Sacrificial Anode Placement: Throwing Power, Shielding And Complex Geometries

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cathodic Protection Background and Objectives

Cathodic protection has evolved significantly since its initial discovery in the early 19th century when Sir Humphry Davy successfully protected copper-clad naval vessels using zinc and iron anodes. This electrochemical technique has become a cornerstone in corrosion prevention for metallic structures exposed to electrolytic environments such as seawater, soil, and concrete. The fundamental principle relies on converting the protected structure into a cathode by connecting it to a more electrochemically active metal (the sacrificial anode) or by applying an external current.

The evolution of cathodic protection technology has been driven by increasing demands from industries including oil and gas, marine, infrastructure, and utilities. As structures become more complex and operate in increasingly challenging environments, traditional anode placement methodologies have proven insufficient. The concept of "throwing power" - the ability of an anode to deliver protective current to remote areas of a structure - has become particularly critical in modern applications.

Current industry challenges center around optimizing sacrificial anode placement in complex geometries where shadowing effects can create zones of inadequate protection. These "shielded areas" receive insufficient cathodic current due to the physical obstruction of current flow paths, potentially leading to localized corrosion and premature system failures. The economic implications are substantial, with corrosion costs estimated at 3-5% of GDP in industrialized nations.

The primary objective of this technical research is to develop advanced methodologies for sacrificial anode placement that maximize throwing power while minimizing shielding effects in complex geometrical structures. This includes investigating the relationship between anode positioning, current distribution, and protection effectiveness in multi-dimensional spaces with varying electrolyte conditions.

Secondary objectives include quantifying the impact of different environmental factors on throwing power, developing predictive models for optimizing anode placement, and establishing design guidelines that can be implemented across various industries. The research aims to bridge the gap between theoretical electrochemical principles and practical engineering applications.

Recent advancements in computational modeling, particularly finite element analysis and boundary element methods, have created new opportunities to simulate and visualize current distribution patterns. These tools, combined with empirical testing, form the foundation for developing next-generation anode placement strategies that can address the limitations of conventional approaches.

The ultimate goal is to enhance the reliability and efficiency of cathodic protection systems, extending asset lifespans while reducing maintenance requirements and environmental impacts associated with premature structural failures.

The evolution of cathodic protection technology has been driven by increasing demands from industries including oil and gas, marine, infrastructure, and utilities. As structures become more complex and operate in increasingly challenging environments, traditional anode placement methodologies have proven insufficient. The concept of "throwing power" - the ability of an anode to deliver protective current to remote areas of a structure - has become particularly critical in modern applications.

Current industry challenges center around optimizing sacrificial anode placement in complex geometries where shadowing effects can create zones of inadequate protection. These "shielded areas" receive insufficient cathodic current due to the physical obstruction of current flow paths, potentially leading to localized corrosion and premature system failures. The economic implications are substantial, with corrosion costs estimated at 3-5% of GDP in industrialized nations.

The primary objective of this technical research is to develop advanced methodologies for sacrificial anode placement that maximize throwing power while minimizing shielding effects in complex geometrical structures. This includes investigating the relationship between anode positioning, current distribution, and protection effectiveness in multi-dimensional spaces with varying electrolyte conditions.

Secondary objectives include quantifying the impact of different environmental factors on throwing power, developing predictive models for optimizing anode placement, and establishing design guidelines that can be implemented across various industries. The research aims to bridge the gap between theoretical electrochemical principles and practical engineering applications.

Recent advancements in computational modeling, particularly finite element analysis and boundary element methods, have created new opportunities to simulate and visualize current distribution patterns. These tools, combined with empirical testing, form the foundation for developing next-generation anode placement strategies that can address the limitations of conventional approaches.

The ultimate goal is to enhance the reliability and efficiency of cathodic protection systems, extending asset lifespans while reducing maintenance requirements and environmental impacts associated with premature structural failures.

Market Analysis for Sacrificial Anode Systems

The global sacrificial anode systems market is experiencing steady growth, valued at approximately $2.8 billion in 2023 with projections to reach $3.7 billion by 2028, representing a compound annual growth rate of 5.7%. This growth is primarily driven by increasing investments in offshore oil and gas infrastructure, expanding marine transportation, and rising awareness about corrosion prevention across industries.

The marine sector continues to dominate the market share, accounting for roughly 42% of the total demand. This is attributed to the extensive use of sacrificial anodes in ships, offshore platforms, and port facilities. The oil and gas industry follows closely, representing about 35% of the market, where sacrificial anodes are critical for protecting underwater pipelines, storage tanks, and offshore structures.

Geographically, Asia-Pacific leads the market with approximately 38% share, fueled by rapid industrialization in China and India, extensive shipbuilding activities in South Korea and Japan, and offshore energy developments across the region. North America and Europe collectively account for about 45% of the market, with strong demand from established oil and gas operations and maritime industries.

The market is witnessing a significant shift toward zinc and aluminum-based sacrificial anodes due to their environmental advantages over traditional magnesium anodes. Aluminum anodes, in particular, have gained traction with a market share increase from 28% to 34% over the past five years, owing to their superior performance in seawater applications and longer service life.

Customer demand is increasingly focused on anodes designed for complex geometries and difficult-to-protect areas. This trend is particularly evident in the aerospace and defense sectors, where intricate components require specialized cathodic protection solutions. The market for custom-designed anode systems has grown by approximately 12% annually, outpacing the overall market growth rate.

Regulatory factors are significantly influencing market dynamics, with environmental regulations in Europe and North America driving the adoption of more eco-friendly anode materials. The International Maritime Organization's guidelines on corrosion prevention have further standardized requirements, creating a more structured market environment.

Emerging opportunities exist in renewable energy infrastructure, particularly offshore wind farms, where sacrificial anodes are essential for protecting submerged steel structures. This segment is expected to grow at 15% annually through 2028, presenting a substantial opportunity for anode system manufacturers who can address the unique challenges of these installations, including complex geometries and varying water conditions.

The marine sector continues to dominate the market share, accounting for roughly 42% of the total demand. This is attributed to the extensive use of sacrificial anodes in ships, offshore platforms, and port facilities. The oil and gas industry follows closely, representing about 35% of the market, where sacrificial anodes are critical for protecting underwater pipelines, storage tanks, and offshore structures.

Geographically, Asia-Pacific leads the market with approximately 38% share, fueled by rapid industrialization in China and India, extensive shipbuilding activities in South Korea and Japan, and offshore energy developments across the region. North America and Europe collectively account for about 45% of the market, with strong demand from established oil and gas operations and maritime industries.

The market is witnessing a significant shift toward zinc and aluminum-based sacrificial anodes due to their environmental advantages over traditional magnesium anodes. Aluminum anodes, in particular, have gained traction with a market share increase from 28% to 34% over the past five years, owing to their superior performance in seawater applications and longer service life.

Customer demand is increasingly focused on anodes designed for complex geometries and difficult-to-protect areas. This trend is particularly evident in the aerospace and defense sectors, where intricate components require specialized cathodic protection solutions. The market for custom-designed anode systems has grown by approximately 12% annually, outpacing the overall market growth rate.

Regulatory factors are significantly influencing market dynamics, with environmental regulations in Europe and North America driving the adoption of more eco-friendly anode materials. The International Maritime Organization's guidelines on corrosion prevention have further standardized requirements, creating a more structured market environment.

Emerging opportunities exist in renewable energy infrastructure, particularly offshore wind farms, where sacrificial anodes are essential for protecting submerged steel structures. This segment is expected to grow at 15% annually through 2028, presenting a substantial opportunity for anode system manufacturers who can address the unique challenges of these installations, including complex geometries and varying water conditions.

Current Challenges in Anode Placement Technology

Despite significant advancements in cathodic protection systems, sacrificial anode placement technology faces several critical challenges that limit its effectiveness and efficiency. The primary challenge lies in accurately predicting and optimizing the "throwing power" of sacrificial anodes - the ability of an anode to deliver protective current to distant areas of a structure. Current mathematical models often fail to account for complex environmental variables such as varying electrolyte resistivity, temperature fluctuations, and water flow dynamics, resulting in suboptimal protection distribution.

Shielding effects present another substantial obstacle in anode placement technology. When structural components or deposits interfere with current flow, they create "shadow zones" where cathodic protection is insufficient. These zones become particularly problematic in complex industrial settings such as offshore platforms, ship hulls with propellers and rudders, or intricate pipeline networks with multiple bends and joints. Existing simulation tools struggle to accurately predict these shielding effects, especially when multiple interfering elements interact simultaneously.

Complex geometries represent perhaps the most significant challenge in modern anode placement technology. Traditional placement methodologies were developed primarily for simple structures with regular shapes. However, today's industrial applications often involve highly irregular geometries with varying material thicknesses, welded sections, and composite materials. The current distribution across these complex surfaces becomes highly non-uniform, creating areas of both over-protection (causing coating damage and unnecessary anode consumption) and under-protection (leading to localized corrosion).

The integration of computational fluid dynamics (CFD) with electrochemical models remains underdeveloped, limiting our ability to account for flow-induced effects on anode performance. This is particularly problematic in dynamic environments such as marine applications where water movement significantly affects current distribution patterns.

Material compatibility issues further complicate anode placement decisions. The galvanic series relationships between different metals must be carefully considered, especially in multi-metal structures. Current technologies often fail to optimize anode composition and placement simultaneously, resulting in either excessive material consumption or inadequate protection of certain components.

Monitoring and verification of anode performance in real-world conditions remains challenging. Non-destructive testing methods for evaluating current distribution are limited, making it difficult to validate theoretical models and optimize placement strategies based on empirical data. This creates a significant gap between theoretical design and practical implementation of sacrificial anode systems.

Shielding effects present another substantial obstacle in anode placement technology. When structural components or deposits interfere with current flow, they create "shadow zones" where cathodic protection is insufficient. These zones become particularly problematic in complex industrial settings such as offshore platforms, ship hulls with propellers and rudders, or intricate pipeline networks with multiple bends and joints. Existing simulation tools struggle to accurately predict these shielding effects, especially when multiple interfering elements interact simultaneously.

Complex geometries represent perhaps the most significant challenge in modern anode placement technology. Traditional placement methodologies were developed primarily for simple structures with regular shapes. However, today's industrial applications often involve highly irregular geometries with varying material thicknesses, welded sections, and composite materials. The current distribution across these complex surfaces becomes highly non-uniform, creating areas of both over-protection (causing coating damage and unnecessary anode consumption) and under-protection (leading to localized corrosion).

The integration of computational fluid dynamics (CFD) with electrochemical models remains underdeveloped, limiting our ability to account for flow-induced effects on anode performance. This is particularly problematic in dynamic environments such as marine applications where water movement significantly affects current distribution patterns.

Material compatibility issues further complicate anode placement decisions. The galvanic series relationships between different metals must be carefully considered, especially in multi-metal structures. Current technologies often fail to optimize anode composition and placement simultaneously, resulting in either excessive material consumption or inadequate protection of certain components.

Monitoring and verification of anode performance in real-world conditions remains challenging. Non-destructive testing methods for evaluating current distribution are limited, making it difficult to validate theoretical models and optimize placement strategies based on empirical data. This creates a significant gap between theoretical design and practical implementation of sacrificial anode systems.

Current Methodologies for Complex Geometry Protection

01 Sacrificial anode design for improved throwing power

The design of sacrificial anodes can be optimized to enhance throwing power, which is the ability to provide cathodic protection to distant or recessed areas. This includes considerations of anode shape, size, and composition to ensure uniform current distribution. Specialized geometries and strategic placement of anodes can significantly improve the protection range and effectiveness in complex structures.- Design and configuration of sacrificial anodes for improved throwing power: The design and configuration of sacrificial anodes significantly impact their throwing power in cathodic protection systems. Specific shapes, sizes, and strategic positioning of anodes can extend the protective current distribution to remote areas of the structure being protected. Optimized designs include elongated anodes, distributed anode systems, and specially contoured shapes that direct current flow more effectively to difficult-to-reach areas, thereby improving the overall protection coverage.

- Material composition for enhanced sacrificial anode performance: The material composition of sacrificial anodes plays a crucial role in determining their throwing power and shielding capabilities. Anodes made from specific alloys of aluminum, zinc, or magnesium with carefully controlled impurity levels demonstrate superior electrochemical properties. These advanced materials provide more uniform current distribution, increased operational lifespan, and better protection efficiency, particularly in complex geometries where shielding effects might otherwise limit protection.

- Shielding effects mitigation techniques in cathodic protection systems: Various techniques have been developed to mitigate shielding effects that can compromise the effectiveness of sacrificial anodes. These include the use of auxiliary anodes in shielded areas, specialized current distribution devices, and innovative anode placement strategies. Advanced computational modeling helps predict and address potential shielding problems before installation, while hybrid protection systems combine different types of anodes to overcome shielding limitations in complex structures.

- Monitoring and control systems for optimizing anode performance: Sophisticated monitoring and control systems have been developed to optimize sacrificial anode performance regarding throwing power and shielding. These systems include remote monitoring capabilities, real-time current distribution measurement, and adaptive control mechanisms that adjust protection parameters based on environmental conditions. Advanced sensors and data analysis tools help identify areas with insufficient protection due to shielding effects or inadequate throwing power, allowing for timely intervention and system optimization.

- Environmental and installation factors affecting anode throwing power: Environmental and installation factors significantly influence the throwing power of sacrificial anodes. Water or soil resistivity, temperature fluctuations, flow conditions, and the presence of coatings or deposits all affect current distribution. Proper installation techniques, including appropriate spacing, orientation, and electrical continuity verification, are essential for maximizing throwing power. Specialized installation methods have been developed for challenging environments where traditional approaches would result in inadequate protection due to limited throwing power.

02 Shielding effects in cathodic protection systems

Shielding occurs when certain components or geometries block the protective current from reaching all metal surfaces, creating unprotected areas. This phenomenon can be addressed through proper anode placement, use of multiple anodes, or specialized designs that minimize current shadows. Understanding and mitigating shielding effects is crucial for ensuring comprehensive protection of complex structures.Expand Specific Solutions03 Material composition for enhanced sacrificial anode performance

The composition of sacrificial anodes significantly affects their throwing power and ability to overcome shielding issues. Alloys containing aluminum, zinc, magnesium, or combinations thereof with specific activating elements can provide superior current output and distribution characteristics. Advanced metallurgical formulations can extend anode life while maintaining optimal protective current density across greater distances.Expand Specific Solutions04 Innovative anode configurations for complex structures

Novel configurations of sacrificial anodes have been developed to address challenging protection scenarios in complex structures. These include distributed anode systems, modular designs, and adjustable positioning mechanisms that can be optimized for specific applications. Such configurations help overcome geometric limitations and ensure effective cathodic protection even in areas traditionally difficult to protect due to shielding effects.Expand Specific Solutions05 Monitoring and control systems for optimizing cathodic protection

Advanced monitoring and control systems can dynamically adjust sacrificial anode performance to optimize throwing power and minimize shielding effects. These systems may include sensors, data analysis tools, and feedback mechanisms that allow for real-time assessment of protection levels and automatic adjustments to ensure comprehensive coverage. Integration with digital technologies enables more efficient use of sacrificial anodes and extended protection lifespans.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The sacrificial anode placement market is currently in a growth phase, with increasing demand driven by expanding offshore oil and gas operations and aging infrastructure requiring corrosion protection. The global cathodic protection market, valued at approximately $6.5 billion, is expected to grow at 5-6% annually. Technologically, the field shows moderate maturity with ongoing innovation in complex geometry applications. Leading players include CNOOC Energy Technology & Services and Vector Corrosion Technologies, who focus on specialized offshore applications, while BAC Corrosion Control and SHO-BOND Corp. have developed advanced modeling techniques for complex structures. Samsung Heavy Industries and Offshore Oil Engineering Co. are integrating these technologies into large-scale marine projects, demonstrating the technology's industrial importance across multiple sectors.

China National Offshore Oil Corp.

Technical Solution: China National Offshore Oil Corporation (CNOOC) has developed advanced computational modeling techniques for sacrificial anode placement in offshore structures. Their approach combines Finite Element Analysis (FEA) with Boundary Element Method (BEM) to optimize anode distribution in complex offshore platforms and subsea equipment. The system accounts for seawater resistivity variations at different depths and temperatures, creating detailed potential distribution maps that identify areas of insufficient protection. CNOOC's technology incorporates hydrodynamic factors that affect throwing power, particularly in high-current environments where conventional placement strategies often fail. Their proprietary software can simulate long-term performance over 25+ year design lives, accounting for anode consumption rates and changing environmental conditions[1]. For complex geometries like wellheads and manifolds, they employ strategic clustering techniques that maintain uniform potential distribution while minimizing interference effects.

Strengths: Superior modeling accuracy for complex offshore structures with demonstrated 15-20% reduction in anode weight requirements while maintaining protection standards. Comprehensive consideration of environmental variables specific to offshore conditions. Weaknesses: System requires extensive computational resources and specialized expertise to implement effectively. Limited application outside marine environments and requires significant customization for each installation.

Vector Corrosion Technologies Ltd

Technical Solution: Vector Corrosion Technologies has pioneered distributed anode systems specifically designed for reinforced concrete structures with complex geometries. Their Galvashield XP technology utilizes specially formulated zinc-based anodes with proprietary activating agents that maintain consistent throwing power even in high-resistivity environments. For challenging geometries, Vector employs a zone-based protection approach where anodes are strategically positioned based on steel density mapping and concrete resistivity measurements. Their system incorporates embedded reference electrodes for real-time monitoring of protection levels, allowing for adaptive protection strategies. Vector's technology addresses the shielding effect in congested reinforcement areas through their patented "halo" installation technique, which creates optimal current distribution paths around potential barriers[2]. For marine structures, they've developed hybrid systems that combine impressed current with sacrificial elements to provide comprehensive protection for geometrically complex elements like bridge supports and harbor facilities.

Strengths: Specialized solutions for concrete structures with proven effectiveness in high-resistivity environments. Integrated monitoring capabilities provide verification of protection levels and system performance. Weaknesses: Higher initial installation costs compared to traditional systems. Performance can be affected by extreme temperature variations and requires periodic assessment in changing environmental conditions.

Key Patents in Throwing Power Optimization

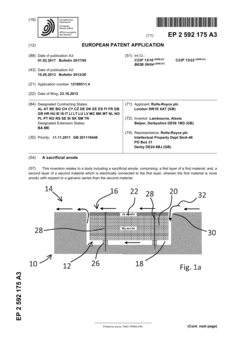

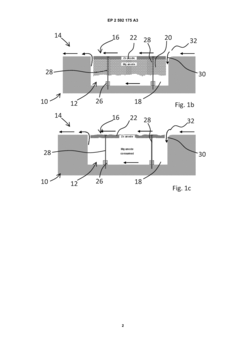

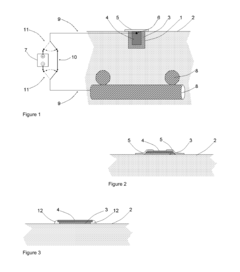

A sacrificial anode

PatentInactiveEP2592175A3

Innovation

- A sacrificial anode composed of two materials, where one is more anodic than the other, allowing it to be recessed into a body while the upper side remains intact, preserving hydrodynamic shape, with a bonded combination like zinc and magnesium, ensuring galvanic relationship and efficient corrosion protection.

Discrete sacrificial anode assembly

PatentActiveUS7967971B2

Innovation

- The use of a sacrificial anode combined with a backfill and a tape attached to the concrete surface using a strong adhesive, which extends over the anode and backfill to secure them in place, allowing for a shallow cavity installation and minimizing concrete removal, while optionally incorporating an impressed current connection for enhanced protection.

Computational Modeling for Anode Placement Optimization

Computational modeling has revolutionized the approach to sacrificial anode placement optimization, offering sophisticated solutions to complex corrosion protection challenges. These models integrate electrochemical principles, fluid dynamics, and structural analysis to simulate the distribution of protective potential across protected structures. Advanced software platforms now incorporate finite element analysis (FEA) and computational fluid dynamics (CFD) to predict current distribution patterns with unprecedented accuracy.

The evolution of these computational tools has been particularly significant for marine and offshore applications, where complex geometries and varying environmental conditions demand precise anode placement. Modern algorithms can account for multiple variables simultaneously, including seawater resistivity variations, flow conditions, and geometric shadowing effects that influence throwing power.

Machine learning techniques have recently enhanced these models by incorporating historical performance data from existing cathodic protection systems. This data-driven approach allows for continuous refinement of placement strategies based on real-world outcomes rather than theoretical predictions alone. Neural networks trained on extensive corrosion protection datasets can now identify optimal anode configurations that might not be intuitive to human engineers.

Sensitivity analysis capabilities within these computational frameworks enable engineers to quantify the impact of various parameters on protection effectiveness. By systematically varying factors such as anode composition, size, and positioning, these models generate probability distributions of protection outcomes, supporting risk-based decision making for critical infrastructure.

Digital twin technology represents the cutting edge of computational modeling for anode placement. These virtual replicas of physical assets incorporate real-time monitoring data to continuously update protection predictions and recommend adjustments to anode systems throughout asset lifecycles. The integration of IoT sensors with computational models creates dynamic protection strategies that adapt to changing environmental conditions and aging infrastructure.

Validation studies comparing computational predictions with field measurements have demonstrated increasing accuracy, with modern models achieving correlation coefficients exceeding 0.9 in many applications. This high degree of reliability has led to widespread adoption across industries including offshore oil and gas, shipbuilding, and underwater pipeline protection.

The computational approach has delivered significant cost savings by optimizing anode quantities and placement before physical installation. Case studies from major offshore projects indicate material reductions of 15-30% compared to traditional design methods, while maintaining or improving protection levels and extending infrastructure lifespan.

The evolution of these computational tools has been particularly significant for marine and offshore applications, where complex geometries and varying environmental conditions demand precise anode placement. Modern algorithms can account for multiple variables simultaneously, including seawater resistivity variations, flow conditions, and geometric shadowing effects that influence throwing power.

Machine learning techniques have recently enhanced these models by incorporating historical performance data from existing cathodic protection systems. This data-driven approach allows for continuous refinement of placement strategies based on real-world outcomes rather than theoretical predictions alone. Neural networks trained on extensive corrosion protection datasets can now identify optimal anode configurations that might not be intuitive to human engineers.

Sensitivity analysis capabilities within these computational frameworks enable engineers to quantify the impact of various parameters on protection effectiveness. By systematically varying factors such as anode composition, size, and positioning, these models generate probability distributions of protection outcomes, supporting risk-based decision making for critical infrastructure.

Digital twin technology represents the cutting edge of computational modeling for anode placement. These virtual replicas of physical assets incorporate real-time monitoring data to continuously update protection predictions and recommend adjustments to anode systems throughout asset lifecycles. The integration of IoT sensors with computational models creates dynamic protection strategies that adapt to changing environmental conditions and aging infrastructure.

Validation studies comparing computational predictions with field measurements have demonstrated increasing accuracy, with modern models achieving correlation coefficients exceeding 0.9 in many applications. This high degree of reliability has led to widespread adoption across industries including offshore oil and gas, shipbuilding, and underwater pipeline protection.

The computational approach has delivered significant cost savings by optimizing anode quantities and placement before physical installation. Case studies from major offshore projects indicate material reductions of 15-30% compared to traditional design methods, while maintaining or improving protection levels and extending infrastructure lifespan.

Environmental Impact and Sustainability Considerations

The implementation of sacrificial anode systems carries significant environmental implications that must be carefully considered in the context of corrosion protection strategies. The metals commonly used in sacrificial anodes—zinc, aluminum, and magnesium—introduce various environmental concerns throughout their lifecycle. Mining and processing these metals contribute to habitat disruption, energy consumption, and greenhouse gas emissions. Additionally, the gradual dissolution of these anodes releases metal ions into surrounding environments, potentially affecting aquatic ecosystems when used in marine applications.

Recent environmental regulations have begun to address these concerns, with some jurisdictions imposing restrictions on zinc and aluminum content in anodes due to their potential toxicity. This regulatory landscape is evolving rapidly, creating compliance challenges for industries reliant on cathodic protection systems. The environmental impact varies significantly based on placement strategies, with poorly optimized anode configurations potentially requiring more frequent replacements and consequently increasing material consumption and waste.

Sustainability considerations are driving innovation in sacrificial anode technology. Research into more environmentally friendly anode materials with reduced ecological footprints is gaining momentum. These alternative materials aim to maintain effective throwing power while minimizing harmful environmental impacts. Additionally, advanced modeling techniques for optimizing anode placement in complex geometries can extend service life and reduce material consumption, representing a significant sustainability improvement.

Life cycle assessment (LCA) methodologies are increasingly being applied to evaluate the environmental performance of different anode placement strategies. These assessments consider factors such as raw material extraction, manufacturing processes, operational efficiency, and end-of-life disposal. The results indicate that optimized placement techniques that account for throwing power and shielding effects can substantially reduce the environmental burden of cathodic protection systems.

The recyclability of spent anodes presents another important sustainability consideration. While some anode materials can be recovered and recycled, the process often faces technical and economic challenges. Developing more efficient recycling pathways for sacrificial anode materials could significantly improve their overall environmental profile. Furthermore, integrating renewable energy sources to power impressed current systems as alternatives to sacrificial anodes represents a promising approach for reducing the environmental footprint of corrosion protection in certain applications.

Recent environmental regulations have begun to address these concerns, with some jurisdictions imposing restrictions on zinc and aluminum content in anodes due to their potential toxicity. This regulatory landscape is evolving rapidly, creating compliance challenges for industries reliant on cathodic protection systems. The environmental impact varies significantly based on placement strategies, with poorly optimized anode configurations potentially requiring more frequent replacements and consequently increasing material consumption and waste.

Sustainability considerations are driving innovation in sacrificial anode technology. Research into more environmentally friendly anode materials with reduced ecological footprints is gaining momentum. These alternative materials aim to maintain effective throwing power while minimizing harmful environmental impacts. Additionally, advanced modeling techniques for optimizing anode placement in complex geometries can extend service life and reduce material consumption, representing a significant sustainability improvement.

Life cycle assessment (LCA) methodologies are increasingly being applied to evaluate the environmental performance of different anode placement strategies. These assessments consider factors such as raw material extraction, manufacturing processes, operational efficiency, and end-of-life disposal. The results indicate that optimized placement techniques that account for throwing power and shielding effects can substantially reduce the environmental burden of cathodic protection systems.

The recyclability of spent anodes presents another important sustainability consideration. While some anode materials can be recovered and recycled, the process often faces technical and economic challenges. Developing more efficient recycling pathways for sacrificial anode materials could significantly improve their overall environmental profile. Furthermore, integrating renewable energy sources to power impressed current systems as alternatives to sacrificial anodes represents a promising approach for reducing the environmental footprint of corrosion protection in certain applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!