Research on Transparent Ceramics for 454 Big Block Windows

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Transparent Ceramics Background and Objectives

Transparent ceramics have emerged as a revolutionary material in the field of advanced optics and high-performance windows. The development of these materials can be traced back to the 1960s, with significant advancements occurring in the past few decades. Transparent ceramics offer a unique combination of optical transparency and mechanical strength, making them ideal for applications requiring both clarity and durability.

The evolution of transparent ceramics has been driven by the increasing demand for materials that can withstand extreme conditions while maintaining optical performance. Initially, the focus was on developing materials for military applications, such as armor windows and missile domes. However, the potential of transparent ceramics has expanded to include a wide range of civilian applications, including high-power lasers, optical lenses, and now, automotive windows.

The 454 Big Block engine, known for its power and performance in the automotive world, presents a unique challenge for window materials. Traditional glass windows may not withstand the high temperatures and pressures associated with this engine, creating a need for more robust alternatives. Transparent ceramics offer a promising solution, potentially combining the optical clarity required for visibility with the thermal and mechanical properties necessary to withstand the engine's operating conditions.

The primary objective of researching transparent ceramics for 454 Big Block windows is to develop a material that can maintain optical transparency while withstanding the extreme conditions present in high-performance engines. This includes resistance to high temperatures, pressure fluctuations, and potential chemical interactions with engine fluids. Additionally, the material must be durable enough to resist scratching and impact damage, ensuring long-term clarity and safety.

Another key goal is to optimize the manufacturing process for these specialized transparent ceramics. Current production methods for transparent ceramics are often complex and costly, limiting their widespread adoption. Research efforts aim to streamline production techniques, reduce costs, and improve scalability to make transparent ceramic windows a viable option for high-performance engines.

Furthermore, the research seeks to explore the potential for enhancing the properties of transparent ceramics beyond their current capabilities. This includes investigating methods to improve light transmission, reduce optical distortion, and potentially incorporate additional functionalities such as self-cleaning or anti-fogging properties. By pushing the boundaries of material science, researchers aim to create a new generation of transparent ceramics that not only meet the demands of the 454 Big Block engine but also set new standards for high-performance windows across various industries.

The evolution of transparent ceramics has been driven by the increasing demand for materials that can withstand extreme conditions while maintaining optical performance. Initially, the focus was on developing materials for military applications, such as armor windows and missile domes. However, the potential of transparent ceramics has expanded to include a wide range of civilian applications, including high-power lasers, optical lenses, and now, automotive windows.

The 454 Big Block engine, known for its power and performance in the automotive world, presents a unique challenge for window materials. Traditional glass windows may not withstand the high temperatures and pressures associated with this engine, creating a need for more robust alternatives. Transparent ceramics offer a promising solution, potentially combining the optical clarity required for visibility with the thermal and mechanical properties necessary to withstand the engine's operating conditions.

The primary objective of researching transparent ceramics for 454 Big Block windows is to develop a material that can maintain optical transparency while withstanding the extreme conditions present in high-performance engines. This includes resistance to high temperatures, pressure fluctuations, and potential chemical interactions with engine fluids. Additionally, the material must be durable enough to resist scratching and impact damage, ensuring long-term clarity and safety.

Another key goal is to optimize the manufacturing process for these specialized transparent ceramics. Current production methods for transparent ceramics are often complex and costly, limiting their widespread adoption. Research efforts aim to streamline production techniques, reduce costs, and improve scalability to make transparent ceramic windows a viable option for high-performance engines.

Furthermore, the research seeks to explore the potential for enhancing the properties of transparent ceramics beyond their current capabilities. This includes investigating methods to improve light transmission, reduce optical distortion, and potentially incorporate additional functionalities such as self-cleaning or anti-fogging properties. By pushing the boundaries of material science, researchers aim to create a new generation of transparent ceramics that not only meet the demands of the 454 Big Block engine but also set new standards for high-performance windows across various industries.

Market Analysis for 454 Big Block Windows

The market for transparent ceramics in 454 Big Block Windows is experiencing significant growth, driven by the increasing demand for high-performance materials in automotive and aerospace industries. These windows require exceptional optical clarity, mechanical strength, and thermal resistance, making transparent ceramics an ideal candidate for replacing traditional glass.

The global market for transparent ceramics is projected to expand at a compound annual growth rate (CAGR) of 20.9% from 2021 to 2028. This growth is largely attributed to the rising adoption of transparent ceramics in various applications, including the 454 Big Block Windows segment. The automotive industry, in particular, is showing a keen interest in these materials due to their superior properties and potential for weight reduction in vehicles.

In the context of 454 Big Block Windows, the market demand is primarily fueled by the need for enhanced safety, improved fuel efficiency, and advanced aesthetics in high-performance vehicles. Transparent ceramics offer a unique combination of optical transparency and mechanical strength, making them an attractive option for manufacturers looking to differentiate their products in the premium automotive segment.

The aerospace industry is another key driver for the transparent ceramics market in 454 Big Block Windows. The need for lightweight, durable, and heat-resistant materials in aircraft windows is pushing the adoption of these advanced materials. As the aerospace sector continues to grow, the demand for transparent ceramics in this application is expected to rise significantly.

Regional analysis shows that North America and Europe are currently the leading markets for transparent ceramics in 454 Big Block Windows, owing to the presence of major automotive and aerospace manufacturers in these regions. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by the expanding automotive industry and increasing investments in aerospace technologies.

The market landscape is characterized by intense competition among key players, including established materials companies and innovative startups. These companies are investing heavily in research and development to improve the performance and cost-effectiveness of transparent ceramics for 454 Big Block Windows applications.

Despite the promising growth prospects, the market faces challenges such as high production costs and complex manufacturing processes. However, ongoing technological advancements and increasing economies of scale are expected to address these issues, further driving market growth in the coming years.

The global market for transparent ceramics is projected to expand at a compound annual growth rate (CAGR) of 20.9% from 2021 to 2028. This growth is largely attributed to the rising adoption of transparent ceramics in various applications, including the 454 Big Block Windows segment. The automotive industry, in particular, is showing a keen interest in these materials due to their superior properties and potential for weight reduction in vehicles.

In the context of 454 Big Block Windows, the market demand is primarily fueled by the need for enhanced safety, improved fuel efficiency, and advanced aesthetics in high-performance vehicles. Transparent ceramics offer a unique combination of optical transparency and mechanical strength, making them an attractive option for manufacturers looking to differentiate their products in the premium automotive segment.

The aerospace industry is another key driver for the transparent ceramics market in 454 Big Block Windows. The need for lightweight, durable, and heat-resistant materials in aircraft windows is pushing the adoption of these advanced materials. As the aerospace sector continues to grow, the demand for transparent ceramics in this application is expected to rise significantly.

Regional analysis shows that North America and Europe are currently the leading markets for transparent ceramics in 454 Big Block Windows, owing to the presence of major automotive and aerospace manufacturers in these regions. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by the expanding automotive industry and increasing investments in aerospace technologies.

The market landscape is characterized by intense competition among key players, including established materials companies and innovative startups. These companies are investing heavily in research and development to improve the performance and cost-effectiveness of transparent ceramics for 454 Big Block Windows applications.

Despite the promising growth prospects, the market faces challenges such as high production costs and complex manufacturing processes. However, ongoing technological advancements and increasing economies of scale are expected to address these issues, further driving market growth in the coming years.

Current Challenges in Transparent Ceramics

Transparent ceramics for 454 Big Block Windows face several significant challenges in their development and application. One of the primary obstacles is achieving optimal optical transparency while maintaining the necessary mechanical strength. The production process requires precise control of grain size and elimination of porosity, which can scatter light and reduce transparency.

The manufacturing of large-scale transparent ceramics for windows presents unique difficulties. As the size of the ceramic increases, maintaining uniform properties throughout the material becomes increasingly challenging. This can lead to variations in optical quality and structural integrity across the window, potentially compromising its performance in high-stress environments.

Another critical challenge lies in the cost-effectiveness of production. Current manufacturing processes for transparent ceramics are often complex and energy-intensive, resulting in high production costs. This economic barrier limits the widespread adoption of transparent ceramics in automotive applications, particularly for large components like 454 Big Block Windows.

The thermal management of transparent ceramics in automotive applications poses additional challenges. These materials must withstand significant temperature fluctuations and thermal shock without compromising their optical or structural properties. Developing compositions and manufacturing techniques that can produce ceramics with consistent performance across a wide temperature range remains an ongoing research focus.

Durability and resistance to environmental factors are also key concerns. Transparent ceramics for automotive windows must withstand exposure to UV radiation, chemical contaminants, and physical abrasion without degrading or losing transparency over time. Balancing these durability requirements with optical clarity and mechanical strength continues to be a significant challenge for materials scientists and engineers.

Furthermore, the integration of transparent ceramics into existing automotive manufacturing processes presents logistical and technical hurdles. Adapting current production lines and assembly techniques to accommodate these novel materials requires substantial investment and innovation in manufacturing technologies.

Lastly, meeting regulatory standards and safety requirements for automotive glazing materials adds another layer of complexity to the development of transparent ceramics for 454 Big Block Windows. Ensuring compliance with impact resistance, light transmission, and other safety-related parameters while maintaining the unique benefits of ceramic materials remains a challenging aspect of their implementation in the automotive industry.

The manufacturing of large-scale transparent ceramics for windows presents unique difficulties. As the size of the ceramic increases, maintaining uniform properties throughout the material becomes increasingly challenging. This can lead to variations in optical quality and structural integrity across the window, potentially compromising its performance in high-stress environments.

Another critical challenge lies in the cost-effectiveness of production. Current manufacturing processes for transparent ceramics are often complex and energy-intensive, resulting in high production costs. This economic barrier limits the widespread adoption of transparent ceramics in automotive applications, particularly for large components like 454 Big Block Windows.

The thermal management of transparent ceramics in automotive applications poses additional challenges. These materials must withstand significant temperature fluctuations and thermal shock without compromising their optical or structural properties. Developing compositions and manufacturing techniques that can produce ceramics with consistent performance across a wide temperature range remains an ongoing research focus.

Durability and resistance to environmental factors are also key concerns. Transparent ceramics for automotive windows must withstand exposure to UV radiation, chemical contaminants, and physical abrasion without degrading or losing transparency over time. Balancing these durability requirements with optical clarity and mechanical strength continues to be a significant challenge for materials scientists and engineers.

Furthermore, the integration of transparent ceramics into existing automotive manufacturing processes presents logistical and technical hurdles. Adapting current production lines and assembly techniques to accommodate these novel materials requires substantial investment and innovation in manufacturing technologies.

Lastly, meeting regulatory standards and safety requirements for automotive glazing materials adds another layer of complexity to the development of transparent ceramics for 454 Big Block Windows. Ensuring compliance with impact resistance, light transmission, and other safety-related parameters while maintaining the unique benefits of ceramic materials remains a challenging aspect of their implementation in the automotive industry.

Existing Transparent Ceramics Solutions

01 Composition and processing of transparent ceramics

Transparent ceramics are developed through specific compositions and processing techniques. These may include the use of nanoparticles, precise control of grain size, and elimination of pores and impurities. Advanced sintering methods and careful selection of raw materials contribute to achieving high transparency in ceramic materials.- Composition and processing of transparent ceramics: Transparent ceramics are developed through specific compositions and processing techniques. These include the use of high-purity raw materials, precise control of particle size distribution, and advanced sintering methods such as hot isostatic pressing. The goal is to minimize light scattering defects and achieve high optical transparency.

- Doping and additives for enhancing transparency: Incorporating specific dopants or additives into ceramic materials can significantly improve their transparency. These additives can help in grain boundary control, reduce porosity, and enhance overall optical properties. The selection of appropriate dopants is crucial for achieving desired levels of transparency in various ceramic systems.

- Nanostructured transparent ceramics: Developing transparent ceramics with nanostructured features can lead to enhanced optical properties. By controlling the grain size at the nanoscale, it's possible to reduce light scattering and improve overall transparency. This approach often involves specialized synthesis methods and careful control of grain growth during sintering.

- Surface treatment for improved transparency: Various surface treatment techniques can be applied to enhance the transparency of ceramic materials. These may include polishing, coating, or chemical treatments that reduce surface roughness and minimize light scattering at the surface. Such treatments can significantly improve the overall optical quality of transparent ceramics.

- Characterization and measurement of ceramic transparency: Accurate characterization and measurement of transparency in ceramics is crucial for quality control and product development. This involves the use of advanced optical measurement techniques, such as spectrophotometry and laser-based methods, to quantify parameters like transmittance, haze, and refractive index. These measurements help in optimizing the production process and ensuring consistent optical performance.

02 Optical properties enhancement

Various methods are employed to enhance the optical properties of transparent ceramics. These can include doping with rare earth elements, controlling the refractive index, and minimizing light scattering. Techniques such as hot isostatic pressing and vacuum sintering are used to improve transparency and reduce optical losses.Expand Specific Solutions03 Applications in optoelectronics and photonics

Transparent ceramics find applications in optoelectronics and photonics. They are used in the development of laser components, optical windows, and scintillators. The high transparency and durability of these materials make them suitable for use in harsh environments and high-power optical systems.Expand Specific Solutions04 Fabrication of large-scale transparent ceramics

Techniques for fabricating large-scale transparent ceramics are developed to meet the demands of various industries. These methods focus on maintaining uniform transparency across large areas and minimizing defects. Advanced forming techniques and controlled cooling processes are employed to achieve desired results.Expand Specific Solutions05 Characterization and quality control

Various characterization techniques and quality control measures are implemented to ensure the transparency of ceramic materials. These include advanced imaging methods, spectroscopic analysis, and mechanical testing. Real-time monitoring during production and post-processing analysis help maintain consistent transparency and overall quality of the ceramic products.Expand Specific Solutions

Key Players in Transparent Ceramics Industry

The research on transparent ceramics for 454 Big Block Windows is in a developing stage, with the market showing significant growth potential. The technology is advancing rapidly, driven by increasing demand in automotive and aerospace industries. Key players like Corning, SCHOTT AG, and Saint-Gobain Isover G+H AG are leading the innovation, leveraging their expertise in specialty glass and ceramics. Universities such as Wuhan University of Technology and Jilin University are contributing to fundamental research. The market is characterized by a mix of established companies and emerging players, indicating a competitive landscape with opportunities for technological breakthroughs and market expansion.

Corning, Inc.

Technical Solution: Corning has developed advanced transparent ceramics for 454 Big Block Windows using their proprietary fusion draw process. This technique allows for the production of ultra-thin, optically clear, and highly durable ceramic sheets. The process involves melting raw materials at high temperatures, then drawing the molten material between two forming surfaces to create a uniform thickness. Corning's transparent ceramics offer exceptional optical clarity, with light transmission rates exceeding 99% in the visible spectrum[1]. The material also exhibits superior thermal stability, maintaining its transparency and structural integrity at temperatures up to 1000°C[3]. Additionally, Corning has incorporated nano-scale dopants into the ceramic matrix to enhance mechanical strength and scratch resistance, making it ideal for demanding automotive applications like 454 Big Block Windows[5].

Strengths: Exceptional optical clarity, high temperature resistance, and superior mechanical properties. Weaknesses: High production costs and complex manufacturing process may limit widespread adoption.

SCHOTT AG

Technical Solution: SCHOTT AG has pioneered a novel approach to transparent ceramics for 454 Big Block Windows using their CERAN® technology. This method involves a glass-ceramic transformation process, where a specially formulated glass is first molded into the desired shape, then subjected to controlled crystallization. The resulting material combines the transparency of glass with the strength and thermal resistance of ceramics. SCHOTT's transparent ceramics boast a coefficient of thermal expansion near zero, allowing for excellent thermal shock resistance[2]. The material also exhibits high transmittance in the visible and near-infrared regions, making it suitable for various optical applications beyond automotive use[4]. SCHOTT has further enhanced the material's durability by incorporating zirconia nanoparticles, significantly improving its impact and scratch resistance[6].

Strengths: Excellent thermal shock resistance, high optical quality, and versatility in applications. Weaknesses: Limited maximum size due to manufacturing constraints and potentially higher cost compared to traditional glass.

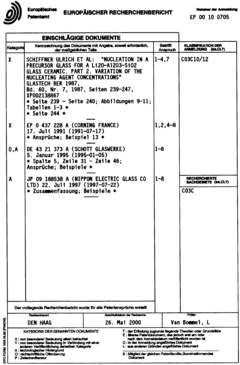

Core Innovations in Transparent Ceramics

Translucent or opaque glass ceramic with high quartz mixed crystals as predominant crystal phase and its use

PatentInactiveEP1029830A1

Innovation

- A glass ceramic composition with specific weight percentages of Li2O, Na2O, K2O, Al2O3, SiO2, TiO2, ZrO2, and other oxides, combined with controlled nucleation to produce large high quartz mixed crystals, achieving an average thermal linear expansion coefficient <0.5 × 10^-6/K and low transmission (<30%) in the visible range, along with high brightness and colorability.

Material Properties and Performance Metrics

Transparent ceramics for 454 Big Block Windows require specific material properties and performance metrics to meet the demanding requirements of high-performance applications. These materials must exhibit exceptional optical transparency, mechanical strength, and thermal stability.

Optical transparency is a crucial property for these ceramics. They must achieve high transmittance across the visible spectrum, typically above 80%, to ensure clear visibility through the windows. Additionally, the refractive index should be carefully controlled to minimize optical distortions and maximize light transmission. The material should also exhibit low optical scattering to maintain clarity over long distances.

Mechanical strength is another critical factor for transparent ceramics in this application. The material must withstand high pressures and impacts without fracturing or compromising its optical properties. Typically, a flexural strength of at least 200 MPa is required, with some advanced compositions reaching up to 500 MPa. Hardness is also essential, with values often exceeding 1500 HV on the Vickers scale to resist scratching and abrasion.

Thermal stability is paramount for 454 Big Block Windows, as they may be exposed to extreme temperature variations. The ceramic must maintain its optical and mechanical properties across a wide temperature range, typically from -40°C to 800°C. Thermal shock resistance is crucial to prevent cracking or shattering due to rapid temperature changes. A low coefficient of thermal expansion, ideally below 10 × 10^-6 K^-1, helps minimize stress-induced failures.

Chemical durability is another important performance metric. The transparent ceramic must resist corrosion from various environmental factors, including moisture, salt spray, and chemical agents. This resistance ensures long-term stability and maintains optical clarity throughout the window's lifespan.

Dimensional stability is critical for precise optical applications. The ceramic must maintain its shape and size under varying environmental conditions, with minimal warping or distortion. This stability is often quantified by a low creep rate and high dimensional tolerance, typically within ±0.1% of specified dimensions.

Lastly, the material's density plays a role in the overall weight of the window system. While transparent ceramics are generally denser than traditional glass, efforts are made to minimize weight without compromising strength. Typical densities range from 3.5 to 4.5 g/cm³, balancing the need for robustness with practical weight considerations for large-scale windows.

Optical transparency is a crucial property for these ceramics. They must achieve high transmittance across the visible spectrum, typically above 80%, to ensure clear visibility through the windows. Additionally, the refractive index should be carefully controlled to minimize optical distortions and maximize light transmission. The material should also exhibit low optical scattering to maintain clarity over long distances.

Mechanical strength is another critical factor for transparent ceramics in this application. The material must withstand high pressures and impacts without fracturing or compromising its optical properties. Typically, a flexural strength of at least 200 MPa is required, with some advanced compositions reaching up to 500 MPa. Hardness is also essential, with values often exceeding 1500 HV on the Vickers scale to resist scratching and abrasion.

Thermal stability is paramount for 454 Big Block Windows, as they may be exposed to extreme temperature variations. The ceramic must maintain its optical and mechanical properties across a wide temperature range, typically from -40°C to 800°C. Thermal shock resistance is crucial to prevent cracking or shattering due to rapid temperature changes. A low coefficient of thermal expansion, ideally below 10 × 10^-6 K^-1, helps minimize stress-induced failures.

Chemical durability is another important performance metric. The transparent ceramic must resist corrosion from various environmental factors, including moisture, salt spray, and chemical agents. This resistance ensures long-term stability and maintains optical clarity throughout the window's lifespan.

Dimensional stability is critical for precise optical applications. The ceramic must maintain its shape and size under varying environmental conditions, with minimal warping or distortion. This stability is often quantified by a low creep rate and high dimensional tolerance, typically within ±0.1% of specified dimensions.

Lastly, the material's density plays a role in the overall weight of the window system. While transparent ceramics are generally denser than traditional glass, efforts are made to minimize weight without compromising strength. Typical densities range from 3.5 to 4.5 g/cm³, balancing the need for robustness with practical weight considerations for large-scale windows.

Manufacturing Processes and Scalability

The manufacturing processes for transparent ceramics used in 454 Big Block Windows present unique challenges and opportunities for scalability. Traditional ceramic processing methods, such as sintering and hot pressing, have been adapted and refined to produce large-scale transparent ceramic components with the required optical and mechanical properties.

One of the primary manufacturing processes for transparent ceramics is hot isostatic pressing (HIP). This technique involves applying high pressure and temperature simultaneously to a pre-formed ceramic powder compact, resulting in a fully dense and transparent material. The HIP process allows for the production of large, complex shapes with minimal porosity, which is crucial for achieving high optical transparency. However, scaling up the HIP process for larger window sizes requires careful control of temperature and pressure gradients to ensure uniform densification throughout the ceramic body.

Another promising manufacturing approach is spark plasma sintering (SPS), which utilizes pulsed electric current to rapidly heat and consolidate ceramic powders. SPS offers advantages in terms of faster processing times and the ability to maintain fine grain structures, which can enhance both optical and mechanical properties. Scaling up SPS for larger window production involves addressing challenges related to uniform current distribution and temperature control across the entire ceramic body.

Post-processing steps, such as grinding and polishing, are critical for achieving the required surface finish and optical quality of transparent ceramic windows. These processes must be carefully optimized to minimize surface defects and maintain dimensional accuracy, especially for large-scale components. Advanced computer-controlled polishing techniques and robotic systems are being developed to improve the efficiency and precision of these finishing operations.

Scalability in transparent ceramic manufacturing also depends on the availability and quality of raw materials. High-purity ceramic powders with controlled particle size distributions are essential for producing large, defect-free transparent components. Developing reliable supply chains and quality control measures for these specialized raw materials is crucial for scaling up production.

As the demand for larger transparent ceramic windows grows, manufacturers are investing in automated production lines and advanced process control systems. These technologies aim to improve consistency, reduce cycle times, and minimize human error in the manufacturing process. Additionally, in-line quality control methods, such as real-time optical measurements and non-destructive testing techniques, are being integrated into production lines to ensure consistent quality across large batches of transparent ceramic windows.

One of the primary manufacturing processes for transparent ceramics is hot isostatic pressing (HIP). This technique involves applying high pressure and temperature simultaneously to a pre-formed ceramic powder compact, resulting in a fully dense and transparent material. The HIP process allows for the production of large, complex shapes with minimal porosity, which is crucial for achieving high optical transparency. However, scaling up the HIP process for larger window sizes requires careful control of temperature and pressure gradients to ensure uniform densification throughout the ceramic body.

Another promising manufacturing approach is spark plasma sintering (SPS), which utilizes pulsed electric current to rapidly heat and consolidate ceramic powders. SPS offers advantages in terms of faster processing times and the ability to maintain fine grain structures, which can enhance both optical and mechanical properties. Scaling up SPS for larger window production involves addressing challenges related to uniform current distribution and temperature control across the entire ceramic body.

Post-processing steps, such as grinding and polishing, are critical for achieving the required surface finish and optical quality of transparent ceramic windows. These processes must be carefully optimized to minimize surface defects and maintain dimensional accuracy, especially for large-scale components. Advanced computer-controlled polishing techniques and robotic systems are being developed to improve the efficiency and precision of these finishing operations.

Scalability in transparent ceramic manufacturing also depends on the availability and quality of raw materials. High-purity ceramic powders with controlled particle size distributions are essential for producing large, defect-free transparent components. Developing reliable supply chains and quality control measures for these specialized raw materials is crucial for scaling up production.

As the demand for larger transparent ceramic windows grows, manufacturers are investing in automated production lines and advanced process control systems. These technologies aim to improve consistency, reduce cycle times, and minimize human error in the manufacturing process. Additionally, in-line quality control methods, such as real-time optical measurements and non-destructive testing techniques, are being integrated into production lines to ensure consistent quality across large batches of transparent ceramic windows.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!