Scramjet's Role in Future Reusable Launch Vehicle Concepts

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Scramjet Evolution

The evolution of scramjet technology has been a crucial factor in advancing the development of future reusable launch vehicle concepts. Scramjets, or supersonic combustion ramjets, have undergone significant advancements since their inception in the 1950s, marking key milestones in hypersonic propulsion.

In the early stages, theoretical work laid the foundation for scramjet design. The 1960s saw the first successful ground tests, demonstrating the feasibility of supersonic combustion. However, it wasn't until the 1990s that flight tests began to validate scramjet technology in real-world conditions.

The NASA X-43A program marked a significant breakthrough in 2004, achieving sustained scramjet-powered flight at Mach 9.6. This success paved the way for further research and development, inspiring programs like the X-51 WaveRider, which achieved Mach 5+ flight for over three minutes in 2013.

Recent years have witnessed a surge in scramjet research, driven by both military and commercial interests. The focus has shifted towards integrating scramjets into reusable launch vehicle designs, aiming to reduce the cost of access to space and enable rapid global transportation.

Technological advancements in materials science have played a crucial role in scramjet evolution. High-temperature resistant materials and advanced cooling systems have addressed the extreme heat generated during hypersonic flight, a critical challenge in scramjet operation.

Computational fluid dynamics and advanced simulation tools have significantly improved scramjet design processes. These technologies allow engineers to optimize engine geometries, fuel injection systems, and combustion dynamics without the need for costly physical prototypes.

The integration of scramjets with other propulsion systems has emerged as a key area of development. Combined cycle engines, which incorporate turbine, ramjet, and scramjet modes, offer the potential for efficient operation across a wide range of speeds, from takeoff to hypersonic flight.

Looking forward, the evolution of scramjets is likely to focus on enhancing reliability, extending operational lifespans, and improving overall system efficiency. Research into novel fuels and combustion techniques may unlock higher performance levels, while advancements in control systems could enable more precise and stable hypersonic flight.

As scramjet technology continues to mature, its role in future reusable launch vehicle concepts becomes increasingly prominent. The potential for air-breathing propulsion to reduce the reliance on carried oxidizers could significantly decrease launch costs and increase payload capacity, revolutionizing access to space and enabling new possibilities in global transportation and defense applications.

In the early stages, theoretical work laid the foundation for scramjet design. The 1960s saw the first successful ground tests, demonstrating the feasibility of supersonic combustion. However, it wasn't until the 1990s that flight tests began to validate scramjet technology in real-world conditions.

The NASA X-43A program marked a significant breakthrough in 2004, achieving sustained scramjet-powered flight at Mach 9.6. This success paved the way for further research and development, inspiring programs like the X-51 WaveRider, which achieved Mach 5+ flight for over three minutes in 2013.

Recent years have witnessed a surge in scramjet research, driven by both military and commercial interests. The focus has shifted towards integrating scramjets into reusable launch vehicle designs, aiming to reduce the cost of access to space and enable rapid global transportation.

Technological advancements in materials science have played a crucial role in scramjet evolution. High-temperature resistant materials and advanced cooling systems have addressed the extreme heat generated during hypersonic flight, a critical challenge in scramjet operation.

Computational fluid dynamics and advanced simulation tools have significantly improved scramjet design processes. These technologies allow engineers to optimize engine geometries, fuel injection systems, and combustion dynamics without the need for costly physical prototypes.

The integration of scramjets with other propulsion systems has emerged as a key area of development. Combined cycle engines, which incorporate turbine, ramjet, and scramjet modes, offer the potential for efficient operation across a wide range of speeds, from takeoff to hypersonic flight.

Looking forward, the evolution of scramjets is likely to focus on enhancing reliability, extending operational lifespans, and improving overall system efficiency. Research into novel fuels and combustion techniques may unlock higher performance levels, while advancements in control systems could enable more precise and stable hypersonic flight.

As scramjet technology continues to mature, its role in future reusable launch vehicle concepts becomes increasingly prominent. The potential for air-breathing propulsion to reduce the reliance on carried oxidizers could significantly decrease launch costs and increase payload capacity, revolutionizing access to space and enabling new possibilities in global transportation and defense applications.

Space Launch Demand

The global space launch market has experienced significant growth in recent years, driven by increasing demand for satellite deployment, space exploration missions, and emerging commercial space activities. This surge in demand has created a pressing need for more efficient and cost-effective launch systems, particularly reusable launch vehicles (RLVs) that can dramatically reduce the cost per kilogram to orbit.

The commercial satellite sector remains the primary driver of space launch demand, with telecommunications, Earth observation, and navigation satellites accounting for a substantial portion of launches. The proliferation of small satellite constellations for global internet coverage and Earth imaging has further intensified the need for frequent and affordable access to space. Companies like SpaceX, OneWeb, and Amazon's Project Kuiper are planning to deploy thousands of satellites in the coming years, necessitating a high launch cadence and lower costs per launch.

Government and military space programs also contribute significantly to launch demand. National space agencies and defense departments worldwide continue to invest in space-based assets for communication, reconnaissance, and scientific research. The renewed interest in lunar exploration and Mars missions by multiple countries has added another dimension to the launch market, requiring heavy-lift capabilities for deep space missions.

The emergence of space tourism and commercial crew transportation to the International Space Station has opened new avenues for launch demand. Companies like Virgin Galactic and Blue Origin are developing suborbital vehicles for space tourism, while SpaceX and Boeing are providing crew transportation services to NASA, further diversifying the launch market.

In this context, scramjet technology holds immense potential for revolutionizing access to space. Scramjets, or supersonic combustion ramjets, offer the promise of hypersonic flight within the atmosphere, potentially enabling single-stage-to-orbit (SSTO) vehicles or serving as efficient first stages for multi-stage RLVs. The ability of scramjets to operate at high Mach numbers without carrying oxidizers could significantly reduce the mass of launch vehicles, thereby increasing payload capacity and reducing launch costs.

As the space launch market continues to evolve, the demand for more frequent, reliable, and cost-effective launches is expected to grow. Scramjet-powered RLVs could play a crucial role in meeting this demand by offering rapid turnaround times, lower operational costs, and increased flexibility in launch operations. The successful integration of scramjet technology into future RLV concepts could potentially disrupt the current launch market dynamics, enabling new business models and expanding access to space for a wider range of applications and users.

The commercial satellite sector remains the primary driver of space launch demand, with telecommunications, Earth observation, and navigation satellites accounting for a substantial portion of launches. The proliferation of small satellite constellations for global internet coverage and Earth imaging has further intensified the need for frequent and affordable access to space. Companies like SpaceX, OneWeb, and Amazon's Project Kuiper are planning to deploy thousands of satellites in the coming years, necessitating a high launch cadence and lower costs per launch.

Government and military space programs also contribute significantly to launch demand. National space agencies and defense departments worldwide continue to invest in space-based assets for communication, reconnaissance, and scientific research. The renewed interest in lunar exploration and Mars missions by multiple countries has added another dimension to the launch market, requiring heavy-lift capabilities for deep space missions.

The emergence of space tourism and commercial crew transportation to the International Space Station has opened new avenues for launch demand. Companies like Virgin Galactic and Blue Origin are developing suborbital vehicles for space tourism, while SpaceX and Boeing are providing crew transportation services to NASA, further diversifying the launch market.

In this context, scramjet technology holds immense potential for revolutionizing access to space. Scramjets, or supersonic combustion ramjets, offer the promise of hypersonic flight within the atmosphere, potentially enabling single-stage-to-orbit (SSTO) vehicles or serving as efficient first stages for multi-stage RLVs. The ability of scramjets to operate at high Mach numbers without carrying oxidizers could significantly reduce the mass of launch vehicles, thereby increasing payload capacity and reducing launch costs.

As the space launch market continues to evolve, the demand for more frequent, reliable, and cost-effective launches is expected to grow. Scramjet-powered RLVs could play a crucial role in meeting this demand by offering rapid turnaround times, lower operational costs, and increased flexibility in launch operations. The successful integration of scramjet technology into future RLV concepts could potentially disrupt the current launch market dynamics, enabling new business models and expanding access to space for a wider range of applications and users.

Scramjet Challenges

Despite the promising potential of scramjets in reusable launch vehicle concepts, several significant challenges must be addressed before their widespread implementation. One of the primary hurdles is the extreme thermal management requirements. Scramjets operate at hypersonic speeds, generating intense heat that can compromise structural integrity and affect engine performance. Developing materials and cooling systems capable of withstanding these extreme temperatures remains a critical challenge.

Another major obstacle is the limited operational envelope of scramjets. These engines only function effectively at high supersonic to hypersonic speeds, typically above Mach 5. This necessitates complex propulsion system integration, often requiring multiple engine types to cover the entire flight regime from takeoff to orbital insertion. The transition between different propulsion modes presents significant engineering challenges and adds complexity to the overall vehicle design.

Fuel efficiency and combustion stability pose additional hurdles. Scramjets require precise fuel injection and mixing to achieve efficient combustion in the supersonic airflow. Maintaining stable combustion across a wide range of flight conditions is crucial for reliable operation. Furthermore, the short residence time of air in the combustion chamber demands rapid and efficient fuel-air mixing, which remains a significant area of ongoing research.

The development of robust control systems for scramjet-powered vehicles is another critical challenge. The hypersonic flight regime is characterized by complex aerodynamics and rapidly changing flight conditions. Designing control systems capable of maintaining vehicle stability and optimizing engine performance in this environment is a formidable task, requiring advanced sensors, algorithms, and actuators.

Scalability and integration issues also present significant challenges. While scramjet technology has been demonstrated in small-scale test vehicles, scaling up to full-size, operational launch vehicles introduces new complexities. Integrating scramjet propulsion with other vehicle systems, such as thermal protection, guidance, and payload accommodation, requires careful design considerations and extensive testing.

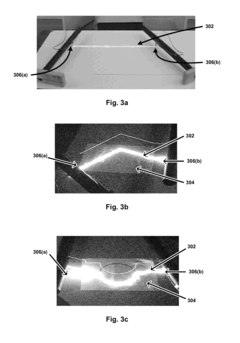

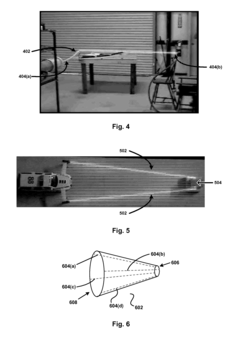

Lastly, the high cost and complexity of ground testing facilities for scramjet engines pose a significant barrier to rapid development and iteration. Simulating the extreme conditions of hypersonic flight in ground-based facilities is technically challenging and expensive, limiting the pace of research and development in this field.

Another major obstacle is the limited operational envelope of scramjets. These engines only function effectively at high supersonic to hypersonic speeds, typically above Mach 5. This necessitates complex propulsion system integration, often requiring multiple engine types to cover the entire flight regime from takeoff to orbital insertion. The transition between different propulsion modes presents significant engineering challenges and adds complexity to the overall vehicle design.

Fuel efficiency and combustion stability pose additional hurdles. Scramjets require precise fuel injection and mixing to achieve efficient combustion in the supersonic airflow. Maintaining stable combustion across a wide range of flight conditions is crucial for reliable operation. Furthermore, the short residence time of air in the combustion chamber demands rapid and efficient fuel-air mixing, which remains a significant area of ongoing research.

The development of robust control systems for scramjet-powered vehicles is another critical challenge. The hypersonic flight regime is characterized by complex aerodynamics and rapidly changing flight conditions. Designing control systems capable of maintaining vehicle stability and optimizing engine performance in this environment is a formidable task, requiring advanced sensors, algorithms, and actuators.

Scalability and integration issues also present significant challenges. While scramjet technology has been demonstrated in small-scale test vehicles, scaling up to full-size, operational launch vehicles introduces new complexities. Integrating scramjet propulsion with other vehicle systems, such as thermal protection, guidance, and payload accommodation, requires careful design considerations and extensive testing.

Lastly, the high cost and complexity of ground testing facilities for scramjet engines pose a significant barrier to rapid development and iteration. Simulating the extreme conditions of hypersonic flight in ground-based facilities is technically challenging and expensive, limiting the pace of research and development in this field.

Current RLV Designs

01 Scramjet engine design and configuration

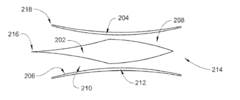

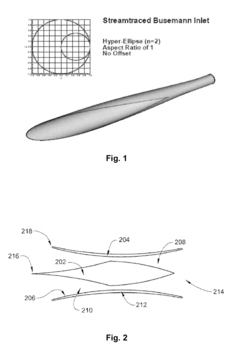

Scramjet engines are designed for hypersonic flight, utilizing supersonic airflow for combustion. Key aspects include inlet design, combustion chamber configuration, and nozzle optimization to achieve efficient propulsion at high Mach numbers. Advanced materials and cooling systems are employed to withstand extreme temperatures and pressures encountered during operation.- Scramjet engine design and configuration: Scramjet engines are designed for hypersonic flight, utilizing supersonic airflow for combustion. Key aspects include inlet design, combustion chamber configuration, and nozzle optimization to achieve efficient propulsion at high Mach numbers. Advanced materials and cooling systems are employed to withstand extreme temperatures and pressures encountered during operation.

- Fuel injection and mixing techniques: Efficient fuel injection and mixing are crucial for scramjet performance. Various techniques are employed, including staged injection, wall injection, and strut-based injection systems. These methods aim to achieve rapid and uniform fuel-air mixing within the supersonic airflow, enhancing combustion efficiency and overall engine performance.

- Thermal management and cooling systems: Scramjet engines operate at extremely high temperatures, necessitating advanced thermal management solutions. Cooling systems may include regenerative cooling, film cooling, and transpiration cooling techniques. These systems protect engine components from thermal damage and maintain structural integrity during sustained hypersonic flight.

- Integration with airframe and flight control: Scramjet engines are often integrated into the airframe design to optimize aerodynamic performance. This integration involves careful consideration of inlet placement, forebody compression, and afterbody expansion. Advanced flight control systems are developed to manage the complex interactions between the engine and airframe during hypersonic flight.

- Testing and simulation methods: Development of scramjet technology relies heavily on advanced testing and simulation methods. These include wind tunnel testing, computational fluid dynamics (CFD) simulations, and flight test programs. Such methods are essential for validating design concepts, optimizing performance, and ensuring the reliability and safety of scramjet-powered vehicles.

02 Fuel injection and mixing in scramjet engines

Efficient fuel injection and mixing are crucial for scramjet performance. Various techniques are employed, including staged injection, wall injection, and strut-based injection systems. Advanced fuel formulations and injection strategies aim to improve combustion efficiency and stability across a wide range of flight conditions.Expand Specific Solutions03 Thermal management and cooling systems

Scramjet engines operate at extremely high temperatures, necessitating advanced thermal management solutions. Cooling systems may incorporate regenerative cooling, film cooling, and transpiration cooling techniques. Novel materials and coatings are developed to enhance heat resistance and protect critical engine components.Expand Specific Solutions04 Integration of scramjet engines with aircraft design

Integrating scramjet engines into aircraft designs presents unique challenges. Considerations include airframe-engine integration, inlet and nozzle placement, and overall vehicle aerodynamics. Advanced computational fluid dynamics (CFD) simulations and wind tunnel testing are employed to optimize the integration for maximum performance and efficiency.Expand Specific Solutions05 Control systems and flight management for scramjet-powered vehicles

Sophisticated control systems are essential for managing scramjet-powered vehicles across various flight regimes. This includes adaptive control algorithms, sensor integration, and real-time performance optimization. Flight management systems must account for the unique characteristics of scramjet propulsion, including fuel consumption, thrust modulation, and trajectory optimization for hypersonic flight.Expand Specific Solutions

Aerospace Leaders

The scramjet technology for future reusable launch vehicles is in an early development stage, with significant potential but limited market maturity. The global market for this technology is projected to grow substantially, driven by increasing demand for cost-effective space access. Key players like United Technologies Corp., Aerojet Rocketdyne, and Northrop Grumman are leading research efforts, while emerging companies such as Beijing I-Space Technology are also making strides. Government entities, including NASA and research institutions like the National University of Defense Technology, play crucial roles in advancing scramjet technology. The field remains highly competitive, with various approaches being explored to overcome technical challenges and improve performance for practical applications in reusable launch vehicles.

Aerojet Rocketdyne, Inc.

Technical Solution: Aerojet Rocketdyne has been at the forefront of scramjet technology development for future reusable launch vehicles. Their approach focuses on integrating scramjet engines into multi-mode propulsion systems for hypersonic vehicles. The company has developed the X-51A WaveRider, a scramjet-powered hypersonic demonstrator that achieved Mach 5+ speeds for over 200 seconds[1]. Their scramjet design incorporates advanced thermal management systems and uses hydrogen fuel for efficient combustion at hypersonic speeds. Aerojet Rocketdyne is also working on scaling up scramjet technology for larger vehicles, potentially enabling single-stage-to-orbit (SSTO) capabilities[2]. They are exploring the use of 3D printing and advanced materials to reduce the weight and improve the durability of scramjet components.

Strengths: Proven track record in hypersonic flight, advanced thermal management, and integration with other propulsion systems. Weaknesses: High development costs and complexity in scaling up for orbital launch vehicles.

Government of the United States of America

Technical Solution: The U.S. government, primarily through NASA and the Department of Defense, has been a key player in scramjet research for future reusable launch vehicles. NASA's X-43 and X-51 programs demonstrated sustained hypersonic flight using scramjet propulsion[9]. Current efforts focus on scaling up scramjet technology for larger vehicles and exploring its integration with other propulsion systems. The government is funding research into advanced materials, such as carbon-carbon composites and ceramic matrix composites, to withstand the extreme temperatures of hypersonic flight. Additionally, there is ongoing work on computational modeling and simulation tools to optimize scramjet design and performance. The U.S. is also investigating the potential of scramjet-powered vehicles for rapid global reach and space access, with programs like the X-60A exploring air-launched scramjet test beds[10].

Strengths: Extensive research infrastructure, funding capabilities, and coordination across multiple agencies and industry partners. Weaknesses: Complex procurement processes and potential for shifting priorities with changes in administration.

Key Scramjet Patents

Step cylinder combustor design

PatentInactiveUS3864907A

Innovation

- A combustor chamber design with multiple stabilizing steps followed by constant area cylindrical sections allows for selective heat addition, avoiding divergent flow issues and enabling greater heat and energy input through progressively increasing diameter chambers.

Energy-Deposition Systems, Equipment and Methods for Modifying and Controlling Shock Waves and Supersonic Flow

PatentActiveUS20150292532A1

Innovation

- The system employs conductive paths along surfaces with energy sources and sensors to assess and control energy discharge, allowing for the modification of shockwaves and fluid flows by depositing energy to start or restart inlets, mitigate blast effects, and manage heat transfer in wind tunnels.

Material Innovations

Material innovations play a crucial role in advancing the development of scramjet-powered reusable launch vehicles (RLVs). The extreme operating conditions of scramjets demand materials that can withstand high temperatures, intense thermal cycling, and severe aerodynamic loads. Recent advancements in materials science have led to the development of novel composites and alloys that show promise for scramjet applications.

One of the most significant material innovations is the development of ultra-high temperature ceramics (UHTCs). These materials, including zirconium diboride and hafnium carbide, exhibit exceptional thermal stability and oxidation resistance at temperatures exceeding 2000°C. UHTCs are being investigated for use in scramjet combustion chambers and leading edges of hypersonic vehicles, where they can provide superior performance compared to traditional superalloys.

Carbon-carbon (C/C) composites have also seen significant improvements in recent years. These materials, consisting of carbon fibers in a carbon matrix, offer excellent strength-to-weight ratios and maintain their properties at high temperatures. Advanced manufacturing techniques, such as 3D weaving and chemical vapor infiltration, have enhanced the performance and reliability of C/C composites for scramjet applications.

Ceramic matrix composites (CMCs) represent another promising class of materials for scramjet-powered RLVs. Silicon carbide-based CMCs, in particular, have demonstrated excellent thermal shock resistance and oxidation protection. These materials are being considered for use in scramjet engine components, such as nozzles and exhaust systems, where they can provide weight savings and improved durability compared to metallic alternatives.

Advancements in thermal barrier coatings (TBCs) have also contributed to the feasibility of scramjet-powered RLVs. Novel TBC systems, incorporating rare earth elements and nanostructured designs, offer enhanced thermal insulation and erosion resistance. These coatings can protect underlying structural materials from the extreme heat generated during scramjet operation, potentially extending the lifespan of critical components.

The development of functionally graded materials (FGMs) has opened new possibilities for optimizing the performance of scramjet structures. By gradually varying material composition and properties across a component, FGMs can provide tailored thermal and mechanical characteristics. This approach allows engineers to design structures that can better withstand the complex stress distributions and thermal gradients encountered in scramjet engines.

As research in material science continues to progress, the integration of these advanced materials into scramjet-powered RLV designs will be crucial for realizing the full potential of these vehicles. The ongoing development of novel manufacturing techniques, such as additive manufacturing and advanced joining methods, will further enhance the ability to incorporate these innovative materials into complex scramjet structures.

One of the most significant material innovations is the development of ultra-high temperature ceramics (UHTCs). These materials, including zirconium diboride and hafnium carbide, exhibit exceptional thermal stability and oxidation resistance at temperatures exceeding 2000°C. UHTCs are being investigated for use in scramjet combustion chambers and leading edges of hypersonic vehicles, where they can provide superior performance compared to traditional superalloys.

Carbon-carbon (C/C) composites have also seen significant improvements in recent years. These materials, consisting of carbon fibers in a carbon matrix, offer excellent strength-to-weight ratios and maintain their properties at high temperatures. Advanced manufacturing techniques, such as 3D weaving and chemical vapor infiltration, have enhanced the performance and reliability of C/C composites for scramjet applications.

Ceramic matrix composites (CMCs) represent another promising class of materials for scramjet-powered RLVs. Silicon carbide-based CMCs, in particular, have demonstrated excellent thermal shock resistance and oxidation protection. These materials are being considered for use in scramjet engine components, such as nozzles and exhaust systems, where they can provide weight savings and improved durability compared to metallic alternatives.

Advancements in thermal barrier coatings (TBCs) have also contributed to the feasibility of scramjet-powered RLVs. Novel TBC systems, incorporating rare earth elements and nanostructured designs, offer enhanced thermal insulation and erosion resistance. These coatings can protect underlying structural materials from the extreme heat generated during scramjet operation, potentially extending the lifespan of critical components.

The development of functionally graded materials (FGMs) has opened new possibilities for optimizing the performance of scramjet structures. By gradually varying material composition and properties across a component, FGMs can provide tailored thermal and mechanical characteristics. This approach allows engineers to design structures that can better withstand the complex stress distributions and thermal gradients encountered in scramjet engines.

As research in material science continues to progress, the integration of these advanced materials into scramjet-powered RLV designs will be crucial for realizing the full potential of these vehicles. The ongoing development of novel manufacturing techniques, such as additive manufacturing and advanced joining methods, will further enhance the ability to incorporate these innovative materials into complex scramjet structures.

Environmental Impact

The environmental impact of scramjet-powered reusable launch vehicles (RLVs) is a critical consideration in their development and deployment. These advanced propulsion systems offer potential benefits in terms of reduced emissions and environmental footprint compared to traditional rocket engines, but they also present unique challenges.

Scramjet engines, operating at hypersonic speeds, primarily use atmospheric oxygen for combustion, reducing the need for onboard oxidizers. This results in a significant decrease in the overall mass of propellants required for launch, potentially lowering the environmental impact associated with fuel production and transportation. Additionally, the reusability aspect of these vehicles further minimizes resource consumption and waste generation typically associated with expendable launch systems.

However, the high-speed flight regime of scramjet-powered RLVs introduces concerns regarding atmospheric pollution and noise. The extreme temperatures and pressures experienced during hypersonic flight can lead to the formation of nitrogen oxides (NOx) and other pollutants in the upper atmosphere. While the overall quantity of emissions may be lower than conventional rockets, the altitude at which these emissions occur could have different environmental implications that require careful study and mitigation strategies.

Noise pollution is another environmental factor to consider. The sonic booms generated by hypersonic vehicles during ascent and descent phases could have significant impacts on wildlife and human populations in launch and landing corridors. Developing flight paths and operational procedures to minimize these disturbances will be crucial for the widespread adoption of scramjet-powered RLVs.

The materials used in scramjet engines and associated thermal protection systems also warrant environmental scrutiny. Advanced composites and exotic alloys required to withstand the extreme conditions of hypersonic flight may present challenges in terms of recyclability and end-of-life disposal. Developing sustainable manufacturing processes and recycling techniques for these specialized materials will be essential to maximize the environmental benefits of reusable launch systems.

Water vapor emissions from scramjet combustion, while generally considered less harmful than other rocket exhaust products, could still have localized effects on atmospheric chemistry and cloud formation at high altitudes. Long-term studies on the cumulative impact of increased water vapor in the upper atmosphere from frequent scramjet operations will be necessary to fully understand and mitigate any potential climate effects.

In conclusion, while scramjet-powered RLVs offer promising environmental advantages over traditional launch systems, a comprehensive assessment of their ecological footprint throughout the entire lifecycle is crucial. This includes considering manufacturing processes, operational impacts, and end-of-life disposal. Continued research and development efforts should focus on optimizing scramjet technology not only for performance but also for minimal environmental impact, ensuring that future space access becomes more sustainable as it becomes more frequent and accessible.

Scramjet engines, operating at hypersonic speeds, primarily use atmospheric oxygen for combustion, reducing the need for onboard oxidizers. This results in a significant decrease in the overall mass of propellants required for launch, potentially lowering the environmental impact associated with fuel production and transportation. Additionally, the reusability aspect of these vehicles further minimizes resource consumption and waste generation typically associated with expendable launch systems.

However, the high-speed flight regime of scramjet-powered RLVs introduces concerns regarding atmospheric pollution and noise. The extreme temperatures and pressures experienced during hypersonic flight can lead to the formation of nitrogen oxides (NOx) and other pollutants in the upper atmosphere. While the overall quantity of emissions may be lower than conventional rockets, the altitude at which these emissions occur could have different environmental implications that require careful study and mitigation strategies.

Noise pollution is another environmental factor to consider. The sonic booms generated by hypersonic vehicles during ascent and descent phases could have significant impacts on wildlife and human populations in launch and landing corridors. Developing flight paths and operational procedures to minimize these disturbances will be crucial for the widespread adoption of scramjet-powered RLVs.

The materials used in scramjet engines and associated thermal protection systems also warrant environmental scrutiny. Advanced composites and exotic alloys required to withstand the extreme conditions of hypersonic flight may present challenges in terms of recyclability and end-of-life disposal. Developing sustainable manufacturing processes and recycling techniques for these specialized materials will be essential to maximize the environmental benefits of reusable launch systems.

Water vapor emissions from scramjet combustion, while generally considered less harmful than other rocket exhaust products, could still have localized effects on atmospheric chemistry and cloud formation at high altitudes. Long-term studies on the cumulative impact of increased water vapor in the upper atmosphere from frequent scramjet operations will be necessary to fully understand and mitigate any potential climate effects.

In conclusion, while scramjet-powered RLVs offer promising environmental advantages over traditional launch systems, a comprehensive assessment of their ecological footprint throughout the entire lifecycle is crucial. This includes considering manufacturing processes, operational impacts, and end-of-life disposal. Continued research and development efforts should focus on optimizing scramjet technology not only for performance but also for minimal environmental impact, ensuring that future space access becomes more sustainable as it becomes more frequent and accessible.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!