Sacrificial Anode Standards: NACE/ISO Criteria, Documentation And Audits

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sacrificial Anode Technology Background and Objectives

Sacrificial anode technology has evolved significantly since its inception in the early 20th century, with major developments occurring during the 1950s and 1960s when offshore oil and gas exploration expanded rapidly. This cathodic protection method has become a cornerstone of corrosion prevention strategies for marine structures, pipelines, and underground storage tanks. The technology leverages the principle of galvanic corrosion, where a more electrochemically active metal (the anode) corrodes preferentially to protect a less active metal (the cathode).

The evolution of sacrificial anode standards has been driven by industry needs for reliable, consistent performance metrics and installation guidelines. Initially, standards were developed independently by various organizations, leading to inconsistencies in application and performance evaluation. The formation of NACE (National Association of Corrosion Engineers) in 1943 marked a significant milestone in standardizing corrosion protection practices, with specific standards for sacrificial anodes following in subsequent decades.

ISO's involvement in the 1970s and 1980s brought international harmonization to these standards, culminating in joint NACE/ISO standards that are now recognized globally. These standards have continuously evolved to address emerging challenges in different environments and applications, from shallow water to deep-sea installations, and from temperate to extreme temperature conditions.

The current technological landscape shows a trend toward more sophisticated alloy compositions for sacrificial anodes, with aluminum, zinc, and magnesium-based systems dominating different application niches based on environmental factors such as water salinity, temperature, and oxygen content. Research indicates a growing focus on optimizing anode efficiency, extending service life, and reducing environmental impact.

The primary objective of modern sacrificial anode technology is to provide reliable, long-term corrosion protection while minimizing maintenance requirements and environmental consequences. This includes developing standardized testing methodologies that accurately predict anode performance in various conditions, establishing clear documentation requirements for installation and maintenance, and creating robust audit protocols to ensure compliance with established standards.

Future technological goals include the development of "smart" sacrificial anode systems with integrated monitoring capabilities, environmentally friendly alloy compositions with reduced heavy metal content, and improved modeling techniques for more accurate prediction of anode consumption rates and protection coverage. Additionally, there is increasing emphasis on standardizing the documentation of anode performance data to facilitate better industry-wide knowledge sharing and continuous improvement of standards.

The evolution of sacrificial anode standards has been driven by industry needs for reliable, consistent performance metrics and installation guidelines. Initially, standards were developed independently by various organizations, leading to inconsistencies in application and performance evaluation. The formation of NACE (National Association of Corrosion Engineers) in 1943 marked a significant milestone in standardizing corrosion protection practices, with specific standards for sacrificial anodes following in subsequent decades.

ISO's involvement in the 1970s and 1980s brought international harmonization to these standards, culminating in joint NACE/ISO standards that are now recognized globally. These standards have continuously evolved to address emerging challenges in different environments and applications, from shallow water to deep-sea installations, and from temperate to extreme temperature conditions.

The current technological landscape shows a trend toward more sophisticated alloy compositions for sacrificial anodes, with aluminum, zinc, and magnesium-based systems dominating different application niches based on environmental factors such as water salinity, temperature, and oxygen content. Research indicates a growing focus on optimizing anode efficiency, extending service life, and reducing environmental impact.

The primary objective of modern sacrificial anode technology is to provide reliable, long-term corrosion protection while minimizing maintenance requirements and environmental consequences. This includes developing standardized testing methodologies that accurately predict anode performance in various conditions, establishing clear documentation requirements for installation and maintenance, and creating robust audit protocols to ensure compliance with established standards.

Future technological goals include the development of "smart" sacrificial anode systems with integrated monitoring capabilities, environmentally friendly alloy compositions with reduced heavy metal content, and improved modeling techniques for more accurate prediction of anode consumption rates and protection coverage. Additionally, there is increasing emphasis on standardizing the documentation of anode performance data to facilitate better industry-wide knowledge sharing and continuous improvement of standards.

Market Analysis of Cathodic Protection Systems

The global cathodic protection systems market has demonstrated robust growth, valued at approximately $6.7 billion in 2022 and projected to reach $8.9 billion by 2027, representing a compound annual growth rate (CAGR) of 5.8%. This growth is primarily driven by increasing infrastructure development, particularly in oil and gas pipelines, water treatment facilities, and marine structures where corrosion prevention is critical.

The sacrificial anode segment, which adheres to NACE/ISO standards, constitutes roughly 40% of the overall cathodic protection market. This segment has shown steady growth due to its cost-effectiveness, simplicity of installation, and minimal maintenance requirements compared to impressed current cathodic protection (ICCP) systems. The oil and gas industry remains the largest end-user, accounting for approximately 35% of sacrificial anode applications, followed by water and wastewater (25%), marine (20%), and other industries (20%).

Regionally, North America dominates the market with a 32% share, followed by Europe (28%), Asia-Pacific (25%), and the rest of the world (15%). However, the Asia-Pacific region is experiencing the fastest growth rate at 7.2% annually, driven by extensive infrastructure development in China, India, and Southeast Asian countries. The Middle East also represents a significant market due to its extensive oil and gas infrastructure.

Key market drivers include aging infrastructure requiring protection, stringent environmental regulations mandating corrosion prevention, and increasing awareness of life-cycle cost benefits. The implementation of NACE SP0169/ISO 15589 standards has significantly influenced market dynamics by establishing consistent quality benchmarks and documentation requirements for sacrificial anode systems.

Market challenges include fluctuating raw material prices, particularly for zinc, aluminum, and magnesium anodes, which can impact profit margins. Additionally, the lack of skilled professionals familiar with NACE/ISO standards and proper documentation procedures presents a barrier to market growth in developing regions.

The market is moderately fragmented with several global players and numerous regional specialists. Leading companies typically differentiate themselves through comprehensive documentation practices, third-party certification, and audit-ready systems that fully comply with NACE/ISO standards. This compliance-focused approach has become a significant competitive advantage as end-users increasingly demand verifiable adherence to international standards.

The sacrificial anode segment, which adheres to NACE/ISO standards, constitutes roughly 40% of the overall cathodic protection market. This segment has shown steady growth due to its cost-effectiveness, simplicity of installation, and minimal maintenance requirements compared to impressed current cathodic protection (ICCP) systems. The oil and gas industry remains the largest end-user, accounting for approximately 35% of sacrificial anode applications, followed by water and wastewater (25%), marine (20%), and other industries (20%).

Regionally, North America dominates the market with a 32% share, followed by Europe (28%), Asia-Pacific (25%), and the rest of the world (15%). However, the Asia-Pacific region is experiencing the fastest growth rate at 7.2% annually, driven by extensive infrastructure development in China, India, and Southeast Asian countries. The Middle East also represents a significant market due to its extensive oil and gas infrastructure.

Key market drivers include aging infrastructure requiring protection, stringent environmental regulations mandating corrosion prevention, and increasing awareness of life-cycle cost benefits. The implementation of NACE SP0169/ISO 15589 standards has significantly influenced market dynamics by establishing consistent quality benchmarks and documentation requirements for sacrificial anode systems.

Market challenges include fluctuating raw material prices, particularly for zinc, aluminum, and magnesium anodes, which can impact profit margins. Additionally, the lack of skilled professionals familiar with NACE/ISO standards and proper documentation procedures presents a barrier to market growth in developing regions.

The market is moderately fragmented with several global players and numerous regional specialists. Leading companies typically differentiate themselves through comprehensive documentation practices, third-party certification, and audit-ready systems that fully comply with NACE/ISO standards. This compliance-focused approach has become a significant competitive advantage as end-users increasingly demand verifiable adherence to international standards.

Current Standards and Technical Challenges in Sacrificial Anodes

The current landscape of sacrificial anode standards is dominated by two major organizations: NACE International (National Association of Corrosion Engineers) and the International Organization for Standardization (ISO). These bodies have established comprehensive frameworks that guide the design, manufacturing, installation, and performance evaluation of sacrificial anodes across various industries, particularly in marine and offshore applications.

NACE standards, such as SP0176 for corrosion control of submerged areas and RP0387 for offshore platform cathodic protection design, provide detailed specifications for material composition, performance requirements, and testing methodologies. Similarly, ISO 15589-2 focuses on cathodic protection for offshore structures, while ISO 12473 addresses general principles of cathodic protection in seawater.

Despite these established standards, significant technical challenges persist in the field of sacrificial anodes. One primary challenge involves the accurate prediction of anode performance and lifespan under varying environmental conditions. Current models often fail to account for complex interactions between water chemistry, temperature fluctuations, and hydrodynamic factors, leading to premature anode depletion or overdesign.

Documentation requirements present another substantial hurdle. The standards mandate extensive record-keeping throughout the lifecycle of sacrificial anode systems, including design calculations, material certifications, installation procedures, and periodic inspection reports. However, there is considerable inconsistency in how these requirements are interpreted and implemented across different regions and industries.

Audit protocols also face challenges in standardization. While both NACE and ISO provide guidelines for inspection and verification, the practical application of these protocols varies significantly. This variability creates difficulties in establishing consistent quality assurance measures and complicates compliance verification, particularly for multinational operations subject to different regulatory regimes.

The integration of sacrificial anode systems with other corrosion protection methods presents additional technical challenges. Current standards provide limited guidance on how to effectively combine sacrificial anodes with impressed current systems or protective coatings, leading to potential inefficiencies or even accelerated corrosion in some cases.

Emerging technologies and materials are outpacing standardization efforts. New alloy formulations, monitoring technologies, and installation techniques are being developed faster than standards can be updated, creating a gap between industry practice and formal requirements. This lag particularly affects innovative offshore renewable energy structures, which may not fit neatly into existing standard frameworks designed primarily for oil and gas applications.

NACE standards, such as SP0176 for corrosion control of submerged areas and RP0387 for offshore platform cathodic protection design, provide detailed specifications for material composition, performance requirements, and testing methodologies. Similarly, ISO 15589-2 focuses on cathodic protection for offshore structures, while ISO 12473 addresses general principles of cathodic protection in seawater.

Despite these established standards, significant technical challenges persist in the field of sacrificial anodes. One primary challenge involves the accurate prediction of anode performance and lifespan under varying environmental conditions. Current models often fail to account for complex interactions between water chemistry, temperature fluctuations, and hydrodynamic factors, leading to premature anode depletion or overdesign.

Documentation requirements present another substantial hurdle. The standards mandate extensive record-keeping throughout the lifecycle of sacrificial anode systems, including design calculations, material certifications, installation procedures, and periodic inspection reports. However, there is considerable inconsistency in how these requirements are interpreted and implemented across different regions and industries.

Audit protocols also face challenges in standardization. While both NACE and ISO provide guidelines for inspection and verification, the practical application of these protocols varies significantly. This variability creates difficulties in establishing consistent quality assurance measures and complicates compliance verification, particularly for multinational operations subject to different regulatory regimes.

The integration of sacrificial anode systems with other corrosion protection methods presents additional technical challenges. Current standards provide limited guidance on how to effectively combine sacrificial anodes with impressed current systems or protective coatings, leading to potential inefficiencies or even accelerated corrosion in some cases.

Emerging technologies and materials are outpacing standardization efforts. New alloy formulations, monitoring technologies, and installation techniques are being developed faster than standards can be updated, creating a gap between industry practice and formal requirements. This lag particularly affects innovative offshore renewable energy structures, which may not fit neatly into existing standard frameworks designed primarily for oil and gas applications.

NACE/ISO Implementation Solutions and Documentation Requirements

01 Material composition standards for sacrificial anodes

Standards for the material composition of sacrificial anodes, particularly focusing on alloys used for cathodic protection. These standards specify the required chemical composition, including primary metals (such as zinc, aluminum, or magnesium) and trace elements that affect performance. The composition standards ensure optimal electrochemical properties, including appropriate potential difference and current capacity for effective corrosion protection in various environments.- Material composition standards for sacrificial anodes: Standards for the material composition of sacrificial anodes, particularly focusing on the use of specific alloys such as aluminum, zinc, and magnesium. These standards specify the required chemical composition, purity levels, and alloying elements to ensure optimal galvanic protection. The composition standards are critical for ensuring consistent electrochemical performance and corrosion protection efficiency in various environments.

- Design and installation standards for sacrificial anode systems: Standards governing the design, sizing, and installation of sacrificial anode systems for various applications. These include specifications for proper anode spacing, attachment methods, electrical connections, and distribution patterns to ensure optimal cathodic protection. The standards also address installation requirements for different environments such as marine structures, pipelines, and underground storage tanks, ensuring effective corrosion protection throughout the system's service life.

- Performance testing and quality control standards: Standards for testing and evaluating the performance of sacrificial anodes, including electrochemical capacity, current output, and dissolution rate measurements. These standards define test methodologies, acceptance criteria, and quality control procedures to ensure anodes meet required protection levels. They also specify inspection protocols, sampling methods, and documentation requirements for manufacturing quality assurance and field performance verification.

- Environmental and safety standards for sacrificial anodes: Standards addressing environmental considerations and safety requirements for sacrificial anode systems. These include regulations on the environmental impact of anode materials, permissible dissolution products in different environments, and disposal requirements for spent anodes. Safety standards cover handling procedures, installation safety, and compatibility with surrounding structures to prevent hydrogen gas accumulation or other potential hazards during operation.

- Application-specific standards for different industries: Specialized standards for sacrificial anode systems in specific industries and applications, such as offshore structures, shipping vessels, underground pipelines, and water heaters. These standards address the unique requirements of each application, including exposure conditions, service life expectations, and industry-specific performance criteria. They provide guidance on anode selection, sizing calculations, and monitoring requirements tailored to particular operational environments.

02 Design and installation standards for marine applications

Standards governing the design, sizing, and installation of sacrificial anodes in marine environments, including ships, offshore structures, and harbor facilities. These standards provide guidelines for anode placement, attachment methods, and required coverage areas to ensure adequate cathodic protection. They also specify installation procedures to maintain electrical continuity between the anode and the protected structure, as well as spacing requirements to achieve uniform protection across submerged surfaces.Expand Specific Solutions03 Performance testing and quality control standards

Standards for testing and evaluating the performance of sacrificial anodes, including electrochemical capacity, current efficiency, and dissolution rate measurements. These standards establish test protocols for determining anode efficiency and lifespan under various operating conditions. Quality control procedures ensure consistent manufacturing quality, including tests for porosity, mechanical strength, and uniformity of composition to maintain reliable corrosion protection performance.Expand Specific Solutions04 Industry-specific standards for pipeline and infrastructure protection

Specialized standards for sacrificial anode systems used in protecting buried pipelines, storage tanks, and other infrastructure. These standards address soil resistivity considerations, anode spacing calculations, and backfill material specifications. They provide guidelines for monitoring anode performance over time and criteria for determining when replacement is necessary. The standards also cover compatibility with coatings and other corrosion protection methods used in conjunction with cathodic protection.Expand Specific Solutions05 Environmental and safety standards for sacrificial anodes

Standards addressing environmental impact and safety considerations of sacrificial anodes, including regulations on metal leaching and disposal requirements. These standards specify acceptable limits for potentially harmful elements in anode composition and provide guidelines for environmentally responsible end-of-life management. They also cover safety aspects during installation, maintenance, and replacement operations, particularly in hazardous environments such as offshore platforms or enclosed tanks.Expand Specific Solutions

Key Industry Players and Manufacturers in Cathodic Protection

The sacrificial anode standards market is currently in a growth phase, driven by increasing infrastructure development and corrosion prevention needs across oil and gas, maritime, and industrial sectors. The global market size is estimated at approximately $2.5 billion, with projected annual growth of 5-7% through 2028. Technologically, the field shows moderate maturity with established NACE/ISO standards, though innovation continues in material science and monitoring systems. Key players demonstrate varying levels of technical sophistication: BAC Corrosion Control and Sunrui Marine lead with comprehensive solutions and proprietary technologies; PetroChina, CNOOC, and Sinopec dominate in large-scale implementation; while research institutions like DRDO, CSIRO, and Xi'an Jiaotong University drive fundamental advances in sacrificial anode materials and testing methodologies.

BAC Corrosion Control Ltd

Technical Solution: BAC Corrosion Control Ltd has developed comprehensive sacrificial anode systems that comply with NACE SP0176 and ISO 15589 standards for cathodic protection. Their technical approach involves custom-designed aluminum, zinc, and magnesium anodes with proprietary alloy compositions optimized for specific environments (seawater, brackish water, soil). Their documentation system includes detailed design calculations, performance modeling software, and comprehensive installation records that track anode depletion rates and protection levels. BAC implements a three-tier quality assurance program with pre-installation testing, regular field inspections using reference electrodes to measure protection potentials, and advanced remote monitoring systems that provide real-time data on protection status, allowing for predictive maintenance before protection levels fall below NACE/ISO thresholds.

Strengths: Extensive field experience across multiple industries provides practical knowledge of real-world performance factors; proprietary alloy formulations offer extended anode life in challenging environments; integrated documentation and monitoring systems ensure compliance with international standards. Weaknesses: Higher initial implementation costs compared to basic systems; requires specialized training for installation and maintenance personnel; system complexity may be excessive for smaller applications.

Sun Rui Corrosion Control & Fouling Co.

Technical Solution: Sun Rui Corrosion Control has developed a comprehensive sacrificial anode system that adheres to both NACE RP0387 and ISO 15589-2 standards. Their technical solution incorporates high-purity aluminum-zinc-indium alloy anodes specifically engineered for offshore structures and marine vessels. The company employs a systematic approach to sacrificial anode implementation, beginning with detailed structure assessment and electrochemical analysis to determine optimal anode placement and quantity. Their proprietary "SunShield" documentation system tracks anode performance throughout the lifecycle, recording initial potentials, current outputs, and depletion rates. This system integrates with their audit protocol that includes quarterly inspections using calibrated reference electrodes to verify protection levels meet the -850mV to -1200mV (vs. Cu/CuSO4) criteria specified by NACE standards. For critical infrastructure, Sun Rui implements remote monitoring technology that provides continuous data on protection status.

Strengths: Specialized expertise in offshore and marine environments; comprehensive documentation system that facilitates regulatory compliance and audit preparation; custom alloy formulations that extend anode life in aggressive environments. Weaknesses: Solutions primarily focused on marine applications with less experience in underground or freshwater systems; higher initial costs compared to standard anode systems; requires specialized training for maintenance personnel to properly interpret monitoring data.

Critical Technical Specifications and Performance Criteria

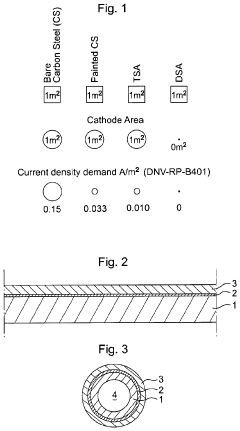

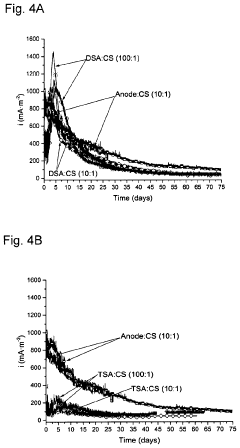

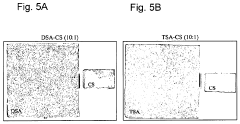

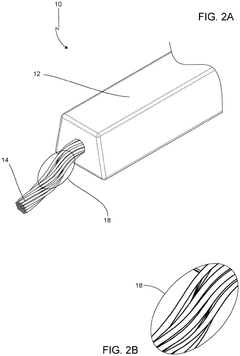

System and method for cathodic protection by distributed sacrificial anodes

PatentPendingUS20230235463A1

Innovation

- A cathodic protection system utilizing a distributed sacrificial anode (DSA) approach, where a metallic second-layer coating with an open circuit potential equal to or more negative than the first-layer coating is applied over the entire surface, reducing the total cathode area and anode mass, while maintaining equivalent protection levels.

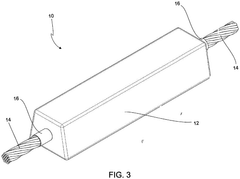

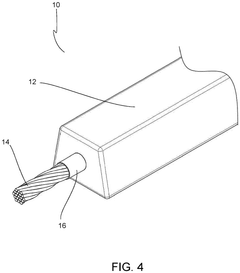

Sacrificial anode and method for producing a sacrificial anode

PatentPendingEP4553190A1

Innovation

- A sacrificial anode design featuring an elongated main part made from a sacrificial metal alloy and a carrying part made from a metal with lower electrical resistance, such as copper, to maintain effectiveness and structural capabilities even in longer anode configurations.

Compliance Audit Methodologies and Best Practices

Effective compliance audit methodologies for sacrificial anode systems require a structured approach that ensures adherence to NACE and ISO standards. The primary audit framework should incorporate both documentation review and physical inspection components, with clear verification protocols for each standard requirement.

Systematic audit planning begins with establishing a comprehensive checklist derived directly from applicable standards such as NACE SP0176, NACE RP0387, and ISO 15589. This checklist should categorize requirements into critical, major, and minor compliance elements to prioritize findings appropriately. Documentation audits must verify the existence and accuracy of design calculations, material certificates, installation records, and maintenance histories.

Field verification techniques constitute a crucial component of the audit process. These include visual inspections of anode installations, electrical potential measurements using reference electrodes, and current output testing. Modern best practices increasingly incorporate underwater ROV inspections for submerged structures and thermal imaging to identify potential connection issues.

Sampling methodologies represent another essential aspect of effective auditing. Statistical approaches should be employed to determine appropriate inspection sample sizes based on the total anode population, with higher sampling rates for critical systems. Industry best practice suggests a minimum 10% random sampling for routine audits, increasing to 25% for systems with previous compliance issues.

Documentation standards have evolved significantly, with digital record-keeping systems now considered best practice. These systems should maintain complete traceability from anode manufacturing specifications through installation verification to periodic performance testing. Audit reports must document compliance gaps using a standardized classification system that clearly communicates the severity and potential consequences of each finding.

Continuous improvement mechanisms should be integrated into the audit methodology. This includes trend analysis of findings across multiple audit cycles, root cause analysis for recurring issues, and feedback loops to update internal standards and procedures. Leading organizations implement a maturity model approach that moves beyond basic compliance to performance optimization.

Training requirements for auditors represent a final critical element. Qualified auditors should possess certification in cathodic protection principles (such as NACE CP Specialist), demonstrated understanding of relevant standards, and experience in corrosion management systems. Regular calibration of audit teams through comparative exercises ensures consistency in findings and recommendations across different facilities and systems.

Systematic audit planning begins with establishing a comprehensive checklist derived directly from applicable standards such as NACE SP0176, NACE RP0387, and ISO 15589. This checklist should categorize requirements into critical, major, and minor compliance elements to prioritize findings appropriately. Documentation audits must verify the existence and accuracy of design calculations, material certificates, installation records, and maintenance histories.

Field verification techniques constitute a crucial component of the audit process. These include visual inspections of anode installations, electrical potential measurements using reference electrodes, and current output testing. Modern best practices increasingly incorporate underwater ROV inspections for submerged structures and thermal imaging to identify potential connection issues.

Sampling methodologies represent another essential aspect of effective auditing. Statistical approaches should be employed to determine appropriate inspection sample sizes based on the total anode population, with higher sampling rates for critical systems. Industry best practice suggests a minimum 10% random sampling for routine audits, increasing to 25% for systems with previous compliance issues.

Documentation standards have evolved significantly, with digital record-keeping systems now considered best practice. These systems should maintain complete traceability from anode manufacturing specifications through installation verification to periodic performance testing. Audit reports must document compliance gaps using a standardized classification system that clearly communicates the severity and potential consequences of each finding.

Continuous improvement mechanisms should be integrated into the audit methodology. This includes trend analysis of findings across multiple audit cycles, root cause analysis for recurring issues, and feedback loops to update internal standards and procedures. Leading organizations implement a maturity model approach that moves beyond basic compliance to performance optimization.

Training requirements for auditors represent a final critical element. Qualified auditors should possess certification in cathodic protection principles (such as NACE CP Specialist), demonstrated understanding of relevant standards, and experience in corrosion management systems. Regular calibration of audit teams through comparative exercises ensures consistency in findings and recommendations across different facilities and systems.

Environmental Impact and Sustainability Considerations

The environmental impact of sacrificial anode systems represents a critical consideration in their application and standardization. While these systems effectively protect marine structures and vessels from corrosion, their operation involves the deliberate dissolution of metals into aquatic environments. Current NACE and ISO standards increasingly incorporate environmental assessment criteria, recognizing the need to balance corrosion protection with ecological responsibility.

The primary environmental concern stems from the release of metal ions—typically zinc, aluminum, or magnesium—into surrounding waters. Research indicates that zinc anodes, in particular, can contribute to elevated metal concentrations in harbor sediments and enclosed marine environments. Studies conducted in major ports have documented zinc concentrations exceeding natural background levels by factors of 5-10 in areas with high densities of cathodically protected structures.

Regulatory frameworks are evolving to address these concerns. The European Union's Water Framework Directive now includes specific provisions for monitoring metal concentrations from cathodic protection systems, while the International Maritime Organization has incorporated environmental considerations into its guidelines for ship protection systems. These developments are driving innovation in anode formulations with reduced environmental footprints.

Sustainability considerations are increasingly prominent in modern standards documentation. The life-cycle assessment (LCA) approach is gaining traction, evaluating the environmental impact from raw material extraction through manufacturing, use, and ultimate disposal. NACE Standard SP0387-2018 now recommends documenting the projected metal release rates and environmental fate modeling as part of system design documentation.

Audit protocols are similarly evolving to incorporate environmental performance metrics. Current best practices include verification of compliance with local discharge regulations, documentation of anode consumption rates against predictions, and monitoring of surrounding water and sediment quality. These elements are becoming standard components of third-party certification processes.

Industry response has focused on developing more environmentally compatible solutions, including lower-impact alloy formulations and improved design methodologies that optimize protection while minimizing metal dissolution. Research into biodegradable and non-metallic alternatives represents a promising frontier, though these technologies remain in early development stages and have not yet been incorporated into mainstream standards.

The integration of environmental considerations into sacrificial anode standards reflects a broader shift toward sustainable engineering practices across industries. As regulatory pressures increase and stakeholder expectations evolve, documentation and audit requirements will likely continue to expand, driving further innovation in this essential but environmentally significant technology.

The primary environmental concern stems from the release of metal ions—typically zinc, aluminum, or magnesium—into surrounding waters. Research indicates that zinc anodes, in particular, can contribute to elevated metal concentrations in harbor sediments and enclosed marine environments. Studies conducted in major ports have documented zinc concentrations exceeding natural background levels by factors of 5-10 in areas with high densities of cathodically protected structures.

Regulatory frameworks are evolving to address these concerns. The European Union's Water Framework Directive now includes specific provisions for monitoring metal concentrations from cathodic protection systems, while the International Maritime Organization has incorporated environmental considerations into its guidelines for ship protection systems. These developments are driving innovation in anode formulations with reduced environmental footprints.

Sustainability considerations are increasingly prominent in modern standards documentation. The life-cycle assessment (LCA) approach is gaining traction, evaluating the environmental impact from raw material extraction through manufacturing, use, and ultimate disposal. NACE Standard SP0387-2018 now recommends documenting the projected metal release rates and environmental fate modeling as part of system design documentation.

Audit protocols are similarly evolving to incorporate environmental performance metrics. Current best practices include verification of compliance with local discharge regulations, documentation of anode consumption rates against predictions, and monitoring of surrounding water and sediment quality. These elements are becoming standard components of third-party certification processes.

Industry response has focused on developing more environmentally compatible solutions, including lower-impact alloy formulations and improved design methodologies that optimize protection while minimizing metal dissolution. Research into biodegradable and non-metallic alternatives represents a promising frontier, though these technologies remain in early development stages and have not yet been incorporated into mainstream standards.

The integration of environmental considerations into sacrificial anode standards reflects a broader shift toward sustainable engineering practices across industries. As regulatory pressures increase and stakeholder expectations evolve, documentation and audit requirements will likely continue to expand, driving further innovation in this essential but environmentally significant technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!