Sacrificial Anode Coating Synergy: Holiday Density, CP Current And Over-Protection

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sacrificial Anode Technology Background and Objectives

Sacrificial anode technology has evolved significantly over the past century, with its origins dating back to the early 1900s when Sir Humphry Davy first demonstrated the principle of cathodic protection using sacrificial metals. This technology fundamentally relies on the galvanic series of metals, where less noble metals corrode preferentially to protect more noble metals. The development trajectory has moved from simple zinc and magnesium anodes to sophisticated alloy compositions and hybrid protection systems that work synergistically with protective coatings.

The synergy between sacrificial anodes and protective coatings represents a critical advancement in corrosion protection strategies, particularly for marine structures, pipelines, and industrial equipment. This relationship is complex and multifaceted, involving the interplay between holiday density (coating defects), cathodic protection (CP) current distribution, and the potential risk of over-protection that can lead to hydrogen embrittlement or coating disbondment.

Recent technological developments have focused on optimizing this synergy through advanced materials science and electrochemical engineering. The industry has witnessed a shift from traditional zinc, aluminum, and magnesium anodes to more sophisticated alloys that offer improved current efficiency, longer service life, and better performance across varying environmental conditions. Concurrently, coating technologies have evolved to include multi-layer systems with enhanced adhesion properties and reduced holiday formation.

The primary objective in this field is to develop integrated protection systems that maximize asset longevity while minimizing maintenance requirements and environmental impact. This involves achieving an optimal balance where sacrificial anodes provide sufficient protection at coating holidays without generating excessive current that could damage the coating itself or the underlying substrate through over-protection mechanisms.

Current research trends are exploring smart anode systems that can adjust their output based on environmental conditions and protection requirements. These include remotely monitored sacrificial anodes, hybrid impressed current/sacrificial systems, and environmentally friendly anode formulations that reduce toxic metal release while maintaining protection efficacy.

The technological trajectory points toward more sophisticated modeling of the coating-anode interaction, allowing for precise prediction of holiday effects on current distribution and protection levels. This includes computational models that can simulate long-term performance under varying conditions, enabling more accurate lifecycle cost analyses and maintenance planning.

As industrial assets continue to be deployed in increasingly challenging environments, from deep-sea installations to arctic conditions, the demand for advanced sacrificial anode technologies that work harmoniously with high-performance coatings continues to grow. The ultimate goal remains developing protection systems that provide reliable, long-term performance with minimal environmental footprint and reduced total cost of ownership.

The synergy between sacrificial anodes and protective coatings represents a critical advancement in corrosion protection strategies, particularly for marine structures, pipelines, and industrial equipment. This relationship is complex and multifaceted, involving the interplay between holiday density (coating defects), cathodic protection (CP) current distribution, and the potential risk of over-protection that can lead to hydrogen embrittlement or coating disbondment.

Recent technological developments have focused on optimizing this synergy through advanced materials science and electrochemical engineering. The industry has witnessed a shift from traditional zinc, aluminum, and magnesium anodes to more sophisticated alloys that offer improved current efficiency, longer service life, and better performance across varying environmental conditions. Concurrently, coating technologies have evolved to include multi-layer systems with enhanced adhesion properties and reduced holiday formation.

The primary objective in this field is to develop integrated protection systems that maximize asset longevity while minimizing maintenance requirements and environmental impact. This involves achieving an optimal balance where sacrificial anodes provide sufficient protection at coating holidays without generating excessive current that could damage the coating itself or the underlying substrate through over-protection mechanisms.

Current research trends are exploring smart anode systems that can adjust their output based on environmental conditions and protection requirements. These include remotely monitored sacrificial anodes, hybrid impressed current/sacrificial systems, and environmentally friendly anode formulations that reduce toxic metal release while maintaining protection efficacy.

The technological trajectory points toward more sophisticated modeling of the coating-anode interaction, allowing for precise prediction of holiday effects on current distribution and protection levels. This includes computational models that can simulate long-term performance under varying conditions, enabling more accurate lifecycle cost analyses and maintenance planning.

As industrial assets continue to be deployed in increasingly challenging environments, from deep-sea installations to arctic conditions, the demand for advanced sacrificial anode technologies that work harmoniously with high-performance coatings continues to grow. The ultimate goal remains developing protection systems that provide reliable, long-term performance with minimal environmental footprint and reduced total cost of ownership.

Market Demand Analysis for Corrosion Protection Systems

The global market for corrosion protection systems has been experiencing steady growth, driven primarily by increasing infrastructure development and the rising costs associated with corrosion-related failures. The sacrificial anode coating market, specifically focusing on synergies between holiday density, cathodic protection (CP) current, and over-protection, represents a critical segment within this broader industry.

Recent market research indicates that the corrosion protection market is expected to reach $10.3 billion by 2026, growing at a CAGR of 5.2% from 2021. Within this market, sacrificial anode systems account for approximately 30% of the total market share, highlighting their significance in comprehensive corrosion protection strategies.

The demand for advanced sacrificial anode coating systems with optimized holiday density management is particularly strong in marine, oil and gas, and infrastructure sectors. These industries collectively represent over 65% of the total market demand, with offshore structures and underwater pipelines being the primary application areas requiring sophisticated protection against aggressive corrosive environments.

The oil and gas sector demonstrates the highest demand growth rate at 6.8% annually, driven by aging infrastructure and expansion into more corrosive environments. This sector's specific requirements for systems that can balance CP current distribution while preventing over-protection has created a specialized market niche estimated at $1.2 billion globally.

Regional analysis reveals that North America and Asia-Pacific dominate the market, collectively accounting for 58% of global demand. The Middle East region shows the fastest growth trajectory at 7.3% annually, attributed to extensive oil and gas infrastructure and challenging environmental conditions that accelerate corrosion processes.

Customer demand patterns indicate a clear shift toward integrated corrosion protection solutions that optimize the synergy between coating systems and cathodic protection. End-users increasingly seek systems that can automatically adjust CP current based on holiday density measurements, reducing maintenance costs by up to 40% and extending asset lifespans by 15-20 years.

The market also shows growing demand for environmentally sustainable sacrificial anode materials that maintain effectiveness while reducing environmental impact. This trend is particularly pronounced in European markets, where regulatory pressures have accelerated the adoption of eco-friendly corrosion protection systems by approximately 22% over the past three years.

Industry surveys reveal that customers are willing to pay premium prices (typically 15-25% higher) for advanced systems that demonstrate superior performance in managing the critical balance between holiday density, CP current distribution, and prevention of over-protection, highlighting significant market opportunities for innovative solutions in this technical domain.

Recent market research indicates that the corrosion protection market is expected to reach $10.3 billion by 2026, growing at a CAGR of 5.2% from 2021. Within this market, sacrificial anode systems account for approximately 30% of the total market share, highlighting their significance in comprehensive corrosion protection strategies.

The demand for advanced sacrificial anode coating systems with optimized holiday density management is particularly strong in marine, oil and gas, and infrastructure sectors. These industries collectively represent over 65% of the total market demand, with offshore structures and underwater pipelines being the primary application areas requiring sophisticated protection against aggressive corrosive environments.

The oil and gas sector demonstrates the highest demand growth rate at 6.8% annually, driven by aging infrastructure and expansion into more corrosive environments. This sector's specific requirements for systems that can balance CP current distribution while preventing over-protection has created a specialized market niche estimated at $1.2 billion globally.

Regional analysis reveals that North America and Asia-Pacific dominate the market, collectively accounting for 58% of global demand. The Middle East region shows the fastest growth trajectory at 7.3% annually, attributed to extensive oil and gas infrastructure and challenging environmental conditions that accelerate corrosion processes.

Customer demand patterns indicate a clear shift toward integrated corrosion protection solutions that optimize the synergy between coating systems and cathodic protection. End-users increasingly seek systems that can automatically adjust CP current based on holiday density measurements, reducing maintenance costs by up to 40% and extending asset lifespans by 15-20 years.

The market also shows growing demand for environmentally sustainable sacrificial anode materials that maintain effectiveness while reducing environmental impact. This trend is particularly pronounced in European markets, where regulatory pressures have accelerated the adoption of eco-friendly corrosion protection systems by approximately 22% over the past three years.

Industry surveys reveal that customers are willing to pay premium prices (typically 15-25% higher) for advanced systems that demonstrate superior performance in managing the critical balance between holiday density, CP current distribution, and prevention of over-protection, highlighting significant market opportunities for innovative solutions in this technical domain.

Current Challenges in Sacrificial Anode Coating Technology

The sacrificial anode coating technology faces several significant challenges that impede its optimal performance and widespread adoption. One of the primary issues is the inconsistent holiday density across coated surfaces. Holidays—small pores, cracks, or defects in the coating—create pathways for corrosive elements to reach the metal substrate. Current manufacturing processes struggle to achieve uniform coating application, resulting in variable holiday densities that compromise the overall protection system's effectiveness.

The synergy between coating integrity and cathodic protection (CP) current distribution presents another complex challenge. When holiday density increases, the CP current demand rises disproportionately, creating "hot spots" of current concentration. This uneven current distribution leads to accelerated consumption of sacrificial anodes in certain areas while leaving other regions inadequately protected. The industry lacks reliable models to predict this relationship accurately, particularly in complex geometries or under varying environmental conditions.

Over-protection represents a significant technical hurdle that has not been adequately addressed. When excessive CP current flows through holidays to the substrate, it can cause hydrogen evolution, leading to coating disbondment and potential hydrogen embrittlement in high-strength steels. This phenomenon creates a negative feedback loop: over-protection damages the coating, creating more holidays, which then require more CP current—ultimately accelerating the degradation of the entire protection system.

Material compatibility issues further complicate the technology's advancement. The electrochemical interactions between different sacrificial anode materials (zinc, aluminum, magnesium alloys) and various coating formulations remain poorly understood. Some combinations exhibit antagonistic effects, where coating degradation accelerates due to the specific electrochemical reactions initiated by the sacrificial anode material.

Environmental factors introduce additional variables that current systems struggle to accommodate. Temperature fluctuations, salinity variations, and microbiologically influenced corrosion can dramatically alter the performance parameters of sacrificial anode coating systems. The technology lacks adaptive capabilities to maintain optimal protection levels across these changing conditions.

Monitoring and maintenance challenges persist despite technological advances. Non-destructive evaluation techniques for assessing holiday density in field conditions remain limited in accuracy and practicality. Without reliable real-time monitoring, operators often resort to conservative over-application of sacrificial anodes, leading to economic inefficiency and potential over-protection issues.

The industry also faces significant knowledge gaps in understanding the long-term performance degradation mechanisms of these systems, particularly in predicting end-of-life scenarios and optimizing replacement schedules for sacrificial anodes in relation to coating condition.

The synergy between coating integrity and cathodic protection (CP) current distribution presents another complex challenge. When holiday density increases, the CP current demand rises disproportionately, creating "hot spots" of current concentration. This uneven current distribution leads to accelerated consumption of sacrificial anodes in certain areas while leaving other regions inadequately protected. The industry lacks reliable models to predict this relationship accurately, particularly in complex geometries or under varying environmental conditions.

Over-protection represents a significant technical hurdle that has not been adequately addressed. When excessive CP current flows through holidays to the substrate, it can cause hydrogen evolution, leading to coating disbondment and potential hydrogen embrittlement in high-strength steels. This phenomenon creates a negative feedback loop: over-protection damages the coating, creating more holidays, which then require more CP current—ultimately accelerating the degradation of the entire protection system.

Material compatibility issues further complicate the technology's advancement. The electrochemical interactions between different sacrificial anode materials (zinc, aluminum, magnesium alloys) and various coating formulations remain poorly understood. Some combinations exhibit antagonistic effects, where coating degradation accelerates due to the specific electrochemical reactions initiated by the sacrificial anode material.

Environmental factors introduce additional variables that current systems struggle to accommodate. Temperature fluctuations, salinity variations, and microbiologically influenced corrosion can dramatically alter the performance parameters of sacrificial anode coating systems. The technology lacks adaptive capabilities to maintain optimal protection levels across these changing conditions.

Monitoring and maintenance challenges persist despite technological advances. Non-destructive evaluation techniques for assessing holiday density in field conditions remain limited in accuracy and practicality. Without reliable real-time monitoring, operators often resort to conservative over-application of sacrificial anodes, leading to economic inefficiency and potential over-protection issues.

The industry also faces significant knowledge gaps in understanding the long-term performance degradation mechanisms of these systems, particularly in predicting end-of-life scenarios and optimizing replacement schedules for sacrificial anodes in relation to coating condition.

Current Solutions for Holiday Density Management

01 Holiday detection and density in sacrificial anode coatings

Holidays (defects or discontinuities) in protective coatings are critical points where corrosion can initiate. The density of these holidays affects the performance of cathodic protection systems. Detection methods include electrical holiday detectors that identify breaks in the coating's insulation properties. Controlling holiday density is essential for ensuring adequate protection while preventing excessive current demand on sacrificial anodes. Lower holiday density generally results in more efficient cathodic protection with reduced anode consumption.- Holiday detection and density in sacrificial anode coatings: Holidays (defects or discontinuities) in protective coatings can significantly impact the effectiveness of cathodic protection systems. The density of these holidays affects the current distribution and overall protection level. Advanced detection methods can identify holidays in sacrificial anode coatings, allowing for quality control during installation and maintenance. Proper holiday detection ensures optimal performance of the cathodic protection system by identifying areas where the metal substrate might be exposed to corrosive environments.

- Cathodic protection current requirements and distribution: The effectiveness of sacrificial anode systems depends on proper current distribution and meeting minimum current density requirements. Factors affecting CP current include the environment's corrosivity, coating quality, and the protected structure's size. Optimizing the current distribution ensures uniform protection across the entire structure while minimizing anode consumption. Advanced monitoring systems can measure and adjust current output to maintain protection levels within the desired range, preventing both under-protection and over-protection scenarios.

- Over-protection prevention and control mechanisms: Over-protection occurs when excessive cathodic protection current is applied to a structure, potentially causing hydrogen embrittlement, coating disbondment, or accelerated anode consumption. Control mechanisms such as resistors, diodes, and intelligent monitoring systems can regulate the current output from sacrificial anodes to prevent over-protection. These systems may include reference electrodes to continuously measure protection potentials and automatically adjust current flow. Proper design of sacrificial anode systems considers the balance between adequate protection and avoiding the negative consequences of over-protection.

- Sacrificial anode coating composition and application techniques: The composition of sacrificial anode coatings significantly impacts their performance and longevity. These coatings typically contain zinc, aluminum, magnesium, or their alloys, selected based on the environment and protection requirements. Application techniques such as thermal spraying, electroplating, or hot-dip galvanizing affect coating adhesion, uniformity, and holiday formation. Advanced coating systems may incorporate multiple layers or additives to enhance conductivity, adhesion, and corrosion resistance. Proper surface preparation before coating application is essential to minimize holidays and ensure optimal performance.

- Monitoring and maintenance of sacrificial anode systems: Regular monitoring and maintenance are essential for ensuring the continued effectiveness of sacrificial anode systems. Monitoring techniques include potential measurements, current output readings, and physical inspections of anodes and protected structures. Remote monitoring systems can provide real-time data on protection levels, allowing for prompt intervention when protection falls outside acceptable ranges. Maintenance activities may include replacing depleted anodes, repairing damaged coatings, and adjusting protection parameters based on monitoring results. Proper documentation of monitoring data helps in predicting anode life and planning maintenance schedules.

02 Cathodic protection current requirements and distribution

The cathodic protection (CP) current required for effective corrosion prevention depends on multiple factors including coating quality, environmental conditions, and protected structure characteristics. Current distribution must be optimized to ensure complete protection without wasteful overconsumption of sacrificial anodes. Advanced monitoring systems can measure and adjust CP current to maintain protection levels within the optimal range. Proper current distribution prevents localized corrosion at holidays while extending the service life of the sacrificial anode system.Expand Specific Solutions03 Over-protection prevention and control mechanisms

Over-protection occurs when excessive cathodic protection current is applied, potentially causing hydrogen embrittlement, coating disbondment, and accelerated anode consumption. Control mechanisms include reference electrodes for potential monitoring, current limiting devices, and intelligent systems that adjust protection levels based on real-time measurements. Proper anode placement and sizing help prevent over-protection in areas close to anodes while ensuring adequate protection in remote areas. Balanced protection systems extend infrastructure lifespan while minimizing maintenance requirements.Expand Specific Solutions04 Sacrificial anode material selection and performance

The selection of sacrificial anode materials significantly impacts protection effectiveness and system longevity. Common materials include zinc, aluminum, and magnesium alloys, each with specific applications based on environmental conditions. Anode composition affects current output, consumption rate, and driving potential. Advanced alloys can provide more uniform current distribution and better performance in varying environments. Material selection must consider factors such as water resistivity, temperature, and the presence of contaminants to optimize protection while preventing over-protection conditions.Expand Specific Solutions05 Monitoring systems for sacrificial anode performance

Monitoring systems are essential for evaluating sacrificial anode performance and detecting issues before failure occurs. These systems measure protection potentials, current output, and anode consumption rates to ensure optimal protection levels. Remote monitoring technologies allow for real-time data collection and analysis without physical inspection. Advanced systems can automatically adjust protection parameters or alert operators when values fall outside acceptable ranges. Effective monitoring prevents both under-protection and over-protection conditions while optimizing anode lifespan and system efficiency.Expand Specific Solutions

Major Industry Players in Sacrificial Anode Market

The sacrificial anode coating synergy market is currently in a growth phase, with increasing demand driven by offshore oil and gas infrastructure expansion and marine applications. The global market size is estimated at $2-3 billion annually, with projected 5-7% CAGR through 2028. Technologically, the field is moderately mature but experiencing innovation in holiday detection and current optimization. Industry leaders include Vetco Gray Scandinavia (Baker Hughes) with advanced CP monitoring systems, China National Offshore Oil Corp. with extensive offshore implementation experience, and Vector Corrosion Technologies offering specialized concrete protection solutions. Emerging players like Dalian Kingmile Anticorrosion and Sunrui Marine Environment Engineering are advancing monitoring technologies, while research institutions such as Ocean University of China and Penn State Research Foundation are developing next-generation synergistic coating systems that balance protection against over-protection risks.

China National Offshore Oil Corp.

Technical Solution: China National Offshore Oil Corp. (CNOOC) has developed an integrated sacrificial anode coating system specifically designed for offshore structures that optimizes the synergy between holiday density, cathodic protection (CP) current, and over-protection concerns. Their approach involves a multi-layer coating system with aluminum-zinc-indium sacrificial anodes strategically positioned to maintain optimal current distribution. The system incorporates real-time monitoring technology that measures coating integrity, holiday formation, and CP current density to prevent both under-protection and over-protection scenarios. CNOOC's research has demonstrated that controlling holiday density to below 1% of total surface area while maintaining CP current densities between 10-20 mA/m² provides optimal protection without hydrogen embrittlement risks in high-strength steels. Their proprietary coating formulation includes self-healing components that can temporarily seal minor holidays, reducing immediate CP current demands and extending anode life.

Strengths: Comprehensive integration of coating and CP systems with real-time monitoring capabilities allows for dynamic adjustment of protection parameters. The self-healing coating technology extends system longevity in harsh offshore environments. Weaknesses: The system requires sophisticated monitoring equipment and expertise to maintain optimal performance, potentially increasing operational costs for smaller operators.

Dalian Kingmile Anticorrosion Technology Co., Ltd.

Technical Solution: Dalian Kingmile has pioneered a dual-phase sacrificial anode coating technology that addresses the critical relationship between holiday density, CP current distribution, and over-protection risks. Their system employs a primary zinc-rich primer layer with controlled conductivity properties, coupled with aluminum-zinc-magnesium secondary anodes for deep-water applications. The company's proprietary "Smart-CP" technology incorporates nano-scale conductive particles in the coating matrix that activate only when holidays develop, creating localized sacrificial protection zones. Laboratory and field testing has shown that this approach maintains CP current densities within 5-15 mA/m² even when holiday density increases to 3-5% of surface area. Dalian Kingmile's system includes specialized edge treatment technology that reinforces typically vulnerable areas, reducing holiday formation at edges and welds by approximately 70% compared to conventional systems. Their research indicates that this balanced approach extends anode life by 30-40% while minimizing hydrogen evolution at the cathode surface, effectively addressing the over-protection concern for high-strength steels used in offshore applications.

Strengths: The adaptive nano-particle technology provides targeted protection at holiday sites, optimizing anode consumption and extending system life. The specialized edge treatment significantly reduces failure at critical points. Weaknesses: The complex coating formulation requires precise application conditions and quality control measures, potentially limiting application in remote or challenging environments.

Key Technical Innovations in CP Current Distribution

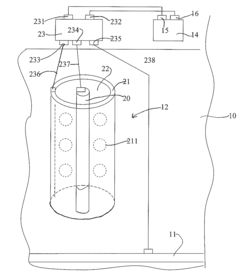

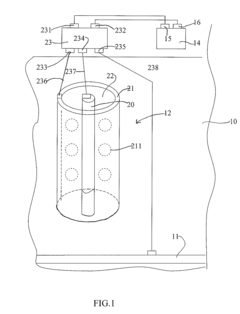

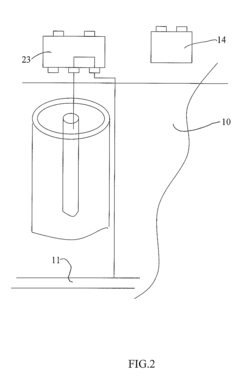

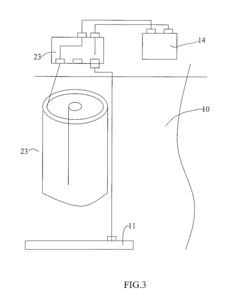

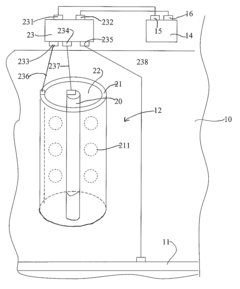

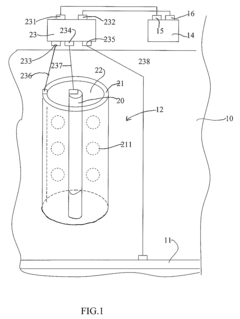

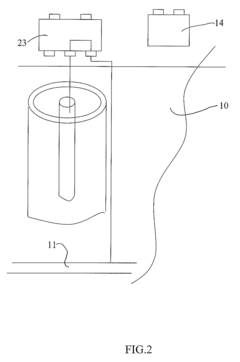

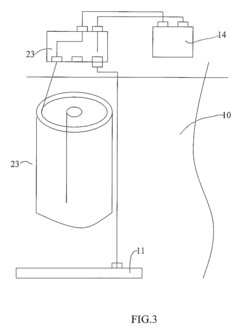

Apparatus for Cathodic Protection System Using an Impressed Current Anode and a Sacrificial Anode

PatentInactiveUS20140021039A1

Innovation

- A dual anode system comprising a sacrificial anode and an impressed current anode, where the sacrificial anode is recharged using a DC power supply, allowing for extended protection by redepositing ions and providing a backup corrosion protection mechanism.

Charging a sacrificial anode with ions of the sacrificial material

PatentActiveUS8961746B2

Innovation

- A method involving a sacrificial anode that is recharged with ions using an impressed current anode and DC power supply, allowing for extended operation by redepositing sacrificial anode ions, thereby enhancing corrosion protection and increasing the anode's lifespan.

Environmental Impact Assessment of Sacrificial Anode Systems

The environmental impact of sacrificial anode systems extends far beyond their immediate protective function, encompassing a complex web of ecological considerations. These systems, while effective for corrosion protection, release metal ions into surrounding environments as they corrode, potentially affecting aquatic ecosystems and sediment quality. The dissolution rate of anodes—typically made of zinc, aluminum, or magnesium alloys—directly correlates with their environmental footprint.

Holiday density in protective coatings significantly influences environmental impact by determining the exposure area where sacrificial anodes must provide protection. Higher holiday density necessitates increased cathodic protection current, accelerating anode consumption and metal ion release. This relationship creates a critical balance between coating integrity and environmental burden.

Over-protection scenarios, where excessive cathodic protection current is applied, present particular environmental concerns. These conditions can lead to accelerated anode consumption without proportional protection benefits, unnecessarily increasing metal loading in marine environments. Additionally, over-protection may generate hydrogen gas at the cathode surface, potentially causing coating disbondment and creating new pathways for corrosion and further environmental contamination.

The geographical context of anode deployment significantly affects environmental impact assessment. Enclosed or sensitive marine ecosystems may experience more pronounced effects from metal ion accumulation compared to open ocean environments with greater dilution capacity. Regulatory frameworks addressing these concerns vary globally, with increasingly stringent standards emerging in regions with vulnerable marine ecosystems.

Long-term environmental monitoring studies have revealed bioaccumulation potential for certain sacrificial anode metals in marine organisms, particularly in benthic communities near offshore structures. The synergistic effects between coating holidays, CP current distribution, and over-protection can create localized "hot spots" of metal concentration that exceed background levels and potentially impact biological communities.

Sustainable alternatives and mitigation strategies are emerging as important considerations in environmental impact assessments. These include optimized anode composition with reduced toxic elements, improved coating technologies to minimize holiday density, and advanced monitoring systems that prevent over-protection scenarios. The development of biodegradable or environmentally benign anode materials represents a promising frontier in reducing the ecological footprint of cathodic protection systems.

Cost-benefit analyses increasingly incorporate environmental externalities when evaluating sacrificial anode systems, recognizing that initial economic advantages may be offset by long-term environmental remediation costs or regulatory penalties. This holistic approach to environmental impact assessment is becoming standard practice in industries utilizing sacrificial anode technology, particularly in offshore energy, shipping, and coastal infrastructure sectors.

Holiday density in protective coatings significantly influences environmental impact by determining the exposure area where sacrificial anodes must provide protection. Higher holiday density necessitates increased cathodic protection current, accelerating anode consumption and metal ion release. This relationship creates a critical balance between coating integrity and environmental burden.

Over-protection scenarios, where excessive cathodic protection current is applied, present particular environmental concerns. These conditions can lead to accelerated anode consumption without proportional protection benefits, unnecessarily increasing metal loading in marine environments. Additionally, over-protection may generate hydrogen gas at the cathode surface, potentially causing coating disbondment and creating new pathways for corrosion and further environmental contamination.

The geographical context of anode deployment significantly affects environmental impact assessment. Enclosed or sensitive marine ecosystems may experience more pronounced effects from metal ion accumulation compared to open ocean environments with greater dilution capacity. Regulatory frameworks addressing these concerns vary globally, with increasingly stringent standards emerging in regions with vulnerable marine ecosystems.

Long-term environmental monitoring studies have revealed bioaccumulation potential for certain sacrificial anode metals in marine organisms, particularly in benthic communities near offshore structures. The synergistic effects between coating holidays, CP current distribution, and over-protection can create localized "hot spots" of metal concentration that exceed background levels and potentially impact biological communities.

Sustainable alternatives and mitigation strategies are emerging as important considerations in environmental impact assessments. These include optimized anode composition with reduced toxic elements, improved coating technologies to minimize holiday density, and advanced monitoring systems that prevent over-protection scenarios. The development of biodegradable or environmentally benign anode materials represents a promising frontier in reducing the ecological footprint of cathodic protection systems.

Cost-benefit analyses increasingly incorporate environmental externalities when evaluating sacrificial anode systems, recognizing that initial economic advantages may be offset by long-term environmental remediation costs or regulatory penalties. This holistic approach to environmental impact assessment is becoming standard practice in industries utilizing sacrificial anode technology, particularly in offshore energy, shipping, and coastal infrastructure sectors.

Standardization and Testing Protocols for CP Effectiveness

Standardized testing protocols are essential for accurately evaluating the effectiveness of cathodic protection (CP) systems, particularly when examining the synergistic relationship between sacrificial anode coatings, holiday density, CP current, and over-protection phenomena. Current industry practices reveal significant variations in testing methodologies, leading to inconsistent results and challenges in comparative analysis across different protection systems.

The establishment of unified testing standards requires consideration of multiple parameters including environmental conditions, coating types, anode materials, and substrate characteristics. NACE International (now AMPP) and ISO have developed several standards, such as NACE SP0169 and ISO 15589, which provide foundational frameworks for CP testing. However, these standards often lack specific protocols for evaluating the complex interactions between coating holidays and CP current distribution.

Key measurement parameters that require standardization include holiday detection thresholds, CP current density measurements, polarization criteria, and protection potential ranges. The industry currently employs various techniques including DCVG (Direct Current Voltage Gradient), CIPS (Close Interval Potential Survey), and EIS (Electrochemical Impedance Spectroscopy), each with distinct advantages but lacking integration into a comprehensive testing protocol.

Laboratory testing environments must simulate real-world conditions while maintaining reproducibility. Accelerated testing protocols need validation against long-term field performance data to establish reliable correlation factors. This includes standardized salt fog chambers, immersion tests, and cyclic exposure regimes that accurately represent operational environments while accelerating degradation mechanisms in a predictable manner.

Field testing standardization presents additional challenges due to variable environmental conditions. Protocols must address seasonal variations, soil resistivity fluctuations, and interference from adjacent structures. Mobile reference electrodes and data logging systems with standardized calibration procedures are essential for ensuring measurement consistency across different geographical locations and time periods.

Data interpretation frameworks represent another critical component requiring standardization. Statistical analysis methods, acceptance criteria, and performance indicators must be clearly defined to enable objective evaluation of CP effectiveness. This includes standardized approaches for distinguishing between coating failure modes and CP current distribution anomalies, particularly in cases where over-protection may accelerate coating disbondment or hydrogen embrittlement in high-strength steels.

Implementation of these standardized protocols would significantly enhance the reliability of CP system design, facilitate meaningful comparison between different protection strategies, and ultimately improve the longevity and safety of protected structures in various industrial applications.

The establishment of unified testing standards requires consideration of multiple parameters including environmental conditions, coating types, anode materials, and substrate characteristics. NACE International (now AMPP) and ISO have developed several standards, such as NACE SP0169 and ISO 15589, which provide foundational frameworks for CP testing. However, these standards often lack specific protocols for evaluating the complex interactions between coating holidays and CP current distribution.

Key measurement parameters that require standardization include holiday detection thresholds, CP current density measurements, polarization criteria, and protection potential ranges. The industry currently employs various techniques including DCVG (Direct Current Voltage Gradient), CIPS (Close Interval Potential Survey), and EIS (Electrochemical Impedance Spectroscopy), each with distinct advantages but lacking integration into a comprehensive testing protocol.

Laboratory testing environments must simulate real-world conditions while maintaining reproducibility. Accelerated testing protocols need validation against long-term field performance data to establish reliable correlation factors. This includes standardized salt fog chambers, immersion tests, and cyclic exposure regimes that accurately represent operational environments while accelerating degradation mechanisms in a predictable manner.

Field testing standardization presents additional challenges due to variable environmental conditions. Protocols must address seasonal variations, soil resistivity fluctuations, and interference from adjacent structures. Mobile reference electrodes and data logging systems with standardized calibration procedures are essential for ensuring measurement consistency across different geographical locations and time periods.

Data interpretation frameworks represent another critical component requiring standardization. Statistical analysis methods, acceptance criteria, and performance indicators must be clearly defined to enable objective evaluation of CP effectiveness. This includes standardized approaches for distinguishing between coating failure modes and CP current distribution anomalies, particularly in cases where over-protection may accelerate coating disbondment or hydrogen embrittlement in high-strength steels.

Implementation of these standardized protocols would significantly enhance the reliability of CP system design, facilitate meaningful comparison between different protection strategies, and ultimately improve the longevity and safety of protected structures in various industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!