Role of 4140 Steel in Seismic-Resistant Construction Design

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

4140 Steel in Seismic Design: Background and Objectives

The role of 4140 steel in seismic-resistant construction design has gained significant attention in recent years due to its exceptional mechanical properties and potential to enhance structural resilience. This high-strength, low-alloy steel has a long history of use in various industrial applications, but its application in seismic design represents a relatively new frontier in civil engineering.

The development of seismic-resistant structures has been an ongoing challenge for engineers and architects, particularly in regions prone to earthquakes. Traditional construction materials often fall short in providing the necessary strength, ductility, and energy absorption capabilities required to withstand seismic forces. This has led to a continuous search for innovative materials and design approaches to improve building performance during seismic events.

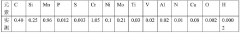

4140 steel, with its unique composition of chromium, molybdenum, and manganese, offers a compelling solution to many of the challenges faced in seismic design. Its high yield strength, combined with good ductility and toughness, makes it an ideal candidate for critical structural components in earthquake-resistant buildings. The material's ability to withstand cyclic loading and its resistance to fatigue are particularly valuable in seismic applications.

The primary objective of incorporating 4140 steel in seismic design is to enhance the overall structural performance and safety of buildings during earthquakes. This includes improving the energy dissipation capacity of structural elements, reducing the likelihood of brittle failures, and maintaining structural integrity under extreme loading conditions. Additionally, the use of high-strength steel like 4140 can potentially lead to more efficient designs with reduced material usage and lighter structures.

As the construction industry moves towards more sustainable and resilient building practices, the exploration of advanced materials like 4140 steel becomes increasingly important. The integration of this material into seismic design practices aligns with the broader goals of creating safer urban environments and reducing the economic and social impacts of earthquakes.

The technical evolution of 4140 steel in construction has been marked by advancements in metallurgy, fabrication techniques, and structural engineering principles. Researchers and engineers have been working to optimize the material's properties for specific seismic applications, develop appropriate design methodologies, and establish relevant building codes and standards.

Understanding the role of 4140 steel in seismic-resistant construction design requires a multidisciplinary approach, combining knowledge from materials science, structural engineering, and seismology. This comprehensive perspective is essential for fully leveraging the potential of 4140 steel and addressing the complex challenges associated with earthquake-resistant building design.

The development of seismic-resistant structures has been an ongoing challenge for engineers and architects, particularly in regions prone to earthquakes. Traditional construction materials often fall short in providing the necessary strength, ductility, and energy absorption capabilities required to withstand seismic forces. This has led to a continuous search for innovative materials and design approaches to improve building performance during seismic events.

4140 steel, with its unique composition of chromium, molybdenum, and manganese, offers a compelling solution to many of the challenges faced in seismic design. Its high yield strength, combined with good ductility and toughness, makes it an ideal candidate for critical structural components in earthquake-resistant buildings. The material's ability to withstand cyclic loading and its resistance to fatigue are particularly valuable in seismic applications.

The primary objective of incorporating 4140 steel in seismic design is to enhance the overall structural performance and safety of buildings during earthquakes. This includes improving the energy dissipation capacity of structural elements, reducing the likelihood of brittle failures, and maintaining structural integrity under extreme loading conditions. Additionally, the use of high-strength steel like 4140 can potentially lead to more efficient designs with reduced material usage and lighter structures.

As the construction industry moves towards more sustainable and resilient building practices, the exploration of advanced materials like 4140 steel becomes increasingly important. The integration of this material into seismic design practices aligns with the broader goals of creating safer urban environments and reducing the economic and social impacts of earthquakes.

The technical evolution of 4140 steel in construction has been marked by advancements in metallurgy, fabrication techniques, and structural engineering principles. Researchers and engineers have been working to optimize the material's properties for specific seismic applications, develop appropriate design methodologies, and establish relevant building codes and standards.

Understanding the role of 4140 steel in seismic-resistant construction design requires a multidisciplinary approach, combining knowledge from materials science, structural engineering, and seismology. This comprehensive perspective is essential for fully leveraging the potential of 4140 steel and addressing the complex challenges associated with earthquake-resistant building design.

Market Demand Analysis for Seismic-Resistant Steel

The market demand for seismic-resistant steel, particularly 4140 steel, has been steadily increasing in recent years due to growing awareness of earthquake risks and stricter building codes in seismically active regions. This trend is driven by urbanization in earthquake-prone areas and the need to retrofit existing structures to meet modern safety standards.

In developed countries, the demand for seismic-resistant steel is primarily fueled by infrastructure renewal projects and the construction of high-rise buildings in major urban centers. The United States, Japan, and New Zealand are leading markets, with stringent seismic design requirements driving the adoption of advanced steel grades like 4140.

Emerging economies, especially those in seismically active regions such as China, India, and Southeast Asian countries, are experiencing rapid growth in demand for seismic-resistant steel. This is attributed to massive infrastructure development projects and the expansion of urban areas, coupled with increasing awareness of earthquake risks.

The global market for seismic-resistant construction materials, including specialized steels, is projected to grow significantly over the next decade. This growth is supported by government initiatives to improve building resilience and reduce potential economic losses from seismic events.

4140 steel, known for its high strength and toughness, is gaining traction in seismic-resistant design due to its superior performance under dynamic loading conditions. Its ability to absorb energy and maintain structural integrity during seismic events makes it particularly valuable for critical components in building frameworks and infrastructure projects.

The automotive and aerospace industries are also contributing to the demand for 4140 steel, as they seek materials that can withstand extreme stress and vibration. This cross-industry demand is driving innovation in steel production and processing techniques, further enhancing the material's properties for seismic applications.

Despite the growing demand, challenges remain in the widespread adoption of 4140 steel for seismic-resistant construction. These include higher initial costs compared to conventional steel grades and the need for specialized fabrication techniques. However, the long-term benefits in terms of improved safety and reduced maintenance costs are expected to outweigh these challenges, driving continued market growth.

In developed countries, the demand for seismic-resistant steel is primarily fueled by infrastructure renewal projects and the construction of high-rise buildings in major urban centers. The United States, Japan, and New Zealand are leading markets, with stringent seismic design requirements driving the adoption of advanced steel grades like 4140.

Emerging economies, especially those in seismically active regions such as China, India, and Southeast Asian countries, are experiencing rapid growth in demand for seismic-resistant steel. This is attributed to massive infrastructure development projects and the expansion of urban areas, coupled with increasing awareness of earthquake risks.

The global market for seismic-resistant construction materials, including specialized steels, is projected to grow significantly over the next decade. This growth is supported by government initiatives to improve building resilience and reduce potential economic losses from seismic events.

4140 steel, known for its high strength and toughness, is gaining traction in seismic-resistant design due to its superior performance under dynamic loading conditions. Its ability to absorb energy and maintain structural integrity during seismic events makes it particularly valuable for critical components in building frameworks and infrastructure projects.

The automotive and aerospace industries are also contributing to the demand for 4140 steel, as they seek materials that can withstand extreme stress and vibration. This cross-industry demand is driving innovation in steel production and processing techniques, further enhancing the material's properties for seismic applications.

Despite the growing demand, challenges remain in the widespread adoption of 4140 steel for seismic-resistant construction. These include higher initial costs compared to conventional steel grades and the need for specialized fabrication techniques. However, the long-term benefits in terms of improved safety and reduced maintenance costs are expected to outweigh these challenges, driving continued market growth.

Current Challenges in Seismic-Resistant Steel Applications

The application of 4140 steel in seismic-resistant construction design faces several significant challenges. One of the primary issues is the material's susceptibility to brittle fracture under high-stress conditions, which is particularly concerning in seismic events. While 4140 steel offers excellent strength and hardness, its relatively low ductility can lead to sudden failures during extreme loading scenarios typical of earthquakes.

Another challenge lies in the welding process of 4140 steel. The high carbon and alloy content that gives this steel its desirable properties also makes it prone to weld cracking and heat-affected zone (HAZ) embrittlement. This necessitates careful control of preheating, interpass temperatures, and post-weld heat treatment, which can significantly increase construction costs and complexity.

Corrosion resistance is another area of concern, especially in coastal regions or areas with high humidity. 4140 steel, without proper surface treatment or coating, can be vulnerable to environmental degradation, potentially compromising the long-term integrity of seismic-resistant structures.

The high strength of 4140 steel, while advantageous in many applications, can lead to challenges in energy dissipation during seismic events. Structures need to absorb and dissipate seismic energy effectively, and the limited plastic deformation capacity of high-strength steels like 4140 can result in less favorable energy absorption characteristics compared to more ductile steels.

Cost considerations also present a significant challenge. The alloying elements in 4140 steel make it more expensive than conventional structural steels, potentially limiting its widespread adoption in seismic-resistant construction. This cost factor becomes particularly significant in large-scale projects or in regions where seismic design is mandatory but budget constraints are tight.

Fabrication difficulties pose another hurdle. The high strength of 4140 steel can lead to increased tool wear and longer machining times, affecting production efficiency and costs. Additionally, the material's sensitivity to heat treatment requires precise control during manufacturing processes to achieve the desired mechanical properties consistently.

Lastly, there is a challenge in terms of industry familiarity and code compliance. Many structural engineers and contractors are more accustomed to working with traditional structural steels. The unique properties of 4140 steel may require additional training and experience to handle effectively in seismic design applications. Moreover, existing building codes and standards may not fully address the use of high-strength alloy steels like 4140 in seismic-resistant structures, necessitating careful interpretation and possibly additional testing and validation.

Another challenge lies in the welding process of 4140 steel. The high carbon and alloy content that gives this steel its desirable properties also makes it prone to weld cracking and heat-affected zone (HAZ) embrittlement. This necessitates careful control of preheating, interpass temperatures, and post-weld heat treatment, which can significantly increase construction costs and complexity.

Corrosion resistance is another area of concern, especially in coastal regions or areas with high humidity. 4140 steel, without proper surface treatment or coating, can be vulnerable to environmental degradation, potentially compromising the long-term integrity of seismic-resistant structures.

The high strength of 4140 steel, while advantageous in many applications, can lead to challenges in energy dissipation during seismic events. Structures need to absorb and dissipate seismic energy effectively, and the limited plastic deformation capacity of high-strength steels like 4140 can result in less favorable energy absorption characteristics compared to more ductile steels.

Cost considerations also present a significant challenge. The alloying elements in 4140 steel make it more expensive than conventional structural steels, potentially limiting its widespread adoption in seismic-resistant construction. This cost factor becomes particularly significant in large-scale projects or in regions where seismic design is mandatory but budget constraints are tight.

Fabrication difficulties pose another hurdle. The high strength of 4140 steel can lead to increased tool wear and longer machining times, affecting production efficiency and costs. Additionally, the material's sensitivity to heat treatment requires precise control during manufacturing processes to achieve the desired mechanical properties consistently.

Lastly, there is a challenge in terms of industry familiarity and code compliance. Many structural engineers and contractors are more accustomed to working with traditional structural steels. The unique properties of 4140 steel may require additional training and experience to handle effectively in seismic design applications. Moreover, existing building codes and standards may not fully address the use of high-strength alloy steels like 4140 in seismic-resistant structures, necessitating careful interpretation and possibly additional testing and validation.

Existing 4140 Steel Solutions for Seismic Design

01 Composition and properties of 4140 steel

4140 steel is a medium carbon, low alloy steel known for its high strength and toughness. It typically contains chromium and molybdenum as alloying elements, which contribute to its improved hardenability and wear resistance. This steel grade is widely used in various applications due to its balanced combination of strength, ductility, and machinability.- Composition and properties of 4140 steel: 4140 steel is a medium carbon, low alloy steel known for its high strength, toughness, and wear resistance. It typically contains chromium and molybdenum as key alloying elements, which contribute to its improved hardenability and mechanical properties. This steel grade is widely used in various applications requiring high strength and durability.

- Heat treatment processes for 4140 steel: Various heat treatment processes can be applied to 4140 steel to enhance its mechanical properties. These may include quenching and tempering, normalizing, and annealing. The specific heat treatment process chosen depends on the desired final properties and intended application of the steel.

- Applications of 4140 steel in machinery and tools: 4140 steel is commonly used in the manufacturing of machinery components, tools, and equipment parts due to its excellent combination of strength and toughness. It is particularly suitable for applications involving high stress and wear, such as gears, shafts, and hydraulic components.

- Welding and fabrication techniques for 4140 steel: Specific welding and fabrication techniques are often employed when working with 4140 steel to maintain its desirable properties. These may include preheating, controlled cooling, and post-weld heat treatment to minimize the risk of cracking and ensure optimal performance of the welded components.

- Surface treatment and coating methods for 4140 steel: Various surface treatment and coating methods can be applied to 4140 steel to further enhance its properties or provide additional functionality. These may include nitriding, carburizing, or the application of protective coatings to improve wear resistance, corrosion resistance, or other specific surface characteristics.

02 Heat treatment processes for 4140 steel

Various heat treatment processes can be applied to 4140 steel to enhance its mechanical properties. These may include quenching and tempering, normalizing, or annealing. The specific heat treatment process chosen depends on the desired final properties and application requirements. Proper heat treatment can significantly improve the steel's strength, hardness, and toughness.Expand Specific Solutions03 Applications of 4140 steel in machinery and equipment

4140 steel is commonly used in the manufacturing of machinery components and equipment parts due to its excellent mechanical properties. It is often employed in the production of gears, shafts, axles, and other high-stress components in various industries, including automotive, aerospace, and oil and gas. The steel's ability to withstand high loads and resist wear makes it suitable for these applications.Expand Specific Solutions04 Welding and fabrication techniques for 4140 steel

Welding and fabrication of 4140 steel require specific techniques to ensure optimal results. Preheating and post-weld heat treatment are often necessary to prevent cracking and maintain desired properties. Various welding methods, such as shielded metal arc welding (SMAW) and gas tungsten arc welding (GTAW), can be used with appropriate filler materials and procedures to achieve strong, durable welds in 4140 steel components.Expand Specific Solutions05 Surface treatment and coating of 4140 steel

Surface treatments and coatings can be applied to 4140 steel to enhance its performance in specific applications. These treatments may include nitriding, carburizing, or the application of wear-resistant coatings. Such processes can improve the steel's surface hardness, wear resistance, and corrosion resistance, extending the service life of components made from 4140 steel in demanding environments.Expand Specific Solutions

Key Players in Seismic-Resistant Steel Industry

The competitive landscape for 4140 steel in seismic-resistant construction design is in a growth phase, with increasing market size due to rising demand for earthquake-resistant structures. The technology is relatively mature but still evolving, with ongoing research to enhance performance. Key players like POSCO Holdings, Baoshan Iron & Steel, and JSW Steel are leading in production capabilities. Universities such as the University of Science & Technology Beijing and South China University of Technology are contributing to technological advancements. Companies like JFE Steel, Hyundai Steel, and HBIS are also significant competitors, focusing on developing high-strength steels for seismic applications.

POSCO Holdings, Inc.

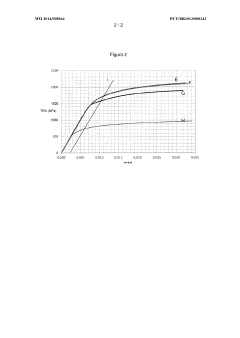

Technical Solution: POSCO has developed a proprietary 4140 steel grade optimized for seismic-resistant construction, marketed under their INNOVILT® brand. Their steel features a carefully controlled microstructure with a combination of bainite and tempered martensite, resulting in a yield strength of 1100 MPa and an elongation of 14%[7]. POSCO's 4140 steel incorporates rare earth elements to improve grain boundary cohesion, enhancing its resistance to brittle fracture during seismic events[8]. The company has also developed an advanced surface treatment process that improves the steel's corrosion resistance, addressing long-term durability concerns in seismic-prone coastal areas[9].

Strengths: High strength-to-ductility ratio, improved fracture resistance, and enhanced corrosion protection. Weaknesses: Higher production costs due to the use of rare earth elements, and potential challenges in large-scale production.

Baoshan Iron & Steel Co., Ltd.

Technical Solution: Baoshan Iron & Steel Co., Ltd. has focused on developing 4140 steel variants tailored for seismic-resistant construction in high-rise buildings. Their approach involves a multi-stage heat treatment process that creates a complex microstructure of fine-grained bainite and retained austenite, achieving a yield strength of 950 MPa with 16% elongation[10]. The company has also implemented advanced vacuum degassing techniques to reduce impurities and improve the steel's toughness, resulting in a 25% increase in Charpy V-notch impact energy compared to standard 4140 steel[11]. Baoshan's 4140 steel has been successfully used in several skyscrapers in seismically active regions of China, demonstrating improved damping characteristics and reduced structural weight[12].

Strengths: Excellent balance of strength and ductility, improved impact resistance, and proven performance in high-rise applications. Weaknesses: Relatively new to the international market, and potential challenges in meeting diverse global building codes.

Core Innovations in 4140 Steel for Seismic Resistance

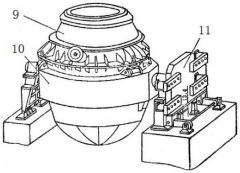

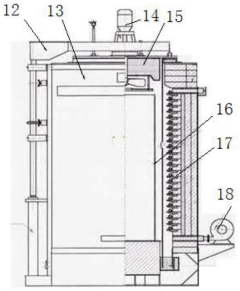

Special steels; cryogenic process for the production thereof; use of special steels in a saline and/or high-pressure environment

PatentWO2014008564A1

Innovation

- A specific cryogenic treatment process involving tempering, cooling, immersion in cryogenic material, and subsequent tempering is applied to carbon steels, reducing retained austenite content and precipitating carbides, transforming martensite morphology and improving mechanical properties.

4140 medium-thick-wall seamless steel pipe and production method

PatentActiveCN113862556A

Innovation

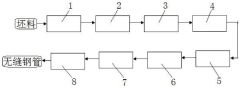

- Using the optimized 4140 composition and the new Diesel hot rolling unit rolling combined with water quenching instead of oil quenching, medium-thick wall seamless products are produced through converter smelting, continuous casting, annealing, heating, rolling, water quenching, tempering and straightening processes. steel pipe.

Environmental Impact of 4140 Steel in Construction

The environmental impact of 4140 steel in construction is a critical consideration for sustainable building practices. This high-strength alloy steel, known for its durability and resistance to wear, offers significant advantages in seismic-resistant construction design. However, its production and use also present environmental challenges that must be carefully evaluated.

The manufacturing process of 4140 steel involves energy-intensive operations, contributing to greenhouse gas emissions. The primary production method, typically using blast furnaces and basic oxygen furnaces, releases substantial amounts of carbon dioxide. Additionally, the alloying elements required for 4140 steel, such as chromium and molybdenum, necessitate mining operations that can lead to habitat disruption and soil contamination.

Despite these concerns, the longevity and strength of 4140 steel in construction applications can offset some of its environmental impacts. Its superior durability means structures built with this material may require less frequent replacement or repair, potentially reducing long-term resource consumption and waste generation. Furthermore, the steel's high strength-to-weight ratio allows for more efficient designs, potentially reducing the overall material requirements for a given project.

Recycling presents a significant opportunity to mitigate the environmental impact of 4140 steel. Steel is highly recyclable, and the use of recycled steel in production can substantially reduce energy consumption and emissions compared to primary production. However, the specific alloying elements in 4140 steel may complicate the recycling process, requiring more sophisticated sorting and processing techniques.

In the context of seismic-resistant construction, the use of 4140 steel can contribute to building resilience and safety. This indirectly impacts the environment by potentially reducing the need for reconstruction and repair after seismic events, thus conserving resources and minimizing waste generation in the long term.

Water consumption and pollution are additional environmental concerns associated with 4140 steel production. The cooling processes in steel manufacturing require significant water resources, and without proper treatment, effluents can contaminate local water bodies. However, advancements in water recycling and treatment technologies in modern steel plants are helping to address these issues.

As the construction industry moves towards more sustainable practices, the role of 4140 steel is evolving. Innovations in production techniques, such as electric arc furnaces and hydrogen-based reduction, offer promising avenues for reducing the environmental footprint of steel manufacturing. Additionally, ongoing research into bio-based alternatives and composite materials may provide future options for reducing reliance on traditional steel alloys in certain applications.

The manufacturing process of 4140 steel involves energy-intensive operations, contributing to greenhouse gas emissions. The primary production method, typically using blast furnaces and basic oxygen furnaces, releases substantial amounts of carbon dioxide. Additionally, the alloying elements required for 4140 steel, such as chromium and molybdenum, necessitate mining operations that can lead to habitat disruption and soil contamination.

Despite these concerns, the longevity and strength of 4140 steel in construction applications can offset some of its environmental impacts. Its superior durability means structures built with this material may require less frequent replacement or repair, potentially reducing long-term resource consumption and waste generation. Furthermore, the steel's high strength-to-weight ratio allows for more efficient designs, potentially reducing the overall material requirements for a given project.

Recycling presents a significant opportunity to mitigate the environmental impact of 4140 steel. Steel is highly recyclable, and the use of recycled steel in production can substantially reduce energy consumption and emissions compared to primary production. However, the specific alloying elements in 4140 steel may complicate the recycling process, requiring more sophisticated sorting and processing techniques.

In the context of seismic-resistant construction, the use of 4140 steel can contribute to building resilience and safety. This indirectly impacts the environment by potentially reducing the need for reconstruction and repair after seismic events, thus conserving resources and minimizing waste generation in the long term.

Water consumption and pollution are additional environmental concerns associated with 4140 steel production. The cooling processes in steel manufacturing require significant water resources, and without proper treatment, effluents can contaminate local water bodies. However, advancements in water recycling and treatment technologies in modern steel plants are helping to address these issues.

As the construction industry moves towards more sustainable practices, the role of 4140 steel is evolving. Innovations in production techniques, such as electric arc furnaces and hydrogen-based reduction, offer promising avenues for reducing the environmental footprint of steel manufacturing. Additionally, ongoing research into bio-based alternatives and composite materials may provide future options for reducing reliance on traditional steel alloys in certain applications.

Cost-Benefit Analysis of 4140 Steel in Seismic Design

The cost-benefit analysis of 4140 steel in seismic design is a critical consideration for construction projects in earthquake-prone regions. This high-strength alloy steel offers several advantages that can significantly impact the overall structural performance and economic viability of seismic-resistant buildings.

One of the primary benefits of using 4140 steel in seismic design is its exceptional strength-to-weight ratio. This property allows for the creation of lighter structural elements without compromising on load-bearing capacity. As a result, buildings can achieve the required seismic resistance with less material, potentially reducing overall construction costs and foundation requirements.

The superior ductility of 4140 steel is another crucial factor in its favor for seismic applications. During an earthquake, structures must be able to absorb and dissipate energy without catastrophic failure. The high ductility of 4140 steel enables greater plastic deformation before fracture, enhancing the building's ability to withstand seismic forces and potentially reducing repair costs after a seismic event.

However, the initial cost of 4140 steel is generally higher than that of more commonly used structural steels. This increased material cost must be weighed against the potential long-term benefits and savings. The higher strength of 4140 steel may allow for smaller cross-sections in structural members, which could offset some of the additional material costs through reduced overall steel tonnage in the structure.

Maintenance costs should also be considered in the cost-benefit analysis. 4140 steel's resistance to fatigue and wear can lead to reduced maintenance requirements over the life of the structure. This can result in significant long-term cost savings, particularly in high-rise buildings or structures subject to frequent seismic activity.

The use of 4140 steel may also impact construction timelines. Its higher strength can potentially lead to faster erection times due to the need for fewer or smaller structural elements. This can translate to reduced labor costs and earlier project completion, which can be particularly valuable in urban construction projects where time is a critical factor.

In terms of lifecycle costs, the enhanced durability and performance of 4140 steel in seismic events may result in lower insurance premiums for the building. Additionally, the potential for reduced damage during earthquakes can lead to savings in repair and retrofit costs over the structure's lifetime.

When considering the cost-benefit analysis, it's also important to factor in the potential for increased usable floor space. The ability to design more slender columns and beams with 4140 steel can result in a larger rentable or saleable area, potentially increasing the return on investment for building owners.

One of the primary benefits of using 4140 steel in seismic design is its exceptional strength-to-weight ratio. This property allows for the creation of lighter structural elements without compromising on load-bearing capacity. As a result, buildings can achieve the required seismic resistance with less material, potentially reducing overall construction costs and foundation requirements.

The superior ductility of 4140 steel is another crucial factor in its favor for seismic applications. During an earthquake, structures must be able to absorb and dissipate energy without catastrophic failure. The high ductility of 4140 steel enables greater plastic deformation before fracture, enhancing the building's ability to withstand seismic forces and potentially reducing repair costs after a seismic event.

However, the initial cost of 4140 steel is generally higher than that of more commonly used structural steels. This increased material cost must be weighed against the potential long-term benefits and savings. The higher strength of 4140 steel may allow for smaller cross-sections in structural members, which could offset some of the additional material costs through reduced overall steel tonnage in the structure.

Maintenance costs should also be considered in the cost-benefit analysis. 4140 steel's resistance to fatigue and wear can lead to reduced maintenance requirements over the life of the structure. This can result in significant long-term cost savings, particularly in high-rise buildings or structures subject to frequent seismic activity.

The use of 4140 steel may also impact construction timelines. Its higher strength can potentially lead to faster erection times due to the need for fewer or smaller structural elements. This can translate to reduced labor costs and earlier project completion, which can be particularly valuable in urban construction projects where time is a critical factor.

In terms of lifecycle costs, the enhanced durability and performance of 4140 steel in seismic events may result in lower insurance premiums for the building. Additionally, the potential for reduced damage during earthquakes can lead to savings in repair and retrofit costs over the structure's lifetime.

When considering the cost-benefit analysis, it's also important to factor in the potential for increased usable floor space. The ability to design more slender columns and beams with 4140 steel can result in a larger rentable or saleable area, potentially increasing the return on investment for building owners.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!