Silicone Rubber: Overcoming Challenges in Complex Engineering

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber Evolution

Silicone rubber has undergone a remarkable evolution since its inception in the 1940s. Initially developed as a high-performance elastomer, it quickly gained traction in various industries due to its unique combination of properties. The early stages of silicone rubber development focused primarily on improving its thermal stability and electrical insulation characteristics, making it ideal for aerospace and electrical applications.

As the demand for more specialized materials grew, researchers began to explore ways to enhance silicone rubber's mechanical properties. This led to the development of reinforced silicone composites in the 1960s and 1970s, incorporating fillers such as silica and carbon black to improve tensile strength and tear resistance. These advancements expanded the material's use in automotive and industrial sectors.

The 1980s and 1990s saw a shift towards customization and functionality. Manufacturers began producing silicone rubbers with specific properties tailored to particular applications. This era witnessed the emergence of optically clear silicones for LED encapsulation, highly conductive silicones for EMI shielding, and biocompatible grades for medical devices.

In the early 2000s, the focus shifted to environmental concerns and sustainability. Researchers developed low-volatile organic compound (VOC) silicone formulations and explored bio-based alternatives to traditional silicone precursors. This period also saw advancements in processing technologies, such as liquid silicone rubber (LSR) injection molding, which allowed for more complex and precise part geometries.

The past decade has been characterized by the integration of silicone rubber with other materials and technologies. This includes the development of silicone-based adhesives, coatings, and hybrid materials that combine the benefits of silicone with other polymers. Additionally, the advent of 3D printing has opened new avenues for silicone rubber applications, enabling the production of complex, customized parts with unique geometries.

Recent innovations have focused on addressing specific challenges in complex engineering applications. These include self-healing silicone rubbers that can repair damage autonomously, ultra-high temperature resistant formulations for extreme environments, and electrically conductive silicones for flexible electronics and wearable devices. Researchers are also exploring the potential of nanocomposite silicone rubbers to achieve unprecedented combinations of properties.

As we look to the future, the evolution of silicone rubber continues to be driven by the need for materials that can withstand increasingly demanding environments and meet the requirements of emerging technologies. The ongoing research into molecular design, processing techniques, and composite formulations promises to further expand the capabilities and applications of this versatile material in complex engineering challenges.

As the demand for more specialized materials grew, researchers began to explore ways to enhance silicone rubber's mechanical properties. This led to the development of reinforced silicone composites in the 1960s and 1970s, incorporating fillers such as silica and carbon black to improve tensile strength and tear resistance. These advancements expanded the material's use in automotive and industrial sectors.

The 1980s and 1990s saw a shift towards customization and functionality. Manufacturers began producing silicone rubbers with specific properties tailored to particular applications. This era witnessed the emergence of optically clear silicones for LED encapsulation, highly conductive silicones for EMI shielding, and biocompatible grades for medical devices.

In the early 2000s, the focus shifted to environmental concerns and sustainability. Researchers developed low-volatile organic compound (VOC) silicone formulations and explored bio-based alternatives to traditional silicone precursors. This period also saw advancements in processing technologies, such as liquid silicone rubber (LSR) injection molding, which allowed for more complex and precise part geometries.

The past decade has been characterized by the integration of silicone rubber with other materials and technologies. This includes the development of silicone-based adhesives, coatings, and hybrid materials that combine the benefits of silicone with other polymers. Additionally, the advent of 3D printing has opened new avenues for silicone rubber applications, enabling the production of complex, customized parts with unique geometries.

Recent innovations have focused on addressing specific challenges in complex engineering applications. These include self-healing silicone rubbers that can repair damage autonomously, ultra-high temperature resistant formulations for extreme environments, and electrically conductive silicones for flexible electronics and wearable devices. Researchers are also exploring the potential of nanocomposite silicone rubbers to achieve unprecedented combinations of properties.

As we look to the future, the evolution of silicone rubber continues to be driven by the need for materials that can withstand increasingly demanding environments and meet the requirements of emerging technologies. The ongoing research into molecular design, processing techniques, and composite formulations promises to further expand the capabilities and applications of this versatile material in complex engineering challenges.

Market Demand Analysis

The market demand for silicone rubber in complex engineering applications has been steadily increasing due to its unique properties and versatility. This material's exceptional heat resistance, electrical insulation, and durability make it indispensable in various high-performance industries. The automotive sector, in particular, has shown a significant uptick in silicone rubber usage, driven by the growing electric vehicle market and the need for lightweight, heat-resistant components.

In the aerospace industry, silicone rubber's ability to withstand extreme temperatures and maintain flexibility in harsh environments has led to increased adoption in sealing and insulation applications. The medical device sector also contributes substantially to market growth, with silicone rubber being the material of choice for many implantable devices and surgical instruments due to its biocompatibility and sterilization resistance.

The construction industry has emerged as another key driver of silicone rubber demand, particularly in high-rise buildings and infrastructure projects. The material's weather resistance and long-term durability make it ideal for sealants, adhesives, and coatings in these applications. Additionally, the electronics industry continues to rely heavily on silicone rubber for encapsulation and protection of sensitive components, especially in the rapidly expanding Internet of Things (IoT) devices market.

Market analysts project the global silicone rubber market to experience robust growth in the coming years. This growth is attributed to the material's expanding applications in emerging technologies such as 5G infrastructure, renewable energy systems, and advanced robotics. The Asia-Pacific region is expected to lead this growth, driven by rapid industrialization and increasing investments in high-tech manufacturing.

Despite the positive outlook, challenges remain in meeting the complex engineering demands of these industries. Manufacturers are under pressure to develop silicone rubber formulations with enhanced properties, such as improved thermal conductivity, self-healing capabilities, and better chemical resistance. The market also faces increasing scrutiny regarding environmental sustainability, prompting research into bio-based alternatives and recycling technologies for silicone rubber products.

As industries continue to push the boundaries of material performance, the demand for specialized silicone rubber solutions is likely to intensify. This trend is expected to drive innovation in material science and manufacturing processes, potentially opening new market segments and applications for silicone rubber in complex engineering scenarios.

In the aerospace industry, silicone rubber's ability to withstand extreme temperatures and maintain flexibility in harsh environments has led to increased adoption in sealing and insulation applications. The medical device sector also contributes substantially to market growth, with silicone rubber being the material of choice for many implantable devices and surgical instruments due to its biocompatibility and sterilization resistance.

The construction industry has emerged as another key driver of silicone rubber demand, particularly in high-rise buildings and infrastructure projects. The material's weather resistance and long-term durability make it ideal for sealants, adhesives, and coatings in these applications. Additionally, the electronics industry continues to rely heavily on silicone rubber for encapsulation and protection of sensitive components, especially in the rapidly expanding Internet of Things (IoT) devices market.

Market analysts project the global silicone rubber market to experience robust growth in the coming years. This growth is attributed to the material's expanding applications in emerging technologies such as 5G infrastructure, renewable energy systems, and advanced robotics. The Asia-Pacific region is expected to lead this growth, driven by rapid industrialization and increasing investments in high-tech manufacturing.

Despite the positive outlook, challenges remain in meeting the complex engineering demands of these industries. Manufacturers are under pressure to develop silicone rubber formulations with enhanced properties, such as improved thermal conductivity, self-healing capabilities, and better chemical resistance. The market also faces increasing scrutiny regarding environmental sustainability, prompting research into bio-based alternatives and recycling technologies for silicone rubber products.

As industries continue to push the boundaries of material performance, the demand for specialized silicone rubber solutions is likely to intensify. This trend is expected to drive innovation in material science and manufacturing processes, potentially opening new market segments and applications for silicone rubber in complex engineering scenarios.

Technical Challenges

Silicone rubber, despite its widespread use in complex engineering applications, faces several significant technical challenges that limit its performance and applicability. One of the primary issues is its relatively low mechanical strength compared to other elastomers. This limitation becomes particularly problematic in high-stress environments or applications requiring long-term durability under extreme conditions.

Another major challenge is the material's susceptibility to degradation when exposed to certain chemicals, oils, and solvents. This vulnerability can lead to swelling, loss of mechanical properties, and even complete breakdown of the material in some cases. Such limitations restrict the use of silicone rubber in certain industrial and automotive applications where exposure to harsh chemicals is inevitable.

The thermal stability of silicone rubber, while generally good, can be compromised at extremely high temperatures. Above certain thresholds, the material may experience thermal decomposition, leading to a loss of its desirable properties. This poses challenges in applications involving prolonged exposure to high-temperature environments, such as in aerospace or certain manufacturing processes.

Adhesion is another area where silicone rubber faces technical hurdles. The material's inherently low surface energy makes it difficult to achieve strong, durable bonds with other materials. This challenge is particularly evident in multi-material assemblies or in applications requiring robust sealing properties.

Furthermore, the electrical properties of silicone rubber, while suitable for many applications, can be a limiting factor in others. Its relatively low dielectric strength and electrical conductivity may not meet the requirements for certain high-performance electrical and electronic applications.

The processing and manufacturing of silicone rubber products also present technical challenges. Achieving consistent quality, especially in complex molded parts, can be difficult due to issues such as air entrapment, uneven curing, and dimensional instability during the molding process.

Lastly, the cost of silicone rubber, particularly for high-performance grades, remains a significant challenge. The relatively high production costs can limit its adoption in price-sensitive applications, especially when competing with other elastomers or engineering plastics.

Addressing these technical challenges requires ongoing research and development efforts. Scientists and engineers are continuously working on improving silicone rubber formulations, developing new processing techniques, and exploring hybrid materials to overcome these limitations. The goal is to expand the material's capabilities and broaden its applicability in increasingly demanding engineering environments.

Another major challenge is the material's susceptibility to degradation when exposed to certain chemicals, oils, and solvents. This vulnerability can lead to swelling, loss of mechanical properties, and even complete breakdown of the material in some cases. Such limitations restrict the use of silicone rubber in certain industrial and automotive applications where exposure to harsh chemicals is inevitable.

The thermal stability of silicone rubber, while generally good, can be compromised at extremely high temperatures. Above certain thresholds, the material may experience thermal decomposition, leading to a loss of its desirable properties. This poses challenges in applications involving prolonged exposure to high-temperature environments, such as in aerospace or certain manufacturing processes.

Adhesion is another area where silicone rubber faces technical hurdles. The material's inherently low surface energy makes it difficult to achieve strong, durable bonds with other materials. This challenge is particularly evident in multi-material assemblies or in applications requiring robust sealing properties.

Furthermore, the electrical properties of silicone rubber, while suitable for many applications, can be a limiting factor in others. Its relatively low dielectric strength and electrical conductivity may not meet the requirements for certain high-performance electrical and electronic applications.

The processing and manufacturing of silicone rubber products also present technical challenges. Achieving consistent quality, especially in complex molded parts, can be difficult due to issues such as air entrapment, uneven curing, and dimensional instability during the molding process.

Lastly, the cost of silicone rubber, particularly for high-performance grades, remains a significant challenge. The relatively high production costs can limit its adoption in price-sensitive applications, especially when competing with other elastomers or engineering plastics.

Addressing these technical challenges requires ongoing research and development efforts. Scientists and engineers are continuously working on improving silicone rubber formulations, developing new processing techniques, and exploring hybrid materials to overcome these limitations. The goal is to expand the material's capabilities and broaden its applicability in increasingly demanding engineering environments.

Current Solutions

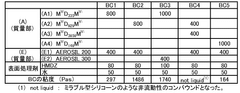

01 Composition and formulation of silicone rubber

Silicone rubber compositions typically include silicone polymers, fillers, and curing agents. The formulation can be adjusted to achieve specific properties such as hardness, elasticity, and heat resistance. Various additives may be incorporated to enhance performance characteristics or processing behavior.- Composition and preparation of silicone rubber: Silicone rubber is typically composed of silicone polymers, fillers, and curing agents. The preparation process often involves mixing these components, shaping the mixture, and then curing it to form the final rubber product. Various additives can be incorporated to modify properties such as strength, flexibility, and heat resistance.

- Modification of silicone rubber properties: The properties of silicone rubber can be modified through the addition of specific compounds or by altering the molecular structure. This can include improving thermal stability, enhancing electrical properties, or increasing chemical resistance. Techniques may involve blending with other polymers or incorporating functional groups into the silicone backbone.

- Applications of silicone rubber in various industries: Silicone rubber finds applications in diverse industries due to its unique properties. It is used in medical devices, automotive parts, electrical insulation, consumer products, and construction materials. Its biocompatibility, heat resistance, and flexibility make it suitable for a wide range of products from gaskets to implants.

- Manufacturing processes for silicone rubber products: Various manufacturing processes are employed to produce silicone rubber products, including injection molding, extrusion, and compression molding. Advanced techniques like liquid silicone rubber injection molding allow for the production of complex shapes with high precision. The choice of process depends on the desired product characteristics and production volume.

- Innovations in silicone rubber technology: Ongoing research in silicone rubber technology focuses on developing new formulations with enhanced properties. This includes self-healing silicone rubbers, conductive silicone composites, and environmentally friendly alternatives. Innovations also extend to processing techniques and the integration of silicone rubber with other materials for advanced applications.

02 Manufacturing processes for silicone rubber products

Manufacturing methods for silicone rubber products include molding, extrusion, and calendering. The process may involve mixing raw materials, shaping the compound, and curing through heat or other means. Specialized techniques can be employed for creating complex shapes or incorporating additional materials.Expand Specific Solutions03 Modifications and improvements to silicone rubber properties

Researchers continually work on modifying silicone rubber to enhance its properties. This can include improving heat resistance, increasing tensile strength, or enhancing chemical resistance. Techniques may involve blending with other polymers, incorporating nanoparticles, or modifying the molecular structure of the silicone polymer.Expand Specific Solutions04 Applications of silicone rubber in various industries

Silicone rubber finds applications in diverse industries due to its unique properties. It is used in medical devices, automotive parts, electrical insulation, consumer products, and construction materials. The material's biocompatibility, durability, and resistance to extreme temperatures make it suitable for specialized applications.Expand Specific Solutions05 Environmental and safety considerations in silicone rubber production

The production and use of silicone rubber involve considerations for environmental impact and safety. This includes developing eco-friendly manufacturing processes, ensuring the safety of workers handling the material, and addressing end-of-life disposal or recycling of silicone rubber products. Efforts are made to reduce volatile organic compound emissions and improve overall sustainability.Expand Specific Solutions

Key Industry Players

The silicone rubber industry is in a mature growth phase, characterized by steady demand across various engineering applications. The global market size for silicone rubber is substantial, estimated to reach over $9 billion by 2025. Technologically, silicone rubber has reached a high level of maturity, with ongoing innovations focused on enhancing performance for specific applications. Key players like Shin-Etsu Chemical, Dow Silicones, and Wacker Chemie are at the forefront of R&D, driving advancements in high-performance silicone formulations. These industry leaders, along with companies such as Momentive Performance Materials and Henkel, are competing to develop specialized silicone rubber products for emerging sectors like electric vehicles and renewable energy, indicating a shift towards value-added, application-specific solutions in this competitive landscape.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed advanced silicone rubber compounds with improved heat resistance and mechanical properties. Their proprietary cross-linking technology enables the production of silicone rubber that maintains its elasticity and electrical insulation properties at temperatures up to 200°C for extended periods[1]. They have also introduced self-adhesive silicone rubbers that bond strongly to various substrates without primers, simplifying manufacturing processes in industries such as automotive and electronics[2]. Additionally, Shin-Etsu has developed specialty silicone rubbers with enhanced oil and chemical resistance for use in harsh industrial environments[3].

Strengths: Industry-leading heat resistance, innovative self-adhesive formulations, and specialized compounds for extreme conditions. Weaknesses: Potentially higher cost compared to standard silicone rubbers, and may require specialized processing equipment for some advanced formulations.

Dow Silicones Corp.

Technical Solution: Dow Silicones has pioneered liquid silicone rubber (LSR) technology, offering a range of products with improved processing characteristics and performance. Their SILASTIC™ LSR series features rapid cure rates and excellent flow properties, enabling complex part designs and high-volume production[4]. Dow has also developed self-lubricating silicone rubbers that reduce friction and wear in dynamic applications, addressing a common limitation of traditional silicone materials[5]. Furthermore, their optically clear silicone rubbers maintain transparency even after prolonged exposure to high temperatures and UV radiation, making them ideal for LED encapsulation and outdoor applications[6].

Strengths: Advanced LSR technology, innovative friction-reducing formulations, and superior optical properties. Weaknesses: May require specialized molding equipment for LSR processing, and some grades may have higher raw material costs.

Innovative Technologies

Liquid silicone rubber composition, cured object obtained therefrom, article including said cured object, and method for producing silicone rubber

PatentWO2020027302A1

Innovation

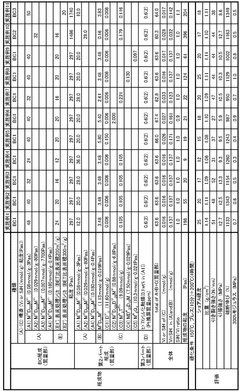

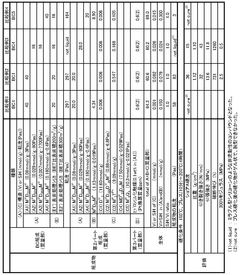

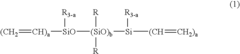

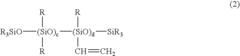

- A liquid silicone rubber composition comprising specific ratios of alkenyl group-containing linear polyorganosiloxanes, hydrogen-bonded polyorganosiloxanes, crosslinkable polyorganosiloxanes, a hydrosilylation catalyst, and silica powder, which provides a cured product with low modulus, high tear strength, and improved fluidity, enabling the production of articles with complex shapes and enhanced adhesion.

Addition reaction-curable liquid silicone rubber compositions and process of preparing same

PatentActiveUS20050277725A1

Innovation

- An addition reaction-curable liquid silicone rubber composition comprising specific organopolysiloxanes, finely divided silica, hexamethyldisilazane, water, and an organohydrogenpolysiloxane, along with a hydrosilation catalyst, is developed, allowing for a cured product with a hardness of at least 75 and an elongation at break of at least 200%, enabling broader application beyond insulation potting.

Environmental Impact

The environmental impact of silicone rubber in complex engineering applications is a critical consideration for sustainable development. Silicone rubber, while offering numerous advantages in various industries, also presents certain environmental challenges throughout its lifecycle.

During the production phase, the manufacturing of silicone rubber involves energy-intensive processes and the use of potentially harmful chemicals. The extraction and processing of silica, a primary raw material, can lead to habitat disruption and contribute to air and water pollution. However, compared to many other synthetic materials, silicone rubber production generally has a lower carbon footprint and requires less energy.

In its use phase, silicone rubber demonstrates several environmentally positive attributes. Its durability and resistance to degradation mean that products made from silicone rubber often have longer lifespans, reducing the need for frequent replacements and thereby minimizing waste generation. Additionally, silicone rubber's thermal insulation properties can contribute to energy efficiency in buildings and industrial applications, potentially lowering overall energy consumption.

One of the main environmental concerns associated with silicone rubber is its end-of-life management. While silicone rubber is not biodegradable, it does not release harmful substances into the environment as it breaks down. However, its persistence in the environment can contribute to long-term accumulation of waste. Recycling silicone rubber presents challenges due to its thermoset nature, which makes it difficult to melt and reshape. Despite these challenges, innovative recycling technologies are being developed to address this issue.

The water repellent nature of silicone rubber can have both positive and negative environmental implications. On one hand, it can help prevent water damage and extend the life of various products. On the other hand, this property can make it challenging to remove silicone contamination from water bodies, potentially affecting aquatic ecosystems.

In response to these environmental concerns, the silicone rubber industry is increasingly focusing on sustainable practices. This includes developing bio-based silicones, improving energy efficiency in production processes, and exploring more effective recycling and disposal methods. Some manufacturers are also implementing closed-loop systems to minimize waste and maximize resource efficiency.

As the demand for silicone rubber in complex engineering applications continues to grow, balancing its performance benefits with environmental considerations remains a key challenge. Future research and development efforts are likely to focus on enhancing the material's sustainability profile while maintaining its valuable engineering properties.

During the production phase, the manufacturing of silicone rubber involves energy-intensive processes and the use of potentially harmful chemicals. The extraction and processing of silica, a primary raw material, can lead to habitat disruption and contribute to air and water pollution. However, compared to many other synthetic materials, silicone rubber production generally has a lower carbon footprint and requires less energy.

In its use phase, silicone rubber demonstrates several environmentally positive attributes. Its durability and resistance to degradation mean that products made from silicone rubber often have longer lifespans, reducing the need for frequent replacements and thereby minimizing waste generation. Additionally, silicone rubber's thermal insulation properties can contribute to energy efficiency in buildings and industrial applications, potentially lowering overall energy consumption.

One of the main environmental concerns associated with silicone rubber is its end-of-life management. While silicone rubber is not biodegradable, it does not release harmful substances into the environment as it breaks down. However, its persistence in the environment can contribute to long-term accumulation of waste. Recycling silicone rubber presents challenges due to its thermoset nature, which makes it difficult to melt and reshape. Despite these challenges, innovative recycling technologies are being developed to address this issue.

The water repellent nature of silicone rubber can have both positive and negative environmental implications. On one hand, it can help prevent water damage and extend the life of various products. On the other hand, this property can make it challenging to remove silicone contamination from water bodies, potentially affecting aquatic ecosystems.

In response to these environmental concerns, the silicone rubber industry is increasingly focusing on sustainable practices. This includes developing bio-based silicones, improving energy efficiency in production processes, and exploring more effective recycling and disposal methods. Some manufacturers are also implementing closed-loop systems to minimize waste and maximize resource efficiency.

As the demand for silicone rubber in complex engineering applications continues to grow, balancing its performance benefits with environmental considerations remains a key challenge. Future research and development efforts are likely to focus on enhancing the material's sustainability profile while maintaining its valuable engineering properties.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and application of silicone rubber in complex engineering projects. As the use of silicone rubber expands across various industries, manufacturers and end-users must navigate an increasingly complex landscape of regulations and standards.

In the United States, the Food and Drug Administration (FDA) regulates silicone rubber used in food contact applications and medical devices. Manufacturers must ensure their products comply with FDA regulations, including 21 CFR 177.2600 for rubber articles intended for repeated use. For medical applications, silicone rubber must meet biocompatibility requirements outlined in ISO 10993.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation impacts the production and use of silicone rubber. Manufacturers must register substances used in silicone rubber production and provide safety data. Additionally, the EU's RoHS (Restriction of Hazardous Substances) directive restricts the use of certain hazardous materials in electrical and electronic equipment, which may affect silicone rubber components.

In the automotive industry, silicone rubber components must comply with various standards, including ASTM D2000 for rubber properties and SAE J200 for classification of rubber compounds. These standards ensure the reliability and performance of silicone rubber parts in vehicles.

For aerospace applications, silicone rubber must meet stringent requirements set by organizations such as NASA and the European Space Agency. These include outgassing specifications (ASTM E595) and flame resistance standards (FAR 25.853).

Environmental regulations also impact silicone rubber production and disposal. Manufacturers must adhere to local and national environmental protection laws regarding emissions, waste management, and recycling. The increasing focus on sustainability has led to the development of eco-friendly silicone rubber formulations and recycling processes.

Occupational safety regulations, such as those enforced by OSHA in the United States, govern the handling and processing of silicone rubber in manufacturing environments. This includes exposure limits for volatile organic compounds (VOCs) and proper ventilation requirements.

As the regulatory landscape continues to evolve, silicone rubber manufacturers and users must stay informed about new and updated regulations. This may involve investing in research and development to create compliant formulations, implementing robust quality control systems, and obtaining necessary certifications for specific applications.

In the United States, the Food and Drug Administration (FDA) regulates silicone rubber used in food contact applications and medical devices. Manufacturers must ensure their products comply with FDA regulations, including 21 CFR 177.2600 for rubber articles intended for repeated use. For medical applications, silicone rubber must meet biocompatibility requirements outlined in ISO 10993.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation impacts the production and use of silicone rubber. Manufacturers must register substances used in silicone rubber production and provide safety data. Additionally, the EU's RoHS (Restriction of Hazardous Substances) directive restricts the use of certain hazardous materials in electrical and electronic equipment, which may affect silicone rubber components.

In the automotive industry, silicone rubber components must comply with various standards, including ASTM D2000 for rubber properties and SAE J200 for classification of rubber compounds. These standards ensure the reliability and performance of silicone rubber parts in vehicles.

For aerospace applications, silicone rubber must meet stringent requirements set by organizations such as NASA and the European Space Agency. These include outgassing specifications (ASTM E595) and flame resistance standards (FAR 25.853).

Environmental regulations also impact silicone rubber production and disposal. Manufacturers must adhere to local and national environmental protection laws regarding emissions, waste management, and recycling. The increasing focus on sustainability has led to the development of eco-friendly silicone rubber formulations and recycling processes.

Occupational safety regulations, such as those enforced by OSHA in the United States, govern the handling and processing of silicone rubber in manufacturing environments. This includes exposure limits for volatile organic compounds (VOCs) and proper ventilation requirements.

As the regulatory landscape continues to evolve, silicone rubber manufacturers and users must stay informed about new and updated regulations. This may involve investing in research and development to create compliant formulations, implementing robust quality control systems, and obtaining necessary certifications for specific applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!