Sacrificial Anode Consumption Rate: Environment Factors, Polarization And Life Prediction

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sacrificial Anode Technology Background and Objectives

Sacrificial anodes have been utilized for cathodic protection since the early 19th century, with Sir Humphry Davy's pioneering work in 1824 demonstrating the protection of copper-clad ship hulls using zinc and iron anodes. This technology has evolved significantly over the past two centuries, becoming a cornerstone of corrosion prevention strategies across multiple industries including marine, pipeline, storage tanks, and offshore structures.

The fundamental principle of sacrificial anodes relies on galvanic corrosion theory, where a more electrochemically active metal (the anode) corrodes preferentially to protect a more noble metal (the cathode). Common sacrificial anode materials include zinc, aluminum, and magnesium alloys, each optimized for specific environmental conditions and applications.

Recent technological advancements have focused on enhancing anode efficiency, extending service life, and developing more accurate consumption rate prediction models. The global market for cathodic protection systems, including sacrificial anodes, has been growing steadily at approximately 5-6% annually, driven by aging infrastructure and expanding industrial applications.

Current research trends are centered on understanding the complex interplay between environmental factors and anode consumption rates. Seawater temperature, salinity, oxygen content, flow velocity, and marine growth all significantly impact anode performance and longevity. Additionally, the polarization behavior of anodes under varying conditions remains a critical area of investigation.

The primary technical objective in this field is to develop more accurate and reliable models for predicting sacrificial anode consumption rates and service life. Traditional models based on Faraday's law often fail to account for the multitude of environmental variables that influence actual field performance, leading to either premature anode depletion or unnecessary over-engineering.

Advanced computational methods, including machine learning algorithms and finite element analysis, are increasingly being applied to create more sophisticated prediction models. These approaches aim to incorporate real-time environmental data and historical performance metrics to optimize anode design and replacement schedules.

The ultimate goal of current research efforts is to establish a comprehensive framework that integrates environmental monitoring, electrochemical measurements, and predictive modeling to enable more efficient and cost-effective cathodic protection systems. This would significantly reduce maintenance costs, minimize environmental impact, and enhance the reliability of critical infrastructure protection across various industries.

The fundamental principle of sacrificial anodes relies on galvanic corrosion theory, where a more electrochemically active metal (the anode) corrodes preferentially to protect a more noble metal (the cathode). Common sacrificial anode materials include zinc, aluminum, and magnesium alloys, each optimized for specific environmental conditions and applications.

Recent technological advancements have focused on enhancing anode efficiency, extending service life, and developing more accurate consumption rate prediction models. The global market for cathodic protection systems, including sacrificial anodes, has been growing steadily at approximately 5-6% annually, driven by aging infrastructure and expanding industrial applications.

Current research trends are centered on understanding the complex interplay between environmental factors and anode consumption rates. Seawater temperature, salinity, oxygen content, flow velocity, and marine growth all significantly impact anode performance and longevity. Additionally, the polarization behavior of anodes under varying conditions remains a critical area of investigation.

The primary technical objective in this field is to develop more accurate and reliable models for predicting sacrificial anode consumption rates and service life. Traditional models based on Faraday's law often fail to account for the multitude of environmental variables that influence actual field performance, leading to either premature anode depletion or unnecessary over-engineering.

Advanced computational methods, including machine learning algorithms and finite element analysis, are increasingly being applied to create more sophisticated prediction models. These approaches aim to incorporate real-time environmental data and historical performance metrics to optimize anode design and replacement schedules.

The ultimate goal of current research efforts is to establish a comprehensive framework that integrates environmental monitoring, electrochemical measurements, and predictive modeling to enable more efficient and cost-effective cathodic protection systems. This would significantly reduce maintenance costs, minimize environmental impact, and enhance the reliability of critical infrastructure protection across various industries.

Market Analysis of Cathodic Protection Systems

The global cathodic protection systems market demonstrates robust growth, valued at approximately $6.7 billion in 2022 and projected to reach $8.9 billion by 2027, representing a compound annual growth rate (CAGR) of 5.8%. This expansion is primarily driven by increasing infrastructure development across oil and gas, water and wastewater, marine, and construction industries, where metal corrosion poses significant economic and safety challenges.

The sacrificial anode segment, particularly relevant to consumption rate studies, holds approximately 40% of the market share, with aluminum, zinc, and magnesium anodes being the predominant materials. The oil and gas sector remains the largest end-user, accounting for roughly 35% of the total market demand, followed by marine applications at 25% and water infrastructure at 20%.

Regionally, North America and Europe currently dominate the market with a combined share of 55%, attributed to aging infrastructure requiring protection and stringent regulatory frameworks. However, the Asia-Pacific region is witnessing the fastest growth at 7.2% CAGR, driven by rapid industrialization in China, India, and Southeast Asian countries.

Market dynamics are increasingly influenced by environmental factors affecting anode consumption rates. Customers are demanding more precise life prediction models that account for varying water salinity, temperature fluctuations, and pollution levels. This has created a specialized niche market for advanced monitoring systems and predictive analytics software, estimated at $780 million globally.

A notable market trend is the integration of digital technologies for remote monitoring of anode consumption and polarization levels. IoT-enabled cathodic protection systems have seen a 35% increase in adoption over the past three years, allowing for real-time data collection on environmental factors affecting consumption rates.

The competitive landscape features established players like Aegion Corporation, Cathodic Protection Co., and MATCOR, alongside emerging specialized firms focusing on advanced materials and predictive technologies. Recent market consolidation through mergers and acquisitions indicates industry recognition of the value in combining traditional protection expertise with advanced analytics capabilities.

Customer purchasing decisions increasingly prioritize total cost of ownership rather than initial installation costs, highlighting the importance of accurate life prediction models for sacrificial anodes. This shift has created market opportunities for companies offering comprehensive solutions that optimize anode consumption rates based on specific environmental conditions.

The sacrificial anode segment, particularly relevant to consumption rate studies, holds approximately 40% of the market share, with aluminum, zinc, and magnesium anodes being the predominant materials. The oil and gas sector remains the largest end-user, accounting for roughly 35% of the total market demand, followed by marine applications at 25% and water infrastructure at 20%.

Regionally, North America and Europe currently dominate the market with a combined share of 55%, attributed to aging infrastructure requiring protection and stringent regulatory frameworks. However, the Asia-Pacific region is witnessing the fastest growth at 7.2% CAGR, driven by rapid industrialization in China, India, and Southeast Asian countries.

Market dynamics are increasingly influenced by environmental factors affecting anode consumption rates. Customers are demanding more precise life prediction models that account for varying water salinity, temperature fluctuations, and pollution levels. This has created a specialized niche market for advanced monitoring systems and predictive analytics software, estimated at $780 million globally.

A notable market trend is the integration of digital technologies for remote monitoring of anode consumption and polarization levels. IoT-enabled cathodic protection systems have seen a 35% increase in adoption over the past three years, allowing for real-time data collection on environmental factors affecting consumption rates.

The competitive landscape features established players like Aegion Corporation, Cathodic Protection Co., and MATCOR, alongside emerging specialized firms focusing on advanced materials and predictive technologies. Recent market consolidation through mergers and acquisitions indicates industry recognition of the value in combining traditional protection expertise with advanced analytics capabilities.

Customer purchasing decisions increasingly prioritize total cost of ownership rather than initial installation costs, highlighting the importance of accurate life prediction models for sacrificial anodes. This shift has created market opportunities for companies offering comprehensive solutions that optimize anode consumption rates based on specific environmental conditions.

Current Challenges in Anode Consumption Rate Prediction

Despite significant advancements in cathodic protection systems, accurate prediction of sacrificial anode consumption rates remains a formidable challenge in corrosion engineering. The complex interplay of environmental factors creates substantial variability in consumption patterns, making standardized prediction models insufficient for real-world applications. Seawater temperature, salinity, dissolved oxygen content, and flow velocity all significantly impact galvanic activity, yet their combined effects are poorly represented in current models.

The heterogeneity of marine environments presents a particular obstacle, as conditions can vary dramatically across different geographical locations and depths. Existing models typically rely on laboratory data obtained under controlled conditions, which often fail to account for the dynamic nature of actual deployment environments. This discrepancy leads to significant errors in service life predictions, sometimes by factors of 1.5 to 2 times the actual performance.

Polarization behavior represents another critical challenge, as the relationship between current demand and protection potential follows non-linear patterns that change over time. Current models inadequately capture the evolution of polarization characteristics as anodes age and protective films form on cathode surfaces. This limitation is particularly problematic for long-term installations where anode performance must be reliable for decades without intervention.

Scale formation and biofouling introduce additional complications by altering the effective surface area and electrochemical properties of both anodes and protected structures. These biological and chemical deposits can either accelerate or inhibit anode consumption in ways that are difficult to predict using conventional methods. The industry lacks standardized approaches for incorporating these factors into consumption rate calculations.

Data collection limitations further compound these challenges. Remote monitoring technologies for in-situ measurement of anode consumption remain costly and technically challenging to implement, especially in deep-water or harsh environments. This creates a significant gap between theoretical models and field validation, hampering the development of more accurate prediction methodologies.

Computational limitations also persist in current modeling approaches. While finite element analysis and machine learning techniques show promise, they require extensive computational resources and specialized expertise not widely available in the industry. Most practitioners still rely on simplified empirical formulas that fail to capture the full complexity of electrochemical interactions in real-world systems.

The integration of multiple protection systems, such as combining sacrificial anodes with impressed current systems or protective coatings, creates additional modeling challenges. Current prediction methods struggle to account for the synergistic or antagonistic effects between these different protection mechanisms, leading to either over-design (increasing costs) or under-design (compromising protection).

The heterogeneity of marine environments presents a particular obstacle, as conditions can vary dramatically across different geographical locations and depths. Existing models typically rely on laboratory data obtained under controlled conditions, which often fail to account for the dynamic nature of actual deployment environments. This discrepancy leads to significant errors in service life predictions, sometimes by factors of 1.5 to 2 times the actual performance.

Polarization behavior represents another critical challenge, as the relationship between current demand and protection potential follows non-linear patterns that change over time. Current models inadequately capture the evolution of polarization characteristics as anodes age and protective films form on cathode surfaces. This limitation is particularly problematic for long-term installations where anode performance must be reliable for decades without intervention.

Scale formation and biofouling introduce additional complications by altering the effective surface area and electrochemical properties of both anodes and protected structures. These biological and chemical deposits can either accelerate or inhibit anode consumption in ways that are difficult to predict using conventional methods. The industry lacks standardized approaches for incorporating these factors into consumption rate calculations.

Data collection limitations further compound these challenges. Remote monitoring technologies for in-situ measurement of anode consumption remain costly and technically challenging to implement, especially in deep-water or harsh environments. This creates a significant gap between theoretical models and field validation, hampering the development of more accurate prediction methodologies.

Computational limitations also persist in current modeling approaches. While finite element analysis and machine learning techniques show promise, they require extensive computational resources and specialized expertise not widely available in the industry. Most practitioners still rely on simplified empirical formulas that fail to capture the full complexity of electrochemical interactions in real-world systems.

The integration of multiple protection systems, such as combining sacrificial anodes with impressed current systems or protective coatings, creates additional modeling challenges. Current prediction methods struggle to account for the synergistic or antagonistic effects between these different protection mechanisms, leading to either over-design (increasing costs) or under-design (compromising protection).

Existing Methods for Consumption Rate Calculation

01 Factors affecting sacrificial anode consumption rate

Various factors influence the consumption rate of sacrificial anodes, including environmental conditions, water chemistry, temperature, and flow rate. The composition of the anode material, its surface area, and the electrical conductivity of the surrounding medium also play significant roles. Understanding these factors is crucial for predicting anode life and designing effective cathodic protection systems with optimal consumption rates.- Factors affecting sacrificial anode consumption rate: Various factors influence the consumption rate of sacrificial anodes, including environmental conditions, water chemistry, temperature, and flow rate. The composition of the anode material, the surface area ratio between the anode and the protected structure, and the electrical conductivity of the environment also play significant roles. Understanding these factors is crucial for predicting anode life and designing effective cathodic protection systems.

- Monitoring and measurement techniques for anode consumption: Advanced monitoring systems and measurement techniques have been developed to track sacrificial anode consumption rates in real-time. These include electrical potential measurements, weight loss calculations, and digital monitoring systems that can predict remaining anode life. Some systems incorporate sensors and data analysis to provide accurate consumption rate information, allowing for timely replacement and maintenance of anodes before protection is compromised.

- Anode material composition and design optimization: The composition and design of sacrificial anodes significantly impact their consumption rate and effectiveness. Alloys containing aluminum, zinc, or magnesium with specific additives can be engineered to provide optimal protection while controlling dissolution rates. Innovations in anode geometry, core materials, and manufacturing processes have led to more efficient anodes with predictable and uniform consumption patterns, extending service life while maintaining protection levels.

- Environmental and installation considerations: The environment in which sacrificial anodes operate greatly affects their consumption rate. Factors such as salinity, oxygen content, pH levels, and pollutants can accelerate or decelerate anode dissolution. Proper installation techniques, including correct positioning, electrical connections, and spacing between anodes, are essential for achieving uniform protection and preventing localized rapid consumption. Special considerations are needed for different applications such as marine structures, pipelines, and storage tanks.

- Mathematical models and prediction methods: Mathematical models and computational methods have been developed to predict sacrificial anode consumption rates under various conditions. These models incorporate electrochemical principles, environmental parameters, and historical performance data to estimate anode life and optimize replacement schedules. Advanced simulation techniques can account for complex geometries and changing environmental conditions, allowing engineers to design more efficient cathodic protection systems with predictable performance characteristics.

02 Monitoring and control systems for sacrificial anodes

Advanced monitoring and control systems can be employed to track and regulate the consumption rate of sacrificial anodes. These systems utilize sensors, data collection devices, and analysis software to measure parameters such as current output, potential difference, and anode mass loss. Real-time monitoring allows for timely replacement of depleted anodes and optimization of cathodic protection systems, ultimately extending the service life of protected structures.Expand Specific Solutions03 Anode material composition and design improvements

Innovations in sacrificial anode material composition and design can significantly impact consumption rates. Alloying elements are carefully selected to achieve desired electrochemical properties and dissolution patterns. Structural modifications, such as reinforcement cores, optimized shapes, and attachment methods, can improve current distribution and utilization efficiency. These advancements help to achieve more uniform and predictable anode consumption rates in various applications.Expand Specific Solutions04 Mathematical models and prediction methods for anode consumption

Mathematical models and computational methods have been developed to predict sacrificial anode consumption rates under various operating conditions. These models incorporate electrochemical principles, environmental factors, and empirical data to calculate expected anode life and performance. Simulation techniques allow engineers to optimize anode placement, size, and quantity before installation, reducing costs and improving the reliability of cathodic protection systems.Expand Specific Solutions05 Application-specific anode consumption considerations

Different applications require specific considerations regarding sacrificial anode consumption rates. Marine environments, underground pipelines, storage tanks, and offshore structures each present unique challenges. Specialized anode configurations, installation techniques, and maintenance protocols have been developed to address these application-specific requirements. These tailored approaches ensure optimal protection while managing anode consumption rates in diverse operating conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The sacrificial anode consumption rate market is currently in a growth phase, with increasing applications in marine, oil & gas, and infrastructure sectors. The global market size is estimated to exceed $2 billion, driven by rising corrosion protection needs in aging infrastructure and offshore installations. Technologically, the field is moderately mature but evolving, with companies like BAC Corrosion Control, Vector Corrosion Technologies, and Galvotec Alloys leading in traditional applications. Research institutions such as Tsinghua University and IIT Bombay are advancing predictive modeling capabilities. Industry leaders like PetroChina and Siemens Healthineers are integrating advanced monitoring systems, while specialized firms like Sun Rui Corrosion Control are developing environment-specific solutions that account for polarization effects and extend anode life prediction accuracy in challenging conditions.

BAC Corrosion Control Ltd

Technical Solution: BAC Corrosion Control has developed advanced cathodic protection systems that precisely monitor and control sacrificial anode consumption rates in various environments. Their technology incorporates real-time monitoring sensors that measure electrical potential, current output, and environmental parameters to predict anode depletion. Their proprietary algorithms account for water salinity, temperature fluctuations, oxygen content, and flow rates to provide accurate life prediction models. BAC's systems include remote monitoring capabilities that allow for continuous data collection and analysis, enabling proactive maintenance scheduling based on actual consumption rates rather than conservative theoretical estimates. Their technology has demonstrated the ability to extend anode life by 15-30% through optimized polarization control and environmental adaptation.

Strengths: Comprehensive environmental factor integration allows for highly accurate consumption rate predictions across diverse operating conditions. Remote monitoring capabilities reduce inspection costs and prevent unexpected protection failures. Weaknesses: Higher initial implementation costs compared to traditional systems, and requires specialized expertise for system calibration and data interpretation.

Tsinghua University

Technical Solution: Tsinghua University's research team has developed an advanced electrochemical modeling framework for sacrificial anode consumption prediction that integrates multi-physics simulation with machine learning algorithms. Their approach combines fundamental electrochemical principles with extensive experimental data to create predictive models that account for complex interactions between environmental factors and anode performance. The university's research has identified critical threshold values for various environmental parameters where consumption behavior undergoes significant changes, allowing for more accurate life prediction across diverse operating conditions. Their technology incorporates impedance spectroscopy techniques to characterize the evolving anode-electrolyte interface properties over time, providing insights into consumption mechanisms beyond simple weight loss measurements. Tsinghua's models account for seasonal variations in water chemistry, temperature fluctuations, and biofilm formation effects on polarization behavior, resulting in more realistic life predictions for marine and industrial applications.

Strengths: Sophisticated multi-physics modeling provides deeper understanding of consumption mechanisms and enables more accurate predictions in complex environments. Academic research approach ensures thorough validation through peer-reviewed methodologies. Weaknesses: Highly theoretical approach may require significant adaptation for commercial implementation, and complex models demand substantial computational resources for real-time applications.

Key Research on Environmental Factor Influences

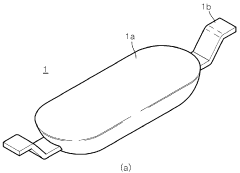

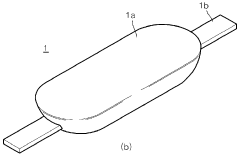

Sacrificial anode having a low corrosion potential for preventing a ship from being corroded

PatentWO2012148016A1

Innovation

- A sacrificial anode with a zinc alloy as the main component and additives such as calcium, magnesium, aluminum, copper, and tin, which are non-heavy metal elements, to achieve a low electrochemical corrosion potential, reducing environmental and health hazards while improving efficiency.

sacrificial anode for anti-corrosion for metal constructions in the oil and gas industry and this sacrificial anode manufacturing process

PatentInactiveVN52040A

Innovation

- Novel composition of sacrificial anode with specific percentages of zinc (2-4%), indium (0.01-0.15%), MnO2 (0.5-1%), and aluminum (94.85-97.49%) designed for high temperature and strongly corrosive environments.

- Incorporation of MnO2 in aluminum-based sacrificial anodes, which is an uncommon additive that likely contributes to improved electrochemical capacity and service life in harsh conditions.

- Specific manufacturing process including precise temperature control, annealing at 200°C, and water cooling, which enhances the physical and mechanical properties of the anode.

Material Science Advancements for Anode Efficiency

Recent advancements in material science have significantly enhanced sacrificial anode efficiency, addressing key challenges in consumption rate optimization and service life extension. Traditional zinc, aluminum, and magnesium anodes have undergone substantial compositional refinements through precise alloying techniques. The incorporation of trace elements such as indium and silicon has demonstrated remarkable improvements in activation properties and current efficiency, particularly in aluminum anodes where silicon additions have reduced parasitic corrosion by up to 30%.

Microstructural engineering represents another breakthrough area, with controlled solidification processes yielding more homogeneous anode structures. Advanced metallurgical techniques have enabled the development of anodes with optimized grain boundaries and reduced impurity segregation, resulting in more uniform dissolution patterns and extended service life. Electron microscopy studies reveal that anodes with refined microstructures exhibit up to 25% improvement in utilization efficiency compared to conventional cast materials.

Surface modification technologies have emerged as a promising approach to enhance anode performance. Techniques such as ion implantation and plasma treatment have been employed to create protective surface layers that regulate dissolution kinetics without compromising electrochemical activity. These treatments have shown particular efficacy in high-temperature applications where traditional anodes suffer accelerated consumption rates.

Composite and gradient materials represent the cutting edge of anode material science. Multi-layered anodes with compositional gradients provide optimized performance across varying environmental conditions. Research indicates that these advanced materials can maintain stable protection potentials even under fluctuating salinity and temperature conditions, addressing a significant limitation of conventional single-alloy anodes.

Nanotechnology applications have opened new frontiers in anode efficiency. Nano-engineered anodes incorporating carbon nanotubes or graphene have demonstrated enhanced electrical conductivity and mechanical integrity. Laboratory tests indicate up to 40% improvement in current capacity without corresponding increases in consumption rate, suggesting a fundamental shift in the efficiency paradigm of sacrificial protection systems.

Computational materials science has accelerated development through predictive modeling of anode behavior under various environmental conditions. Machine learning algorithms trained on extensive corrosion datasets now enable precise tailoring of anode compositions for specific deployment environments, reducing the traditional trial-and-error approach to material selection and significantly shortening development cycles for next-generation protective systems.

Microstructural engineering represents another breakthrough area, with controlled solidification processes yielding more homogeneous anode structures. Advanced metallurgical techniques have enabled the development of anodes with optimized grain boundaries and reduced impurity segregation, resulting in more uniform dissolution patterns and extended service life. Electron microscopy studies reveal that anodes with refined microstructures exhibit up to 25% improvement in utilization efficiency compared to conventional cast materials.

Surface modification technologies have emerged as a promising approach to enhance anode performance. Techniques such as ion implantation and plasma treatment have been employed to create protective surface layers that regulate dissolution kinetics without compromising electrochemical activity. These treatments have shown particular efficacy in high-temperature applications where traditional anodes suffer accelerated consumption rates.

Composite and gradient materials represent the cutting edge of anode material science. Multi-layered anodes with compositional gradients provide optimized performance across varying environmental conditions. Research indicates that these advanced materials can maintain stable protection potentials even under fluctuating salinity and temperature conditions, addressing a significant limitation of conventional single-alloy anodes.

Nanotechnology applications have opened new frontiers in anode efficiency. Nano-engineered anodes incorporating carbon nanotubes or graphene have demonstrated enhanced electrical conductivity and mechanical integrity. Laboratory tests indicate up to 40% improvement in current capacity without corresponding increases in consumption rate, suggesting a fundamental shift in the efficiency paradigm of sacrificial protection systems.

Computational materials science has accelerated development through predictive modeling of anode behavior under various environmental conditions. Machine learning algorithms trained on extensive corrosion datasets now enable precise tailoring of anode compositions for specific deployment environments, reducing the traditional trial-and-error approach to material selection and significantly shortening development cycles for next-generation protective systems.

Corrosion Testing Standards and Certification Requirements

Corrosion testing standards and certification requirements play a crucial role in evaluating sacrificial anode performance and ensuring reliable corrosion protection systems. These standards provide systematic methodologies for measuring anode consumption rates under various environmental conditions, establishing benchmarks for quality assurance, and validating life prediction models.

The primary international standards governing sacrificial anode testing include NACE TM0190, ASTM G8, and ISO 15589, which specify procedures for evaluating galvanic anode materials in different environments. These standards outline specific test parameters such as electrolyte composition, temperature ranges, and exposure durations that must be controlled to obtain reproducible results when measuring consumption rates.

Environmental factor assessment is standardized through ASTM G52, which provides guidelines for evaluating the effects of temperature, salinity, pH, and dissolved oxygen on anode performance. This standard is particularly important as these factors significantly influence polarization behavior and ultimately affect consumption rate predictions.

Certification requirements typically mandate accelerated testing protocols that simulate long-term exposure conditions. NACE SP0387 establishes certification criteria for sacrificial anodes used in seawater applications, requiring documentation of chemical composition, electrochemical capacity, and current efficiency under standardized conditions. Similarly, DNV-RP-B401 provides certification guidelines specifically for offshore structures, emphasizing the importance of proper anode selection based on environmental parameters.

For polarization testing, ASTM G97 outlines procedures for measuring electrochemical characteristics of sacrificial anodes, including current output and polarization behavior. These measurements are essential for accurate life prediction models and must be conducted according to standardized protocols to ensure certification compliance.

Life prediction methodologies must adhere to ISO 12473 and NACE SP0176, which establish frameworks for calculating anode consumption rates and service life expectations. These standards require comprehensive documentation of environmental parameters, material properties, and polarization data to validate prediction models.

Certification bodies such as DNV GL, ABS, and Lloyd's Register enforce these standards through rigorous testing requirements and periodic audits. Manufacturers must demonstrate compliance through documented test results from accredited laboratories, material traceability, and quality control procedures that align with ISO 9001 requirements.

Recent developments in standardization include efforts to incorporate digital monitoring systems into certification requirements, allowing real-time verification of anode performance against predicted consumption rates. These emerging standards aim to bridge the gap between laboratory testing and field performance, enhancing the reliability of life prediction models in complex environmental conditions.

The primary international standards governing sacrificial anode testing include NACE TM0190, ASTM G8, and ISO 15589, which specify procedures for evaluating galvanic anode materials in different environments. These standards outline specific test parameters such as electrolyte composition, temperature ranges, and exposure durations that must be controlled to obtain reproducible results when measuring consumption rates.

Environmental factor assessment is standardized through ASTM G52, which provides guidelines for evaluating the effects of temperature, salinity, pH, and dissolved oxygen on anode performance. This standard is particularly important as these factors significantly influence polarization behavior and ultimately affect consumption rate predictions.

Certification requirements typically mandate accelerated testing protocols that simulate long-term exposure conditions. NACE SP0387 establishes certification criteria for sacrificial anodes used in seawater applications, requiring documentation of chemical composition, electrochemical capacity, and current efficiency under standardized conditions. Similarly, DNV-RP-B401 provides certification guidelines specifically for offshore structures, emphasizing the importance of proper anode selection based on environmental parameters.

For polarization testing, ASTM G97 outlines procedures for measuring electrochemical characteristics of sacrificial anodes, including current output and polarization behavior. These measurements are essential for accurate life prediction models and must be conducted according to standardized protocols to ensure certification compliance.

Life prediction methodologies must adhere to ISO 12473 and NACE SP0176, which establish frameworks for calculating anode consumption rates and service life expectations. These standards require comprehensive documentation of environmental parameters, material properties, and polarization data to validate prediction models.

Certification bodies such as DNV GL, ABS, and Lloyd's Register enforce these standards through rigorous testing requirements and periodic audits. Manufacturers must demonstrate compliance through documented test results from accredited laboratories, material traceability, and quality control procedures that align with ISO 9001 requirements.

Recent developments in standardization include efforts to incorporate digital monitoring systems into certification requirements, allowing real-time verification of anode performance against predicted consumption rates. These emerging standards aim to bridge the gap between laboratory testing and field performance, enhancing the reliability of life prediction models in complex environmental conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!