Sacrificial Anode Vs Impressed Current: CAPEX, Maintenance And Protection Uniformity

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cathodic Protection Technology Background and Objectives

Cathodic protection technology has evolved significantly since its inception in the early 19th century when Sir Humphry Davy first demonstrated the principle by attaching zinc and iron plates to copper-clad ships. This groundbreaking discovery laid the foundation for modern corrosion prevention methods that are now essential across numerous industries including oil and gas, marine structures, pipelines, and underground storage tanks.

The evolution of cathodic protection has followed two distinct technological paths: sacrificial anode systems and impressed current cathodic protection (ICCP). Sacrificial anode technology, the simpler and historically older approach, relies on the natural electrochemical potential difference between metals. In contrast, ICCP systems, which emerged with the advancement of electrical engineering, utilize external power sources to force protective current flow.

Recent decades have witnessed significant technological advancements in both methodologies, driven by increasing demands for infrastructure longevity, environmental regulations, and cost optimization. The global cathodic protection market has experienced steady growth, projected to reach approximately $7.5 billion by 2026, with a CAGR of around 5.2% from 2021.

The primary objective of modern cathodic protection technology development is to optimize the balance between capital expenditure (CAPEX), maintenance requirements, and protection uniformity. This tripartite consideration has become increasingly critical as infrastructure ages worldwide and operates in increasingly challenging environments, from deep-sea installations to arctic pipelines.

Current technological trends focus on enhancing monitoring capabilities through IoT integration, developing more durable anode materials, improving power efficiency in ICCP systems, and creating hybrid solutions that leverage the advantages of both protection methodologies. Remote monitoring systems now allow for real-time corrosion rate assessment and protection level verification, significantly reducing inspection costs while improving reliability.

The industry is also witnessing a shift toward more sustainable practices, with research focused on environmentally friendly anode materials and reduced energy consumption. This evolution is partly driven by stricter environmental regulations and corporate sustainability goals across sectors that heavily rely on cathodic protection.

Looking forward, the technological trajectory points toward more intelligent, adaptive systems that can automatically adjust protection parameters based on environmental conditions, infrastructure usage patterns, and detected corrosion threats. The integration of machine learning algorithms for predictive maintenance and optimization represents the next frontier in cathodic protection technology.

The evolution of cathodic protection has followed two distinct technological paths: sacrificial anode systems and impressed current cathodic protection (ICCP). Sacrificial anode technology, the simpler and historically older approach, relies on the natural electrochemical potential difference between metals. In contrast, ICCP systems, which emerged with the advancement of electrical engineering, utilize external power sources to force protective current flow.

Recent decades have witnessed significant technological advancements in both methodologies, driven by increasing demands for infrastructure longevity, environmental regulations, and cost optimization. The global cathodic protection market has experienced steady growth, projected to reach approximately $7.5 billion by 2026, with a CAGR of around 5.2% from 2021.

The primary objective of modern cathodic protection technology development is to optimize the balance between capital expenditure (CAPEX), maintenance requirements, and protection uniformity. This tripartite consideration has become increasingly critical as infrastructure ages worldwide and operates in increasingly challenging environments, from deep-sea installations to arctic pipelines.

Current technological trends focus on enhancing monitoring capabilities through IoT integration, developing more durable anode materials, improving power efficiency in ICCP systems, and creating hybrid solutions that leverage the advantages of both protection methodologies. Remote monitoring systems now allow for real-time corrosion rate assessment and protection level verification, significantly reducing inspection costs while improving reliability.

The industry is also witnessing a shift toward more sustainable practices, with research focused on environmentally friendly anode materials and reduced energy consumption. This evolution is partly driven by stricter environmental regulations and corporate sustainability goals across sectors that heavily rely on cathodic protection.

Looking forward, the technological trajectory points toward more intelligent, adaptive systems that can automatically adjust protection parameters based on environmental conditions, infrastructure usage patterns, and detected corrosion threats. The integration of machine learning algorithms for predictive maintenance and optimization represents the next frontier in cathodic protection technology.

Market Analysis of Corrosion Prevention Solutions

The global corrosion prevention market is experiencing significant growth, valued at approximately $66.5 billion in 2022 and projected to reach $85.4 billion by 2027, with a compound annual growth rate (CAGR) of 5.2%. This expansion is primarily driven by increasing infrastructure development, growing awareness of corrosion-related economic losses, and stricter regulatory frameworks across industries.

Within this market, cathodic protection systems represent a crucial segment, accounting for roughly $7.3 billion in 2022. These systems are broadly categorized into two main technologies: sacrificial anode systems and impressed current cathodic protection (ICCP) systems, each serving distinct market needs based on application requirements and environmental conditions.

The oil and gas sector remains the largest consumer of cathodic protection solutions, constituting approximately 35% of the total market share. This dominance stems from extensive pipeline networks, offshore platforms, and storage facilities requiring robust corrosion prevention. Marine applications follow at 22%, while water and wastewater infrastructure accounts for 18% of market demand.

Regional analysis reveals that North America currently leads the market with a 32% share, followed closely by Asia-Pacific at 28%, which demonstrates the fastest growth rate at 6.8% annually. This growth in Asia-Pacific is attributed to rapid industrialization and massive infrastructure development in countries like China and India.

Market segmentation by technology shows that sacrificial anode systems currently hold a larger market share (58%) compared to impressed current systems (42%). However, impressed current technology is growing at a faster rate due to its advantages in large-scale applications and long-term cost efficiency despite higher initial capital expenditure.

Customer demand patterns indicate a growing preference for integrated corrosion management solutions rather than standalone products. End-users increasingly seek comprehensive packages that include monitoring capabilities, predictive maintenance features, and extended service life guarantees.

The competitive landscape features both specialized cathodic protection providers and diversified industrial conglomerates. Key market players include Aegion Corporation, Cathodic Protection Co., MATCOR, Inc., and Corrosion Service Company Limited, collectively controlling approximately 45% of the global market share.

Future market trends point toward increased adoption of remote monitoring technologies, development of environmentally friendly anode materials, and growing demand for retrofit solutions in aging infrastructure. The market is also witnessing a shift toward performance-based contracts and service models rather than pure equipment sales.

Within this market, cathodic protection systems represent a crucial segment, accounting for roughly $7.3 billion in 2022. These systems are broadly categorized into two main technologies: sacrificial anode systems and impressed current cathodic protection (ICCP) systems, each serving distinct market needs based on application requirements and environmental conditions.

The oil and gas sector remains the largest consumer of cathodic protection solutions, constituting approximately 35% of the total market share. This dominance stems from extensive pipeline networks, offshore platforms, and storage facilities requiring robust corrosion prevention. Marine applications follow at 22%, while water and wastewater infrastructure accounts for 18% of market demand.

Regional analysis reveals that North America currently leads the market with a 32% share, followed closely by Asia-Pacific at 28%, which demonstrates the fastest growth rate at 6.8% annually. This growth in Asia-Pacific is attributed to rapid industrialization and massive infrastructure development in countries like China and India.

Market segmentation by technology shows that sacrificial anode systems currently hold a larger market share (58%) compared to impressed current systems (42%). However, impressed current technology is growing at a faster rate due to its advantages in large-scale applications and long-term cost efficiency despite higher initial capital expenditure.

Customer demand patterns indicate a growing preference for integrated corrosion management solutions rather than standalone products. End-users increasingly seek comprehensive packages that include monitoring capabilities, predictive maintenance features, and extended service life guarantees.

The competitive landscape features both specialized cathodic protection providers and diversified industrial conglomerates. Key market players include Aegion Corporation, Cathodic Protection Co., MATCOR, Inc., and Corrosion Service Company Limited, collectively controlling approximately 45% of the global market share.

Future market trends point toward increased adoption of remote monitoring technologies, development of environmentally friendly anode materials, and growing demand for retrofit solutions in aging infrastructure. The market is also witnessing a shift toward performance-based contracts and service models rather than pure equipment sales.

Current Challenges in Cathodic Protection Systems

Despite significant advancements in cathodic protection technologies, both sacrificial anode and impressed current cathodic protection (ICCP) systems face several critical challenges in modern applications. The increasing complexity of protected structures, coupled with more demanding operational environments, has exposed limitations in existing protection methodologies.

One of the primary challenges is achieving uniform protection distribution across complex geometries. Traditional sacrificial anode systems often struggle to provide consistent protection levels throughout intricate structures, resulting in underprotected zones susceptible to accelerated corrosion. This is particularly problematic in offshore structures with complex underwater components or pipeline networks with varying soil resistivity.

Monitoring and assessment capabilities represent another significant hurdle. While ICCP systems offer remote monitoring advantages, the reliability and accuracy of these monitoring systems remain inconsistent. Many installations lack comprehensive real-time monitoring capabilities, making it difficult to detect protection failures before significant damage occurs. The industry still relies heavily on periodic manual inspections, which are both costly and potentially insufficient for early problem detection.

Environmental considerations have also emerged as a growing concern. The environmental impact of anode materials, particularly in marine applications, has raised questions about long-term ecological effects. Additionally, interference issues between adjacent cathodic protection systems or with other underground metallic structures continue to challenge system designers, especially in congested industrial areas.

Energy efficiency presents a particular challenge for ICCP systems. The power requirements for these systems can be substantial, especially for large structures or in high-resistivity environments. This creates operational cost concerns and sustainability issues, particularly as industries face increasing pressure to reduce carbon footprints.

Material limitations affect both protection methodologies. Sacrificial anodes face consumption rate uncertainties that complicate lifecycle planning, while ICCP systems contend with durability issues for anodes and reference electrodes in harsh environments. The development of more resilient materials that maintain consistent performance over extended periods remains an ongoing challenge.

Cost optimization continues to be a critical issue, with initial installation expenses often competing against long-term maintenance considerations. Organizations frequently struggle to determine the optimal balance between CAPEX and OPEX when selecting between sacrificial and impressed current systems, particularly when factoring in the total lifecycle costs including maintenance, monitoring, and eventual replacement.

One of the primary challenges is achieving uniform protection distribution across complex geometries. Traditional sacrificial anode systems often struggle to provide consistent protection levels throughout intricate structures, resulting in underprotected zones susceptible to accelerated corrosion. This is particularly problematic in offshore structures with complex underwater components or pipeline networks with varying soil resistivity.

Monitoring and assessment capabilities represent another significant hurdle. While ICCP systems offer remote monitoring advantages, the reliability and accuracy of these monitoring systems remain inconsistent. Many installations lack comprehensive real-time monitoring capabilities, making it difficult to detect protection failures before significant damage occurs. The industry still relies heavily on periodic manual inspections, which are both costly and potentially insufficient for early problem detection.

Environmental considerations have also emerged as a growing concern. The environmental impact of anode materials, particularly in marine applications, has raised questions about long-term ecological effects. Additionally, interference issues between adjacent cathodic protection systems or with other underground metallic structures continue to challenge system designers, especially in congested industrial areas.

Energy efficiency presents a particular challenge for ICCP systems. The power requirements for these systems can be substantial, especially for large structures or in high-resistivity environments. This creates operational cost concerns and sustainability issues, particularly as industries face increasing pressure to reduce carbon footprints.

Material limitations affect both protection methodologies. Sacrificial anodes face consumption rate uncertainties that complicate lifecycle planning, while ICCP systems contend with durability issues for anodes and reference electrodes in harsh environments. The development of more resilient materials that maintain consistent performance over extended periods remains an ongoing challenge.

Cost optimization continues to be a critical issue, with initial installation expenses often competing against long-term maintenance considerations. Organizations frequently struggle to determine the optimal balance between CAPEX and OPEX when selecting between sacrificial and impressed current systems, particularly when factoring in the total lifecycle costs including maintenance, monitoring, and eventual replacement.

Technical Comparison of Sacrificial Anode vs Impressed Current

01 Cost comparison between sacrificial anode and impressed current systems

The capital expenditure (CAPEX) for cathodic protection systems varies significantly between sacrificial anode and impressed current systems. Sacrificial anode systems typically have lower initial installation costs but higher long-term material replacement expenses. Impressed current systems require higher upfront investment for power supplies, control systems, and monitoring equipment, but may offer cost advantages for large structures or long-term protection scenarios. The economic analysis should consider factors such as structure size, design life, and accessibility for maintenance.- Cost comparison between sacrificial anode and impressed current systems: Sacrificial anode systems generally have lower initial capital expenditure (CAPEX) but higher long-term maintenance costs due to the need for periodic anode replacement. In contrast, impressed current systems have higher upfront costs for power supplies and control systems but can offer lower long-term maintenance expenses and extended operational lifespans. The total cost of ownership depends on factors such as structure size, environment, and protection duration requirements.

- Maintenance requirements for cathodic protection systems: Sacrificial anode systems require regular inspection and replacement of depleted anodes, but have minimal electronic component maintenance. Impressed current systems need more complex maintenance including power source verification, rectifier inspections, and electrical connection checks. Remote monitoring technologies can reduce maintenance costs for both systems by enabling real-time performance tracking and predictive maintenance scheduling, minimizing site visits and extending system lifespans.

- Protection uniformity comparison between cathodic protection methods: Impressed current systems offer superior protection uniformity for complex or large structures due to adjustable current output and strategic anode placement. These systems can be fine-tuned to address varying environmental conditions and structure geometries. Sacrificial anode systems provide more localized protection with potential current distribution limitations, making them less uniform for complex structures but adequate for smaller, simpler applications where uniform current distribution is less critical.

- Hybrid cathodic protection systems combining technologies: Hybrid systems integrate both sacrificial anodes and impressed current technologies to optimize protection while balancing costs. These systems leverage the reliability of sacrificial anodes with the adjustability of impressed current, providing redundancy and improved protection uniformity. Initial CAPEX may be higher than single-technology systems, but maintenance costs can be reduced through optimized anode consumption rates and extended system lifespans. Hybrid approaches are particularly effective for critical infrastructure with varying environmental conditions.

- Monitoring and control systems for optimizing cathodic protection performance: Advanced monitoring and control systems can significantly reduce maintenance costs while improving protection uniformity for both sacrificial and impressed current systems. Remote monitoring technologies enable real-time data collection on protection levels, anode consumption rates, and system performance. Automated control systems can adjust current output based on environmental changes, extending anode life and ensuring consistent protection. These technologies require higher initial CAPEX but deliver long-term operational benefits through reduced maintenance requirements and optimized protection.

02 Maintenance requirements and operational considerations

Maintenance requirements differ substantially between cathodic protection system types. Sacrificial anode systems require periodic anode replacement but minimal electronic monitoring. Impressed current systems need regular electrical inspections, rectifier adjustments, and power source maintenance. Remote monitoring technologies have improved maintenance efficiency for impressed current systems, allowing for real-time performance tracking and predictive maintenance scheduling. Accessibility of the protected structure significantly impacts maintenance costs, particularly for underwater or underground applications.Expand Specific Solutions03 Protection uniformity and distribution effectiveness

Protection uniformity is a critical factor in cathodic protection system design. Impressed current systems offer superior control over current distribution and can be adjusted to provide more uniform protection across complex structures. Sacrificial anode systems may provide less uniform protection, particularly for geometrically complex structures, due to their fixed current output and positioning limitations. Advanced modeling techniques help optimize anode placement for both system types to achieve more uniform protection and minimize areas of under or over-protection.Expand Specific Solutions04 Hybrid and innovative protection systems

Hybrid cathodic protection systems combine elements of both sacrificial anode and impressed current technologies to optimize performance and cost-effectiveness. These systems may use sacrificial anodes for baseline protection with impressed current components for areas requiring additional or more precise protection. Innovative designs incorporate solar power, wind energy, or other renewable sources to power impressed current systems in remote locations. Advanced materials and configurations have been developed to extend anode life and improve current distribution efficiency.Expand Specific Solutions05 Monitoring and control systems for optimizing performance

Modern cathodic protection systems increasingly incorporate sophisticated monitoring and control technologies to optimize performance and reduce lifecycle costs. Remote monitoring systems allow for continuous data collection on protection levels, anode consumption rates, and system efficiency. Smart control systems can automatically adjust current output in impressed current systems based on environmental conditions and protection requirements. These technologies help extend system life, reduce maintenance visits, and provide better documentation of protection effectiveness for regulatory compliance.Expand Specific Solutions

Key Industry Players in Cathodic Protection Market

The cathodic protection market for corrosion control is currently in a mature growth phase, with an expanding global market driven by increasing infrastructure investments in oil & gas, marine, and industrial sectors. The competition between sacrificial anode and impressed current cathodic protection (ICCP) systems centers on their distinct cost profiles and performance characteristics. Vector Corrosion Technologies leads in specialized concrete protection solutions, while major energy corporations like CNOOC, Shell, and Offshore Oil Engineering dominate in large-scale marine applications. Companies such as Sunrui Marine Environment and Dalian Kingmile focus on innovative marine-specific solutions. The technology landscape shows ICCP systems gaining market share due to their superior protection uniformity and remote monitoring capabilities, despite higher initial CAPEX compared to sacrificial anodes, which maintain advantages in simplicity and lower maintenance requirements.

Vector Corrosion Technologies Ltd

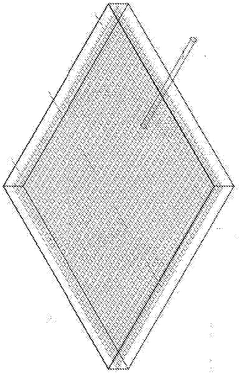

Technical Solution: Vector Corrosion Technologies specializes in both sacrificial anode and impressed current cathodic protection (ICCP) systems with distinct approaches to each. Their sacrificial anode solutions utilize high-potential metals (zinc, aluminum, magnesium) that naturally corrode to protect the target structure without external power. Their ICCP systems employ rectifiers converting AC to DC power, with inert anodes (mixed metal oxide, platinum-coated titanium) distributing protective current across large structures. Vector's comparative analysis shows sacrificial systems have lower CAPEX ($5-15/ft² vs $15-30/ft² for ICCP) but higher long-term material replacement costs. Their proprietary Galvashield® technology for concrete structures and GalvaCorr® for marine applications demonstrate how material selection significantly impacts protection uniformity, with specialized anode spacing calculations to ensure complete coverage even in complex geometries[1][3].

Strengths: Comprehensive expertise in both technologies allows tailored solutions based on structure requirements rather than limited offerings. Their specialized concrete protection systems address unique challenges in that sector. Weaknesses: Higher initial engineering costs for system design compared to standardized solutions, and their ICCP systems require more specialized maintenance personnel than competitors' more automated options.

China National Offshore Oil Corp.

Technical Solution: CNOOC has developed specialized cathodic protection strategies for offshore platforms and subsea infrastructure in challenging marine environments. Their approach differentiates between shallow and deep-water applications, with sacrificial anodes (primarily aluminum-zinc-indium alloys) preferred for depths below 500m due to reliability concerns with power delivery for ICCP. For shallow water and splash zone applications, CNOOC employs hybrid systems with sacrificial anodes providing baseline protection and targeted ICCP for high-risk areas. Their economic analysis demonstrates that while sacrificial systems have lower CAPEX (approximately 3-5% of total structure cost vs 5-8% for ICCP), the maintenance costs over a 25-year lifecycle can be 2-3 times higher due to periodic anode replacement requirements. CNOOC's research has focused on protection uniformity challenges, developing computational models that account for seawater resistivity variations with depth and temperature to optimize anode placement. Their field data shows that properly designed sacrificial systems can achieve ±50mV potential variation across protected structures, while ICCP systems can maintain ±30mV with active control[4][7].

Strengths: Extensive practical experience in harsh offshore environments has led to highly reliable protection systems with documented long-term performance. Their hybrid approach balances reliability with cost-effectiveness. Weaknesses: Conservative engineering approach sometimes results in over-designed systems with higher material costs than necessary, and their sacrificial anode designs often require more frequent inspection than competitors' solutions.

Critical Patents and Innovations in Cathodic Protection

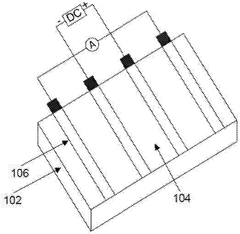

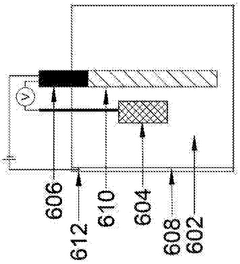

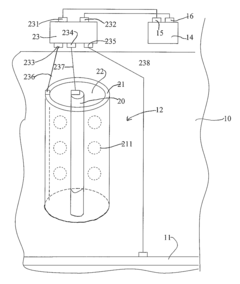

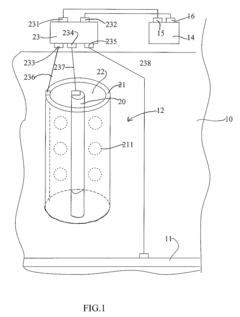

Conductive coating anode for impressed current cathodic protection of reinforced concrete structures

PatentActiveGB2598800A

Innovation

- A conductive coating anode system comprising a ratio of 9.6 parts zinc to 1 part electrically conductive carbon base material, applied directly to the concrete surface without thermal treatment, forming a durable matrix that supports the flow of protective current and includes a platinum clad wire embedded in a carbon fibre mat for enhanced durability and bond strength.

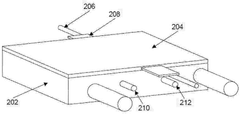

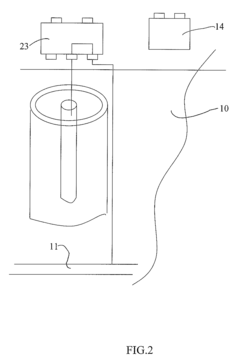

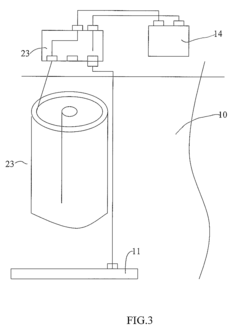

Two stage cathodic protection system using impressed current and galvanic action

PatentActiveUS8968549B2

Innovation

- A two-stage cathodic protection system combining an impressed current anode and a sacrificial anode, where the impressed current anode provides initial protection and the sacrificial anode continues protection after the impressed current is terminated, with a DC power supply connecting the anodes to the metal section to enhance corrosion protection.

Life Cycle Cost Analysis of Protection Systems

When evaluating cathodic protection systems, life cycle cost analysis provides a comprehensive economic perspective that extends beyond initial installation expenses. For sacrificial anode systems, the capital expenditure (CAPEX) is typically lower than impressed current systems, with simpler installation requirements and fewer components. However, this advantage diminishes when considering long-term operational costs, particularly in large structures or high-resistivity environments where more anodes are required.

The operational expenditure (OPEX) for sacrificial anodes primarily involves periodic replacement of depleted anodes, which necessitates downtime and potentially costly access procedures, especially for submerged or buried structures. Conversely, impressed current systems incur ongoing electricity costs and require more sophisticated maintenance of rectifiers, control systems, and monitoring equipment, but often achieve longer operational periods between major interventions.

Maintenance requirements differ significantly between the two systems. Sacrificial anodes operate passively without external power, reducing routine maintenance needs but offering limited monitoring capabilities. This can lead to unexpected protection failures and potentially higher emergency repair costs. Impressed current systems demand regular technical inspections and adjustments but provide superior monitoring options that enable predictive maintenance strategies, potentially reducing overall lifecycle costs through early problem detection.

Protection uniformity also impacts long-term costs. Impressed current systems offer adjustable protection levels that can be optimized for different sections of complex structures, potentially extending asset life and reducing localized corrosion repair expenses. Sacrificial anodes provide less uniform protection, which may result in premature failure of inadequately protected areas and subsequent repair costs.

Environmental factors significantly influence lifecycle economics. In high-resistivity environments, sacrificial anodes become less efficient and require more frequent replacement, while impressed current systems maintain effectiveness with minimal additional costs. Similarly, temperature variations affect anode consumption rates in sacrificial systems, potentially accelerating replacement cycles in warmer environments.

The analysis must also account for risk-associated costs. Protection failures can lead to substantial consequential damages, production losses, and safety incidents. The superior monitoring capabilities of impressed current systems may justify their higher initial investment through reduced risk exposure, particularly for critical infrastructure where protection failures carry significant consequences.

The operational expenditure (OPEX) for sacrificial anodes primarily involves periodic replacement of depleted anodes, which necessitates downtime and potentially costly access procedures, especially for submerged or buried structures. Conversely, impressed current systems incur ongoing electricity costs and require more sophisticated maintenance of rectifiers, control systems, and monitoring equipment, but often achieve longer operational periods between major interventions.

Maintenance requirements differ significantly between the two systems. Sacrificial anodes operate passively without external power, reducing routine maintenance needs but offering limited monitoring capabilities. This can lead to unexpected protection failures and potentially higher emergency repair costs. Impressed current systems demand regular technical inspections and adjustments but provide superior monitoring options that enable predictive maintenance strategies, potentially reducing overall lifecycle costs through early problem detection.

Protection uniformity also impacts long-term costs. Impressed current systems offer adjustable protection levels that can be optimized for different sections of complex structures, potentially extending asset life and reducing localized corrosion repair expenses. Sacrificial anodes provide less uniform protection, which may result in premature failure of inadequately protected areas and subsequent repair costs.

Environmental factors significantly influence lifecycle economics. In high-resistivity environments, sacrificial anodes become less efficient and require more frequent replacement, while impressed current systems maintain effectiveness with minimal additional costs. Similarly, temperature variations affect anode consumption rates in sacrificial systems, potentially accelerating replacement cycles in warmer environments.

The analysis must also account for risk-associated costs. Protection failures can lead to substantial consequential damages, production losses, and safety incidents. The superior monitoring capabilities of impressed current systems may justify their higher initial investment through reduced risk exposure, particularly for critical infrastructure where protection failures carry significant consequences.

Environmental Impact and Sustainability Considerations

The environmental impact of cathodic protection systems has become increasingly important as industries strive for more sustainable practices. When comparing sacrificial anode and impressed current cathodic protection (ICCP) systems, several environmental considerations emerge that influence decision-making beyond traditional cost and performance metrics.

Sacrificial anode systems generate metal waste as the anodes deplete over time, introducing metals such as zinc, aluminum, and magnesium into marine or soil environments. While these metals occur naturally, concentrated releases may potentially affect local ecosystems, particularly in sensitive marine habitats. The manufacturing process for these anodes also carries an environmental footprint related to mining, processing, and transportation of the metals used.

In contrast, ICCP systems require continuous electrical power throughout their operational lifetime, contributing to carbon emissions when powered by non-renewable energy sources. This ongoing energy consumption represents a significant environmental consideration, especially for large-scale installations. However, modern ICCP systems increasingly incorporate renewable energy sources such as solar panels or wind turbines, substantially reducing their carbon footprint and improving sustainability credentials.

The longevity of protection systems also factors into environmental impact assessments. ICCP systems typically require fewer physical replacements, reducing the frequency of maintenance operations that may disturb marine environments or require excavation in buried pipeline applications. This advantage becomes particularly significant in environmentally sensitive areas where minimizing disturbance is a priority.

Material efficiency represents another important sustainability metric. Sacrificial anodes are consumed entirely during their protective function, requiring complete replacement at regular intervals. ICCP systems utilize more durable anodes that experience significantly less consumption, resulting in reduced material requirements over the system's lifetime. This efficiency translates to lower resource extraction demands and reduced waste generation.

Regulatory frameworks increasingly incorporate environmental impact assessments for industrial installations, including cathodic protection systems. Many jurisdictions now require consideration of potential environmental effects, disposal protocols for spent materials, and energy efficiency metrics. These regulations may influence system selection, particularly in areas with stringent environmental protection standards or in proximity to protected habitats.

Life cycle assessment (LCA) methodologies provide comprehensive evaluations of environmental impacts across all stages from production through operation to end-of-life disposal. Recent LCA studies suggest that local environmental conditions, energy sources, and operational requirements significantly influence which system presents the lower overall environmental impact, highlighting the importance of site-specific sustainability evaluations rather than universal recommendations.

Sacrificial anode systems generate metal waste as the anodes deplete over time, introducing metals such as zinc, aluminum, and magnesium into marine or soil environments. While these metals occur naturally, concentrated releases may potentially affect local ecosystems, particularly in sensitive marine habitats. The manufacturing process for these anodes also carries an environmental footprint related to mining, processing, and transportation of the metals used.

In contrast, ICCP systems require continuous electrical power throughout their operational lifetime, contributing to carbon emissions when powered by non-renewable energy sources. This ongoing energy consumption represents a significant environmental consideration, especially for large-scale installations. However, modern ICCP systems increasingly incorporate renewable energy sources such as solar panels or wind turbines, substantially reducing their carbon footprint and improving sustainability credentials.

The longevity of protection systems also factors into environmental impact assessments. ICCP systems typically require fewer physical replacements, reducing the frequency of maintenance operations that may disturb marine environments or require excavation in buried pipeline applications. This advantage becomes particularly significant in environmentally sensitive areas where minimizing disturbance is a priority.

Material efficiency represents another important sustainability metric. Sacrificial anodes are consumed entirely during their protective function, requiring complete replacement at regular intervals. ICCP systems utilize more durable anodes that experience significantly less consumption, resulting in reduced material requirements over the system's lifetime. This efficiency translates to lower resource extraction demands and reduced waste generation.

Regulatory frameworks increasingly incorporate environmental impact assessments for industrial installations, including cathodic protection systems. Many jurisdictions now require consideration of potential environmental effects, disposal protocols for spent materials, and energy efficiency metrics. These regulations may influence system selection, particularly in areas with stringent environmental protection standards or in proximity to protected habitats.

Life cycle assessment (LCA) methodologies provide comprehensive evaluations of environmental impacts across all stages from production through operation to end-of-life disposal. Recent LCA studies suggest that local environmental conditions, energy sources, and operational requirements significantly influence which system presents the lower overall environmental impact, highlighting the importance of site-specific sustainability evaluations rather than universal recommendations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!