Scramjet’s Role in Water Rocketry: Enhancements and Innovations

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Scramjet Water Rocket Background and Objectives

Water rocketry has been a popular educational and recreational activity for decades, demonstrating basic principles of propulsion and aerodynamics. The integration of scramjet technology into water rockets represents a significant leap forward in this field, combining the simplicity of water propulsion with advanced aerospace concepts.

The evolution of water rocketry can be traced back to the mid-20th century when it emerged as a safe and accessible way to teach rocket science fundamentals. Traditional water rockets rely on compressed air to expel water, creating thrust through Newton's third law of motion. However, these designs have limitations in terms of efficiency and maximum achievable altitude.

Scramjet technology, originally developed for hypersonic flight applications, offers a promising avenue for enhancing water rocket performance. A scramjet, or supersonic combustion ramjet, is an air-breathing jet engine designed to operate efficiently at hypersonic speeds. By adapting this concept to water rocketry, researchers aim to overcome the constraints of conventional designs and push the boundaries of what can be achieved with water-propelled rockets.

The primary objective of incorporating scramjet principles into water rocketry is to significantly increase the efficiency and performance of these educational tools. This involves redesigning the rocket's nozzle and internal geometry to create a supersonic flow of the water-air mixture, potentially leading to higher thrust and longer sustained flight times.

Another key goal is to expand the educational value of water rockets by introducing more complex fluid dynamics and propulsion concepts. By bridging the gap between simple water rockets and advanced aerospace technologies, educators can provide students with hands-on experience in cutting-edge engineering principles.

Furthermore, the integration of scramjet technology aims to inspire innovation in small-scale propulsion systems. The insights gained from this fusion of technologies could potentially lead to advancements in micro-propulsion for small satellites or other miniaturized aerospace applications.

As research in this area progresses, the ultimate objective is to develop a new generation of water rockets that can achieve unprecedented altitudes and flight characteristics. This not only enhances the recreational aspect of water rocketry but also opens up new possibilities for scientific experiments and data collection at higher altitudes using cost-effective and environmentally friendly propulsion methods.

The evolution of water rocketry can be traced back to the mid-20th century when it emerged as a safe and accessible way to teach rocket science fundamentals. Traditional water rockets rely on compressed air to expel water, creating thrust through Newton's third law of motion. However, these designs have limitations in terms of efficiency and maximum achievable altitude.

Scramjet technology, originally developed for hypersonic flight applications, offers a promising avenue for enhancing water rocket performance. A scramjet, or supersonic combustion ramjet, is an air-breathing jet engine designed to operate efficiently at hypersonic speeds. By adapting this concept to water rocketry, researchers aim to overcome the constraints of conventional designs and push the boundaries of what can be achieved with water-propelled rockets.

The primary objective of incorporating scramjet principles into water rocketry is to significantly increase the efficiency and performance of these educational tools. This involves redesigning the rocket's nozzle and internal geometry to create a supersonic flow of the water-air mixture, potentially leading to higher thrust and longer sustained flight times.

Another key goal is to expand the educational value of water rockets by introducing more complex fluid dynamics and propulsion concepts. By bridging the gap between simple water rockets and advanced aerospace technologies, educators can provide students with hands-on experience in cutting-edge engineering principles.

Furthermore, the integration of scramjet technology aims to inspire innovation in small-scale propulsion systems. The insights gained from this fusion of technologies could potentially lead to advancements in micro-propulsion for small satellites or other miniaturized aerospace applications.

As research in this area progresses, the ultimate objective is to develop a new generation of water rockets that can achieve unprecedented altitudes and flight characteristics. This not only enhances the recreational aspect of water rocketry but also opens up new possibilities for scientific experiments and data collection at higher altitudes using cost-effective and environmentally friendly propulsion methods.

Market Analysis for Advanced Water Rockets

The market for advanced water rockets has been experiencing significant growth in recent years, driven by increasing interest in STEM education, hobbyist activities, and scientific research. This niche market segment has evolved from simple toy rockets to sophisticated devices incorporating advanced propulsion technologies like scramjets.

The primary consumer base for advanced water rockets includes educational institutions, science clubs, hobbyist groups, and research organizations. Schools and universities are increasingly incorporating water rocket projects into their curricula to teach principles of physics, engineering, and aerodynamics. This educational focus has led to a steady demand for more advanced and customizable water rocket kits.

Hobbyist groups and enthusiasts represent another significant market segment. These consumers are often willing to invest in high-end water rocket systems that offer enhanced performance and innovative features. The growing popularity of competitive water rocket events has further fueled demand for advanced designs and materials.

Research institutions and aerospace companies have also shown interest in advanced water rockets as cost-effective platforms for testing new propulsion concepts, including scramjet technology. This has opened up a niche but potentially lucrative market for specialized, high-performance water rocket systems.

The global market size for advanced water rockets, while difficult to quantify precisely, is estimated to be in the tens of millions of dollars annually. Growth rates in this sector have been robust, with some industry analysts suggesting year-over-year increases of 8-12% over the past five years.

Geographically, North America and Europe lead in market share, primarily due to the strong presence of STEM education initiatives and a well-established hobbyist community. However, emerging markets in Asia-Pacific, particularly in countries like China, Japan, and South Korea, are showing rapid growth as STEM education gains prominence.

The integration of scramjet technology into water rocketry represents a significant market opportunity. While currently a niche within a niche, it has the potential to revolutionize the advanced water rocket market. Early adopters of this technology are likely to be research institutions and advanced hobbyists, with potential for broader adoption as the technology matures and becomes more accessible.

Key market trends include the increasing use of 3D printing for custom rocket components, the integration of electronic systems for data collection and flight control, and a growing emphasis on eco-friendly materials. These trends are expected to continue shaping the market landscape in the coming years.

The primary consumer base for advanced water rockets includes educational institutions, science clubs, hobbyist groups, and research organizations. Schools and universities are increasingly incorporating water rocket projects into their curricula to teach principles of physics, engineering, and aerodynamics. This educational focus has led to a steady demand for more advanced and customizable water rocket kits.

Hobbyist groups and enthusiasts represent another significant market segment. These consumers are often willing to invest in high-end water rocket systems that offer enhanced performance and innovative features. The growing popularity of competitive water rocket events has further fueled demand for advanced designs and materials.

Research institutions and aerospace companies have also shown interest in advanced water rockets as cost-effective platforms for testing new propulsion concepts, including scramjet technology. This has opened up a niche but potentially lucrative market for specialized, high-performance water rocket systems.

The global market size for advanced water rockets, while difficult to quantify precisely, is estimated to be in the tens of millions of dollars annually. Growth rates in this sector have been robust, with some industry analysts suggesting year-over-year increases of 8-12% over the past five years.

Geographically, North America and Europe lead in market share, primarily due to the strong presence of STEM education initiatives and a well-established hobbyist community. However, emerging markets in Asia-Pacific, particularly in countries like China, Japan, and South Korea, are showing rapid growth as STEM education gains prominence.

The integration of scramjet technology into water rocketry represents a significant market opportunity. While currently a niche within a niche, it has the potential to revolutionize the advanced water rocket market. Early adopters of this technology are likely to be research institutions and advanced hobbyists, with potential for broader adoption as the technology matures and becomes more accessible.

Key market trends include the increasing use of 3D printing for custom rocket components, the integration of electronic systems for data collection and flight control, and a growing emphasis on eco-friendly materials. These trends are expected to continue shaping the market landscape in the coming years.

Current Scramjet Technology in Water Rocketry

Current scramjet technology in water rocketry represents a significant advancement in propulsion systems for high-speed water-based projectiles. Scramjets, or supersonic combustion ramjets, have been adapted from aerospace applications to enhance the performance of water rockets, offering improved thrust and efficiency at supersonic speeds.

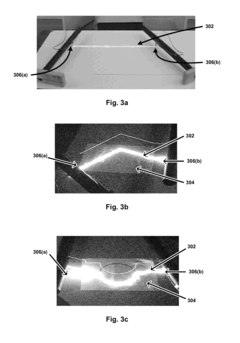

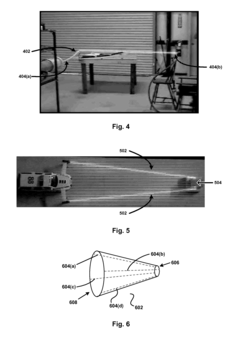

The primary principle behind scramjet-powered water rockets involves the compression and combustion of a water-air mixture at supersonic velocities. Unlike traditional water rockets that rely solely on pressurized water expulsion, scramjet-equipped models utilize the forward motion of the rocket to compress incoming air, which is then mixed with a fine water mist and ignited in a combustion chamber.

One of the key innovations in current scramjet technology for water rocketry is the development of miniaturized combustion chambers capable of sustaining stable combustion at high speeds. These chambers are designed with precise geometry to ensure optimal mixing of air and water droplets, maximizing combustion efficiency and thrust generation.

Advanced nozzle designs have also been implemented to manage the expansion of hot gases and convert thermal energy into kinetic energy more effectively. Variable geometry nozzles, in particular, allow for adaptive performance across a range of flight speeds and altitudes, enhancing overall rocket efficiency.

Material science has played a crucial role in enabling scramjet technology for water rockets. Heat-resistant composites and advanced ceramics are now used to construct combustion chambers and nozzles, capable of withstanding the extreme temperatures and pressures associated with supersonic combustion.

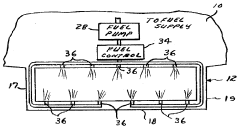

Fuel injection systems have been refined to deliver precise quantities of water into the airstream, creating an optimal fuel-air ratio for combustion. High-pressure pumps and atomizers ensure that water is introduced as a fine mist, promoting rapid vaporization and efficient burning.

Control systems and sensors have been integrated to monitor and adjust combustion parameters in real-time. These systems regulate water flow, air intake, and combustion timing to maintain optimal performance throughout the flight envelope.

Recent advancements have also focused on improving the transition from subsonic to supersonic flight, a critical phase for scramjet operation. Dual-mode engines that can function as both ramjets and scramjets have been developed, allowing for efficient operation across a broader range of speeds.

While current scramjet technology in water rocketry shows promising results in laboratory and controlled environments, challenges remain in scaling up these systems for practical applications. Ongoing research aims to address issues such as combustion stability at varying altitudes and the development of more robust ignition systems for reliable operation in diverse conditions.

The primary principle behind scramjet-powered water rockets involves the compression and combustion of a water-air mixture at supersonic velocities. Unlike traditional water rockets that rely solely on pressurized water expulsion, scramjet-equipped models utilize the forward motion of the rocket to compress incoming air, which is then mixed with a fine water mist and ignited in a combustion chamber.

One of the key innovations in current scramjet technology for water rocketry is the development of miniaturized combustion chambers capable of sustaining stable combustion at high speeds. These chambers are designed with precise geometry to ensure optimal mixing of air and water droplets, maximizing combustion efficiency and thrust generation.

Advanced nozzle designs have also been implemented to manage the expansion of hot gases and convert thermal energy into kinetic energy more effectively. Variable geometry nozzles, in particular, allow for adaptive performance across a range of flight speeds and altitudes, enhancing overall rocket efficiency.

Material science has played a crucial role in enabling scramjet technology for water rockets. Heat-resistant composites and advanced ceramics are now used to construct combustion chambers and nozzles, capable of withstanding the extreme temperatures and pressures associated with supersonic combustion.

Fuel injection systems have been refined to deliver precise quantities of water into the airstream, creating an optimal fuel-air ratio for combustion. High-pressure pumps and atomizers ensure that water is introduced as a fine mist, promoting rapid vaporization and efficient burning.

Control systems and sensors have been integrated to monitor and adjust combustion parameters in real-time. These systems regulate water flow, air intake, and combustion timing to maintain optimal performance throughout the flight envelope.

Recent advancements have also focused on improving the transition from subsonic to supersonic flight, a critical phase for scramjet operation. Dual-mode engines that can function as both ramjets and scramjets have been developed, allowing for efficient operation across a broader range of speeds.

While current scramjet technology in water rocketry shows promising results in laboratory and controlled environments, challenges remain in scaling up these systems for practical applications. Ongoing research aims to address issues such as combustion stability at varying altitudes and the development of more robust ignition systems for reliable operation in diverse conditions.

Existing Scramjet Solutions for Water Rockets

01 Fuel injection and mixing optimization

Improving fuel injection and mixing processes in scramjet engines is crucial for enhancing performance. This involves developing advanced fuel injection systems, optimizing fuel-air mixing, and designing efficient combustion chambers to ensure proper fuel distribution and combustion efficiency.- Fuel injection and mixing optimization: Improving fuel injection and mixing processes in scramjet engines is crucial for enhancing performance. This involves developing advanced injection systems, optimizing fuel distribution, and ensuring efficient combustion. Techniques may include using multiple injection points, adjusting injection angles, and implementing novel mixing strategies to achieve better fuel-air interaction and combustion efficiency.

- Thermal management and cooling systems: Effective thermal management is essential for scramjet performance. This includes developing advanced cooling systems to protect engine components from extreme temperatures. Strategies may involve using regenerative cooling, film cooling, or advanced materials with high heat resistance. Efficient heat dissipation and temperature control contribute to improved engine durability and overall performance.

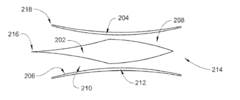

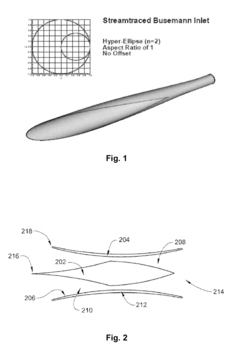

- Inlet design and flow control: Optimizing the inlet design and implementing effective flow control mechanisms are critical for scramjet performance. This involves shaping the inlet geometry to efficiently compress and decelerate incoming air, managing shock waves, and controlling boundary layer separation. Advanced flow control techniques, such as plasma actuators or variable geometry inlets, can enhance engine performance across a wide range of operating conditions.

- Combustion chamber optimization: Improving combustion chamber design is crucial for enhancing scramjet performance. This includes optimizing the chamber geometry, implementing flame holding mechanisms, and developing strategies for stable supersonic combustion. Advanced combustion techniques, such as staged combustion or plasma-assisted ignition, can be employed to improve combustion efficiency and engine thrust.

- Integration of advanced materials and manufacturing techniques: Incorporating advanced materials and manufacturing techniques can significantly improve scramjet performance. This includes using high-temperature alloys, ceramic matrix composites, or other novel materials to enhance engine durability and efficiency. Advanced manufacturing methods, such as additive manufacturing or novel joining techniques, can enable the production of complex geometries and integrated cooling systems, leading to improved overall engine performance.

02 Thermal management and cooling systems

Effective thermal management is essential for scramjet performance. This includes developing advanced cooling systems, heat-resistant materials, and thermal protection techniques to manage the extreme temperatures experienced during hypersonic flight and maintain engine integrity.Expand Specific Solutions03 Inlet design and flow control

Optimizing the inlet design and implementing effective flow control mechanisms are critical for scramjet performance. This involves developing variable geometry inlets, shock wave management techniques, and boundary layer control systems to ensure efficient air compression and flow characteristics across a wide range of flight conditions.Expand Specific Solutions04 Combustion stability and flame holding

Maintaining stable combustion and effective flame holding in supersonic airflow is crucial for scramjet performance. This includes developing innovative combustor designs, flame stabilization techniques, and ignition systems to ensure reliable and efficient combustion across various flight regimes.Expand Specific Solutions05 Integration with vehicle systems and flight control

Seamless integration of scramjet engines with vehicle systems and flight control is essential for overall performance. This involves developing advanced control systems, propulsion-airframe integration techniques, and optimizing the engine's performance in conjunction with the vehicle's aerodynamics and flight characteristics.Expand Specific Solutions

Key Players in Scramjet Water Rocket Development

The scramjet technology in water rocketry is in an early development stage, with a relatively small but growing market. The technology's maturity is still evolving, with key players like National University of Defense Technology, Harbin Engineering University, and Northwestern Polytechnical University leading research efforts. Companies such as Aerojet Rocketdyne and Beijing Tianbing Technology are also contributing to advancements. The competitive landscape is characterized by a mix of academic institutions and aerospace companies, with potential for significant growth as the technology matures and finds more applications in the water rocketry field.

National University of Defense Technology

Technical Solution: The National University of Defense Technology (NUDT) in China has been conducting extensive research on scramjet technology that could be applied to enhance water rocketry. Their approach involves developing advanced computational models for supersonic combustion and experimental validation of scramjet designs. NUDT's research focuses on improving fuel-air mixing in supersonic flows, which is crucial for efficient scramjet operation in water rocket applications. They have made significant progress in understanding the complex flow physics and chemical kinetics involved in scramjet propulsion[7]. NUDT's work also includes the development of novel materials and cooling techniques to manage the extreme temperatures encountered in scramjet operation, which could be crucial for integrating this technology into water rockets[8].

Strengths: Strong theoretical foundation in hypersonic propulsion, advanced computational capabilities, and extensive experimental facilities. Weaknesses: Research may be primarily oriented towards military applications, potentially limiting open collaboration and knowledge sharing.

Northwestern Polytechnical University

Technical Solution: Northwestern Polytechnical University (NPU) in China has been at the forefront of scramjet research that could potentially enhance water rocketry. Their approach involves a combination of theoretical modeling, numerical simulation, and experimental testing of scramjet engines. NPU's research focuses on optimizing the geometry of scramjet inlets and combustors to improve performance across a wide range of flight conditions, which could be beneficial for water rocket applications. They have made significant advancements in understanding and controlling supersonic combustion instabilities, a critical factor in scramjet operation[9]. NPU's work also extends to the development of advanced diagnostic techniques for high-speed flows, which could aid in the design and testing of scramjet-enhanced water rockets. Additionally, they are exploring the use of plasma-assisted combustion to enhance scramjet performance, which could lead to more efficient and powerful water rocket designs[10].

Strengths: Comprehensive research approach combining theory, simulation, and experimentation; expertise in supersonic combustion and flow diagnostics. Weaknesses: Potential limitations in translating large-scale scramjet research to small-scale water rocket applications.

Core Innovations in Scramjet Water Rocket Design

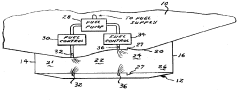

Energy-Deposition Systems, Equipment and Methods for Modifying and Controlling Shock Waves and Supersonic Flow

PatentActiveUS20150292532A1

Innovation

- The system employs conductive paths along surfaces with energy sources and sensors to assess and control energy discharge, allowing for the modification of shockwaves and fluid flows by depositing energy to start or restart inlets, mitigate blast effects, and manage heat transfer in wind tunnels.

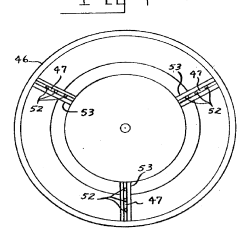

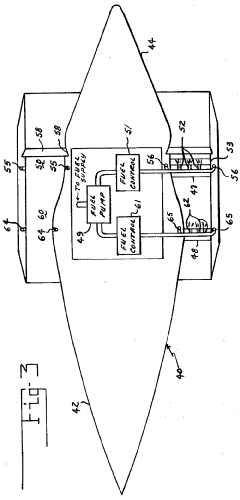

Dual mode supersonic combustion ramjet engine

PatentInactiveUS3667233A

Innovation

- A dual-mode combustion system with a combustor featuring a fixed geometry and parallel combustion section with uniform cross-section, utilizing fuel injection to stabilize flames and create choked flow, transitioning from subsonic to supersonic mode by manipulating shock waves through diverging sections and fuel distribution.

Safety Considerations for Scramjet Water Rockets

The integration of scramjet technology into water rocketry introduces significant safety considerations that must be carefully addressed. The high-speed nature of scramjet propulsion, combined with the use of water as a propellant, creates unique challenges and potential hazards. One primary concern is the increased pressure and temperature within the rocket body during operation. The rapid compression and acceleration of water through the scramjet engine can lead to extreme internal pressures, necessitating robust structural design and materials selection to prevent catastrophic failure.

Thermal management is another critical safety aspect. The high-speed airflow and compression in the scramjet can generate substantial heat, potentially causing material degradation or failure if not properly managed. This requires the implementation of effective cooling systems or heat-resistant materials to maintain structural integrity throughout the flight.

The control and stability of scramjet-powered water rockets present additional safety challenges. The increased thrust and velocity compared to traditional water rockets can make the vehicle more difficult to control, potentially leading to erratic flight paths or unintended trajectories. Advanced guidance and control systems may be necessary to ensure safe and predictable flight characteristics.

Launch and recovery procedures for scramjet water rockets must be carefully designed and implemented. The high-speed nature of these vehicles requires larger safety zones and more stringent launch protocols to protect operators and spectators. Recovery systems must be capable of safely decelerating the rocket from potentially higher velocities and altitudes than traditional water rockets.

Environmental considerations are also paramount. The use of water as a propellant generally presents lower environmental risks compared to chemical propellants. However, the potential for high-speed impacts or disintegration during flight could lead to debris scatter over a wider area. Proper flight termination systems and recovery protocols are essential to minimize environmental impact and ensure public safety.

Lastly, the complexity of scramjet water rocket systems necessitates comprehensive training and safety protocols for operators and researchers. This includes detailed understanding of system operation, potential failure modes, and emergency procedures. Regular safety audits, equipment inspections, and adherence to strict operational guidelines are crucial to maintaining a safe research and development environment for this innovative technology.

Thermal management is another critical safety aspect. The high-speed airflow and compression in the scramjet can generate substantial heat, potentially causing material degradation or failure if not properly managed. This requires the implementation of effective cooling systems or heat-resistant materials to maintain structural integrity throughout the flight.

The control and stability of scramjet-powered water rockets present additional safety challenges. The increased thrust and velocity compared to traditional water rockets can make the vehicle more difficult to control, potentially leading to erratic flight paths or unintended trajectories. Advanced guidance and control systems may be necessary to ensure safe and predictable flight characteristics.

Launch and recovery procedures for scramjet water rockets must be carefully designed and implemented. The high-speed nature of these vehicles requires larger safety zones and more stringent launch protocols to protect operators and spectators. Recovery systems must be capable of safely decelerating the rocket from potentially higher velocities and altitudes than traditional water rockets.

Environmental considerations are also paramount. The use of water as a propellant generally presents lower environmental risks compared to chemical propellants. However, the potential for high-speed impacts or disintegration during flight could lead to debris scatter over a wider area. Proper flight termination systems and recovery protocols are essential to minimize environmental impact and ensure public safety.

Lastly, the complexity of scramjet water rocket systems necessitates comprehensive training and safety protocols for operators and researchers. This includes detailed understanding of system operation, potential failure modes, and emergency procedures. Regular safety audits, equipment inspections, and adherence to strict operational guidelines are crucial to maintaining a safe research and development environment for this innovative technology.

Environmental Impact of Scramjet Water Rockets

The integration of scramjet technology into water rocketry presents both opportunities and challenges in terms of environmental impact. Scramjet-powered water rockets offer potential advantages in efficiency and performance, which could lead to reduced fuel consumption and lower emissions compared to traditional rocket propulsion systems. However, the environmental implications of this technology must be carefully considered.

One of the primary environmental benefits of scramjet water rockets is their potential for increased fuel efficiency. By utilizing atmospheric oxygen for combustion, scramjets reduce the need for onboard oxidizers, resulting in lighter vehicles and potentially lower fuel requirements. This efficiency gain could translate to reduced emissions per flight, particularly in terms of carbon dioxide and other greenhouse gases associated with conventional rocket propulsion.

Water as a propellant in these systems offers another environmental advantage. Unlike traditional rocket fuels, water is non-toxic and abundant, minimizing the risk of harmful chemical releases during launch or in the event of a malfunction. The use of water also eliminates the need for complex and potentially hazardous fuel handling and storage procedures, further reducing environmental risks associated with rocket operations.

However, the environmental impact of scramjet water rockets extends beyond fuel considerations. The high-speed, high-temperature operation of scramjets may lead to increased noise pollution and thermal emissions in the upper atmosphere. These factors could potentially affect local ecosystems and contribute to atmospheric heating, although the extent of these impacts requires further study.

The manufacturing and testing of scramjet components also present environmental considerations. Advanced materials and precision engineering required for scramjet production may involve energy-intensive processes and the use of rare or potentially harmful substances. Ensuring sustainable manufacturing practices and proper disposal of materials will be crucial in mitigating these environmental concerns.

Water consumption is another factor to consider, especially in regions where water scarcity is an issue. While water rockets use relatively small amounts of water compared to many industrial processes, the cumulative impact of frequent launches could be significant in certain areas. Implementing water recycling systems and selecting launch sites with abundant water resources could help address this concern.

In terms of space debris, scramjet water rockets may offer some advantages. Their potential for increased efficiency and performance could lead to more precise orbital insertions and controlled re-entries, potentially reducing the amount of debris left in orbit. However, as with any space technology, proper end-of-life management for satellites and other payloads launched by these systems will remain crucial for minimizing space debris.

One of the primary environmental benefits of scramjet water rockets is their potential for increased fuel efficiency. By utilizing atmospheric oxygen for combustion, scramjets reduce the need for onboard oxidizers, resulting in lighter vehicles and potentially lower fuel requirements. This efficiency gain could translate to reduced emissions per flight, particularly in terms of carbon dioxide and other greenhouse gases associated with conventional rocket propulsion.

Water as a propellant in these systems offers another environmental advantage. Unlike traditional rocket fuels, water is non-toxic and abundant, minimizing the risk of harmful chemical releases during launch or in the event of a malfunction. The use of water also eliminates the need for complex and potentially hazardous fuel handling and storage procedures, further reducing environmental risks associated with rocket operations.

However, the environmental impact of scramjet water rockets extends beyond fuel considerations. The high-speed, high-temperature operation of scramjets may lead to increased noise pollution and thermal emissions in the upper atmosphere. These factors could potentially affect local ecosystems and contribute to atmospheric heating, although the extent of these impacts requires further study.

The manufacturing and testing of scramjet components also present environmental considerations. Advanced materials and precision engineering required for scramjet production may involve energy-intensive processes and the use of rare or potentially harmful substances. Ensuring sustainable manufacturing practices and proper disposal of materials will be crucial in mitigating these environmental concerns.

Water consumption is another factor to consider, especially in regions where water scarcity is an issue. While water rockets use relatively small amounts of water compared to many industrial processes, the cumulative impact of frequent launches could be significant in certain areas. Implementing water recycling systems and selecting launch sites with abundant water resources could help address this concern.

In terms of space debris, scramjet water rockets may offer some advantages. Their potential for increased efficiency and performance could lead to more precise orbital insertions and controlled re-entries, potentially reducing the amount of debris left in orbit. However, as with any space technology, proper end-of-life management for satellites and other payloads launched by these systems will remain crucial for minimizing space debris.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!