Sacrificial Anode Monitoring: Potential Surveys, Coupon Data And Acceptance

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sacrificial Anode Technology Background and Objectives

Sacrificial anode technology has evolved significantly since its inception in the early 20th century, becoming a cornerstone of corrosion protection strategies for metallic structures in various environments. The fundamental principle behind this technology relies on galvanic corrosion theory, where a more electrochemically active metal (the anode) corrodes preferentially to protect a less active metal (the cathode). This electrochemical process has been extensively applied in marine environments, underground pipelines, storage tanks, and various industrial facilities.

The evolution of sacrificial anode systems has been marked by significant advancements in material science, with the development of specialized alloys designed to optimize protection efficiency and longevity. Traditional zinc, aluminum, and magnesium anodes have been refined through precise alloying techniques to enhance their electrochemical properties and extend service life under specific environmental conditions.

Monitoring methodologies for sacrificial anode systems have progressed from basic visual inspections to sophisticated electronic measurement techniques. The integration of potential surveys, which measure the electrical potential between the protected structure and its environment, has enabled more accurate assessment of protection levels. Concurrently, coupon data collection has emerged as a valuable method for quantifying corrosion rates and evaluating protection effectiveness under actual service conditions.

The primary objective of modern sacrificial anode monitoring is to ensure continuous and adequate cathodic protection while optimizing anode consumption rates. This involves establishing reliable acceptance criteria that define the minimum protection potentials required for different materials and environments, in accordance with international standards such as NACE SP0169 and ISO 15589.

Current technological goals in this field focus on developing more accurate, reliable, and cost-effective monitoring systems that can provide real-time data on protection status. The integration of remote monitoring capabilities, wireless data transmission, and automated analysis tools represents a significant advancement toward more proactive maintenance strategies and extended asset lifespans.

Another critical objective is the development of environmentally sustainable anode materials that maintain effective protection while minimizing ecological impact. This includes research into biodegradable alloys and reduced heavy metal content in anode compositions, addressing growing environmental concerns associated with traditional sacrificial anode materials.

The industry is also moving toward establishing more standardized acceptance criteria that account for varying environmental conditions, material compositions, and application-specific requirements. This standardization aims to enhance reliability and consistency in protection assessment across different industries and geographical regions.

The evolution of sacrificial anode systems has been marked by significant advancements in material science, with the development of specialized alloys designed to optimize protection efficiency and longevity. Traditional zinc, aluminum, and magnesium anodes have been refined through precise alloying techniques to enhance their electrochemical properties and extend service life under specific environmental conditions.

Monitoring methodologies for sacrificial anode systems have progressed from basic visual inspections to sophisticated electronic measurement techniques. The integration of potential surveys, which measure the electrical potential between the protected structure and its environment, has enabled more accurate assessment of protection levels. Concurrently, coupon data collection has emerged as a valuable method for quantifying corrosion rates and evaluating protection effectiveness under actual service conditions.

The primary objective of modern sacrificial anode monitoring is to ensure continuous and adequate cathodic protection while optimizing anode consumption rates. This involves establishing reliable acceptance criteria that define the minimum protection potentials required for different materials and environments, in accordance with international standards such as NACE SP0169 and ISO 15589.

Current technological goals in this field focus on developing more accurate, reliable, and cost-effective monitoring systems that can provide real-time data on protection status. The integration of remote monitoring capabilities, wireless data transmission, and automated analysis tools represents a significant advancement toward more proactive maintenance strategies and extended asset lifespans.

Another critical objective is the development of environmentally sustainable anode materials that maintain effective protection while minimizing ecological impact. This includes research into biodegradable alloys and reduced heavy metal content in anode compositions, addressing growing environmental concerns associated with traditional sacrificial anode materials.

The industry is also moving toward establishing more standardized acceptance criteria that account for varying environmental conditions, material compositions, and application-specific requirements. This standardization aims to enhance reliability and consistency in protection assessment across different industries and geographical regions.

Market Analysis for Cathodic Protection Systems

The global cathodic protection systems market has demonstrated robust growth, valued at approximately $6.7 billion in 2022 and projected to reach $8.9 billion by 2027, growing at a CAGR of 5.8%. This expansion is primarily driven by increasing infrastructure investments in oil and gas, water and wastewater, marine, and construction industries where metal structures face significant corrosion challenges.

The sacrificial anode segment, particularly relevant to monitoring technologies like potential surveys and coupon data collection, represents about 40% of the overall cathodic protection market. This segment is experiencing faster growth than impressed current systems in certain applications due to its reliability, lower maintenance requirements, and absence of external power needs.

Regionally, North America and Europe currently dominate the market with combined market share exceeding 55%, attributed to aging infrastructure requiring protection and stringent regulatory frameworks. However, the Asia-Pacific region is emerging as the fastest-growing market with annual growth rates approaching 7%, driven by rapid industrialization in China, India, and Southeast Asian countries.

Industry-wise, oil and gas remains the largest application sector, consuming approximately 38% of cathodic protection systems, followed by water and wastewater (22%), marine applications (18%), and other industries including mining and construction. The offshore segment specifically shows promising growth prospects with increasing deep-water exploration activities.

The monitoring systems segment, which includes potential surveys and coupon data collection technologies, is witnessing particularly strong demand growth at 6.5% annually, outpacing the overall market. This acceleration reflects the industry's shift toward preventive maintenance strategies and remote monitoring capabilities that reduce operational costs.

Market trends indicate growing demand for integrated solutions that combine sacrificial anode systems with advanced monitoring technologies, allowing for real-time data collection and predictive maintenance. Companies offering comprehensive packages that include installation, monitoring services, and data analysis are gaining competitive advantage.

Customer preferences are evolving toward solutions offering longer anode life, more accurate monitoring capabilities, and systems that can be retrofitted to existing infrastructure. The increasing adoption of digital technologies for monitoring sacrificial anode performance represents a significant market opportunity, with potential survey equipment and data analysis software emerging as high-growth product categories.

The sacrificial anode segment, particularly relevant to monitoring technologies like potential surveys and coupon data collection, represents about 40% of the overall cathodic protection market. This segment is experiencing faster growth than impressed current systems in certain applications due to its reliability, lower maintenance requirements, and absence of external power needs.

Regionally, North America and Europe currently dominate the market with combined market share exceeding 55%, attributed to aging infrastructure requiring protection and stringent regulatory frameworks. However, the Asia-Pacific region is emerging as the fastest-growing market with annual growth rates approaching 7%, driven by rapid industrialization in China, India, and Southeast Asian countries.

Industry-wise, oil and gas remains the largest application sector, consuming approximately 38% of cathodic protection systems, followed by water and wastewater (22%), marine applications (18%), and other industries including mining and construction. The offshore segment specifically shows promising growth prospects with increasing deep-water exploration activities.

The monitoring systems segment, which includes potential surveys and coupon data collection technologies, is witnessing particularly strong demand growth at 6.5% annually, outpacing the overall market. This acceleration reflects the industry's shift toward preventive maintenance strategies and remote monitoring capabilities that reduce operational costs.

Market trends indicate growing demand for integrated solutions that combine sacrificial anode systems with advanced monitoring technologies, allowing for real-time data collection and predictive maintenance. Companies offering comprehensive packages that include installation, monitoring services, and data analysis are gaining competitive advantage.

Customer preferences are evolving toward solutions offering longer anode life, more accurate monitoring capabilities, and systems that can be retrofitted to existing infrastructure. The increasing adoption of digital technologies for monitoring sacrificial anode performance represents a significant market opportunity, with potential survey equipment and data analysis software emerging as high-growth product categories.

Current Monitoring Challenges and Technical Limitations

Despite significant advancements in sacrificial anode monitoring technologies, several persistent challenges and technical limitations continue to impede optimal cathodic protection system performance assessment. The current potential survey methodologies, while established, suffer from significant spatial and temporal limitations. Fixed reference electrode installations provide only localized measurements, creating blind spots in large-scale infrastructure protection systems such as pipelines, offshore platforms, and ship hulls. This incomplete coverage can lead to undetected localized corrosion in areas between measurement points.

Traditional potential measurement techniques are also highly susceptible to interference from stray currents, neighboring cathodic protection systems, and telluric currents, particularly in congested industrial environments or marine settings. These external influences can significantly distort readings, leading to misinterpretation of protection status and potentially flawed maintenance decisions.

Coupon data collection presents its own set of challenges. The physical retrieval of coupons from remote or underwater installations requires specialized equipment and personnel, substantially increasing monitoring costs. Furthermore, the time lag between coupon installation and retrieval creates significant delays in data acquisition, preventing real-time system assessment and timely intervention when protection levels become inadequate.

The interpretation of coupon data introduces additional complexity due to the inherent variability in environmental conditions. Factors such as temperature fluctuations, salinity gradients, and microbiological activity can significantly alter corrosion rates, making it difficult to extrapolate coupon results to the entire protected structure with high confidence.

Current acceptance criteria for sacrificial anode systems lack standardization across different industries and geographical regions. The commonly used -850mV criterion (vs. Cu/CuSO₄) may be insufficient in high-resistivity environments or in the presence of sulfate-reducing bacteria. Conversely, this same criterion might lead to overprotection in other scenarios, causing unnecessary anode consumption and potential hydrogen embrittlement in high-strength steels.

Remote monitoring technologies, while promising, face significant implementation barriers including power supply limitations for offshore installations, data transmission challenges in remote locations, and sensor durability issues in harsh environments. The integration of these monitoring systems with existing infrastructure often requires substantial modifications, further complicating widespread adoption.

Additionally, the correlation between laboratory-derived models and actual field performance remains problematic. Accelerated testing methods frequently fail to accurately predict long-term anode performance, particularly in dynamic environments where conditions fluctuate significantly over time.

Traditional potential measurement techniques are also highly susceptible to interference from stray currents, neighboring cathodic protection systems, and telluric currents, particularly in congested industrial environments or marine settings. These external influences can significantly distort readings, leading to misinterpretation of protection status and potentially flawed maintenance decisions.

Coupon data collection presents its own set of challenges. The physical retrieval of coupons from remote or underwater installations requires specialized equipment and personnel, substantially increasing monitoring costs. Furthermore, the time lag between coupon installation and retrieval creates significant delays in data acquisition, preventing real-time system assessment and timely intervention when protection levels become inadequate.

The interpretation of coupon data introduces additional complexity due to the inherent variability in environmental conditions. Factors such as temperature fluctuations, salinity gradients, and microbiological activity can significantly alter corrosion rates, making it difficult to extrapolate coupon results to the entire protected structure with high confidence.

Current acceptance criteria for sacrificial anode systems lack standardization across different industries and geographical regions. The commonly used -850mV criterion (vs. Cu/CuSO₄) may be insufficient in high-resistivity environments or in the presence of sulfate-reducing bacteria. Conversely, this same criterion might lead to overprotection in other scenarios, causing unnecessary anode consumption and potential hydrogen embrittlement in high-strength steels.

Remote monitoring technologies, while promising, face significant implementation barriers including power supply limitations for offshore installations, data transmission challenges in remote locations, and sensor durability issues in harsh environments. The integration of these monitoring systems with existing infrastructure often requires substantial modifications, further complicating widespread adoption.

Additionally, the correlation between laboratory-derived models and actual field performance remains problematic. Accelerated testing methods frequently fail to accurately predict long-term anode performance, particularly in dynamic environments where conditions fluctuate significantly over time.

Existing Monitoring Solutions and Survey Methodologies

01 Electrical monitoring systems for sacrificial anodes

Electrical monitoring systems are used to assess the effectiveness of sacrificial anodes by measuring electrical parameters such as potential difference, current flow, and electrical resistance. These systems typically include sensors, reference electrodes, and data acquisition units that continuously monitor the cathodic protection system's performance. The electrical measurements provide real-time information about the condition of sacrificial anodes and their ability to protect the underlying metal structures from corrosion.- Electrochemical monitoring systems for sacrificial anodes: Electrochemical monitoring systems are used to assess the effectiveness of sacrificial anodes by measuring parameters such as potential difference, current flow, and electrical resistance. These systems typically employ reference electrodes and specialized sensors to provide real-time data on the protection status of the cathodic protection system. Advanced monitoring solutions may include data logging capabilities and remote monitoring features to track anode performance over time.

- Visual inspection and physical measurement techniques: Visual inspection and physical measurement techniques involve the direct assessment of sacrificial anode condition through observation and measurement of physical parameters. This includes monitoring anode consumption rates, measuring remaining anode mass, and inspecting for signs of deterioration or passivation. These methods often require periodic inspection by maintenance personnel and may involve specialized tools to measure anode thickness or weight loss over time.

- Remote monitoring and wireless sensor networks: Remote monitoring systems and wireless sensor networks enable continuous assessment of sacrificial anode performance without requiring physical access to the protected structure. These systems typically consist of sensors that collect data on protection parameters and transmit this information wirelessly to a central monitoring station. Advanced implementations may include IoT connectivity, cloud-based data storage, and automated alert systems that notify operators when protection levels fall below critical thresholds.

- Integrated monitoring systems with automated control: Integrated monitoring systems combine sacrificial anode monitoring with automated control mechanisms to optimize cathodic protection. These systems continuously assess protection levels and can automatically adjust protection parameters or activate backup anodes when needed. Advanced implementations may include adaptive algorithms that learn from historical data to predict anode depletion and optimize replacement schedules, thereby ensuring continuous protection while minimizing maintenance costs.

- Corrosion rate measurement and analysis techniques: Corrosion rate measurement and analysis techniques focus on assessing the effectiveness of sacrificial anodes by directly measuring the corrosion rate of the protected structure. These methods may employ corrosion coupons, linear polarization resistance measurements, or electrical resistance probes to quantify the level of protection provided. Advanced systems may incorporate computational models that analyze corrosion data to predict anode lifespan and optimize replacement intervals based on environmental conditions and protection requirements.

02 Remote monitoring and data transmission technologies

Remote monitoring systems enable the assessment of sacrificial anode effectiveness without physical inspection. These systems incorporate wireless communication technologies, IoT devices, and cloud-based platforms to transmit and analyze data from cathodic protection systems. Remote monitoring allows for continuous surveillance of sacrificial anode performance, early detection of protection failures, and optimization of maintenance schedules. These technologies are particularly valuable for monitoring sacrificial anodes in hard-to-reach locations or underwater structures.Expand Specific Solutions03 Visual inspection and physical measurement techniques

Visual inspection and physical measurement techniques involve direct assessment of sacrificial anode condition through observation and measurement of physical parameters. These methods include visual examination of anode consumption, weight loss measurements, thickness measurements, and physical sampling. Special tools and equipment such as underwater cameras, calipers, and specialized probes are used to evaluate the remaining life of sacrificial anodes and determine their effectiveness in providing cathodic protection to the protected structure.Expand Specific Solutions04 Integrated monitoring systems with multiple sensors

Integrated monitoring systems combine multiple sensor types and measurement techniques to provide comprehensive assessment of sacrificial anode effectiveness. These systems typically incorporate potential measurements, current density sensors, environmental parameter monitoring (such as temperature, salinity, and pH), and structural health monitoring. By correlating data from various sensors, these integrated systems can provide more accurate evaluation of cathodic protection performance and predict anode consumption rates under varying environmental conditions.Expand Specific Solutions05 Intelligent analysis and predictive maintenance

Advanced analytical methods and algorithms are employed to process monitoring data and predict sacrificial anode performance over time. These approaches utilize machine learning, statistical analysis, and computational modeling to interpret complex data patterns and forecast anode degradation. Intelligent systems can automatically identify protection inadequacies, optimize replacement schedules, and recommend maintenance actions. These predictive capabilities enable more efficient management of cathodic protection systems and extend the service life of protected structures.Expand Specific Solutions

Leading Providers in Cathodic Protection Industry

The sacrificial anode monitoring market is in a growth phase, driven by increasing offshore infrastructure investments and stringent corrosion prevention regulations. The global market size is estimated to exceed $2 billion, with annual growth rates of 5-7%. Technologically, the field is moderately mature but evolving toward more sophisticated monitoring solutions. Key players include established energy corporations like PetroChina, CNOOC, and Shell-USA, alongside specialized corrosion control companies such as Vector Corrosion Technologies and Sun Rui Corrosion Control. Research institutions like Dalian University of Technology and Suzhou Nuclear Power Research Institute are advancing monitoring methodologies, while companies like Qingdao Gangyannake and CNOOC Energy Technology are developing integrated monitoring systems combining traditional potential surveys with advanced data analytics.

China National Offshore Oil Corp.

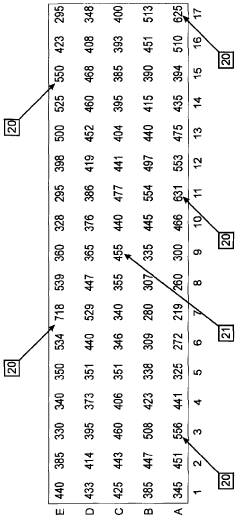

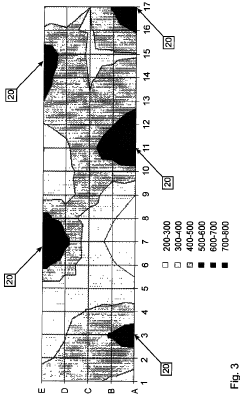

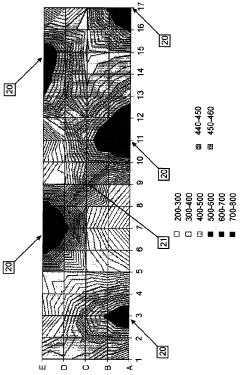

Technical Solution: China National Offshore Oil Corporation (CNOOC) has developed an integrated sacrificial anode monitoring system for offshore platforms that combines remote monitoring technology with traditional inspection methods. Their approach utilizes potential surveys conducted through permanently installed reference electrodes at critical locations on offshore structures, allowing for continuous monitoring of cathodic protection levels. The system incorporates data acquisition units that collect and transmit real-time potential readings to onshore monitoring centers, enabling immediate detection of protection failures. CNOOC has also implemented a coupon-based monitoring program where standardized metal specimens are installed at strategic locations and periodically retrieved for analysis of corrosion rates, calcareous deposit formation, and protection effectiveness. Their acceptance criteria are particularly stringent, requiring potential readings between -0.80V and -1.10V (vs Ag/AgCl reference electrode) for steel structures in seawater, with comprehensive documentation of potential distribution across the entire protected structure.

Strengths: The integrated approach combines continuous remote monitoring with physical inspection, providing comprehensive protection status data. The system enables early detection of protection failures, potentially extending infrastructure lifetime and reducing maintenance costs. Weaknesses: The system requires significant initial investment in monitoring infrastructure and expertise in data interpretation. The fixed reference electrode positions may not always represent the most critical or vulnerable areas of complex structures.

CNOOC Energy Technology & Services Ltd.

Technical Solution: CNOOC Energy Technology & Services Ltd. has developed an advanced sacrificial anode monitoring solution specifically tailored for subsea pipeline systems. Their technology integrates remotely operated vehicle (ROV) inspection capabilities with fixed monitoring stations at critical pipeline sections. The system employs specialized potential survey techniques using contact probes and proximity probes that can be deployed by ROVs to measure protection potentials at predetermined intervals along pipelines. Their proprietary data management platform correlates coupon test data with environmental parameters such as temperature, salinity, and water flow rates to create predictive models for anode consumption rates. The company has established a comprehensive acceptance framework that includes initial baseline surveys, periodic verification measurements, and long-term trend analysis. Their criteria specify that for offshore pipelines, protection potentials must maintain a minimum of -0.80V (vs Ag/AgCl) at all points, with particular attention to pipeline crossings, risers, and areas with damaged coatings. The system generates automated alerts when potentials approach threshold values, allowing for proactive maintenance planning.

Strengths: The solution is specifically optimized for subsea pipeline applications, with specialized ROV-deployable measurement tools. The correlation of environmental data with protection measurements provides more accurate prediction of anode depletion rates. Weaknesses: Heavy reliance on ROV operations increases monitoring costs and may limit frequency of inspections. The system may have limited effectiveness in extremely deep water or harsh environmental conditions.

Key Innovations in Potential Survey and Coupon Testing

Monitoring method

PatentInactiveGB2430939A

Innovation

- A method involving closely spaced potential measurements within selected areas of the concrete structure to assess the electrochemical condition of the steel, identifying anodic areas and determining the effectiveness of sacrificial anodes without controlling current output or embedding probes, using a movable reference electrode for data collection.

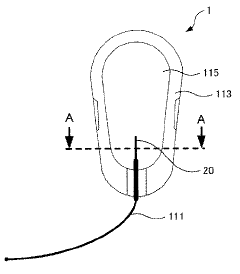

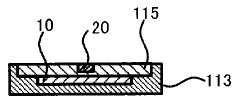

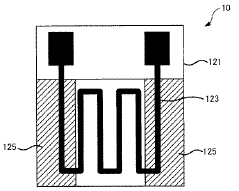

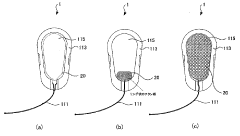

Sacrificial anode monitoring sensor and monitoring method

PatentActiveJP2021162491A

Innovation

- A sacrificial anode monitoring sensor system comprising a corrosion sensor and an anode member connected to the sensor, where the anode member is made of a less noble metal than iron, allowing for accurate monitoring of anode consumption and reinforcing steel corrosion without direct connection to the reinforcing bars.

Corrosion Standards and Acceptance Criteria

Corrosion standards and acceptance criteria for sacrificial anode systems are essential for ensuring the effectiveness of cathodic protection systems in various industries, particularly in marine and offshore environments. These standards provide quantifiable metrics and thresholds that determine whether a cathodic protection system is functioning adequately to prevent corrosion.

The primary standard for sacrificial anode systems is the protective potential criterion, which typically requires a minimum negative potential of -0.80V versus a silver/silver chloride (Ag/AgCl) reference electrode for steel structures in seawater. For structures in aerobic soils, the criterion is often -0.85V versus a copper/copper sulfate (Cu/CuSO4) reference electrode. These values represent the minimum potentials required to mitigate corrosion processes effectively.

NACE International (now AMPP - Association for Materials Protection and Performance) has established comprehensive standards such as SP0176 and SP0169, which provide detailed guidelines for cathodic protection systems. These standards specify not only the required potential values but also the methodologies for measuring and interpreting these potentials during surveys.

For sacrificial anode monitoring, acceptance criteria typically include current output measurements, which should fall within the designed range for each anode. Deviations may indicate either premature consumption or insufficient protection. The anode-to-electrolyte potential should also remain stable within specified ranges, typically between -1.05V and -1.10V for zinc anodes and between -1.05V and -1.15V for aluminum anodes in seawater.

Coupon data analysis forms another critical component of acceptance criteria. Test coupons, which are small metal specimens installed within the protected system, provide valuable information about the actual corrosion rates. The acceptance criterion typically specifies a maximum allowable corrosion rate, often expressed in mils per year (mpy) or millimeters per year (mm/y). For most offshore structures, corrosion rates below 0.001 inches (0.025 mm) per year are generally considered acceptable.

International standards such as ISO 15589-2 for offshore structures and DNV-RP-B401 for cathodic protection design provide additional acceptance criteria specific to different environments and applications. These standards often include requirements for periodic inspection intervals, documentation procedures, and remedial actions when systems fail to meet the specified criteria.

The acceptance criteria also address the physical condition of anodes, including consumption patterns, physical damage, and coating breakdown. Uniform consumption patterns are preferred, while localized severe consumption may indicate design flaws or unexpected environmental conditions that require further investigation.

The primary standard for sacrificial anode systems is the protective potential criterion, which typically requires a minimum negative potential of -0.80V versus a silver/silver chloride (Ag/AgCl) reference electrode for steel structures in seawater. For structures in aerobic soils, the criterion is often -0.85V versus a copper/copper sulfate (Cu/CuSO4) reference electrode. These values represent the minimum potentials required to mitigate corrosion processes effectively.

NACE International (now AMPP - Association for Materials Protection and Performance) has established comprehensive standards such as SP0176 and SP0169, which provide detailed guidelines for cathodic protection systems. These standards specify not only the required potential values but also the methodologies for measuring and interpreting these potentials during surveys.

For sacrificial anode monitoring, acceptance criteria typically include current output measurements, which should fall within the designed range for each anode. Deviations may indicate either premature consumption or insufficient protection. The anode-to-electrolyte potential should also remain stable within specified ranges, typically between -1.05V and -1.10V for zinc anodes and between -1.05V and -1.15V for aluminum anodes in seawater.

Coupon data analysis forms another critical component of acceptance criteria. Test coupons, which are small metal specimens installed within the protected system, provide valuable information about the actual corrosion rates. The acceptance criterion typically specifies a maximum allowable corrosion rate, often expressed in mils per year (mpy) or millimeters per year (mm/y). For most offshore structures, corrosion rates below 0.001 inches (0.025 mm) per year are generally considered acceptable.

International standards such as ISO 15589-2 for offshore structures and DNV-RP-B401 for cathodic protection design provide additional acceptance criteria specific to different environments and applications. These standards often include requirements for periodic inspection intervals, documentation procedures, and remedial actions when systems fail to meet the specified criteria.

The acceptance criteria also address the physical condition of anodes, including consumption patterns, physical damage, and coating breakdown. Uniform consumption patterns are preferred, while localized severe consumption may indicate design flaws or unexpected environmental conditions that require further investigation.

Environmental Impact of Sacrificial Anode Systems

Sacrificial anode systems, while effective for corrosion protection, introduce several environmental considerations that merit careful examination. The dissolution of metals such as zinc, aluminum, and magnesium into marine or soil environments creates potential ecological impacts that vary depending on the deployment context and scale of implementation.

The primary environmental concern relates to the gradual release of metal ions into surrounding ecosystems. In marine applications, these metals can accumulate in sediments near offshore structures, potentially affecting benthic organisms and entering the marine food chain. Studies have shown that zinc and aluminum, commonly used in sacrificial anodes, may reach concentrations exceeding natural background levels in proximity to heavily protected structures such as pipelines and offshore platforms.

Water chemistry alterations represent another significant impact, particularly in enclosed or slow-moving water bodies. The electrochemical reactions occurring during cathodic protection can locally increase pH levels and modify water chemistry parameters, potentially creating microenvironments that affect sensitive aquatic species or encourage biofouling on protected structures.

The manufacturing process of sacrificial anodes itself carries an environmental footprint. Energy consumption during production, mining impacts for raw materials, and carbon emissions contribute to the overall environmental cost of implementing these protection systems. Life cycle assessments indicate that while sacrificial anodes provide essential protection, their environmental impact must be factored into sustainability evaluations of marine and underground infrastructure projects.

Regulatory frameworks increasingly address these environmental considerations. Many jurisdictions now require environmental impact assessments before large-scale deployment of sacrificial anode systems, particularly in sensitive marine ecosystems or protected waters. Standards often specify maximum allowable metal release rates and mandate monitoring programs to track potential accumulation in surrounding environments.

Emerging research focuses on developing more environmentally compatible sacrificial anode formulations. These include anodes with reduced heavy metal content, controlled dissolution rates, and compositions designed to minimize ecological impact while maintaining effective corrosion protection. Some innovative approaches incorporate biodegradable components or utilize naturally occurring minerals that pose fewer environmental concerns when released.

Monitoring protocols for environmental impact have become increasingly sophisticated, employing sediment sampling, water quality testing, and biological indicators to assess the ecological footprint of sacrificial anode systems throughout their operational lifespan. These data inform both regulatory compliance and the ongoing refinement of more sustainable cathodic protection strategies.

The primary environmental concern relates to the gradual release of metal ions into surrounding ecosystems. In marine applications, these metals can accumulate in sediments near offshore structures, potentially affecting benthic organisms and entering the marine food chain. Studies have shown that zinc and aluminum, commonly used in sacrificial anodes, may reach concentrations exceeding natural background levels in proximity to heavily protected structures such as pipelines and offshore platforms.

Water chemistry alterations represent another significant impact, particularly in enclosed or slow-moving water bodies. The electrochemical reactions occurring during cathodic protection can locally increase pH levels and modify water chemistry parameters, potentially creating microenvironments that affect sensitive aquatic species or encourage biofouling on protected structures.

The manufacturing process of sacrificial anodes itself carries an environmental footprint. Energy consumption during production, mining impacts for raw materials, and carbon emissions contribute to the overall environmental cost of implementing these protection systems. Life cycle assessments indicate that while sacrificial anodes provide essential protection, their environmental impact must be factored into sustainability evaluations of marine and underground infrastructure projects.

Regulatory frameworks increasingly address these environmental considerations. Many jurisdictions now require environmental impact assessments before large-scale deployment of sacrificial anode systems, particularly in sensitive marine ecosystems or protected waters. Standards often specify maximum allowable metal release rates and mandate monitoring programs to track potential accumulation in surrounding environments.

Emerging research focuses on developing more environmentally compatible sacrificial anode formulations. These include anodes with reduced heavy metal content, controlled dissolution rates, and compositions designed to minimize ecological impact while maintaining effective corrosion protection. Some innovative approaches incorporate biodegradable components or utilize naturally occurring minerals that pose fewer environmental concerns when released.

Monitoring protocols for environmental impact have become increasingly sophisticated, employing sediment sampling, water quality testing, and biological indicators to assess the ecological footprint of sacrificial anode systems throughout their operational lifespan. These data inform both regulatory compliance and the ongoing refinement of more sustainable cathodic protection strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!