Role of Polyglutamic Acid in Developing Rheological Agents for Construction

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PGA in Construction Rheology: Background and Objectives

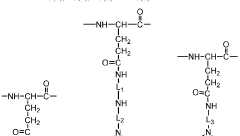

Polyglutamic acid (PGA) has emerged as a promising candidate in the development of rheological agents for the construction industry. This biopolymer, derived from microbial fermentation, has garnered significant attention due to its unique properties and potential to address various challenges in construction materials.

The construction industry has long sought innovative solutions to enhance the performance and sustainability of building materials. Traditional rheological agents, often derived from petrochemical sources, have limitations in terms of environmental impact and long-term durability. As the industry moves towards more sustainable practices, there is a growing need for bio-based alternatives that can provide superior rheological properties while minimizing ecological footprints.

PGA's journey in construction applications can be traced back to the early 2000s when researchers began exploring its potential as a viscosity modifier in cement-based materials. Initial studies focused on its ability to improve the workability and stability of concrete mixtures. Over the years, the scope of PGA research in construction has expanded to include its use in grouts, mortars, and other cementitious systems.

The primary objective of incorporating PGA into construction materials is to enhance their rheological properties, which directly impact the ease of application, stability, and overall performance of the final product. Specifically, PGA aims to improve the viscosity, yield stress, and thixotropic behavior of construction mixtures. These enhancements can lead to better pumpability, reduced segregation, and improved shape retention in various applications.

Another critical goal in the development of PGA-based rheological agents is to address sustainability concerns. By utilizing a biodegradable and renewable resource, the construction industry can reduce its reliance on petroleum-based additives, aligning with global efforts to minimize carbon footprints and promote circular economy principles.

The evolution of PGA technology in construction has been marked by several key milestones. Early research focused on understanding the fundamental interactions between PGA and cementitious materials. This was followed by optimization studies to determine effective dosage ranges and compatibility with other construction additives. Recent advancements have explored the synergistic effects of combining PGA with other biopolymers or nanomaterials to create hybrid rheological systems with enhanced performance characteristics.

As research in this field progresses, the objectives have expanded to include the development of PGA-based admixtures that not only improve rheological properties but also contribute to the mechanical strength and durability of construction materials. This multifunctional approach aims to create a new generation of high-performance, sustainable construction additives that can meet the evolving demands of the industry.

The construction industry has long sought innovative solutions to enhance the performance and sustainability of building materials. Traditional rheological agents, often derived from petrochemical sources, have limitations in terms of environmental impact and long-term durability. As the industry moves towards more sustainable practices, there is a growing need for bio-based alternatives that can provide superior rheological properties while minimizing ecological footprints.

PGA's journey in construction applications can be traced back to the early 2000s when researchers began exploring its potential as a viscosity modifier in cement-based materials. Initial studies focused on its ability to improve the workability and stability of concrete mixtures. Over the years, the scope of PGA research in construction has expanded to include its use in grouts, mortars, and other cementitious systems.

The primary objective of incorporating PGA into construction materials is to enhance their rheological properties, which directly impact the ease of application, stability, and overall performance of the final product. Specifically, PGA aims to improve the viscosity, yield stress, and thixotropic behavior of construction mixtures. These enhancements can lead to better pumpability, reduced segregation, and improved shape retention in various applications.

Another critical goal in the development of PGA-based rheological agents is to address sustainability concerns. By utilizing a biodegradable and renewable resource, the construction industry can reduce its reliance on petroleum-based additives, aligning with global efforts to minimize carbon footprints and promote circular economy principles.

The evolution of PGA technology in construction has been marked by several key milestones. Early research focused on understanding the fundamental interactions between PGA and cementitious materials. This was followed by optimization studies to determine effective dosage ranges and compatibility with other construction additives. Recent advancements have explored the synergistic effects of combining PGA with other biopolymers or nanomaterials to create hybrid rheological systems with enhanced performance characteristics.

As research in this field progresses, the objectives have expanded to include the development of PGA-based admixtures that not only improve rheological properties but also contribute to the mechanical strength and durability of construction materials. This multifunctional approach aims to create a new generation of high-performance, sustainable construction additives that can meet the evolving demands of the industry.

Market Analysis for PGA-based Rheological Agents

The market for PGA-based rheological agents in the construction industry is experiencing significant growth, driven by the increasing demand for high-performance and sustainable construction materials. Polyglutamic acid (PGA), a biodegradable and environmentally friendly polymer, has emerged as a promising candidate for developing advanced rheological agents that can enhance the properties of concrete and other construction materials.

The global construction chemicals market, which includes rheological agents, is projected to reach $50 billion by 2025, with a compound annual growth rate (CAGR) of 6.2%. Within this market, the demand for eco-friendly and bio-based additives is growing rapidly, presenting a substantial opportunity for PGA-based products. The Asia-Pacific region, particularly China and India, is expected to be the fastest-growing market due to rapid urbanization and infrastructure development.

Key drivers for the adoption of PGA-based rheological agents include stringent environmental regulations, increasing focus on sustainable construction practices, and the need for improved durability and performance of construction materials. The construction industry is actively seeking alternatives to traditional petroleum-based additives, creating a favorable market environment for PGA-based solutions.

The market for PGA-based rheological agents can be segmented into various applications, including ready-mix concrete, precast concrete, mortars, and grouts. Among these, ready-mix concrete represents the largest market segment, accounting for over 40% of the total market share. The precast concrete segment is expected to witness the highest growth rate due to the increasing adoption of prefabricated construction methods.

Major players in the construction chemicals industry, such as BASF, Sika, and Mapei, are investing in research and development of bio-based additives, including PGA-based products. This trend indicates a growing recognition of the potential of PGA in the construction sector and is likely to drive further market expansion.

However, challenges such as higher production costs compared to traditional additives and limited awareness among end-users about the benefits of PGA-based products may hinder market growth. Overcoming these barriers through technological advancements and educational initiatives will be crucial for widespread adoption.

In conclusion, the market for PGA-based rheological agents in construction shows promising growth potential, driven by sustainability trends and performance requirements. As research and development efforts intensify and production costs decrease, PGA-based products are expected to gain a significant market share in the coming years, revolutionizing the construction chemicals industry.

The global construction chemicals market, which includes rheological agents, is projected to reach $50 billion by 2025, with a compound annual growth rate (CAGR) of 6.2%. Within this market, the demand for eco-friendly and bio-based additives is growing rapidly, presenting a substantial opportunity for PGA-based products. The Asia-Pacific region, particularly China and India, is expected to be the fastest-growing market due to rapid urbanization and infrastructure development.

Key drivers for the adoption of PGA-based rheological agents include stringent environmental regulations, increasing focus on sustainable construction practices, and the need for improved durability and performance of construction materials. The construction industry is actively seeking alternatives to traditional petroleum-based additives, creating a favorable market environment for PGA-based solutions.

The market for PGA-based rheological agents can be segmented into various applications, including ready-mix concrete, precast concrete, mortars, and grouts. Among these, ready-mix concrete represents the largest market segment, accounting for over 40% of the total market share. The precast concrete segment is expected to witness the highest growth rate due to the increasing adoption of prefabricated construction methods.

Major players in the construction chemicals industry, such as BASF, Sika, and Mapei, are investing in research and development of bio-based additives, including PGA-based products. This trend indicates a growing recognition of the potential of PGA in the construction sector and is likely to drive further market expansion.

However, challenges such as higher production costs compared to traditional additives and limited awareness among end-users about the benefits of PGA-based products may hinder market growth. Overcoming these barriers through technological advancements and educational initiatives will be crucial for widespread adoption.

In conclusion, the market for PGA-based rheological agents in construction shows promising growth potential, driven by sustainability trends and performance requirements. As research and development efforts intensify and production costs decrease, PGA-based products are expected to gain a significant market share in the coming years, revolutionizing the construction chemicals industry.

Current Challenges in Construction Rheology

The construction industry faces several significant challenges in the realm of rheology, particularly in developing effective rheological agents. One of the primary issues is achieving optimal workability and flowability of concrete mixtures while maintaining stability and preventing segregation. This balance is crucial for ensuring proper placement and consolidation of concrete in various construction applications.

Another major challenge lies in controlling the rheological properties of concrete under different environmental conditions. Temperature fluctuations, humidity levels, and varying atmospheric pressures can significantly impact the behavior of concrete mixtures. Developing rheological agents that can maintain consistent performance across diverse climatic conditions remains a complex task for researchers and engineers.

The need for sustainable and eco-friendly construction practices has also introduced new challenges in rheology. Traditional rheological agents often contain synthetic polymers or chemicals that may have adverse environmental impacts. There is a growing demand for bio-based and biodegradable alternatives that can provide comparable or superior rheological properties without compromising environmental sustainability.

Furthermore, the increasing use of high-performance and ultra-high-performance concrete in modern construction projects has raised the bar for rheological control. These advanced concrete mixtures often require precise management of rheological properties to achieve desired strength, durability, and aesthetic qualities. Developing rheological agents capable of meeting these stringent requirements while remaining cost-effective is a significant challenge.

The compatibility of rheological agents with various cement types and admixtures presents another hurdle. As the construction industry embraces a wider range of cement blends and supplementary cementitious materials, ensuring that rheological agents perform consistently across different mix designs becomes increasingly complex. This challenge is further compounded by the need to maintain long-term stability and prevent unwanted interactions between rheological agents and other concrete components.

Lastly, the construction industry faces challenges in accurately measuring and predicting rheological properties in real-time during concrete production and placement. Current testing methods often provide limited information and may not fully capture the dynamic behavior of concrete mixtures under actual construction conditions. Developing more sophisticated and reliable rheological measurement techniques and predictive models remains an ongoing challenge in the field.

Another major challenge lies in controlling the rheological properties of concrete under different environmental conditions. Temperature fluctuations, humidity levels, and varying atmospheric pressures can significantly impact the behavior of concrete mixtures. Developing rheological agents that can maintain consistent performance across diverse climatic conditions remains a complex task for researchers and engineers.

The need for sustainable and eco-friendly construction practices has also introduced new challenges in rheology. Traditional rheological agents often contain synthetic polymers or chemicals that may have adverse environmental impacts. There is a growing demand for bio-based and biodegradable alternatives that can provide comparable or superior rheological properties without compromising environmental sustainability.

Furthermore, the increasing use of high-performance and ultra-high-performance concrete in modern construction projects has raised the bar for rheological control. These advanced concrete mixtures often require precise management of rheological properties to achieve desired strength, durability, and aesthetic qualities. Developing rheological agents capable of meeting these stringent requirements while remaining cost-effective is a significant challenge.

The compatibility of rheological agents with various cement types and admixtures presents another hurdle. As the construction industry embraces a wider range of cement blends and supplementary cementitious materials, ensuring that rheological agents perform consistently across different mix designs becomes increasingly complex. This challenge is further compounded by the need to maintain long-term stability and prevent unwanted interactions between rheological agents and other concrete components.

Lastly, the construction industry faces challenges in accurately measuring and predicting rheological properties in real-time during concrete production and placement. Current testing methods often provide limited information and may not fully capture the dynamic behavior of concrete mixtures under actual construction conditions. Developing more sophisticated and reliable rheological measurement techniques and predictive models remains an ongoing challenge in the field.

Existing PGA-based Rheological Solutions

01 Rheological properties of polyglutamic acid solutions

Polyglutamic acid solutions exhibit unique rheological properties, including shear-thinning behavior and viscoelasticity. These properties are influenced by factors such as concentration, molecular weight, and pH. The rheological characteristics of polyglutamic acid make it suitable for various applications in cosmetics, food, and biomedical fields.- Rheological properties of polyglutamic acid solutions: Polyglutamic acid solutions exhibit unique rheological properties, including shear-thinning behavior and viscoelasticity. These properties are influenced by factors such as concentration, molecular weight, and pH. The rheological characteristics of polyglutamic acid make it suitable for various applications in cosmetics, food, and biomedical fields.

- Effect of molecular weight on polyglutamic acid rheology: The molecular weight of polyglutamic acid significantly impacts its rheological properties. Higher molecular weight polymers generally exhibit increased viscosity and enhanced viscoelastic behavior. This relationship between molecular weight and rheology is crucial for tailoring polyglutamic acid for specific applications and controlling its performance in various formulations.

- Influence of pH on polyglutamic acid rheological behavior: The pH of the environment significantly affects the rheological properties of polyglutamic acid. Changes in pH can alter the polymer's conformation and charge distribution, leading to variations in viscosity and gel-forming ability. Understanding this pH-dependent behavior is essential for optimizing polyglutamic acid's performance in different applications and formulations.

- Polyglutamic acid as a rheology modifier in cosmetic formulations: Polyglutamic acid serves as an effective rheology modifier in cosmetic formulations. It can enhance the texture, stability, and sensory properties of various cosmetic products. The polymer's ability to form hydrogels and its film-forming properties make it valuable for improving the spreadability and skin feel of cosmetic applications.

- Crosslinking effects on polyglutamic acid rheology: Crosslinking of polyglutamic acid can significantly alter its rheological properties. The introduction of crosslinks can lead to the formation of hydrogels with enhanced mechanical strength and controlled swelling behavior. This modification allows for the tailoring of polyglutamic acid's rheological characteristics for specific applications in drug delivery, tissue engineering, and other biomedical fields.

02 Effect of molecular weight on polyglutamic acid rheology

The molecular weight of polyglutamic acid significantly impacts its rheological properties. Higher molecular weight polymers generally exhibit increased viscosity and enhanced viscoelastic behavior. This relationship between molecular weight and rheology is crucial for tailoring polyglutamic acid for specific applications and controlling its performance in various formulations.Expand Specific Solutions03 Influence of pH on polyglutamic acid rheological behavior

The pH of the environment plays a critical role in determining the rheological properties of polyglutamic acid. Changes in pH can affect the polymer's conformation, charge distribution, and intermolecular interactions, leading to alterations in viscosity, gel formation, and flow characteristics. Understanding this pH-dependent behavior is essential for optimizing polyglutamic acid's performance in different applications.Expand Specific Solutions04 Polyglutamic acid as a rheology modifier in formulations

Polyglutamic acid serves as an effective rheology modifier in various formulations. Its ability to control viscosity, improve stability, and enhance texture makes it valuable in cosmetics, personal care products, and pharmaceutical preparations. The polymer's biocompatibility and biodegradability further contribute to its appeal as a natural rheology modifier.Expand Specific Solutions05 Crosslinking effects on polyglutamic acid rheology

Crosslinking of polyglutamic acid can significantly alter its rheological properties. The introduction of crosslinks between polymer chains can lead to increased viscosity, enhanced gel formation, and improved mechanical strength. This modification technique allows for fine-tuning of the polymer's rheological behavior to meet specific application requirements in areas such as drug delivery and tissue engineering.Expand Specific Solutions

Key Players in PGA and Construction Chemistry

The development of polyglutamic acid as a rheological agent for construction is in its early stages, with the market still emerging. The global market for advanced construction materials is growing, driven by increasing demand for sustainable and high-performance solutions. While the technology is promising, it is not yet fully mature, with ongoing research and development efforts. Companies like Kao Corp., MOA Life Plus Co., Ltd., and Nitto Denko Corp. are at the forefront of this field, leveraging their expertise in polymer science and materials engineering. Other players, such as research institutions like Korea Research Institute of Bioscience & Biotechnology and Shanghai University, are contributing to the advancement of this technology through collaborative research efforts and potential industry partnerships.

Kao Corp.

Technical Solution: Kao Corp. has developed a novel rheological agent using polyglutamic acid (PGA) for construction applications. Their approach involves synthesizing high molecular weight PGA through fermentation of Bacillus subtilis[1]. The PGA is then chemically modified to enhance its rheological properties, resulting in a highly effective thickening and stabilizing agent for cement-based materials[2]. Kao's PGA-based rheological agent demonstrates excellent water retention capabilities, improving the workability and durability of concrete mixtures. The company has also incorporated nanotechnology to further enhance the performance of their PGA-based additives, allowing for better dispersion and interaction with cement particles[3].

Strengths: Improved workability and durability of concrete, excellent water retention, and enhanced dispersion of cement particles. Weaknesses: Potentially higher production costs compared to traditional rheological agents, and limited long-term performance data in extreme environmental conditions.

Nitto Denko Corp.

Technical Solution: Nitto Denko Corp. has developed a proprietary PGA-based rheological agent for construction applications, focusing on improving the performance of self-compacting concrete (SCC). Their technology involves the synthesis of PGA with controlled molecular weight distribution and specific side-chain modifications[4]. This tailored PGA is then combined with other polymeric additives to create a synergistic effect, enhancing the viscosity and yield stress of cement pastes[5]. Nitto Denko's PGA-based rheological agent has shown remarkable ability to prevent segregation and bleeding in SCC, while maintaining excellent flowability. The company has also developed a unique encapsulation technique to protect the PGA from premature hydration, ensuring its effectiveness throughout the concrete mixing and placement process[6].

Strengths: Excellent performance in self-compacting concrete, prevention of segregation and bleeding, and controlled release mechanism. Weaknesses: Potentially higher cost compared to traditional superplasticizers, and possible limitations in high-temperature applications.

Innovations in PGA for Rheological Control

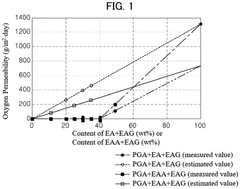

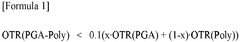

Poly(glycolic acid)-containing resin composition and film including the same

PatentPendingEP4450542A1

Innovation

- A poly(glycolic acid)-containing resin composition combining PGA with an ethylene-(meth)acrylic polymer and an ethylene-based terpolymer, such as copolymers of ethylene and alkyl (meth)acrylate or ethylene, glycidyl methacrylate, and alkyl acrylate, to enhance molecular weight, melt strength, and impact resistance, while maintaining biodegradability and improving film-forming properties.

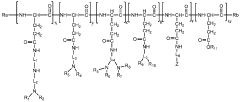

Polyaminated polyglutamic acid-containing compounds and uses thereof for delivering oligonucleotides

PatentWO2017056095A1

Innovation

- Development of polyaminated polyglutamic acid (PGA)-based polymers that form electrostatic complexes with siRNA/miRNA, enhancing stability, targeting tumor sites, and facilitating cellular uptake and endosomal escape through proton sponge effects, while being biodegradable by cathepsin B.

Environmental Impact of PGA in Construction

The environmental impact of polyglutamic acid (PGA) in construction is a crucial aspect to consider as the industry moves towards more sustainable practices. PGA, a biodegradable polymer, offers several environmental benefits when used as a rheological agent in construction materials.

One of the primary advantages of PGA is its biodegradability. Unlike traditional synthetic polymers used in construction, PGA can be broken down by natural processes, reducing long-term environmental pollution. This characteristic is particularly important in the context of construction waste management, as it helps minimize the accumulation of non-degradable materials in landfills.

PGA's production process also contributes to its positive environmental profile. The polymer can be produced through fermentation of renewable resources, such as agricultural by-products. This bio-based production method reduces reliance on fossil fuels and decreases the carbon footprint associated with the manufacturing of construction additives.

In terms of water conservation, PGA demonstrates significant potential. When used as a rheological agent, it can improve the water retention properties of construction materials. This leads to reduced water consumption during the mixing and curing processes, addressing a critical environmental concern in the construction industry, which is known for its high water usage.

The use of PGA in construction materials can also contribute to improved air quality. By enhancing the cohesion and stability of mixtures, it can reduce dust emissions during handling and application of construction materials. This not only creates a healthier work environment but also minimizes the release of particulate matter into the surrounding ecosystem.

Furthermore, PGA's ability to enhance the mechanical properties of construction materials may lead to more durable structures. This increased durability can extend the lifespan of buildings and infrastructure, reducing the need for frequent repairs or replacements. Consequently, this results in lower resource consumption and waste generation over the long term.

However, it is important to note that the environmental impact of PGA is not entirely without challenges. The large-scale production of PGA for construction applications may require significant agricultural resources, potentially leading to land-use conflicts. Additionally, while PGA is biodegradable, its breakdown products and their effects on soil and water ecosystems need further study to ensure long-term environmental safety.

In conclusion, the incorporation of PGA as a rheological agent in construction materials presents a promising avenue for improving the environmental sustainability of the construction industry. Its biodegradability, renewable sourcing, water conservation properties, and potential for enhancing material durability all contribute to a reduced environmental footprint. However, ongoing research and life cycle assessments are necessary to fully understand and optimize its environmental impact across various construction applications.

One of the primary advantages of PGA is its biodegradability. Unlike traditional synthetic polymers used in construction, PGA can be broken down by natural processes, reducing long-term environmental pollution. This characteristic is particularly important in the context of construction waste management, as it helps minimize the accumulation of non-degradable materials in landfills.

PGA's production process also contributes to its positive environmental profile. The polymer can be produced through fermentation of renewable resources, such as agricultural by-products. This bio-based production method reduces reliance on fossil fuels and decreases the carbon footprint associated with the manufacturing of construction additives.

In terms of water conservation, PGA demonstrates significant potential. When used as a rheological agent, it can improve the water retention properties of construction materials. This leads to reduced water consumption during the mixing and curing processes, addressing a critical environmental concern in the construction industry, which is known for its high water usage.

The use of PGA in construction materials can also contribute to improved air quality. By enhancing the cohesion and stability of mixtures, it can reduce dust emissions during handling and application of construction materials. This not only creates a healthier work environment but also minimizes the release of particulate matter into the surrounding ecosystem.

Furthermore, PGA's ability to enhance the mechanical properties of construction materials may lead to more durable structures. This increased durability can extend the lifespan of buildings and infrastructure, reducing the need for frequent repairs or replacements. Consequently, this results in lower resource consumption and waste generation over the long term.

However, it is important to note that the environmental impact of PGA is not entirely without challenges. The large-scale production of PGA for construction applications may require significant agricultural resources, potentially leading to land-use conflicts. Additionally, while PGA is biodegradable, its breakdown products and their effects on soil and water ecosystems need further study to ensure long-term environmental safety.

In conclusion, the incorporation of PGA as a rheological agent in construction materials presents a promising avenue for improving the environmental sustainability of the construction industry. Its biodegradability, renewable sourcing, water conservation properties, and potential for enhancing material durability all contribute to a reduced environmental footprint. However, ongoing research and life cycle assessments are necessary to fully understand and optimize its environmental impact across various construction applications.

Regulatory Framework for Novel Construction Additives

The regulatory framework for novel construction additives, such as polyglutamic acid-based rheological agents, is a complex and evolving landscape that requires careful navigation. In many jurisdictions, the introduction of new construction materials and additives is subject to rigorous testing and approval processes to ensure safety, performance, and environmental compatibility.

At the international level, organizations like the International Organization for Standardization (ISO) and the European Committee for Standardization (CEN) play crucial roles in setting standards that often influence national regulations. These standards typically cover aspects such as material properties, performance criteria, and testing methodologies.

In the United States, the regulatory framework is multi-layered, involving federal, state, and local authorities. The American Society for Testing and Materials (ASTM) develops many of the standards used in the construction industry, which are often incorporated into building codes. The International Code Council (ICC) also plays a significant role in developing model building codes that are widely adopted across the country.

For novel additives like polyglutamic acid-based rheological agents, obtaining approval from relevant authorities often requires extensive documentation of safety data, performance characteristics, and environmental impact assessments. This may include toxicology studies, durability tests, and lifecycle analyses.

Environmental regulations are becoming increasingly stringent, with a focus on sustainability and reducing the carbon footprint of construction materials. Novel additives may need to demonstrate their eco-friendly credentials, such as biodegradability or contribution to energy efficiency in buildings.

In the European Union, the Construction Products Regulation (CPR) governs the marketing of construction products. Novel additives would need to comply with the CPR's requirements, including obtaining a CE marking to indicate conformity with health, safety, and environmental protection standards.

Regulatory bodies often require manufacturers to provide detailed technical documentation, including product composition, intended use, and potential risks. This information is crucial for assessing the suitability of the additive for various construction applications and ensuring it meets all relevant safety and performance standards.

As the construction industry moves towards more sustainable practices, there is a growing trend towards regulations that favor innovative, eco-friendly additives. This presents both opportunities and challenges for developers of novel construction additives, who must navigate a complex regulatory landscape while demonstrating the unique benefits of their products.

At the international level, organizations like the International Organization for Standardization (ISO) and the European Committee for Standardization (CEN) play crucial roles in setting standards that often influence national regulations. These standards typically cover aspects such as material properties, performance criteria, and testing methodologies.

In the United States, the regulatory framework is multi-layered, involving federal, state, and local authorities. The American Society for Testing and Materials (ASTM) develops many of the standards used in the construction industry, which are often incorporated into building codes. The International Code Council (ICC) also plays a significant role in developing model building codes that are widely adopted across the country.

For novel additives like polyglutamic acid-based rheological agents, obtaining approval from relevant authorities often requires extensive documentation of safety data, performance characteristics, and environmental impact assessments. This may include toxicology studies, durability tests, and lifecycle analyses.

Environmental regulations are becoming increasingly stringent, with a focus on sustainability and reducing the carbon footprint of construction materials. Novel additives may need to demonstrate their eco-friendly credentials, such as biodegradability or contribution to energy efficiency in buildings.

In the European Union, the Construction Products Regulation (CPR) governs the marketing of construction products. Novel additives would need to comply with the CPR's requirements, including obtaining a CE marking to indicate conformity with health, safety, and environmental protection standards.

Regulatory bodies often require manufacturers to provide detailed technical documentation, including product composition, intended use, and potential risks. This information is crucial for assessing the suitability of the additive for various construction applications and ensuring it meets all relevant safety and performance standards.

As the construction industry moves towards more sustainable practices, there is a growing trend towards regulations that favor innovative, eco-friendly additives. This presents both opportunities and challenges for developers of novel construction additives, who must navigate a complex regulatory landscape while demonstrating the unique benefits of their products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!