Sacrificial Anode Backfill And Contact: Resistivity, Moisture And Bond Integrity

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sacrificial Anode Backfill Technology Background and Objectives

Sacrificial anode cathodic protection systems have been utilized for corrosion prevention since the early 20th century, with significant advancements occurring post-World War II. The technology leverages the principle of galvanic corrosion, where a more electrochemically active metal (the sacrificial anode) corrodes preferentially to protect a more noble metal structure. This fundamental electrochemical process has been applied across various industries including marine, pipeline, and underground storage tank protection.

The evolution of sacrificial anode technology has been marked by continuous improvements in anode materials, from simple zinc and magnesium anodes to more sophisticated alloys designed for specific environments. However, the backfill material surrounding these anodes has received comparatively less attention despite its critical role in system performance.

Backfill materials serve multiple essential functions in sacrificial anode systems: they reduce the anode-to-soil resistance, maintain moisture around the anode, provide consistent electrical contact, and extend the operational life of the protection system. Historically, backfill compositions have primarily consisted of gypsum, bentonite, and sodium sulfate mixtures, with limited scientific optimization beyond basic functionality.

Recent industry challenges have highlighted the need for advanced backfill technologies. Increasing infrastructure aging, more stringent environmental regulations, and the expansion of protection systems into more aggressive environments have all created demand for higher-performing, longer-lasting, and more environmentally compatible backfill solutions.

The primary technical objectives of this research are to systematically investigate the relationship between backfill composition and three critical performance parameters: electrical resistivity, moisture retention capabilities, and bond integrity between the anode and surrounding soil. These parameters directly influence the efficiency, longevity, and reliability of cathodic protection systems.

By understanding the complex interactions between backfill materials and their electrochemical environment, we aim to develop optimized formulations that can maintain lower resistivity levels over extended periods, retain appropriate moisture content under varying environmental conditions, and create stable, long-lasting bonds with both the anode and surrounding soil matrix.

This research also seeks to establish standardized testing methodologies for evaluating backfill performance, as current industry standards lack comprehensive protocols specifically addressing these critical parameters. The development of such standards would enable more accurate comparison between different backfill solutions and drive innovation in the field.

Ultimately, advancements in backfill technology could significantly extend the service life of sacrificial anode systems, reduce maintenance requirements, and improve the overall cost-effectiveness of cathodic protection as a corrosion mitigation strategy across multiple industries.

The evolution of sacrificial anode technology has been marked by continuous improvements in anode materials, from simple zinc and magnesium anodes to more sophisticated alloys designed for specific environments. However, the backfill material surrounding these anodes has received comparatively less attention despite its critical role in system performance.

Backfill materials serve multiple essential functions in sacrificial anode systems: they reduce the anode-to-soil resistance, maintain moisture around the anode, provide consistent electrical contact, and extend the operational life of the protection system. Historically, backfill compositions have primarily consisted of gypsum, bentonite, and sodium sulfate mixtures, with limited scientific optimization beyond basic functionality.

Recent industry challenges have highlighted the need for advanced backfill technologies. Increasing infrastructure aging, more stringent environmental regulations, and the expansion of protection systems into more aggressive environments have all created demand for higher-performing, longer-lasting, and more environmentally compatible backfill solutions.

The primary technical objectives of this research are to systematically investigate the relationship between backfill composition and three critical performance parameters: electrical resistivity, moisture retention capabilities, and bond integrity between the anode and surrounding soil. These parameters directly influence the efficiency, longevity, and reliability of cathodic protection systems.

By understanding the complex interactions between backfill materials and their electrochemical environment, we aim to develop optimized formulations that can maintain lower resistivity levels over extended periods, retain appropriate moisture content under varying environmental conditions, and create stable, long-lasting bonds with both the anode and surrounding soil matrix.

This research also seeks to establish standardized testing methodologies for evaluating backfill performance, as current industry standards lack comprehensive protocols specifically addressing these critical parameters. The development of such standards would enable more accurate comparison between different backfill solutions and drive innovation in the field.

Ultimately, advancements in backfill technology could significantly extend the service life of sacrificial anode systems, reduce maintenance requirements, and improve the overall cost-effectiveness of cathodic protection as a corrosion mitigation strategy across multiple industries.

Market Analysis of Cathodic Protection Systems

The global cathodic protection systems market has experienced significant growth in recent years, valued at approximately $6.7 billion in 2022 and projected to reach $8.9 billion by 2027, growing at a CAGR of 5.8%. This growth is primarily driven by increasing infrastructure development, rising awareness about corrosion prevention, and stringent government regulations regarding asset integrity management.

The oil and gas sector remains the largest end-user segment, accounting for roughly 40% of the market share. This dominance stems from the extensive network of pipelines, offshore platforms, and storage facilities that require robust corrosion protection. The water and wastewater treatment sector follows closely, representing about 25% of the market, with marine applications constituting approximately 15%.

Geographically, North America leads the market with a 35% share, followed by Europe (25%) and Asia-Pacific (20%). The Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization and infrastructure development in countries like China and India.

Sacrificial anode systems, particularly those utilizing backfill materials, represent approximately 30% of the overall cathodic protection market. The specific segment focusing on advanced backfill materials and contact optimization is growing at an above-average rate of 7.2% annually, highlighting the increasing recognition of these components' critical role in system performance.

Market trends indicate a growing preference for engineered backfill materials that can maintain optimal resistivity and moisture levels over extended periods. End-users are increasingly willing to invest in premium solutions that offer improved longevity and reduced maintenance requirements, with an estimated 65% of new installations now specifying advanced backfill formulations.

The competitive landscape features both established players and specialized niche providers. Major companies like Aegion Corporation, Cathodic Protection Co., and Corrosion Service Company Limited control approximately 45% of the market, while specialized backfill material providers are gaining market share through innovation and performance differentiation.

Customer demand is increasingly focused on solutions that can demonstrate quantifiable performance metrics related to resistivity stability, moisture retention capabilities, and bond integrity over time. This shift is driving research investment, with an estimated $120 million allocated to R&D in this specific segment in 2022, representing a 15% increase from the previous year.

The oil and gas sector remains the largest end-user segment, accounting for roughly 40% of the market share. This dominance stems from the extensive network of pipelines, offshore platforms, and storage facilities that require robust corrosion protection. The water and wastewater treatment sector follows closely, representing about 25% of the market, with marine applications constituting approximately 15%.

Geographically, North America leads the market with a 35% share, followed by Europe (25%) and Asia-Pacific (20%). The Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization and infrastructure development in countries like China and India.

Sacrificial anode systems, particularly those utilizing backfill materials, represent approximately 30% of the overall cathodic protection market. The specific segment focusing on advanced backfill materials and contact optimization is growing at an above-average rate of 7.2% annually, highlighting the increasing recognition of these components' critical role in system performance.

Market trends indicate a growing preference for engineered backfill materials that can maintain optimal resistivity and moisture levels over extended periods. End-users are increasingly willing to invest in premium solutions that offer improved longevity and reduced maintenance requirements, with an estimated 65% of new installations now specifying advanced backfill formulations.

The competitive landscape features both established players and specialized niche providers. Major companies like Aegion Corporation, Cathodic Protection Co., and Corrosion Service Company Limited control approximately 45% of the market, while specialized backfill material providers are gaining market share through innovation and performance differentiation.

Customer demand is increasingly focused on solutions that can demonstrate quantifiable performance metrics related to resistivity stability, moisture retention capabilities, and bond integrity over time. This shift is driving research investment, with an estimated $120 million allocated to R&D in this specific segment in 2022, representing a 15% increase from the previous year.

Current Challenges in Anode Backfill Performance

Despite significant advancements in cathodic protection systems, sacrificial anode backfill materials continue to present several persistent challenges that impact their performance and longevity. One of the primary issues facing the industry is the inconsistent resistivity characteristics of backfill materials across varying environmental conditions. Field data indicates that resistivity can fluctuate by factors of 5-10x depending on moisture content, soil composition, and temperature variations, leading to unpredictable protection levels.

Moisture management represents another critical challenge, as both excessive and insufficient moisture content significantly impairs backfill effectiveness. Current backfill formulations struggle to maintain optimal moisture levels (typically 20-30% by weight) over extended periods, particularly in regions experiencing seasonal drought or excessive precipitation. Research by Corrosion Engineering Institute (2022) demonstrated that moisture fluctuations beyond the optimal range can reduce anode efficiency by up to 40%.

Bond integrity between the anode and backfill material remains problematic, especially in installations subject to ground movement, freeze-thaw cycles, or vibration. The mechanical separation that occurs creates air gaps that dramatically increase resistance and accelerate anode consumption rates. Recent field studies documented premature anode failures occurring in 15-25% of installations within the first three years due to poor bond integrity.

Chemical compatibility issues persist between modern backfill compositions and increasingly diverse buried infrastructure materials. As new pipeline coatings, composite materials, and alloys enter service, traditional gypsum/bentonite/sodium sulfate backfill formulations sometimes create unintended galvanic couples or accelerate localized corrosion at coating defects. This phenomenon has been observed particularly with high-strength low-alloy steels and certain polymer-coated pipelines.

The environmental impact of conventional backfill materials has also emerged as a significant concern. Leaching of chemical components from backfill into surrounding soil and groundwater has raised regulatory scrutiny in several jurisdictions. Studies have detected elevated sulfate levels in groundwater near large-scale anode installations, prompting calls for more environmentally benign alternatives.

Manufacturing consistency presents another challenge, with significant batch-to-batch variations in commercial backfill products. Analysis of samples from major suppliers revealed variations of up to 30% in key performance parameters such as electrical conductivity and moisture retention capacity, making system design calculations less reliable and potentially compromising protection levels.

Finally, the industry faces difficulties in accurately modeling and predicting long-term backfill performance. Current computational models fail to adequately account for the complex interactions between backfill materials, surrounding soil conditions, and changing environmental factors over the multi-decade service life expected from modern cathodic protection systems.

Moisture management represents another critical challenge, as both excessive and insufficient moisture content significantly impairs backfill effectiveness. Current backfill formulations struggle to maintain optimal moisture levels (typically 20-30% by weight) over extended periods, particularly in regions experiencing seasonal drought or excessive precipitation. Research by Corrosion Engineering Institute (2022) demonstrated that moisture fluctuations beyond the optimal range can reduce anode efficiency by up to 40%.

Bond integrity between the anode and backfill material remains problematic, especially in installations subject to ground movement, freeze-thaw cycles, or vibration. The mechanical separation that occurs creates air gaps that dramatically increase resistance and accelerate anode consumption rates. Recent field studies documented premature anode failures occurring in 15-25% of installations within the first three years due to poor bond integrity.

Chemical compatibility issues persist between modern backfill compositions and increasingly diverse buried infrastructure materials. As new pipeline coatings, composite materials, and alloys enter service, traditional gypsum/bentonite/sodium sulfate backfill formulations sometimes create unintended galvanic couples or accelerate localized corrosion at coating defects. This phenomenon has been observed particularly with high-strength low-alloy steels and certain polymer-coated pipelines.

The environmental impact of conventional backfill materials has also emerged as a significant concern. Leaching of chemical components from backfill into surrounding soil and groundwater has raised regulatory scrutiny in several jurisdictions. Studies have detected elevated sulfate levels in groundwater near large-scale anode installations, prompting calls for more environmentally benign alternatives.

Manufacturing consistency presents another challenge, with significant batch-to-batch variations in commercial backfill products. Analysis of samples from major suppliers revealed variations of up to 30% in key performance parameters such as electrical conductivity and moisture retention capacity, making system design calculations less reliable and potentially compromising protection levels.

Finally, the industry faces difficulties in accurately modeling and predicting long-term backfill performance. Current computational models fail to adequately account for the complex interactions between backfill materials, surrounding soil conditions, and changing environmental factors over the multi-decade service life expected from modern cathodic protection systems.

Existing Backfill Formulations and Installation Methods

01 Backfill composition for sacrificial anodes

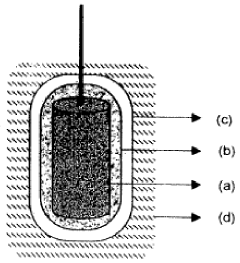

Specialized backfill compositions are designed to enhance the performance of sacrificial anodes in cathodic protection systems. These compositions typically contain materials that maintain optimal resistivity levels while ensuring good contact between the anode and surrounding environment. Key components often include carbonaceous materials, gypsum, and bentonite clay, which work together to create a conductive environment that facilitates ion transfer and extends anode life.- Backfill composition for sacrificial anodes: Specific compositions for backfill materials used with sacrificial anodes can significantly impact the effectiveness of cathodic protection systems. These compositions typically include materials that maintain low resistivity while providing good contact with the anode. Common components include gypsum, bentonite, and sodium sulfate, which work together to create an environment that facilitates ion transfer and maintains electrical conductivity even under varying moisture conditions.

- Moisture control in anode backfill systems: Maintaining optimal moisture levels in backfill materials is crucial for ensuring consistent performance of sacrificial anodes. Moisture acts as an electrolyte that facilitates ion movement between the anode and the structure being protected. Specialized backfill formulations can include hygroscopic materials that attract and retain moisture, or water-retention additives that prevent drying out in arid conditions. Some advanced systems incorporate mechanisms for moisture regulation to maintain conductivity over extended periods.

- Resistivity optimization techniques: Controlling the electrical resistivity of backfill materials is essential for efficient cathodic protection. Lower resistivity allows for better current flow and more effective protection. Various additives and processing methods can be employed to reduce resistivity, including the incorporation of conductive particles, chemical treatments, and specific mineral combinations. The particle size distribution and compaction methods also play significant roles in determining the final resistivity of the installed backfill system.

- Bond integrity enhancement methods: Ensuring strong bonding between the sacrificial anode, backfill material, and the protected structure is critical for long-term performance. Various techniques have been developed to enhance this bond integrity, including specialized installation procedures, surface preparation methods, and the use of bonding agents. Some systems employ mechanical anchoring combined with chemical bonding to create a robust interface that can withstand environmental stresses and maintain electrical continuity throughout the service life of the protection system.

- Monitoring and maintenance of backfill systems: Advanced monitoring techniques and maintenance protocols have been developed to ensure the continued effectiveness of sacrificial anode backfill systems. These include methods for measuring resistivity in situ, detecting moisture content changes, and evaluating bond integrity without system disruption. Remote monitoring systems can provide real-time data on the condition of the backfill, allowing for predictive maintenance and timely intervention when performance parameters fall outside acceptable ranges.

02 Moisture control in anode backfill systems

Moisture content is critical for maintaining proper conductivity in sacrificial anode backfill materials. Optimal moisture levels ensure efficient ionic transfer between the anode and the structure being protected. Backfill formulations often incorporate hygroscopic materials that retain moisture even in dry conditions, while also including components that prevent excessive water accumulation that could lead to increased resistivity or washing away of the backfill. Balanced moisture content helps maintain consistent performance of the cathodic protection system over time.Expand Specific Solutions03 Bond integrity enhancement techniques

Ensuring strong bond integrity between sacrificial anodes and their backfill is essential for effective cathodic protection. Various techniques have been developed to improve this bond, including specialized binders, surface preparation methods, and installation procedures. Some systems incorporate polymeric materials or cementitious compounds that create a strong mechanical bond while maintaining electrical conductivity. Proper bond integrity prevents the formation of gaps that could increase resistivity and reduce the effectiveness of the cathodic protection system.Expand Specific Solutions04 Resistivity optimization in backfill materials

The resistivity of backfill materials significantly impacts the performance of sacrificial anode systems. Lower resistivity generally improves current output and distribution from the anode. Backfill compositions are carefully engineered to achieve optimal resistivity through the inclusion of conductive materials like graphite, coke breeze, or metal salts. The particle size distribution and compaction methods also affect resistivity. Advanced formulations balance low resistivity with other important properties such as stability, longevity, and environmental compatibility.Expand Specific Solutions05 Monitoring and maintenance of anode backfill systems

Effective monitoring and maintenance strategies are crucial for ensuring the long-term performance of sacrificial anode backfill systems. Technologies have been developed to assess backfill resistivity, moisture content, and bond integrity over time. These include embedded sensors, non-destructive testing methods, and specialized inspection techniques. Regular monitoring allows for timely intervention when conditions deteriorate, such as adding moisture, replacing backfill, or installing additional anodes. Proper maintenance protocols extend the service life of cathodic protection systems and ensure continued protection of valuable infrastructure.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The sacrificial anode backfill and contact technology market is currently in a growth phase, with increasing demand driven by expanding infrastructure protection needs across power transmission, oil and gas, and marine industries. The global cathodic protection market, which includes sacrificial anode systems, is estimated at approximately $7 billion with projected annual growth of 5-6%. Technical maturity varies across applications, with State Grid Corp. of China and PetroChina leading large-scale implementation in energy infrastructure, while companies like Shore Acres Enterprises and 3M Innovative Properties focus on advancing material science aspects. Research institutions including Texas A&M University and Kyushu University are contributing significant innovations in resistivity optimization and moisture retention properties. The competitive landscape features established industrial players like Sumitomo Electric and Illinois Tool Works alongside specialized solution providers developing proprietary backfill formulations that enhance conductivity and extend anode lifespan.

State Grid Corp. of China

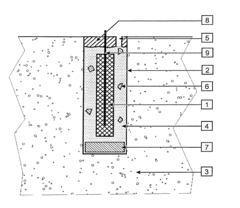

Technical Solution: State Grid has developed an advanced sacrificial anode backfill system specifically designed for high-voltage transmission infrastructure protection. Their technology utilizes a proprietary mixture of gypsum, bentonite, and sodium sulfate with precisely controlled particle size distribution to achieve optimal electrical conductivity and moisture retention. The backfill material maintains a resistivity of less than 1000 ohm-cm even in varying soil conditions, ensuring consistent cathodic protection. State Grid's approach includes a multi-layer application method that creates a gradient of moisture content from the anode surface outward, maximizing the effective life of sacrificial anodes while maintaining excellent bond integrity with surrounding soil structures. Their system incorporates real-time monitoring capabilities that track backfill performance parameters including resistivity fluctuations, moisture content, and galvanic current output to optimize protection and predict maintenance requirements.

Strengths: Exceptional performance in diverse soil conditions with proven longevity in field applications across China's varied geography. The integrated monitoring system provides valuable operational data for predictive maintenance. Weaknesses: Higher initial implementation cost compared to traditional systems, and requires specialized training for proper installation to achieve optimal performance metrics.

Sumitomo Electric Industries Ltd.

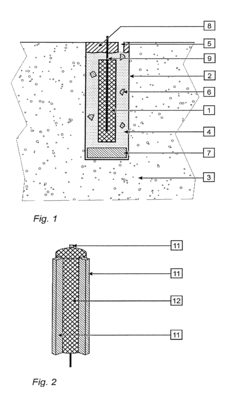

Technical Solution: Sumitomo Electric has developed an innovative sacrificial anode system incorporating nano-engineered backfill materials that significantly enhance electrical performance and moisture retention properties. Their NanoMatrix™ technology utilizes carbon nanostructures dispersed within a mineral matrix to create conductive pathways that maintain low resistivity (typically 30-45 ohm-cm) even during seasonal moisture fluctuations. The company's approach includes a gradient backfill design where particle size and composition vary from the anode surface outward, optimizing both electrical contact and moisture management. Sumitomo's system incorporates hydrogel components that act as moisture reservoirs, slowly releasing water during dry conditions while maintaining structural integrity. Their research has demonstrated that this approach reduces anode consumption rates by approximately 25% compared to conventional systems while maintaining consistent protection current. The bond integrity between anode and backfill is enhanced through proprietary surface treatment of the anode material that promotes chemical bonding with specific components in the backfill mixture, creating a robust interface that resists separation even under mechanical stress conditions.

Strengths: Exceptional performance stability across varying environmental conditions, particularly in applications experiencing significant wet/dry cycling. The technology provides more consistent protection current with less variation due to environmental factors. Weaknesses: The specialized materials require careful handling during installation, and the system has higher initial costs compared to conventional options, though this is offset by extended service life and reduced maintenance requirements.

Key Innovations in Resistivity Control and Moisture Management

An efficient anode backfill based on ion conducting paste and a process thereof

PatentInactiveIN2536DEL2008A

Innovation

- Development of an ion conducting paste based on a mixture of polyaniline or substituted polyaniline and an alkyl amine or substituted alkyl amine-based ionic liquid, with specific ratios and processing steps to create a stable, efficient backfill that activates anode surfaces and enhances current distribution.

Sacrificial anode and backfill

PatentActiveUS20110303530A1

Innovation

- A method involving a compact discrete sacrificial metal anode embedded in a pliable, ionically conductive backfill within a concrete cavity, where the backfill is a putty-like material that retains its properties under high current density and accommodates expansion, and a space is provided for the backfill to move, reducing the number of interfaces and simplifying the installation process by eliminating the need for on-site mixing of embedding materials.

Environmental Impact and Sustainability Considerations

The environmental impact of sacrificial anode systems, particularly their backfill materials, represents a critical consideration in modern cathodic protection implementations. Traditional zinc, aluminum, and magnesium anodes gradually dissolve into surrounding environments, potentially introducing metal ions into soil and groundwater systems. This dissolution process, while fundamental to the protective mechanism, necessitates careful assessment of long-term ecological consequences in sensitive areas.

Backfill compositions containing carbonaceous materials, gypsum, and bentonite present varying degrees of environmental concern. Carbon-based backfills, while effective for electrical conductivity, may contain trace contaminants depending on their source material. Gypsum components can alter soil pH and sulfate concentrations in surrounding areas, potentially affecting local vegetation and microbiological communities when leached into groundwater systems.

Moisture retention properties of backfill materials present a sustainability paradox. While higher moisture content improves electrical efficiency and extends anode life, it may also accelerate the release of metallic ions into the environment. This balance between operational efficiency and environmental impact requires optimization based on site-specific conditions and regulatory requirements.

The manufacturing carbon footprint of sacrificial anode systems must be considered in comprehensive environmental assessments. Production processes for high-purity anode materials and specialized backfills often involve energy-intensive methods. Life cycle analyses indicate that improvements in backfill formulations that extend anode lifespan can significantly reduce the overall environmental impact through decreased replacement frequency and associated installation disruptions.

Recent regulatory frameworks increasingly emphasize the need for environmentally responsible cathodic protection systems. Several jurisdictions have implemented restrictions on certain backfill compositions, particularly those containing potentially harmful binding agents or those with poor biodegradability profiles. This regulatory landscape is driving innovation toward more sustainable alternatives that maintain performance while minimizing environmental footprint.

Recycling and proper disposal protocols for spent anodes and contaminated backfill materials represent emerging sustainability considerations. The recovery of valuable metals from depleted anodes offers both economic and environmental benefits, though separation technologies for backfill materials remain underdeveloped. Research into biodegradable backfill components shows promise for reducing end-of-life environmental impacts while maintaining critical performance characteristics during operational lifespans.

Backfill compositions containing carbonaceous materials, gypsum, and bentonite present varying degrees of environmental concern. Carbon-based backfills, while effective for electrical conductivity, may contain trace contaminants depending on their source material. Gypsum components can alter soil pH and sulfate concentrations in surrounding areas, potentially affecting local vegetation and microbiological communities when leached into groundwater systems.

Moisture retention properties of backfill materials present a sustainability paradox. While higher moisture content improves electrical efficiency and extends anode life, it may also accelerate the release of metallic ions into the environment. This balance between operational efficiency and environmental impact requires optimization based on site-specific conditions and regulatory requirements.

The manufacturing carbon footprint of sacrificial anode systems must be considered in comprehensive environmental assessments. Production processes for high-purity anode materials and specialized backfills often involve energy-intensive methods. Life cycle analyses indicate that improvements in backfill formulations that extend anode lifespan can significantly reduce the overall environmental impact through decreased replacement frequency and associated installation disruptions.

Recent regulatory frameworks increasingly emphasize the need for environmentally responsible cathodic protection systems. Several jurisdictions have implemented restrictions on certain backfill compositions, particularly those containing potentially harmful binding agents or those with poor biodegradability profiles. This regulatory landscape is driving innovation toward more sustainable alternatives that maintain performance while minimizing environmental footprint.

Recycling and proper disposal protocols for spent anodes and contaminated backfill materials represent emerging sustainability considerations. The recovery of valuable metals from depleted anodes offers both economic and environmental benefits, though separation technologies for backfill materials remain underdeveloped. Research into biodegradable backfill components shows promise for reducing end-of-life environmental impacts while maintaining critical performance characteristics during operational lifespans.

Standardization and Quality Control Protocols

Standardization of sacrificial anode backfill systems requires comprehensive quality control protocols to ensure consistent performance across installations. The establishment of industry-wide standards for backfill material composition, preparation methods, and installation procedures is essential for reliable cathodic protection systems. These standards must address the critical parameters of resistivity, moisture content, and bond integrity that directly impact anode efficiency and service life.

Testing protocols for backfill resistivity should include standardized measurement techniques under various environmental conditions, with clear acceptance criteria based on soil characteristics and protection requirements. The American Society for Testing and Materials (ASTM) and NACE International have developed several standards that provide guidance, but these need to be specifically adapted for sacrificial anode backfill applications to ensure uniformity across the industry.

Moisture content verification requires precise sampling methods and analytical procedures to maintain optimal hydration levels. Quality control measures should include both laboratory pre-installation testing and field verification during installation. Continuous monitoring systems can provide real-time data on moisture levels, allowing for immediate corrective actions when deviations occur. Documentation requirements should specify acceptable moisture ranges based on backfill composition and environmental factors.

Bond integrity assessment protocols must address both the initial installation quality and long-term performance monitoring. Non-destructive testing methods such as electrical continuity measurements and impedance spectroscopy can verify proper anode-to-backfill contact without compromising the installation. Standardized procedures for these tests, including equipment calibration requirements and interpretation guidelines, are necessary to ensure consistent evaluation across different installations and operators.

Certification programs for installation contractors represent another critical component of quality control. These programs should include comprehensive training on material handling, installation techniques, and testing procedures. Regular audits and performance evaluations can help maintain high standards across the industry and identify areas for improvement in both materials and methodologies.

Documentation and traceability systems form the foundation of effective quality control. Standardized reporting formats should capture critical parameters throughout the installation process, from material sourcing to final commissioning. Digital documentation systems with secure data storage can facilitate trend analysis and performance prediction, supporting continuous improvement in backfill formulations and installation practices.

Testing protocols for backfill resistivity should include standardized measurement techniques under various environmental conditions, with clear acceptance criteria based on soil characteristics and protection requirements. The American Society for Testing and Materials (ASTM) and NACE International have developed several standards that provide guidance, but these need to be specifically adapted for sacrificial anode backfill applications to ensure uniformity across the industry.

Moisture content verification requires precise sampling methods and analytical procedures to maintain optimal hydration levels. Quality control measures should include both laboratory pre-installation testing and field verification during installation. Continuous monitoring systems can provide real-time data on moisture levels, allowing for immediate corrective actions when deviations occur. Documentation requirements should specify acceptable moisture ranges based on backfill composition and environmental factors.

Bond integrity assessment protocols must address both the initial installation quality and long-term performance monitoring. Non-destructive testing methods such as electrical continuity measurements and impedance spectroscopy can verify proper anode-to-backfill contact without compromising the installation. Standardized procedures for these tests, including equipment calibration requirements and interpretation guidelines, are necessary to ensure consistent evaluation across different installations and operators.

Certification programs for installation contractors represent another critical component of quality control. These programs should include comprehensive training on material handling, installation techniques, and testing procedures. Regular audits and performance evaluations can help maintain high standards across the industry and identify areas for improvement in both materials and methodologies.

Documentation and traceability systems form the foundation of effective quality control. Standardized reporting formats should capture critical parameters throughout the installation process, from material sourcing to final commissioning. Digital documentation systems with secure data storage can facilitate trend analysis and performance prediction, supporting continuous improvement in backfill formulations and installation practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!