Sacrificial Anode Safety: Hydrogen, Confined Spaces And Hot Work Controls

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sacrificial Anode Technology Background and Objectives

Sacrificial anodes have been utilized for cathodic protection since the early 19th century, with Sir Humphry Davy pioneering their application in protecting copper-clad ships in 1824. This technology has evolved significantly over the decades, becoming a cornerstone in corrosion prevention across multiple industries including maritime, oil and gas, water treatment, and infrastructure protection. The fundamental principle remains unchanged: sacrificial anodes, composed of more electrochemically active metals such as zinc, aluminum, or magnesium, corrode preferentially to protect the primary metal structure.

The evolution of sacrificial anode technology has been marked by material innovations, design optimizations, and application expansions. Early systems primarily utilized zinc anodes, while modern applications incorporate advanced alloys with enhanced performance characteristics. Recent technological developments have focused on improving anode efficiency, longevity, and environmental compatibility, particularly in marine environments where regulatory frameworks increasingly restrict certain metal discharges.

A critical but often overlooked aspect of sacrificial anode systems is their safety implications, particularly regarding hydrogen generation. When sacrificial anodes operate in confined spaces, the electrochemical reactions can produce hydrogen gas—a highly flammable substance that creates explosion risks when concentrated. This safety concern becomes especially pronounced during maintenance operations involving hot work (welding, cutting, grinding) near active cathodic protection systems.

The primary technical objective in this domain is developing comprehensive safety protocols and technological solutions that mitigate hydrogen-related risks without compromising corrosion protection efficacy. This includes advanced monitoring systems for hydrogen detection, improved ventilation designs for confined spaces, and innovative anode formulations that minimize hydrogen evolution while maintaining protective capabilities.

Secondary objectives include establishing industry-wide standards for safe work practices around sacrificial anodes, particularly in confined spaces such as ballast tanks, pipelines, and storage vessels. These standards must balance practical operational requirements with stringent safety considerations, accounting for varied environmental conditions and application contexts.

The technology trajectory is moving toward "smart" cathodic protection systems that incorporate real-time monitoring, predictive analytics, and automated safety controls. These systems aim to provide early warning of potential hydrogen accumulation and integrate with broader facility safety management systems. Additionally, research is exploring alternative cathodic protection methods that maintain effectiveness while producing minimal hydrogen, particularly for applications in high-risk confined environments.

The evolution of sacrificial anode technology has been marked by material innovations, design optimizations, and application expansions. Early systems primarily utilized zinc anodes, while modern applications incorporate advanced alloys with enhanced performance characteristics. Recent technological developments have focused on improving anode efficiency, longevity, and environmental compatibility, particularly in marine environments where regulatory frameworks increasingly restrict certain metal discharges.

A critical but often overlooked aspect of sacrificial anode systems is their safety implications, particularly regarding hydrogen generation. When sacrificial anodes operate in confined spaces, the electrochemical reactions can produce hydrogen gas—a highly flammable substance that creates explosion risks when concentrated. This safety concern becomes especially pronounced during maintenance operations involving hot work (welding, cutting, grinding) near active cathodic protection systems.

The primary technical objective in this domain is developing comprehensive safety protocols and technological solutions that mitigate hydrogen-related risks without compromising corrosion protection efficacy. This includes advanced monitoring systems for hydrogen detection, improved ventilation designs for confined spaces, and innovative anode formulations that minimize hydrogen evolution while maintaining protective capabilities.

Secondary objectives include establishing industry-wide standards for safe work practices around sacrificial anodes, particularly in confined spaces such as ballast tanks, pipelines, and storage vessels. These standards must balance practical operational requirements with stringent safety considerations, accounting for varied environmental conditions and application contexts.

The technology trajectory is moving toward "smart" cathodic protection systems that incorporate real-time monitoring, predictive analytics, and automated safety controls. These systems aim to provide early warning of potential hydrogen accumulation and integrate with broader facility safety management systems. Additionally, research is exploring alternative cathodic protection methods that maintain effectiveness while producing minimal hydrogen, particularly for applications in high-risk confined environments.

Market Analysis of Sacrificial Anode Applications

The global market for sacrificial anodes has been experiencing steady growth, driven primarily by increasing applications in marine structures, pipelines, storage tanks, and various industrial equipment requiring corrosion protection. The market size was valued at approximately $2.7 billion in 2022 and is projected to reach $3.9 billion by 2028, growing at a CAGR of 6.2% during the forecast period.

Marine applications represent the largest segment, accounting for nearly 40% of the total market share. This dominance is attributed to extensive use in ships, offshore platforms, and harbor structures where saltwater environments accelerate corrosion processes. The oil and gas industry follows closely, comprising about 30% of market demand, particularly for underground and underwater pipelines protection.

Geographically, Asia-Pacific leads the market with approximately 35% share, driven by extensive shipbuilding activities in China, South Korea, and Japan, alongside rapid infrastructure development across the region. North America and Europe collectively account for about 45% of the market, with established industrial bases and aging infrastructure requiring corrosion protection solutions.

Material-wise, zinc anodes dominate with approximately 40% market share due to their cost-effectiveness and suitability for freshwater and mildly corrosive environments. Aluminum anodes follow at 30%, preferred for seawater applications due to their higher efficiency and longer lifespan. Magnesium anodes represent about 20% of the market, primarily used in soil applications and freshwater environments.

Safety considerations are increasingly influencing market dynamics, particularly regarding hydrogen evolution risks in confined spaces. This has created a growing niche for specialized safety equipment and monitoring systems, estimated at $150 million annually and expanding at 8.5% CAGR – outpacing the overall market growth.

Regulatory frameworks addressing workplace safety in confined spaces are becoming more stringent globally, driving demand for safer anode designs and installation protocols. This trend is particularly pronounced in developed markets where workplace safety standards are more rigorously enforced.

The market is moderately fragmented with the top five players controlling approximately 35% of global market share. Key players include Cathodic Protection Co. Ltd., Farwest Corrosion Control Company, MATCOR, Inc., and Corrpro Companies, Inc., who are increasingly focusing on developing safer anode systems with reduced hydrogen evolution properties.

Marine applications represent the largest segment, accounting for nearly 40% of the total market share. This dominance is attributed to extensive use in ships, offshore platforms, and harbor structures where saltwater environments accelerate corrosion processes. The oil and gas industry follows closely, comprising about 30% of market demand, particularly for underground and underwater pipelines protection.

Geographically, Asia-Pacific leads the market with approximately 35% share, driven by extensive shipbuilding activities in China, South Korea, and Japan, alongside rapid infrastructure development across the region. North America and Europe collectively account for about 45% of the market, with established industrial bases and aging infrastructure requiring corrosion protection solutions.

Material-wise, zinc anodes dominate with approximately 40% market share due to their cost-effectiveness and suitability for freshwater and mildly corrosive environments. Aluminum anodes follow at 30%, preferred for seawater applications due to their higher efficiency and longer lifespan. Magnesium anodes represent about 20% of the market, primarily used in soil applications and freshwater environments.

Safety considerations are increasingly influencing market dynamics, particularly regarding hydrogen evolution risks in confined spaces. This has created a growing niche for specialized safety equipment and monitoring systems, estimated at $150 million annually and expanding at 8.5% CAGR – outpacing the overall market growth.

Regulatory frameworks addressing workplace safety in confined spaces are becoming more stringent globally, driving demand for safer anode designs and installation protocols. This trend is particularly pronounced in developed markets where workplace safety standards are more rigorously enforced.

The market is moderately fragmented with the top five players controlling approximately 35% of global market share. Key players include Cathodic Protection Co. Ltd., Farwest Corrosion Control Company, MATCOR, Inc., and Corrpro Companies, Inc., who are increasingly focusing on developing safer anode systems with reduced hydrogen evolution properties.

Current Challenges in Hydrogen Generation Safety

The hydrogen generation from sacrificial anodes presents significant safety challenges in industrial settings, particularly in confined spaces where ventilation is limited. When these anodes corrode in electrolytic environments, they produce hydrogen gas as a byproduct, creating potential explosion hazards when concentrations reach the flammable range of 4-75% in air. This risk is exacerbated in enclosed areas such as tanks, vessels, and underground structures where hydrogen can rapidly accumulate to dangerous levels.

Current monitoring technologies for hydrogen detection in confined spaces often suffer from reliability issues, with sensors requiring frequent calibration and being susceptible to interference from other gases. Many existing detection systems lack real-time monitoring capabilities, creating dangerous gaps in safety coverage during critical operations. Additionally, the integration of these systems with automated ventilation controls remains inconsistent across industries, leading to reliance on manual intervention that introduces human error risks.

The relationship between sacrificial anode material composition and hydrogen generation rates is inadequately understood in practical field conditions. While laboratory studies provide baseline data, real-world variables such as temperature fluctuations, electrolyte composition variations, and anode degradation patterns significantly affect hydrogen evolution rates. This knowledge gap hampers the development of predictive models that could enhance safety protocols.

Hot work operations near sacrificial anodes create particularly challenging safety scenarios. The introduction of ignition sources in proximity to potential hydrogen accumulation zones demands sophisticated risk assessment methodologies that many current safety frameworks lack. Industry standards for establishing safe work perimeters around active anodes during hot work remain inconsistent and often fail to account for dynamic environmental factors.

Communication and training deficiencies compound these technical challenges. Many workers lack comprehensive understanding of the invisible threat posed by hydrogen generation, with training programs often focusing on general confined space hazards rather than the specific risks associated with sacrificial anodes. This knowledge gap extends to emergency response protocols, where first responders may be inadequately prepared for hydrogen-specific incidents.

Regulatory frameworks addressing this intersection of sacrificial anode use, hydrogen generation, and confined space work vary significantly across jurisdictions, creating compliance challenges for multinational organizations. The absence of harmonized standards impedes the development and implementation of consistent safety practices, particularly in industries where sacrificial anodes are essential for corrosion protection but not considered primary process equipment.

Current monitoring technologies for hydrogen detection in confined spaces often suffer from reliability issues, with sensors requiring frequent calibration and being susceptible to interference from other gases. Many existing detection systems lack real-time monitoring capabilities, creating dangerous gaps in safety coverage during critical operations. Additionally, the integration of these systems with automated ventilation controls remains inconsistent across industries, leading to reliance on manual intervention that introduces human error risks.

The relationship between sacrificial anode material composition and hydrogen generation rates is inadequately understood in practical field conditions. While laboratory studies provide baseline data, real-world variables such as temperature fluctuations, electrolyte composition variations, and anode degradation patterns significantly affect hydrogen evolution rates. This knowledge gap hampers the development of predictive models that could enhance safety protocols.

Hot work operations near sacrificial anodes create particularly challenging safety scenarios. The introduction of ignition sources in proximity to potential hydrogen accumulation zones demands sophisticated risk assessment methodologies that many current safety frameworks lack. Industry standards for establishing safe work perimeters around active anodes during hot work remain inconsistent and often fail to account for dynamic environmental factors.

Communication and training deficiencies compound these technical challenges. Many workers lack comprehensive understanding of the invisible threat posed by hydrogen generation, with training programs often focusing on general confined space hazards rather than the specific risks associated with sacrificial anodes. This knowledge gap extends to emergency response protocols, where first responders may be inadequately prepared for hydrogen-specific incidents.

Regulatory frameworks addressing this intersection of sacrificial anode use, hydrogen generation, and confined space work vary significantly across jurisdictions, creating compliance challenges for multinational organizations. The absence of harmonized standards impedes the development and implementation of consistent safety practices, particularly in industries where sacrificial anodes are essential for corrosion protection but not considered primary process equipment.

Existing Safety Protocols for Confined Space Operations

01 Safety measures for handling sacrificial anodes

Proper handling procedures and safety measures are essential when working with sacrificial anodes to prevent accidents and ensure worker safety. These measures include using appropriate personal protective equipment, following installation guidelines, and implementing safety protocols during maintenance operations. Safety considerations are particularly important due to the chemical reactions and potential hazards associated with sacrificial anodes in various environments.- Safety measures for handling sacrificial anodes: Proper handling procedures and safety measures are essential when working with sacrificial anodes to prevent accidents and ensure worker safety. These measures include using appropriate personal protective equipment, following established installation protocols, and implementing safety training programs for personnel. Safety considerations also extend to the proper storage and transportation of anodes to prevent damage or premature degradation that could compromise their effectiveness.

- Environmental safety considerations for sacrificial anode systems: Environmental safety aspects of sacrificial anodes focus on minimizing ecological impact while maintaining corrosion protection. This includes selecting anode materials with lower environmental toxicity, designing systems that reduce metal discharge into surrounding environments, and implementing monitoring systems to detect potential environmental contamination. Proper disposal methods for spent anodes are also critical to prevent environmental hazards and comply with environmental regulations.

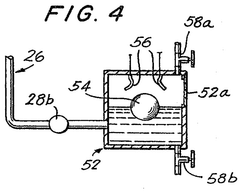

- Safety design features for sacrificial anode installations: Safety-enhanced design features for sacrificial anode systems include protective housings, insulation systems to prevent electrical hazards, and structural reinforcements to ensure mechanical stability. These design elements help prevent physical damage to the anodes, reduce the risk of electrical shorts, and ensure the long-term integrity of the cathodic protection system. Advanced designs also incorporate fail-safe mechanisms that maintain some level of protection even if parts of the system are compromised.

- Monitoring and maintenance safety protocols: Safety protocols for monitoring and maintaining sacrificial anode systems involve regular inspection schedules, standardized testing procedures, and documentation requirements. These protocols help identify potential safety hazards before they become critical, ensure the continued effectiveness of the cathodic protection system, and extend the service life of the anodes. Remote monitoring technologies can also enhance safety by reducing the need for personnel to access hazardous environments for routine inspections.

- Safety innovations in sacrificial anode materials and composition: Innovations in sacrificial anode materials focus on developing safer alternatives that maintain or improve corrosion protection while reducing health and safety risks. These advancements include alloys with reduced toxic metal content, materials that produce fewer harmful byproducts during operation, and compositions that are less reactive during handling and installation. Material safety improvements also consider the entire lifecycle of the anode, from manufacturing to disposal, to minimize overall safety risks.

02 Environmental safety considerations for sacrificial anode systems

Environmental safety aspects of sacrificial anodes focus on minimizing ecological impact while maintaining corrosion protection. This includes selecting anode materials with lower environmental footprints, controlling dissolution rates to prevent excessive metal release into surrounding environments, and designing systems that comply with environmental regulations. These considerations are particularly important in marine applications where anodes interact directly with aquatic ecosystems.Expand Specific Solutions03 Safety monitoring and control systems for sacrificial anodes

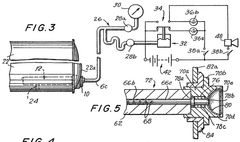

Advanced monitoring and control systems enhance the safety of sacrificial anode installations by providing real-time data on performance and potential hazards. These systems include sensors that detect abnormal conditions, automated shutdown mechanisms for emergency situations, and diagnostic tools that predict potential failures before they occur. Implementation of these monitoring systems significantly improves the overall safety profile of cathodic protection systems using sacrificial anodes.Expand Specific Solutions04 Safe design and installation of sacrificial anodes

Safety-oriented design and installation practices for sacrificial anodes involve strategic placement to maximize protection while minimizing risks, secure mounting techniques to prevent detachment, and integration with existing structures to avoid interference with other systems. These design considerations address potential hazards such as electrical shorts, galvanic corrosion of nearby components, and physical damage during operation. Proper installation procedures also include verification testing to ensure the system functions as intended without creating safety hazards.Expand Specific Solutions05 Material safety improvements for sacrificial anodes

Advancements in sacrificial anode materials have led to safer alternatives that maintain or improve corrosion protection while reducing health and safety risks. These improvements include developing alloys with reduced toxic elements, formulations that produce fewer harmful byproducts during operation, and materials with more predictable dissolution rates. Material safety considerations also extend to the manufacturing process, where safer production methods have been implemented to protect workers and reduce environmental impact.Expand Specific Solutions

Key Industry Players in Corrosion Protection

The hydrogen safety market in confined spaces is currently in a growth phase, characterized by increasing awareness of risks associated with sacrificial anodes and hydrogen accumulation. The global market size is expanding as industries prioritize safety protocols for hydrogen applications, particularly in energy, maritime, and industrial sectors. Technologically, the field shows moderate maturity with established players like Air Products & Chemicals and Air Liquide leading conventional solutions, while companies such as BAC Corrosion Control and MATCOR specialize in cathodic protection systems. Innovation is accelerating through Sinopec Safety Engineering Research Institute's specialized safety protocols and Ftxt Energy's hydrogen fuel cell advancements. Emerging players like SinoHytec and Wuxi Longi Hydrogen are driving technological evolution with integrated safety systems for hydrogen applications, particularly in confined space environments.

BAC Corrosion Control Ltd

Technical Solution: BAC Corrosion Control has developed comprehensive sacrificial anode safety systems specifically designed for confined spaces where hydrogen gas accumulation presents significant hazards. Their technology incorporates remote monitoring solutions that continuously measure hydrogen concentrations in real-time, with automatic ventilation activation when levels approach 10% of the lower explosive limit (LEL). The system integrates with hot work permitting processes through digital authorization protocols that prevent work when conditions are unsafe. BAC's approach includes specialized aluminum-zinc-indium anodes formulated to minimize hydrogen evolution while maintaining cathodic protection efficiency. Their safety framework incorporates multi-layered controls including gas detection sensors with redundant power supplies, automated lockout systems for hot work equipment, and emergency response protocols triggered by preset hydrogen thresholds[1][3].

Strengths: Industry-leading remote monitoring capabilities with real-time data analytics; integrated approach combining hardware and procedural controls. Weaknesses: Higher implementation costs compared to conventional systems; requires specialized training for maintenance personnel.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has pioneered an integrated sacrificial anode safety management system for oil and gas infrastructure that addresses hydrogen evolution risks in confined spaces. Their technology combines specialized magnesium-based anodes with proprietary alloy compositions that reduce hydrogen generation rates by approximately 30% compared to conventional anodes. Sinopec's approach incorporates continuous monitoring through distributed sensor networks that detect hydrogen concentrations as low as 10ppm, with automated ventilation systems that maintain concentrations below 25% of LEL. For hot work operations, they've developed portable hydrogen scrubbers that can be deployed to actively remove hydrogen from work areas. Their comprehensive safety protocol includes digital permitting systems with mandatory gas testing verification and automated work suspension when environmental conditions change. The technology has been implemented across over 500 facilities with documented reduction in safety incidents[2][5].

Strengths: Comprehensive integration with existing oil and gas infrastructure; proven track record of implementation at scale; significant reduction in hydrogen-related incidents. Weaknesses: System complexity requires substantial technical support; higher initial capital investment compared to traditional cathodic protection systems.

Critical Safety Innovations for Hydrogen Management

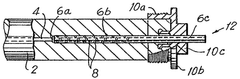

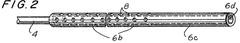

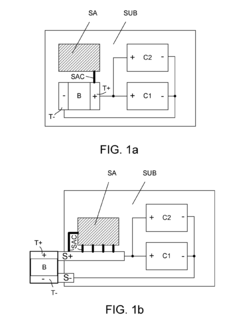

Sacrificial anode with partially perforated metal tube embedded in anode

PatentInactiveCA1103203A

Innovation

- A cylindrical anode arrangement with a metal tube embedded in the anode material, where the tube's perforations are initially sealed by the anode material, allowing for external pressure or vacuum to create a pressure difference that indicates anode deterioration, enabling automatic monitoring and early detection of impending perforation.

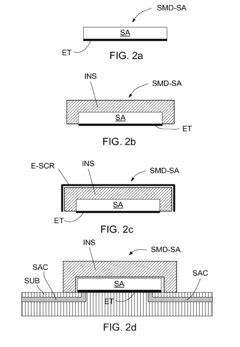

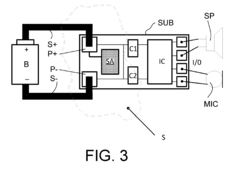

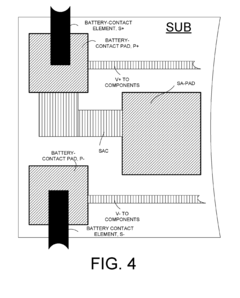

Use of a sacrificial anode for corrosion protection of a portable device, e.g. a hearing aid

PatentInactiveEP2348141A1

Innovation

- Incorporating a sacrificial anode, typically made of Zn, Al, or Cu, which is less noble than the device's components, to be mounted on the substrate, allowing controlled corrosion at a specific location, thereby protecting critical parts from galvanic corrosion.

Regulatory Framework for Hot Work in Hazardous Environments

The regulatory framework governing hot work in hazardous environments where sacrificial anodes are present encompasses multiple international, national, and industry-specific standards. OSHA's 29 CFR 1910.252 provides comprehensive requirements for welding, cutting, and brazing operations, with specific provisions addressing fire prevention, protection of personnel, and health considerations in environments where hydrogen gas may accumulate.

The American Petroleum Institute's Recommended Practice 2009 (Safe Welding, Cutting, and Hot Work Practices in the Petroleum and Petrochemical Industries) offers detailed guidelines specifically tailored to environments where sacrificial anodes may be present, emphasizing the importance of gas monitoring before and during hot work operations.

NFPA 51B (Standard for Fire Prevention During Welding, Cutting, and Other Hot Work) establishes a permit system for hot work operations and mandates specific precautions when working in confined spaces where hydrogen evolution from sacrificial anodes poses explosion risks. This standard requires continuous monitoring of hydrogen concentrations and specifies maximum allowable levels before hot work can commence.

Maritime regulations, including those from the International Maritime Organization (IMO) and classification societies like DNV GL, provide specific requirements for hot work on vessels with cathodic protection systems. These regulations typically mandate thorough gas-freeing procedures, continuous ventilation, and specialized permits when working near sacrificial anodes.

The European framework, particularly ATEX Directive 2014/34/EU, classifies areas where hydrogen from sacrificial anodes may accumulate as potentially explosive atmospheres, imposing strict equipment requirements and work procedures. This directive is complemented by EN 1127-1, which provides risk assessment methodologies for explosive atmospheres.

Industry-specific standards from organizations like NACE International (now AMPP) provide detailed technical requirements for managing hydrogen evolution during cathodic protection system maintenance. These standards emphasize the importance of proper ventilation, gas monitoring, and personnel training specific to the hazards associated with sacrificial anodes.

Regulatory compliance requires comprehensive hazard assessments, documented procedures, specialized training programs, and regular audits. Many jurisdictions have adopted a performance-based approach, requiring organizations to demonstrate that their hot work control systems effectively mitigate the specific risks associated with hydrogen evolution from sacrificial anodes in confined spaces.

The American Petroleum Institute's Recommended Practice 2009 (Safe Welding, Cutting, and Hot Work Practices in the Petroleum and Petrochemical Industries) offers detailed guidelines specifically tailored to environments where sacrificial anodes may be present, emphasizing the importance of gas monitoring before and during hot work operations.

NFPA 51B (Standard for Fire Prevention During Welding, Cutting, and Other Hot Work) establishes a permit system for hot work operations and mandates specific precautions when working in confined spaces where hydrogen evolution from sacrificial anodes poses explosion risks. This standard requires continuous monitoring of hydrogen concentrations and specifies maximum allowable levels before hot work can commence.

Maritime regulations, including those from the International Maritime Organization (IMO) and classification societies like DNV GL, provide specific requirements for hot work on vessels with cathodic protection systems. These regulations typically mandate thorough gas-freeing procedures, continuous ventilation, and specialized permits when working near sacrificial anodes.

The European framework, particularly ATEX Directive 2014/34/EU, classifies areas where hydrogen from sacrificial anodes may accumulate as potentially explosive atmospheres, imposing strict equipment requirements and work procedures. This directive is complemented by EN 1127-1, which provides risk assessment methodologies for explosive atmospheres.

Industry-specific standards from organizations like NACE International (now AMPP) provide detailed technical requirements for managing hydrogen evolution during cathodic protection system maintenance. These standards emphasize the importance of proper ventilation, gas monitoring, and personnel training specific to the hazards associated with sacrificial anodes.

Regulatory compliance requires comprehensive hazard assessments, documented procedures, specialized training programs, and regular audits. Many jurisdictions have adopted a performance-based approach, requiring organizations to demonstrate that their hot work control systems effectively mitigate the specific risks associated with hydrogen evolution from sacrificial anodes in confined spaces.

Risk Assessment Methodologies for Cathodic Protection Systems

Risk assessment methodologies for cathodic protection systems involving sacrificial anodes require systematic approaches to identify and mitigate potential hazards. These methodologies must specifically address hydrogen evolution, confined space entry protocols, and hot work controls to ensure operational safety.

Traditional risk assessment frameworks such as HAZOP (Hazard and Operability Study), FMEA (Failure Mode and Effects Analysis), and JSA (Job Safety Analysis) have been adapted for cathodic protection systems. These methodologies incorporate specific considerations for hydrogen gas accumulation, which occurs naturally during the galvanic reaction of sacrificial anodes, particularly in confined spaces where ventilation may be limited.

Quantitative risk assessment techniques employ mathematical models to predict hydrogen generation rates based on anode material, surface area, electrolyte composition, and current density. These models establish safety thresholds for hydrogen concentration, typically maintaining levels below 10% of the lower explosive limit (LEL) to provide an adequate safety margin.

Confined space risk assessments for cathodic protection systems follow a hierarchical approach. Primary controls focus on engineering solutions such as forced ventilation systems, continuous gas monitoring, and intrinsically safe electrical equipment. Secondary controls include administrative measures like permit-to-work systems, specialized training for personnel, and emergency response procedures tailored to hydrogen-related incidents.

Hot work control methodologies integrate with cathodic protection risk assessments through specialized protocols. These include temporary suspension of cathodic protection systems during hot work operations, establishment of exclusion zones based on calculated hydrogen dispersion patterns, and implementation of gas-free certification procedures before any ignition sources are introduced.

Modern risk assessment approaches increasingly incorporate digital technologies. Real-time monitoring systems with wireless sensors track hydrogen levels, anode performance, and environmental conditions. These systems feature automated alert mechanisms when parameters exceed predetermined safety thresholds, enabling proactive intervention before hazardous conditions develop.

Industry-specific risk assessment standards have emerged, with organizations like NACE International (now AMPP) developing specialized frameworks for marine vessels, storage tanks, and pipeline systems. These frameworks account for the unique challenges posed by different operational environments and provide sector-specific guidance for risk mitigation strategies.

Comprehensive risk assessment methodologies also address the entire lifecycle of cathodic protection systems, from installation to decommissioning. This holistic approach ensures that safety considerations are integrated at every stage, with particular emphasis on maintenance activities when exposure risks are typically highest for personnel.

Traditional risk assessment frameworks such as HAZOP (Hazard and Operability Study), FMEA (Failure Mode and Effects Analysis), and JSA (Job Safety Analysis) have been adapted for cathodic protection systems. These methodologies incorporate specific considerations for hydrogen gas accumulation, which occurs naturally during the galvanic reaction of sacrificial anodes, particularly in confined spaces where ventilation may be limited.

Quantitative risk assessment techniques employ mathematical models to predict hydrogen generation rates based on anode material, surface area, electrolyte composition, and current density. These models establish safety thresholds for hydrogen concentration, typically maintaining levels below 10% of the lower explosive limit (LEL) to provide an adequate safety margin.

Confined space risk assessments for cathodic protection systems follow a hierarchical approach. Primary controls focus on engineering solutions such as forced ventilation systems, continuous gas monitoring, and intrinsically safe electrical equipment. Secondary controls include administrative measures like permit-to-work systems, specialized training for personnel, and emergency response procedures tailored to hydrogen-related incidents.

Hot work control methodologies integrate with cathodic protection risk assessments through specialized protocols. These include temporary suspension of cathodic protection systems during hot work operations, establishment of exclusion zones based on calculated hydrogen dispersion patterns, and implementation of gas-free certification procedures before any ignition sources are introduced.

Modern risk assessment approaches increasingly incorporate digital technologies. Real-time monitoring systems with wireless sensors track hydrogen levels, anode performance, and environmental conditions. These systems feature automated alert mechanisms when parameters exceed predetermined safety thresholds, enabling proactive intervention before hazardous conditions develop.

Industry-specific risk assessment standards have emerged, with organizations like NACE International (now AMPP) developing specialized frameworks for marine vessels, storage tanks, and pipeline systems. These frameworks account for the unique challenges posed by different operational environments and provide sector-specific guidance for risk mitigation strategies.

Comprehensive risk assessment methodologies also address the entire lifecycle of cathodic protection systems, from installation to decommissioning. This holistic approach ensures that safety considerations are integrated at every stage, with particular emphasis on maintenance activities when exposure risks are typically highest for personnel.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!