightness and stability.

Core-shell quantum dot, preparation method thereof, and electroluminescent light-emitting device containing the same

PatentActiveUS11912919B2

Innovation

- A core-shell quantum dot structure is developed, where a CdSeXS core is coated with a first shell of ZnSe, ZnSeYS, or Cd(Z)Zn(1-Z)S, and a second shell of Cd(Z)Zn(1-Z)S or ZnS, optimizing the energy band alignment to facilitate easier hole injection and reduce carrier barriers, while the second shell enhances stability.

QLED Manufacturing Process

The QLED manufacturing process involves several intricate steps to produce high-quality quantum dot light-emitting diodes. The process begins with the synthesis of quantum dots, typically using colloidal synthesis methods. These nanocrystals are carefully engineered to emit specific wavelengths of light when excited, resulting in the vibrant colors characteristic of QLED displays.

Once the quantum dots are synthesized, they are incorporated into a thin film layer. This layer is typically sandwiched between electron transport and hole transport layers. The precise deposition of these layers is crucial for optimal device performance. Advanced techniques such as inkjet printing or photolithography are often employed to achieve the required precision and uniformity.

The next stage involves the integration of the quantum dot layer with other components of the display. This includes the addition of electrodes, color filters, and protective layers. The entire stack is then encapsulated to protect the sensitive quantum dot layer from environmental factors such as moisture and oxygen, which can degrade performance over time.

Quality control is a critical aspect of the QLED manufacturing process. Each stage of production undergoes rigorous testing to ensure consistency and performance. This includes spectral analysis of the quantum dots, uniformity checks of the deposited layers, and comprehensive testing of the final display units.

One of the key challenges in QLED manufacturing is scaling up production while maintaining quality and cost-effectiveness. Manufacturers are continually refining their processes to improve yield rates and reduce material waste. This often involves the development of specialized equipment and the optimization of production line layouts.

The choice of materials used in QLED manufacturing significantly impacts the final product's performance. Research is ongoing to develop quantum dots with improved stability, efficiency, and color purity. Similarly, advancements in electrode materials and encapsulation techniques are being pursued to enhance overall device longevity and performance.

Environmental considerations are increasingly important in QLED manufacturing. Efforts are being made to reduce the use of toxic materials and improve the recyclability of QLED displays. This includes research into alternative quantum dot compositions that avoid heavy metals, as well as the development of more environmentally friendly production processes.

Once the quantum dots are synthesized, they are incorporated into a thin film layer. This layer is typically sandwiched between electron transport and hole transport layers. The precise deposition of these layers is crucial for optimal device performance. Advanced techniques such as inkjet printing or photolithography are often employed to achieve the required precision and uniformity.

The next stage involves the integration of the quantum dot layer with other components of the display. This includes the addition of electrodes, color filters, and protective layers. The entire stack is then encapsulated to protect the sensitive quantum dot layer from environmental factors such as moisture and oxygen, which can degrade performance over time.

Quality control is a critical aspect of the QLED manufacturing process. Each stage of production undergoes rigorous testing to ensure consistency and performance. This includes spectral analysis of the quantum dots, uniformity checks of the deposited layers, and comprehensive testing of the final display units.

One of the key challenges in QLED manufacturing is scaling up production while maintaining quality and cost-effectiveness. Manufacturers are continually refining their processes to improve yield rates and reduce material waste. This often involves the development of specialized equipment and the optimization of production line layouts.

The choice of materials used in QLED manufacturing significantly impacts the final product's performance. Research is ongoing to develop quantum dots with improved stability, efficiency, and color purity. Similarly, advancements in electrode materials and encapsulation techniques are being pursued to enhance overall device longevity and performance.

Environmental considerations are increasingly important in QLED manufacturing. Efforts are being made to reduce the use of toxic materials and improve the recyclability of QLED displays. This includes research into alternative quantum dot compositions that avoid heavy metals, as well as the development of more environmentally friendly production processes.

Environmental Impact of QLED

The environmental impact of QLED technology is a crucial consideration as this display technology continues to gain prominence in the consumer electronics market. QLED, or Quantum Dot Light Emitting Diode, offers significant advantages in terms of color vibrancy and brightness, but its environmental footprint warrants careful examination.

One of the primary environmental concerns associated with QLED technology is the use of heavy metals, particularly cadmium, in the quantum dot composition. While cadmium-based quantum dots offer superior color performance, they pose potential risks to human health and the environment if not properly managed throughout the product lifecycle. However, recent advancements have led to the development of cadmium-free quantum dots, which mitigate these concerns while maintaining high color quality.

Energy efficiency is another critical aspect of QLED's environmental impact. Compared to traditional LED and OLED technologies, QLED displays generally consume less power while delivering higher brightness levels. This improved energy efficiency can lead to reduced electricity consumption and, consequently, lower carbon emissions over the lifespan of the device.

The manufacturing process of QLED displays also has environmental implications. The production of quantum dots and the assembly of QLED panels involve complex procedures that may require significant energy inputs and potentially harmful chemicals. However, as the technology matures, manufacturers are increasingly adopting more sustainable production methods and materials, aiming to minimize the environmental footprint of QLED manufacturing.

End-of-life considerations for QLED displays are an important aspect of their overall environmental impact. The presence of quantum dots and other specialized materials in these displays necessitates careful recycling and disposal procedures to prevent environmental contamination. Many manufacturers are developing take-back programs and partnering with recycling facilities to ensure proper handling of end-of-life QLED products.

The longevity of QLED displays can positively contribute to their environmental profile. With their resistance to burn-in and potential for longer operational lifespans compared to some other display technologies, QLED devices may reduce the frequency of replacements, thereby decreasing electronic waste generation over time.

As QLED technology continues to evolve, ongoing research is focused on further improving its environmental performance. This includes developing more eco-friendly quantum dot materials, enhancing energy efficiency, and designing products with easier disassembly and recycling in mind. These efforts aim to position QLED as a more sustainable option in the competitive display technology landscape.

One of the primary environmental concerns associated with QLED technology is the use of heavy metals, particularly cadmium, in the quantum dot composition. While cadmium-based quantum dots offer superior color performance, they pose potential risks to human health and the environment if not properly managed throughout the product lifecycle. However, recent advancements have led to the development of cadmium-free quantum dots, which mitigate these concerns while maintaining high color quality.

Energy efficiency is another critical aspect of QLED's environmental impact. Compared to traditional LED and OLED technologies, QLED displays generally consume less power while delivering higher brightness levels. This improved energy efficiency can lead to reduced electricity consumption and, consequently, lower carbon emissions over the lifespan of the device.

The manufacturing process of QLED displays also has environmental implications. The production of quantum dots and the assembly of QLED panels involve complex procedures that may require significant energy inputs and potentially harmful chemicals. However, as the technology matures, manufacturers are increasingly adopting more sustainable production methods and materials, aiming to minimize the environmental footprint of QLED manufacturing.

End-of-life considerations for QLED displays are an important aspect of their overall environmental impact. The presence of quantum dots and other specialized materials in these displays necessitates careful recycling and disposal procedures to prevent environmental contamination. Many manufacturers are developing take-back programs and partnering with recycling facilities to ensure proper handling of end-of-life QLED products.

The longevity of QLED displays can positively contribute to their environmental profile. With their resistance to burn-in and potential for longer operational lifespans compared to some other display technologies, QLED devices may reduce the frequency of replacements, thereby decreasing electronic waste generation over time.

As QLED technology continues to evolve, ongoing research is focused on further improving its environmental performance. This includes developing more eco-friendly quantum dot materials, enhancing energy efficiency, and designing products with easier disassembly and recycling in mind. These efforts aim to position QLED as a more sustainable option in the competitive display technology landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!