Sacrificial Anode in Marine Hulls: Biofouling, Flow Velocity And Galvanic Couples

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Marine Corrosion Protection Background and Objectives

Marine corrosion represents one of the most significant challenges in maritime industries, with annual global costs exceeding $2.5 trillion. Since the early 20th century, sacrificial anodes have emerged as a cornerstone technology in combating galvanic corrosion on marine vessels. This passive protection system leverages the electrochemical potential difference between metals to protect critical hull structures.

The evolution of sacrificial anode technology has progressed from simple zinc blocks to sophisticated alloy compositions incorporating aluminum, zinc, and magnesium. Recent advancements have focused on optimizing anode composition, placement strategies, and monitoring systems to enhance protection efficiency while minimizing environmental impact.

Current industry trends indicate a growing emphasis on sustainable corrosion protection solutions that balance effectiveness with ecological considerations. The regulatory landscape has shifted toward restricting certain anode materials due to environmental concerns, particularly regarding heavy metal leaching into marine ecosystems.

The primary objective of this research is to comprehensively investigate the complex interplay between biofouling accumulation and varying flow velocities on the performance of sacrificial anodes in marine environments. Specifically, we aim to quantify how these factors affect galvanic couple formation and the resulting protection efficiency.

Secondary objectives include developing predictive models for anode consumption rates under various biofouling conditions, establishing optimal anode replacement schedules based on operational profiles, and identifying potential innovations in anode design that could mitigate biofouling effects.

The maritime industry faces increasing pressure to extend vessel operational lifespans while reducing maintenance costs and environmental footprint. Understanding the fundamental mechanisms by which biofouling and flow dynamics influence galvanic protection systems represents a critical knowledge gap with significant economic implications.

This research addresses the technical challenge of maintaining effective cathodic protection under real-world conditions where biofouling organisms create complex microenvironments on hull surfaces. These microenvironments can dramatically alter local electrochemical conditions, potentially compromising protection systems designed under idealized laboratory conditions.

By advancing our understanding of these complex interactions, this research aims to contribute to the development of next-generation marine protection systems that maintain effectiveness throughout varying operational conditions while meeting increasingly stringent environmental regulations and sustainability goals.

The evolution of sacrificial anode technology has progressed from simple zinc blocks to sophisticated alloy compositions incorporating aluminum, zinc, and magnesium. Recent advancements have focused on optimizing anode composition, placement strategies, and monitoring systems to enhance protection efficiency while minimizing environmental impact.

Current industry trends indicate a growing emphasis on sustainable corrosion protection solutions that balance effectiveness with ecological considerations. The regulatory landscape has shifted toward restricting certain anode materials due to environmental concerns, particularly regarding heavy metal leaching into marine ecosystems.

The primary objective of this research is to comprehensively investigate the complex interplay between biofouling accumulation and varying flow velocities on the performance of sacrificial anodes in marine environments. Specifically, we aim to quantify how these factors affect galvanic couple formation and the resulting protection efficiency.

Secondary objectives include developing predictive models for anode consumption rates under various biofouling conditions, establishing optimal anode replacement schedules based on operational profiles, and identifying potential innovations in anode design that could mitigate biofouling effects.

The maritime industry faces increasing pressure to extend vessel operational lifespans while reducing maintenance costs and environmental footprint. Understanding the fundamental mechanisms by which biofouling and flow dynamics influence galvanic protection systems represents a critical knowledge gap with significant economic implications.

This research addresses the technical challenge of maintaining effective cathodic protection under real-world conditions where biofouling organisms create complex microenvironments on hull surfaces. These microenvironments can dramatically alter local electrochemical conditions, potentially compromising protection systems designed under idealized laboratory conditions.

By advancing our understanding of these complex interactions, this research aims to contribute to the development of next-generation marine protection systems that maintain effectiveness throughout varying operational conditions while meeting increasingly stringent environmental regulations and sustainability goals.

Market Analysis of Sacrificial Anode Technologies

The global market for sacrificial anode technologies has experienced steady growth over the past decade, primarily driven by increasing maritime activities and offshore installations. The market value reached approximately $2.7 billion in 2022, with projections indicating a compound annual growth rate of 4.8% through 2028. This growth trajectory is supported by expanding shipbuilding industries in Asia-Pacific regions, particularly China, South Korea, and Japan, which collectively account for over 60% of global ship production.

The sacrificial anode market segmentation reveals aluminum anodes dominating with roughly 45% market share, followed by zinc anodes at 35% and magnesium anodes at 20%. This distribution reflects the balance between cost-effectiveness, performance characteristics, and specific application requirements across different marine environments. The commercial shipping sector represents the largest end-user segment, consuming nearly 40% of all sacrificial anodes produced globally.

Regional analysis shows Asia-Pacific leading the market with 38% share, followed by Europe (27%), North America (22%), and other regions (13%). The concentration in Asia-Pacific correlates directly with the region's shipbuilding dominance and extensive coastal infrastructure development projects.

Demand drivers for sacrificial anode technologies include stringent maritime safety regulations, increasing vessel lifespans, growing offshore wind farm installations, and rising awareness about corrosion-related economic losses. The International Maritime Organization's regulations on vessel maintenance and safety standards have particularly influenced adoption rates across commercial fleets.

Market challenges include price volatility of raw materials, particularly aluminum and zinc, which has created margin pressures for manufacturers. Additionally, the emergence of alternative corrosion protection systems, such as impressed current cathodic protection (ICCP) systems, presents competitive challenges in certain applications, especially for larger vessels and permanent offshore structures.

Customer needs analysis reveals increasing demand for anodes with enhanced performance under biofouling conditions and variable flow velocities. End-users are seeking solutions that maintain effectiveness despite marine growth accumulation, which currently reduces anode efficiency by 15-30% depending on severity. Furthermore, there is growing interest in environmentally friendly anode materials that minimize toxic metal release into marine ecosystems while maintaining protective capabilities.

The market exhibits moderate fragmentation with the top five manufacturers controlling approximately 35% of global market share. Recent merger and acquisition activities suggest industry consolidation trends, as companies seek economies of scale and expanded geographical presence to strengthen competitive positioning.

The sacrificial anode market segmentation reveals aluminum anodes dominating with roughly 45% market share, followed by zinc anodes at 35% and magnesium anodes at 20%. This distribution reflects the balance between cost-effectiveness, performance characteristics, and specific application requirements across different marine environments. The commercial shipping sector represents the largest end-user segment, consuming nearly 40% of all sacrificial anodes produced globally.

Regional analysis shows Asia-Pacific leading the market with 38% share, followed by Europe (27%), North America (22%), and other regions (13%). The concentration in Asia-Pacific correlates directly with the region's shipbuilding dominance and extensive coastal infrastructure development projects.

Demand drivers for sacrificial anode technologies include stringent maritime safety regulations, increasing vessel lifespans, growing offshore wind farm installations, and rising awareness about corrosion-related economic losses. The International Maritime Organization's regulations on vessel maintenance and safety standards have particularly influenced adoption rates across commercial fleets.

Market challenges include price volatility of raw materials, particularly aluminum and zinc, which has created margin pressures for manufacturers. Additionally, the emergence of alternative corrosion protection systems, such as impressed current cathodic protection (ICCP) systems, presents competitive challenges in certain applications, especially for larger vessels and permanent offshore structures.

Customer needs analysis reveals increasing demand for anodes with enhanced performance under biofouling conditions and variable flow velocities. End-users are seeking solutions that maintain effectiveness despite marine growth accumulation, which currently reduces anode efficiency by 15-30% depending on severity. Furthermore, there is growing interest in environmentally friendly anode materials that minimize toxic metal release into marine ecosystems while maintaining protective capabilities.

The market exhibits moderate fragmentation with the top five manufacturers controlling approximately 35% of global market share. Recent merger and acquisition activities suggest industry consolidation trends, as companies seek economies of scale and expanded geographical presence to strengthen competitive positioning.

Current Challenges in Marine Galvanic Protection

Despite significant advancements in marine galvanic protection systems, several critical challenges continue to impede optimal performance of sacrificial anodes in marine environments. The primary challenge remains the accurate prediction of anode consumption rates under varying real-world conditions. Laboratory tests often fail to replicate the complex interplay of environmental factors encountered in actual marine settings, leading to discrepancies between theoretical and practical anode lifespans.

Biofouling represents a particularly vexing challenge for galvanic protection systems. Marine organisms that colonize hull surfaces create oxygen concentration cells and alter the electrochemical environment around anodes. Research indicates that biofilm formation can reduce cathodic protection effectiveness by up to 30% in certain conditions, yet current design standards inadequately account for these biological interactions.

Flow velocity variations present another significant obstacle. High-speed vessels experience dramatically different flow patterns compared to stationary or slow-moving marine structures. These variations affect the mass transport of dissolved oxygen and corrosion products, subsequently altering the galvanic couple dynamics. Studies show that protection current densities may need to increase by 2-3 times in high-flow areas compared to stagnant conditions, yet existing models struggle to incorporate these hydrodynamic effects accurately.

The growing use of composite materials and advanced coatings in marine construction introduces compatibility issues with traditional galvanic protection systems. These materials often exhibit different electrical properties and surface characteristics, complicating the design of effective cathodic protection. Industry standards have not kept pace with these material innovations, creating uncertainty in protection system design.

Environmental regulations present additional constraints, particularly regarding zinc and aluminum anodes. Zinc dissolution contributes to marine pollution, while aluminum anodes can release potentially harmful indium and mercury in older formulations. Regulatory frameworks in Europe and North America increasingly restrict these materials, necessitating the development of environmentally friendly alternatives without compromising protection efficiency.

Monitoring and maintenance challenges persist, with many vessels lacking real-time corrosion monitoring capabilities. Traditional inspection methods require dry-docking, which is costly and disruptive. While remote monitoring technologies exist, their reliability in harsh marine environments remains problematic, with sensor fouling and data transmission difficulties limiting widespread adoption.

Cost-effectiveness continues to be a significant barrier, particularly for smaller vessels and operators in developing regions. The initial investment in advanced galvanic protection systems, combined with maintenance requirements, often leads to suboptimal protection choices based on economic rather than technical considerations.

Biofouling represents a particularly vexing challenge for galvanic protection systems. Marine organisms that colonize hull surfaces create oxygen concentration cells and alter the electrochemical environment around anodes. Research indicates that biofilm formation can reduce cathodic protection effectiveness by up to 30% in certain conditions, yet current design standards inadequately account for these biological interactions.

Flow velocity variations present another significant obstacle. High-speed vessels experience dramatically different flow patterns compared to stationary or slow-moving marine structures. These variations affect the mass transport of dissolved oxygen and corrosion products, subsequently altering the galvanic couple dynamics. Studies show that protection current densities may need to increase by 2-3 times in high-flow areas compared to stagnant conditions, yet existing models struggle to incorporate these hydrodynamic effects accurately.

The growing use of composite materials and advanced coatings in marine construction introduces compatibility issues with traditional galvanic protection systems. These materials often exhibit different electrical properties and surface characteristics, complicating the design of effective cathodic protection. Industry standards have not kept pace with these material innovations, creating uncertainty in protection system design.

Environmental regulations present additional constraints, particularly regarding zinc and aluminum anodes. Zinc dissolution contributes to marine pollution, while aluminum anodes can release potentially harmful indium and mercury in older formulations. Regulatory frameworks in Europe and North America increasingly restrict these materials, necessitating the development of environmentally friendly alternatives without compromising protection efficiency.

Monitoring and maintenance challenges persist, with many vessels lacking real-time corrosion monitoring capabilities. Traditional inspection methods require dry-docking, which is costly and disruptive. While remote monitoring technologies exist, their reliability in harsh marine environments remains problematic, with sensor fouling and data transmission difficulties limiting widespread adoption.

Cost-effectiveness continues to be a significant barrier, particularly for smaller vessels and operators in developing regions. The initial investment in advanced galvanic protection systems, combined with maintenance requirements, often leads to suboptimal protection choices based on economic rather than technical considerations.

Existing Sacrificial Anode Solutions for Marine Applications

01 Sacrificial anode design for biofouling prevention

Specialized sacrificial anode designs can help prevent biofouling in marine environments. These anodes are engineered with specific compositions and surface treatments that release ions which inhibit the attachment and growth of marine organisms. The design considerations include the anode material composition, surface area, and distribution pattern to ensure effective biofouling prevention while maintaining cathodic protection capabilities.- Sacrificial anode design for biofouling prevention: Specialized sacrificial anode designs can help prevent biofouling in marine environments. These anodes are engineered with specific compositions and surface characteristics that inhibit the attachment and growth of marine organisms while still providing cathodic protection. The design may incorporate antimicrobial elements or surface treatments that create an environment hostile to biofouling organisms without compromising the electrochemical protection function.

- Flow velocity effects on sacrificial anode performance: The flow velocity of water significantly impacts the performance and longevity of sacrificial anodes. Higher flow rates can accelerate the dissolution rate of anodes through erosion-corrosion mechanisms, while also affecting the distribution of protective current. Specialized anode designs account for various flow conditions to ensure optimal cathodic protection while maintaining structural integrity. These designs may include hydrodynamic shapes or strategic positioning to balance protection and anode consumption rate.

- Integrated systems combining biofouling control and cathodic protection: Integrated protection systems combine sacrificial anodes with other biofouling control methods to provide comprehensive protection for marine structures. These systems may incorporate controlled release of biocides, ultrasonic deterrents, or specialized coatings working in conjunction with sacrificial anodes. The synergistic approach ensures both electrochemical protection against corrosion and prevention of biological growth, particularly in high-fouling environments where traditional methods alone would be insufficient.

- Monitoring and control systems for sacrificial anodes in variable flow conditions: Advanced monitoring systems allow for real-time assessment of sacrificial anode performance under varying flow velocities and biofouling conditions. These systems incorporate sensors to measure parameters such as current output, anode consumption rate, and surrounding water conditions. The data enables automated adjustments to protection systems or alerts maintenance personnel when intervention is needed, optimizing anode life and protection effectiveness while accounting for changing environmental factors.

- Material composition innovations for dual-purpose anodes: Novel material compositions for sacrificial anodes provide both enhanced cathodic protection and biofouling resistance. These specialized alloys may incorporate elements that create an inhospitable environment for marine organisms while maintaining optimal electrochemical properties. The materials are engineered to perform consistently across varying flow velocities, with controlled dissolution rates that ensure predictable service life even in challenging conditions with high biofouling potential.

02 Flow velocity effects on sacrificial anode performance

Flow velocity significantly impacts the performance and longevity of sacrificial anodes. Higher flow rates can accelerate anode dissolution through erosion-corrosion mechanisms, while also affecting the distribution of protective current. Specialized anode designs account for varying flow conditions by incorporating hydrodynamic shapes and strategic positioning to maintain optimal protection levels while minimizing premature consumption in high-velocity environments.Expand Specific Solutions03 Integrated systems combining biofouling control and cathodic protection

Integrated protection systems combine sacrificial anodes with additional biofouling control mechanisms. These systems may incorporate controlled release of biocides, surface modifications, or electrical field generation to create a comprehensive approach to both corrosion and biofouling prevention. The synergistic effect of these combined technologies provides more effective protection than either approach alone, particularly in challenging marine environments.Expand Specific Solutions04 Material composition optimization for dual protection

Advanced material compositions for sacrificial anodes can provide both cathodic protection and biofouling resistance. These specialized alloys incorporate elements that generate biostatic or biocidal effects when released during the normal galvanic process. The careful selection and proportion of these elements ensures effective protection against both corrosion and biological growth without causing environmental harm or compromising the primary cathodic protection function.Expand Specific Solutions05 Monitoring and control systems for sacrificial anodes in variable flow conditions

Sophisticated monitoring and control systems help optimize sacrificial anode performance under variable flow velocity and biofouling conditions. These systems utilize sensors to track anode consumption rates, water flow parameters, and biofouling development, allowing for real-time adjustments to protection strategies. Advanced systems may incorporate automated responses such as adjusting current output or triggering cleaning mechanisms based on environmental conditions to maintain protection efficiency.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The marine sacrificial anode market is in a growth phase, driven by increasing maritime activities and offshore infrastructure development. The market is estimated to reach $1.2 billion by 2027, with a CAGR of 5.8%. Technologically, the field is evolving from traditional zinc/aluminum anodes toward more efficient solutions addressing biofouling challenges. Leading research institutions like The Hong Kong University of Science & Technology and Naval Research Laboratory are advancing fundamental understanding, while companies such as China National Offshore Oil Corp., Jotun AS, and WesternGeco Ltd. focus on practical applications. The integration of environmental considerations and performance optimization under varying flow conditions represents the current technological frontier, with collaborative efforts between academic and industrial players accelerating innovation in this critical marine protection technology.

China National Offshore Oil Corp.

Technical Solution: China National Offshore Oil Corporation (CNOOC) has developed advanced sacrificial anode systems specifically designed for offshore platforms and marine structures in varying oceanic conditions. Their research focuses on aluminum-zinc-indium alloy anodes that demonstrate superior performance in biofouling-rich environments. CNOOC has conducted extensive field testing across different water depths and flow velocities, creating computational models that predict anode consumption rates under various biofouling conditions. Their proprietary coating technology integrates with sacrificial anodes to create a dual protection system that maintains effectiveness even when marine growth accumulates. Recent innovations include smart monitoring systems that track galvanic current outputs in real-time, allowing for predictive maintenance before protection failure occurs.

Strengths: Extensive offshore field testing capabilities provide real-world validation data; integrated approach combining coatings with sacrificial anodes creates more robust protection systems. Weaknesses: Solutions primarily optimized for offshore oil installations may have limited applicability in other marine environments; higher implementation costs compared to traditional sacrificial anode systems.

Ocean University of China

Technical Solution: Ocean University of China has established a comprehensive research program examining the fundamental electrochemical interactions between marine biofouling organisms and sacrificial anode systems. Their laboratory has developed novel experimental protocols that isolate the effects of specific marine organisms on galvanic protection efficiency, identifying critical species that significantly impact anode performance. Their flow simulation chambers allow precise control of water velocity while monitoring real-time changes in galvanic current distribution across hull surfaces with varying degrees of biofouling. The university's research has led to the development of zinc-aluminum-magnesium-rare earth element alloys specifically formulated to maintain galvanic protection effectiveness under heavy biofouling conditions. Their computational models integrate biological growth patterns with electrochemical principles to predict protection lifespans across different operational profiles and marine environments, enabling more accurate maintenance scheduling for vessel operators.

Strengths: Strong fundamental research approach provides deep understanding of electrochemical mechanisms; extensive collaboration with commercial shipping industry ensures practical applicability of research findings. Weaknesses: Academic research focus may result in solutions that require further development for commercial implementation; limited global testing capabilities compared to multinational corporations.

Key Research on Biofouling-Galvanic Interaction Mechanisms

Mixed transition metal oxides silica xerogels as antifouling/fouling release surfaces

PatentWO2017100629A1

Innovation

- Development of mixed transition metal oxide and silica xerogels that incorporate titanium tetraisopropoxide or other transition metal alkoxides and oxides within the sol-gel matrix, which catalyze the oxidation of halide salts with hydrogen peroxide to produce hypohalous acids, reducing biofouling settlement without compromising fouling release properties.

Functionalization process for biocide immobilization in polymer matrices

PatentWO2016093719A1

Innovation

- A process for immobilizing biocides in polymeric matrices through functionalization with isocyanate reactive functions, ensuring compatibility and maintaining the biocide's structure, which allows for the development of antifouling polymeric systems that prevent toxic agent leaching into the environment, using diisocyanates and biocides like EM-NCO and IM-NCO, with specific reaction conditions and solvent selection to achieve high conversion rates and bioactivity retention.

Environmental Impact of Sacrificial Anode Systems

The environmental impact of sacrificial anode systems in marine applications represents a significant concern for maritime industries and environmental regulatory bodies. These galvanic protection systems, while essential for vessel integrity, release substantial quantities of metals into aquatic ecosystems during their operational lifetime. Primarily composed of zinc, aluminum, or magnesium alloys, sacrificial anodes dissolve gradually, introducing these metallic elements into seawater at rates influenced by factors such as biofouling accumulation and water flow velocity.

Research indicates that zinc anodes, commonly used in marine environments, can contribute to elevated zinc concentrations in harbor sediments and water columns. Studies have documented zinc levels exceeding environmental quality standards in poorly flushed marinas and harbors with high densities of protected vessels. This metal accumulation poses potential toxicity risks to sensitive marine organisms, particularly in their larval stages, potentially disrupting reproductive cycles and population dynamics of various species.

Aluminum anodes, while gaining popularity as alternatives, present their own environmental considerations. Though generally considered less environmentally harmful than zinc variants, aluminum anodes release aluminum ions that may form hydroxide precipitates affecting benthic communities. Additionally, some aluminum anodes contain trace elements like indium and mercury as activators, which can bioaccumulate in marine food webs despite their low concentrations.

The interaction between biofouling and sacrificial anodes creates complex environmental dynamics. Biofouling layers can reduce anode efficiency, leading to increased anode consumption rates and consequently higher metal release into marine environments. Conversely, certain biofilm compositions may temporarily sequester released metals, altering their bioavailability and environmental transport patterns.

Flow velocity significantly influences the environmental footprint of sacrificial anode systems. Higher water flow rates can disperse released metals more widely, potentially reducing localized concentration hotspots but expanding the geographical impact zone. Conversely, in low-flow environments such as enclosed harbors, metal ions tend to accumulate in sediments, creating persistent environmental reservoirs that may affect benthic ecosystems for extended periods.

Recent regulatory frameworks have begun addressing these environmental concerns. The European Union's Water Framework Directive and similar international regulations increasingly recognize sacrificial anodes as potential sources of water pollution. This has prompted research into more environmentally compatible cathodic protection systems, including impressed current systems that can reduce overall metal discharge and biodegradable anode formulations designed to minimize long-term environmental persistence of released elements.

Research indicates that zinc anodes, commonly used in marine environments, can contribute to elevated zinc concentrations in harbor sediments and water columns. Studies have documented zinc levels exceeding environmental quality standards in poorly flushed marinas and harbors with high densities of protected vessels. This metal accumulation poses potential toxicity risks to sensitive marine organisms, particularly in their larval stages, potentially disrupting reproductive cycles and population dynamics of various species.

Aluminum anodes, while gaining popularity as alternatives, present their own environmental considerations. Though generally considered less environmentally harmful than zinc variants, aluminum anodes release aluminum ions that may form hydroxide precipitates affecting benthic communities. Additionally, some aluminum anodes contain trace elements like indium and mercury as activators, which can bioaccumulate in marine food webs despite their low concentrations.

The interaction between biofouling and sacrificial anodes creates complex environmental dynamics. Biofouling layers can reduce anode efficiency, leading to increased anode consumption rates and consequently higher metal release into marine environments. Conversely, certain biofilm compositions may temporarily sequester released metals, altering their bioavailability and environmental transport patterns.

Flow velocity significantly influences the environmental footprint of sacrificial anode systems. Higher water flow rates can disperse released metals more widely, potentially reducing localized concentration hotspots but expanding the geographical impact zone. Conversely, in low-flow environments such as enclosed harbors, metal ions tend to accumulate in sediments, creating persistent environmental reservoirs that may affect benthic ecosystems for extended periods.

Recent regulatory frameworks have begun addressing these environmental concerns. The European Union's Water Framework Directive and similar international regulations increasingly recognize sacrificial anodes as potential sources of water pollution. This has prompted research into more environmentally compatible cathodic protection systems, including impressed current systems that can reduce overall metal discharge and biodegradable anode formulations designed to minimize long-term environmental persistence of released elements.

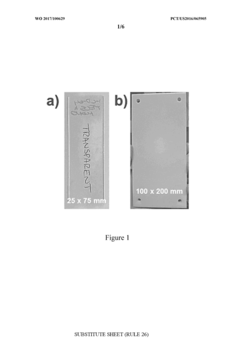

Standardization and Testing Methodologies

The standardization of testing methodologies for sacrificial anodes in marine environments is crucial for ensuring reliable corrosion protection across the shipping industry. Current standards such as ASTM G97 and DNV-RP-B401 provide baseline protocols for anode performance evaluation, but lack comprehensive guidelines addressing the complex interplay between biofouling and flow velocity on galvanic protection systems.

Existing testing methodologies typically employ accelerated laboratory tests that fail to accurately simulate real-world marine conditions where biofouling organisms progressively colonize hull surfaces and alter electrochemical dynamics. This disconnect between laboratory testing and operational reality creates significant challenges in predicting actual service life and performance of sacrificial anodes in working vessels.

Field testing protocols currently show considerable variation across research institutions and classification societies, making cross-study comparisons difficult and limiting the development of universal performance metrics. The International Association of Classification Societies (IACS) has recognized this gap and initiated efforts toward harmonizing testing procedures, particularly focusing on standardized methods for evaluating anode performance under varying flow conditions and biofilm formation stages.

Recent advancements in testing methodology include the development of dynamic flow chambers that can simulate variable velocity conditions while maintaining controlled biofilm growth. These systems enable researchers to measure polarization behavior and current output of anodes under conditions more representative of actual marine operations. However, calibration and validation of these systems against real-world performance remains challenging.

Electrochemical Impedance Spectroscopy (EIS) has emerged as a valuable technique for quantifying the effects of biofilm formation on anode performance, offering insights into the changing interfacial properties at the anode surface. Integration of EIS into standardized testing protocols would significantly enhance the industry's ability to predict long-term anode behavior in biofouling-prone environments.

The development of standardized biofouling simulants represents another critical area requiring attention. Current approaches vary widely in their methods for cultivating and applying representative marine biofilms to test specimens, leading to inconsistent results across studies. Establishing reference biofilm communities and application procedures would greatly improve test reproducibility and relevance.

International collaboration between academic institutions, classification societies, and industry stakeholders is essential for developing comprehensive testing standards that address the multifaceted nature of sacrificial anode performance in real marine environments. Such standards must incorporate protocols for evaluating performance across varying flow regimes, water chemistry conditions, and biofouling progression stages to provide truly predictive data for marine engineers and vessel operators.

Existing testing methodologies typically employ accelerated laboratory tests that fail to accurately simulate real-world marine conditions where biofouling organisms progressively colonize hull surfaces and alter electrochemical dynamics. This disconnect between laboratory testing and operational reality creates significant challenges in predicting actual service life and performance of sacrificial anodes in working vessels.

Field testing protocols currently show considerable variation across research institutions and classification societies, making cross-study comparisons difficult and limiting the development of universal performance metrics. The International Association of Classification Societies (IACS) has recognized this gap and initiated efforts toward harmonizing testing procedures, particularly focusing on standardized methods for evaluating anode performance under varying flow conditions and biofilm formation stages.

Recent advancements in testing methodology include the development of dynamic flow chambers that can simulate variable velocity conditions while maintaining controlled biofilm growth. These systems enable researchers to measure polarization behavior and current output of anodes under conditions more representative of actual marine operations. However, calibration and validation of these systems against real-world performance remains challenging.

Electrochemical Impedance Spectroscopy (EIS) has emerged as a valuable technique for quantifying the effects of biofilm formation on anode performance, offering insights into the changing interfacial properties at the anode surface. Integration of EIS into standardized testing protocols would significantly enhance the industry's ability to predict long-term anode behavior in biofouling-prone environments.

The development of standardized biofouling simulants represents another critical area requiring attention. Current approaches vary widely in their methods for cultivating and applying representative marine biofilms to test specimens, leading to inconsistent results across studies. Establishing reference biofilm communities and application procedures would greatly improve test reproducibility and relevance.

International collaboration between academic institutions, classification societies, and industry stakeholders is essential for developing comprehensive testing standards that address the multifaceted nature of sacrificial anode performance in real marine environments. Such standards must incorporate protocols for evaluating performance across varying flow regimes, water chemistry conditions, and biofouling progression stages to provide truly predictive data for marine engineers and vessel operators.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!